Patents

Literature

56results about How to "Spray glue evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for manufacturing tobacco sheet taking substrate as carrier through dry paper making method

A method for manufacturing tobacco sheet taking substrate as a carrier through a dry paper making method comprises the following steps: spraying slurry onto the right side of the substrate through a high pressure spraying method, and meanwhile carrying out negative pressure suction across a wire belt to the reverse side of the substrate; then sending the substrate into an oven and carrying out medium temperature baking and humidity discharging under the condition that the temperature of the substrate is 55 DEG to 70 DEG, and enabling hot air inside the oven to flow directional from the right surface of the substrate to the reverse surface of the substrate to carry out humidity discharging; sequentially, carrying out normal temperature humidity discharging treatment; setting medium temperature baking and humidity discharging time and the normal temperature baking and humidity discharging alternatively; and repeating the steps on the reverse side of the substrate, namely a tobacco sheet is prepared. The substrate is prepared by that scattered material is evenly paved and absorbed onto a formation fabric for dry paper making to form a fiber thin layer under the vacuumpumping of a vacuum air pumping device under the formation fabric, and carrying out antistatic-electricity treatment; and spraying adhesion agent onto a fiber thin layer, under the combination of mist spraying and vacuum take-off on sprayed back surface; and finally carrying out drying.

Owner:CHINA TOBACCO HUNAN INDAL CORP +1

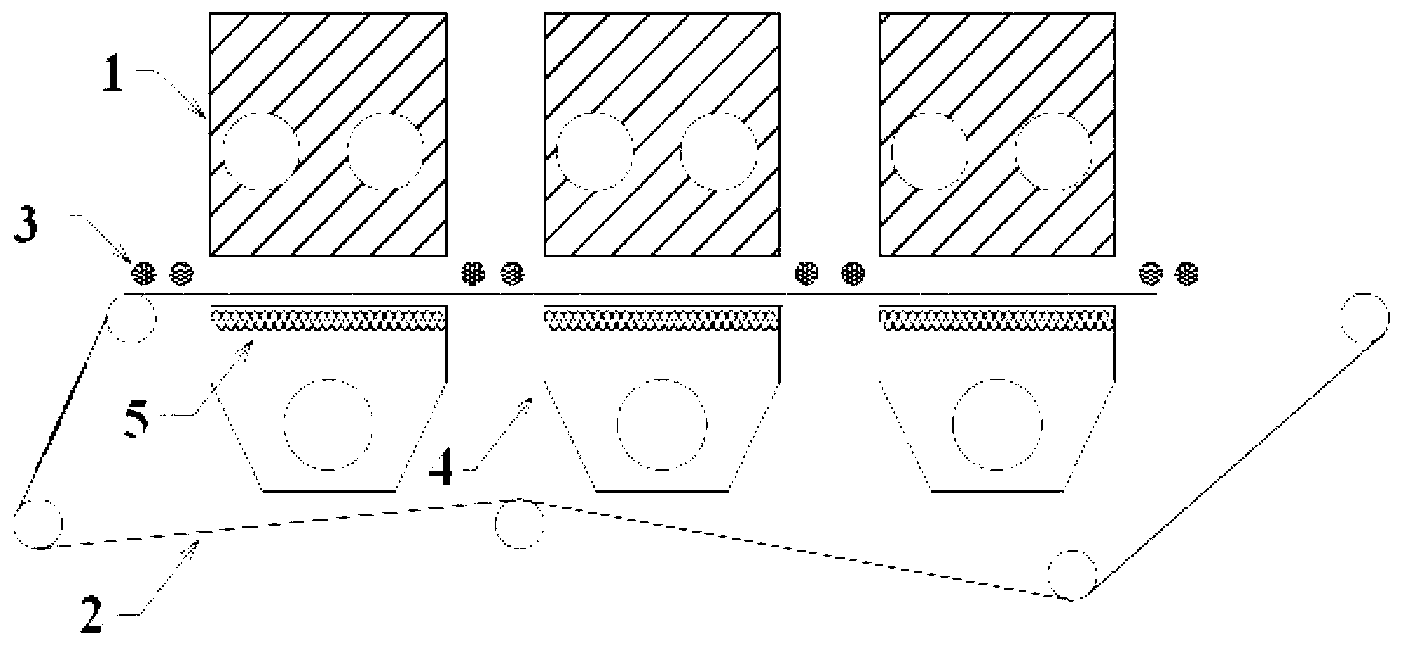

Method for manufacturing remanufactured tobacco base sheets with dry paper-making method

