Use method of frame outer wall gluing mechanism

A frame and glue technology, which is applied in the field of gluing mechanism on the outer wall of the frame, can solve the problems of high labor intensity, difficulty in guaranteeing product quality, and large influence of human factors, so as to improve glue spraying efficiency, ensure service life, and glue Gives constant and stable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

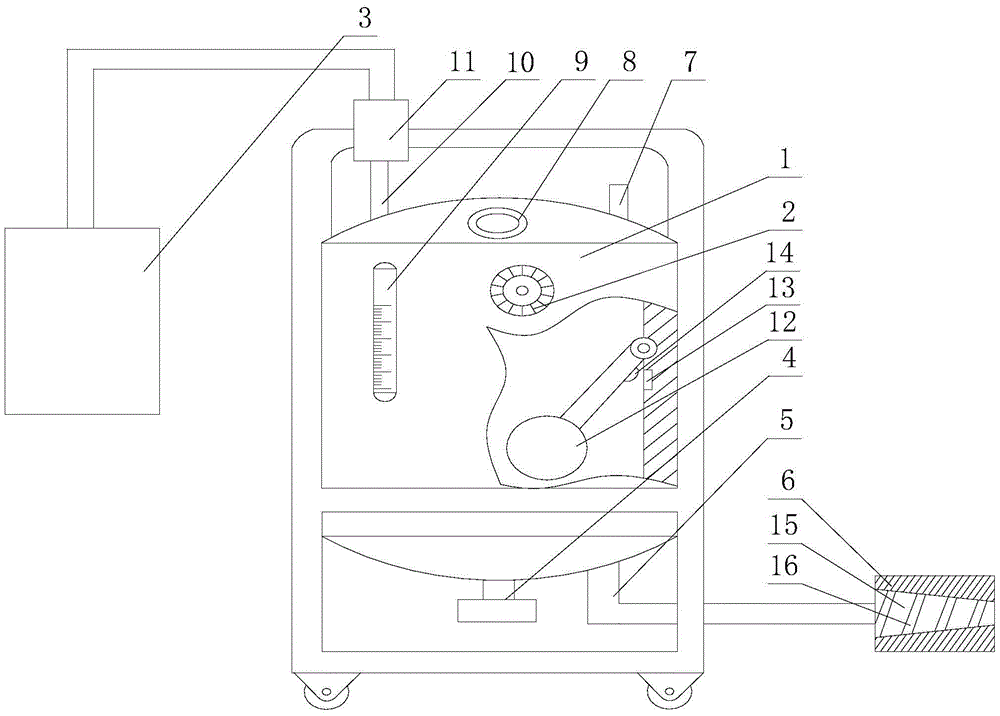

[0026] Such as figure 1 As shown, this embodiment includes the following steps:

[0027] A Fill a certain amount of glue into the tank through the glue inlet, and read the initial amount of glue inside the tank in real time through the liquid level gauge;

[0028] B Start the air pump, and the air flow starts to inject into the tank through the intake pipe. With the increase of the pressure in the tank, the glue is directly sprayed on the working surface of the wooden board through the glue outlet pipe and the nozzle under the action of air pressure, so as to realize automatic glue application;

[0029] C When the liquid level of glue in the tank fluctuates, the floating ball starts to make a circular motion around the hinge point of the connecting rod; when the liquid level of the glue drops, the floating ball makes a counterclockwise circular motion around the hinge point of the connecting rod. The protruding part on the bottom surface of the rod is directly in contact with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com