Load self-adaptive pneumatic balance hoisting device

A pneumatic balance crane, self-adaptive technology, applied in the direction of load hanging components, transportation and packaging, cranes, etc., can solve problems such as potential safety hazards, and achieve the effect of improving work efficiency, reducing labor intensity, and good space flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

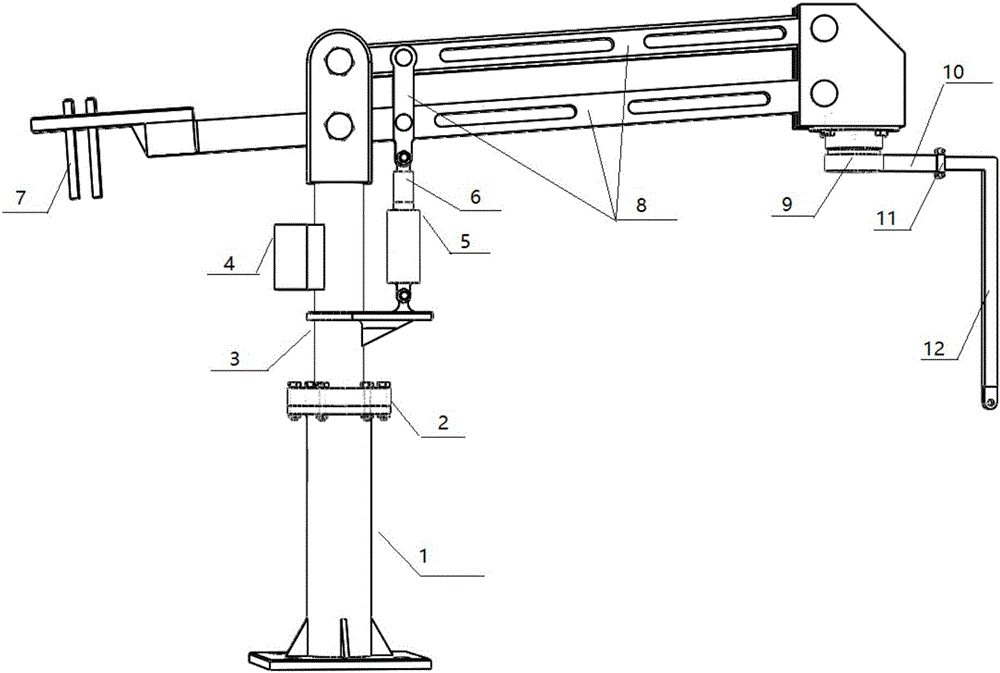

[0031] Such as figure 1 As shown, a load-adaptive pneumatic balance lifting device includes a lower base 1, an upper base 3 connected to the lower base 1 through a first built-in bearing 2, a four connecting rod 8 hinged on the top of the upper base 3, and four The pneumatic control system connected by the connecting rod 8, the lifting fixing unit and the weight block 7 respectively arranged at the front and rear ends of the four connecting rod 8. The pneumatic control system includes a pneumatic control box 4 fixedly connected to the upper base 3 and a pneumatic control box 4 The connected pneumatic cylinder 5, the top of the pneumatic rod 6 of the pneumatic cylinder 5 is articulated with the four connecting rod 8. The pneumatic rod 6 is controlled by the pneumatic cylinder 5 to drive the four connecting rod 8 above the base 3 and the four connecting rod 8 hinge It is a lever fulcrum for lever lifting operations.

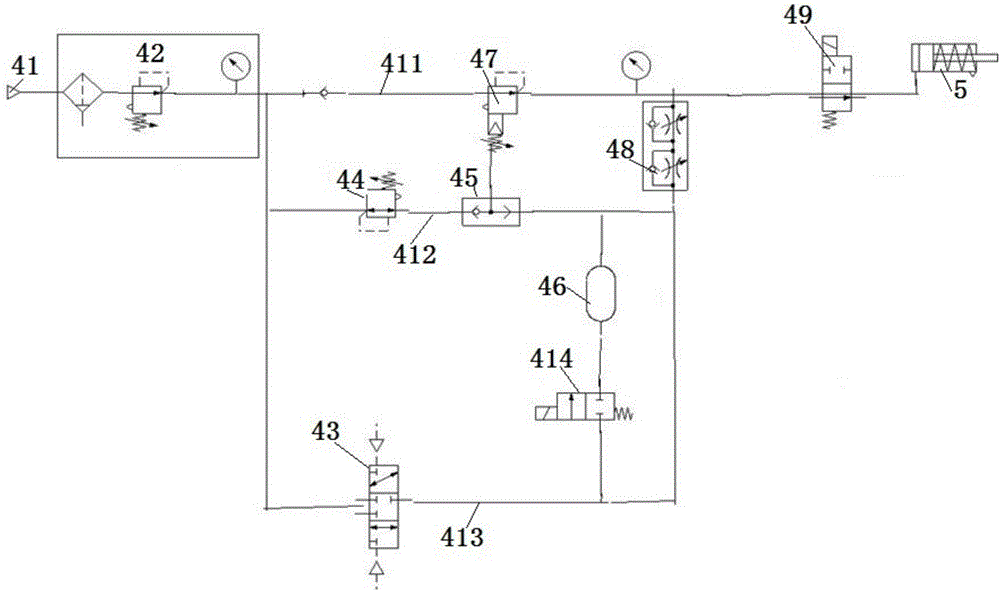

[0032] Among them, the pneumatic control box 4 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com