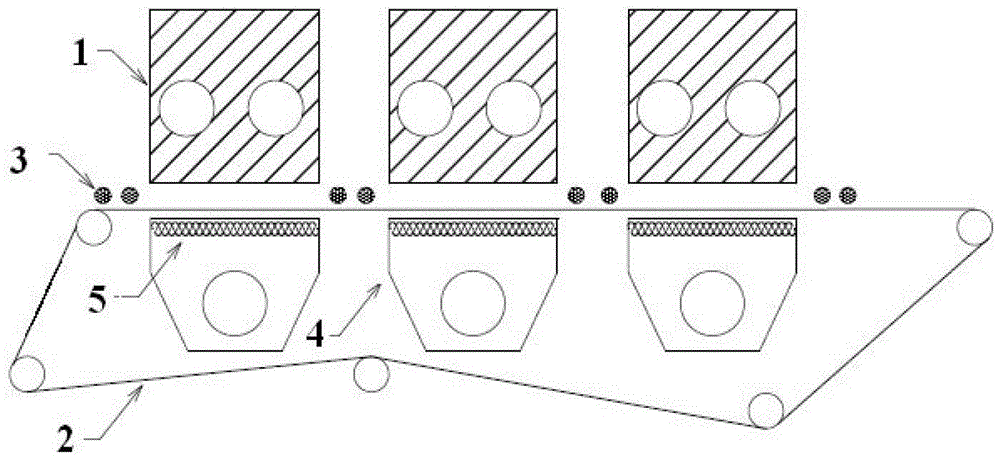

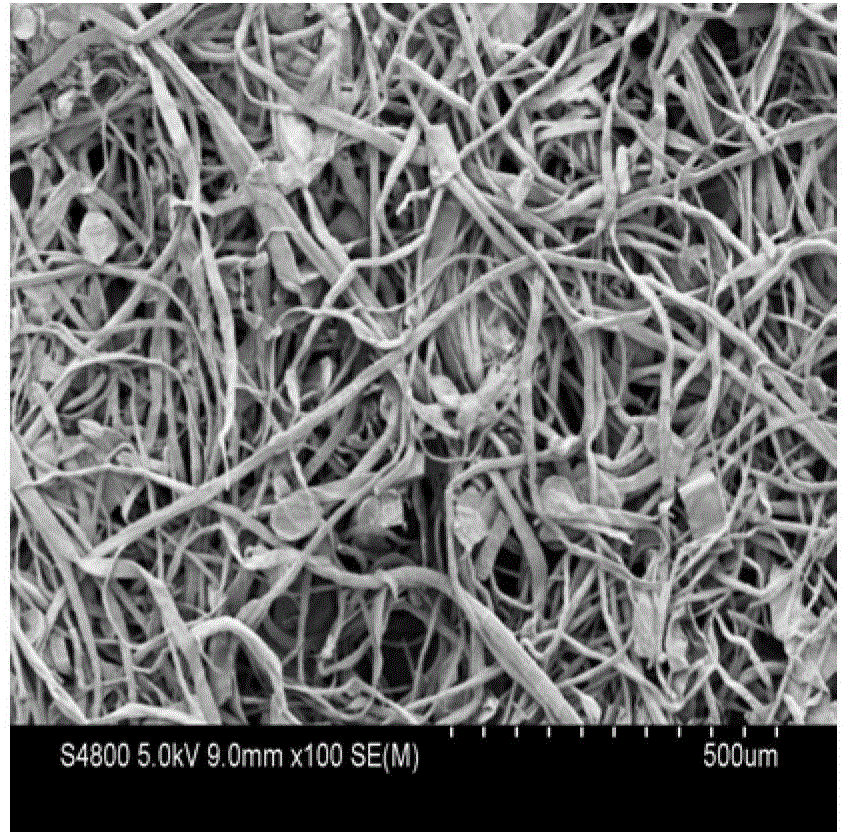

The invention discloses a method for manufacturing remanufactured tobacco base sheets with a dry paper-making method. The method comprises the steps as follows: raw materials including cabo and plant fibers are ground and broken into short fibers, and then fed by wind into a forming head box for breaking up; by the aid of the vacuum pumping action of a vacuum evacuating device under a forming net, the broken-up materials are uniformly laid and adsorbed on the forming net for dry paper-making, so that a thin fiber layer is formed; the thin fiber layer is sprayed with an adhesion agent, and a manner combing mist spraying and vacuum drawing of a prayed back surface is adopted; finally the materials are dried and the tobacco base sheets are obtained; an antistatic rope is laid between the forming net and the forming head box and / or between the forming net and an opening of a vacuum box; or / and an antistatic net is arranged between the forming net and the opening of the vacuum box; the adhesion agent comprises chitosan and the like; and the remanufactured tobacco base sheets having higher wet strength stretching-resistant capacity and filling value and good processing performance are prepared with the dry paper-making method successfully for the first time.

