Sole glue spraying device and method based on monocular vision

A technology of monocular vision and glue spraying, which is applied in the direction of footwear, bonding shoe parts, shoemaking machinery, etc. It can solve the problems of affecting the quality of the vision system to take pictures, affecting the quality of glue spraying, low efficiency, etc., and achieve high glue spraying accuracy , Reduce labor intensity, spray glue evenly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The invention will be further described below in conjunction with specific embodiments:

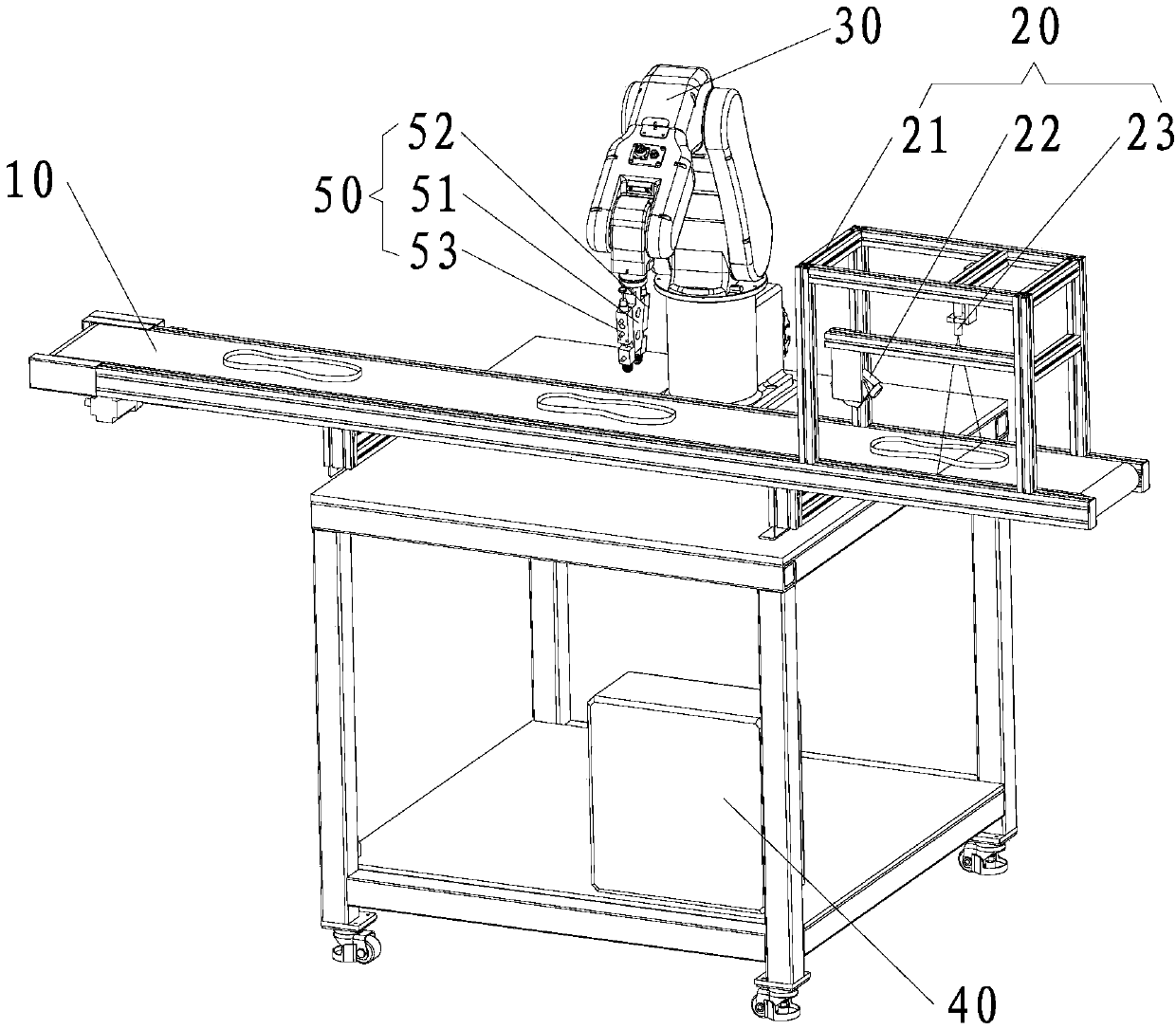

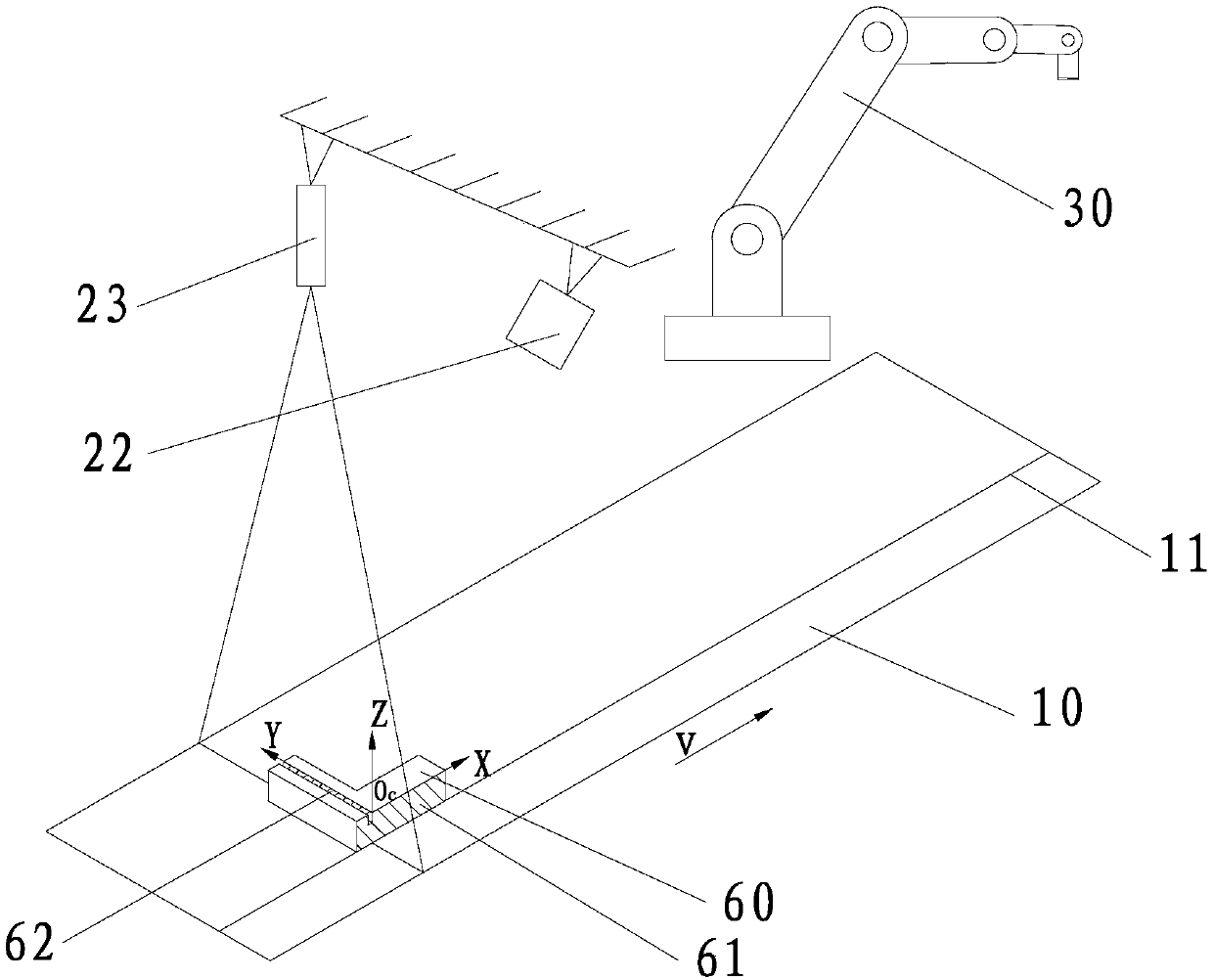

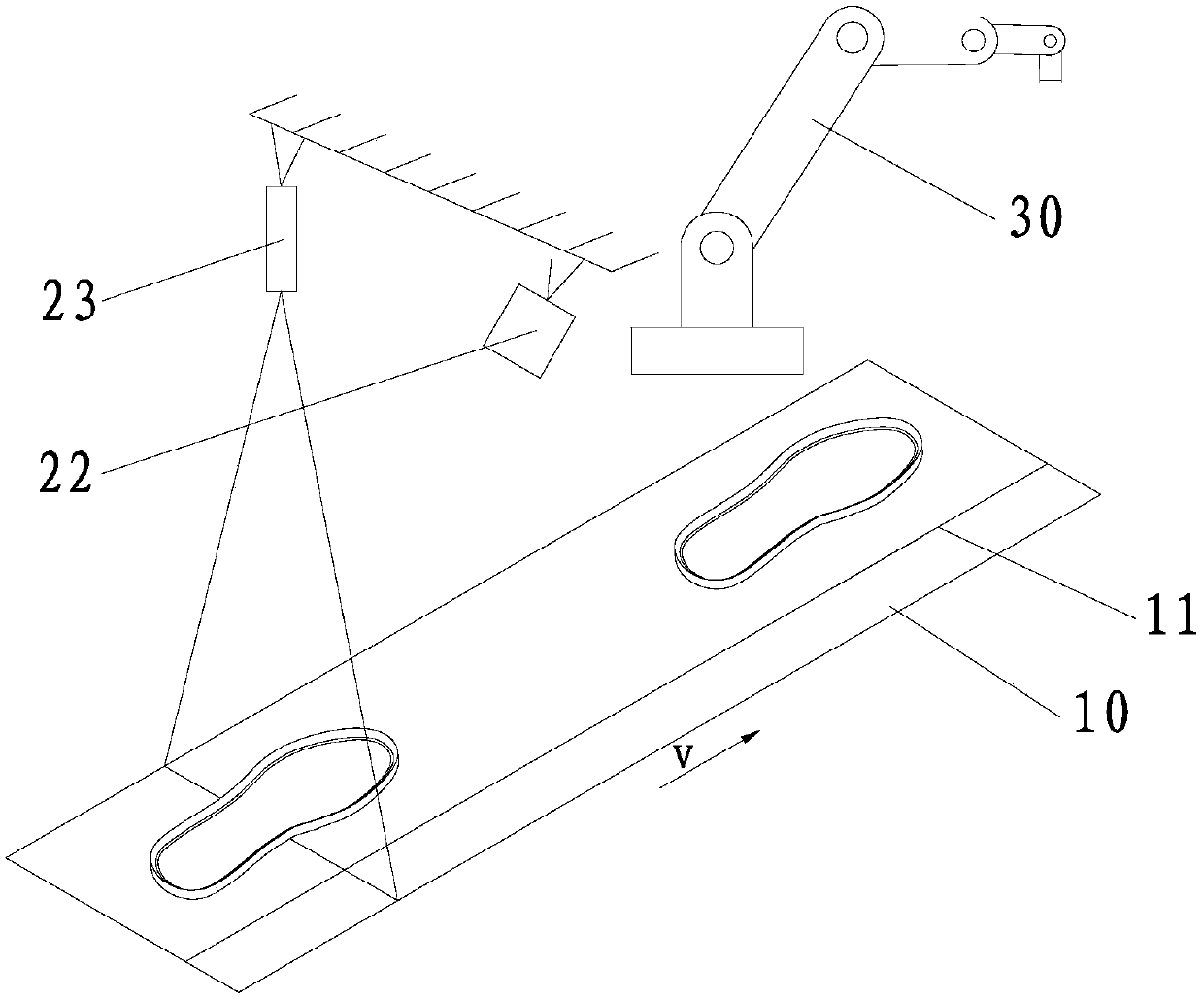

[0046] Such as figure 1Shown, the present embodiment provides a kind of sole glue spraying equipment based on monocular vision, comprises conveyor belt device 10, is arranged on the visual device 20 on conveyor belt device 10, is positioned at the manipulator device 30 beside conveyor belt device 10 and respectively with conveyor belt device 10. A control system 40 in which the visual device 20 and the manipulator device 30 are communicatively connected, wherein the motor of the conveyor belt device 10 is provided with an encoder connected to the control system 40, and the conveyor belt device 10 is a conventional linear transmission device, and the manipulator device 30 It is a six-joint series manipulator device. The conveyor belt device 10, the manipulator device 30 and the control system 40 in this embodiment can all be purchased directly from the market, and their specific st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com