Control method of spinning pressure in spin forming and control system applied by same

A spinning forming and control method technology, applied in the direction of presses, forming tools, manufacturing tools, etc., can solve the problems of product wall thickness thinning area, bulging, and unpredictable changes in material thickness, so as to improve the technical level and forming efficiency , expand the range interval, and control the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

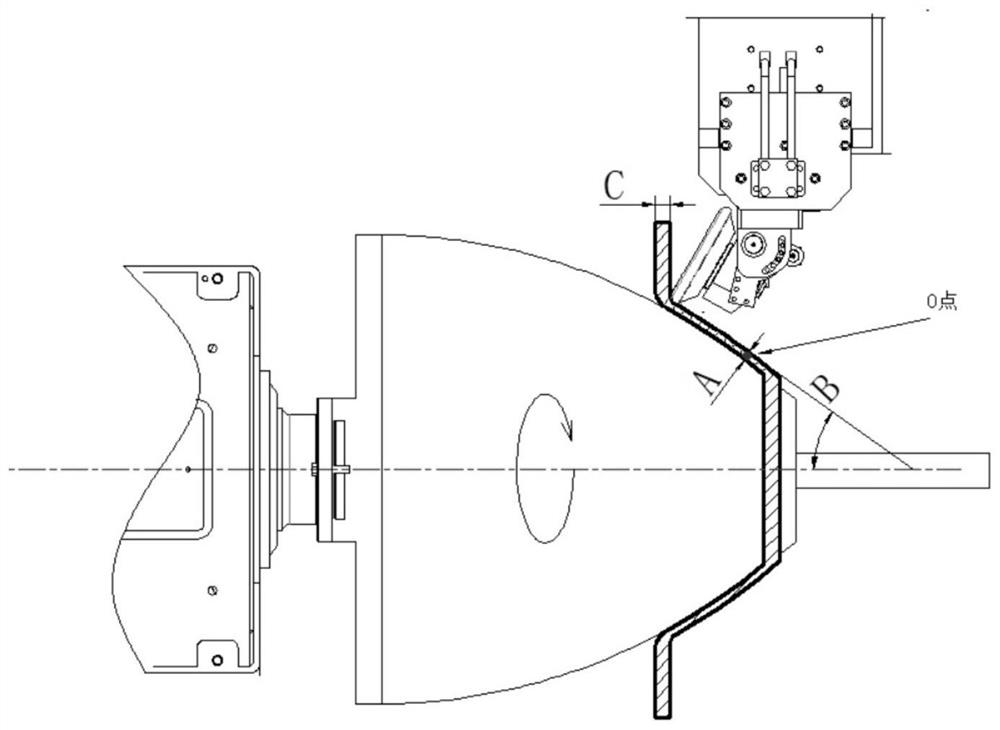

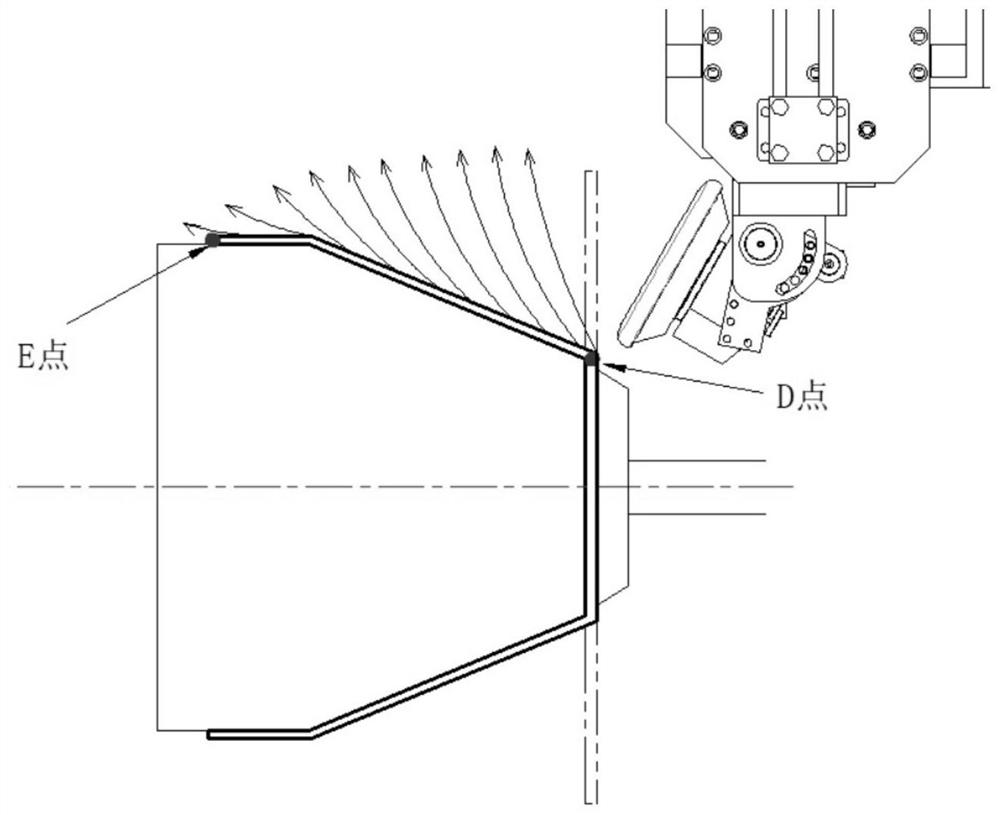

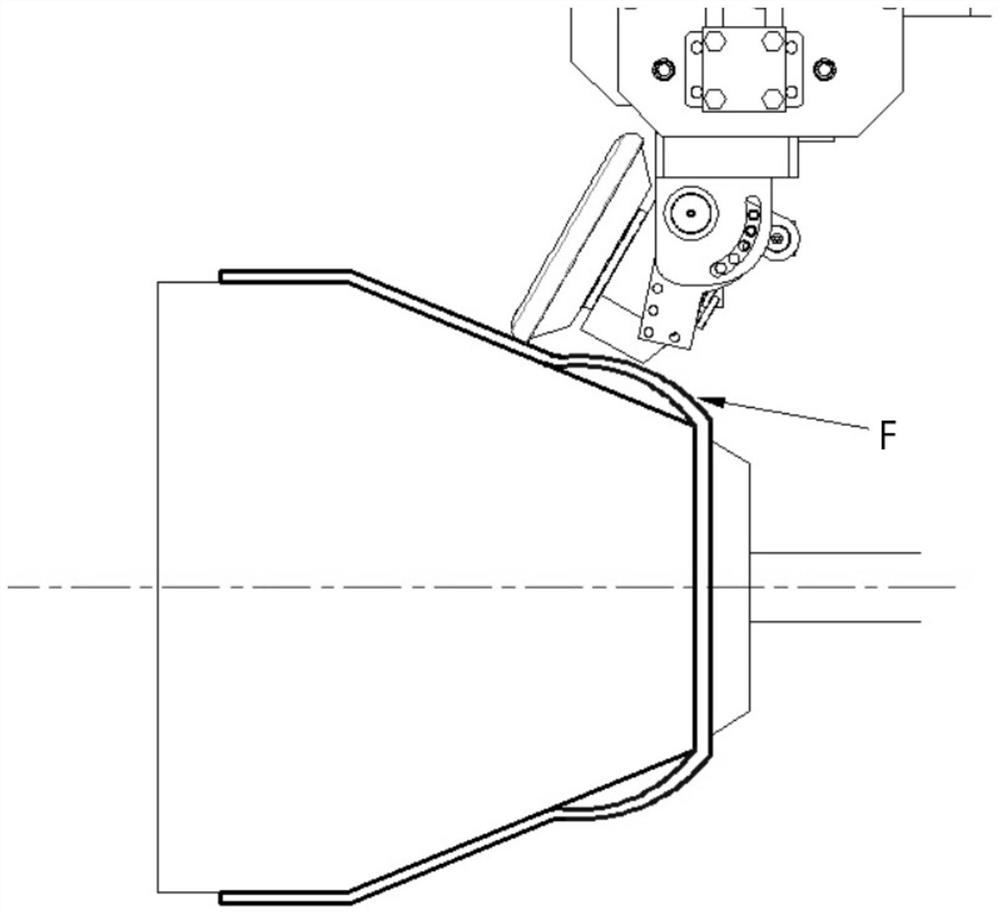

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1: The selected material specifications are as follows:

[0045] Brand: 3A21 aluminum plate;

[0046] Thickness: 2mm;

[0047] Shape: conical body with a unilateral angle of 20 degrees;

[0048] State: O state;

[0049] Tensile strength σb (MPa): 120-160;

[0050] Spinning wheel diameter: R8mm;

[0051] According to the spinning pressure control method proposed in this embodiment Figure 9 The 10-pass forming process is carried out by spinning to obtain Figure 10 The molding pass-spinning pressure curve table shown, through Figure 10 It can be seen that when the spinning force is 130kg, the material has a good shape change and the thickness change is negligible.

[0052] It should be noted that in the forming pass-spinning pressure curve table of the present application, the abscissa is the time corresponding to each pass, and the ordinate is the spinning pressure value measured by the strain gauge. It is reflected as pulling force and pushing force...

Embodiment 2

[0053] Embodiment 2: the selected material specifications are as follows:

[0054] Brand: 3A21 aluminum alloy;

[0055] Thickness: 5mm

[0056] State: H1 state;

[0057] Hardness: HL;

[0058] Spinning wheel diameter: R8mm;

[0059] pass Figure 11 It can be seen that when the spinning force is 500kg, the material has a good shape change and the thickness change is negligible.

Embodiment 3

[0060] Embodiment 3: the selected material specifications are as follows:

[0061] Brand: SPHE carbon plate;

[0062] Thickness: 6mm;

[0063] State: Annealed

[0064] Tensile strength (σb / MPa): ≥270

[0065] Spinning wheel diameter: R5mm;

[0066] pass Figure 12 It can be seen that when the pressure is 1200kg, the material has a good shape change and the thickness change is negligible.

[0067] These data directly provide the preferred preset target pressure data reference for the subsequent spinning of these materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com