Owner:CHINA TOBACCO HUNAN INDAL CORP +1

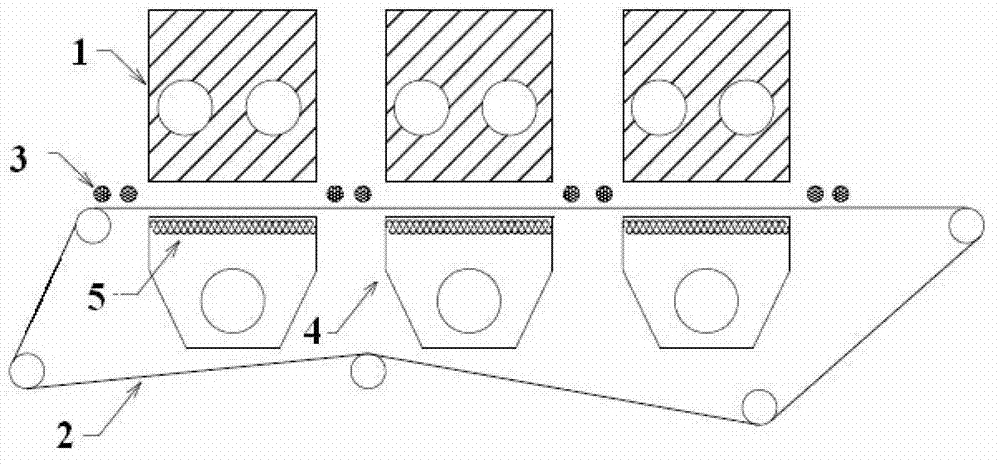

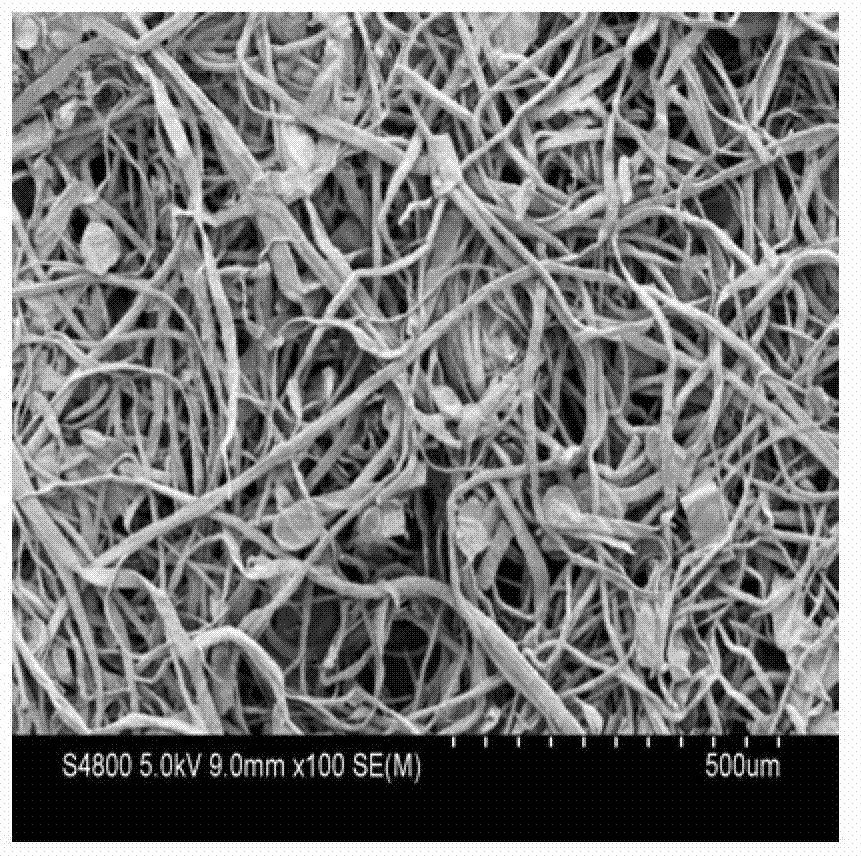

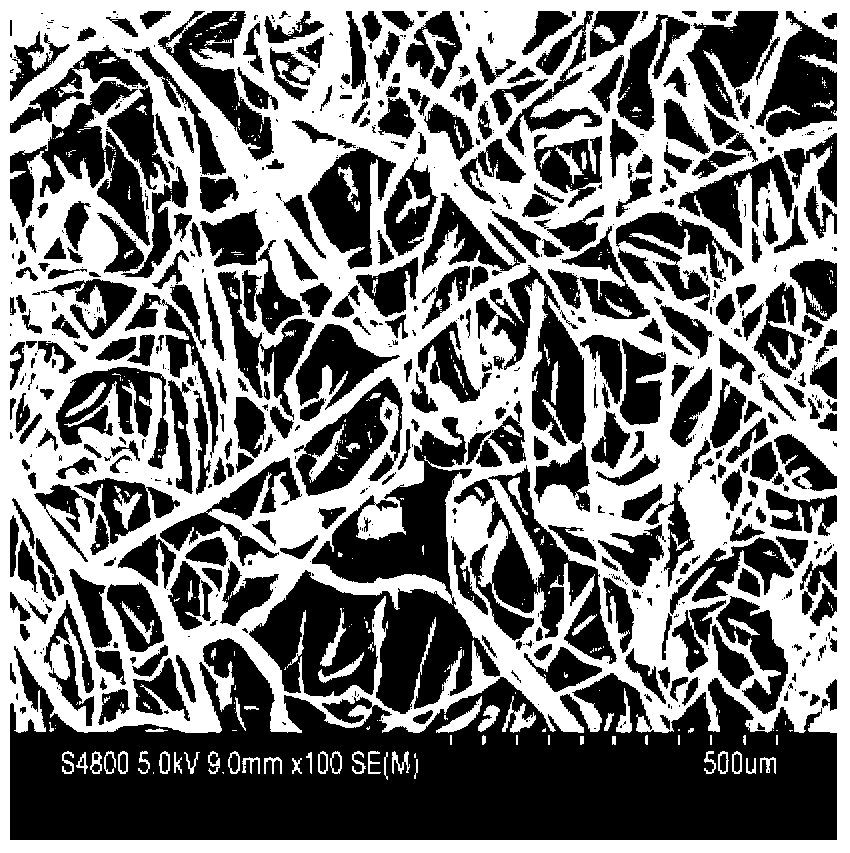

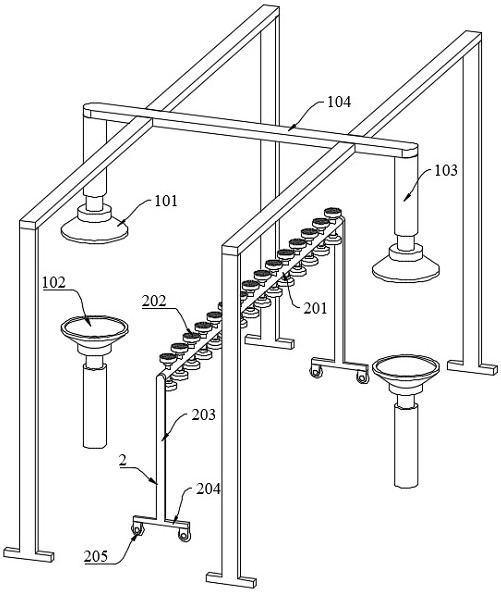

Method for manufacturing reconstituted tobacco substrate by using dry method of paper making

ActiveCN103222676AMake a qualitative leapNo significant emissionsTobacco preparationFiberCarrying capacity

A method for manufacturing a reconstituted tobacco substrate by using a dry method of paper making comprises the following steps: after tobacco stems, plant fiber materials become short fibers by crushing and fiber dissolving, the short fibers are conveyed to forming head boxes to be broken up by wind, and the broken-up materials are evenly laid and adsorbed on a forming net of the dry method of paper making by the vacuumizing effect of an air suction device below the forming net to form a fiber film; an adhesive is added into the fiber film in a spraying manner, wherein a manner combining spraying through mist spray with vacuum suction on the back face of the spraying is adopted; and finally the reconstituted tobacco substrate with a dimensional lattice structure is obtained by oven-drying. Antistatic ropes are laid between the upper part of the forming net and the forming head boxes or between the forming net and openings of vacuum boxes, and / or antistatic nets are laid between the forming net and the openings of the vacuum boxes. According to the invention, dry method of paper making is firstly used successfully to manufacture the reconstituted tobacco substrate which has better wet strength, a stronger tensile capacity, a high load-carrying capacity, a high filling value and an excellent processing capability.

Owner:CHINA TOBACCO HUNAN INDAL CORP

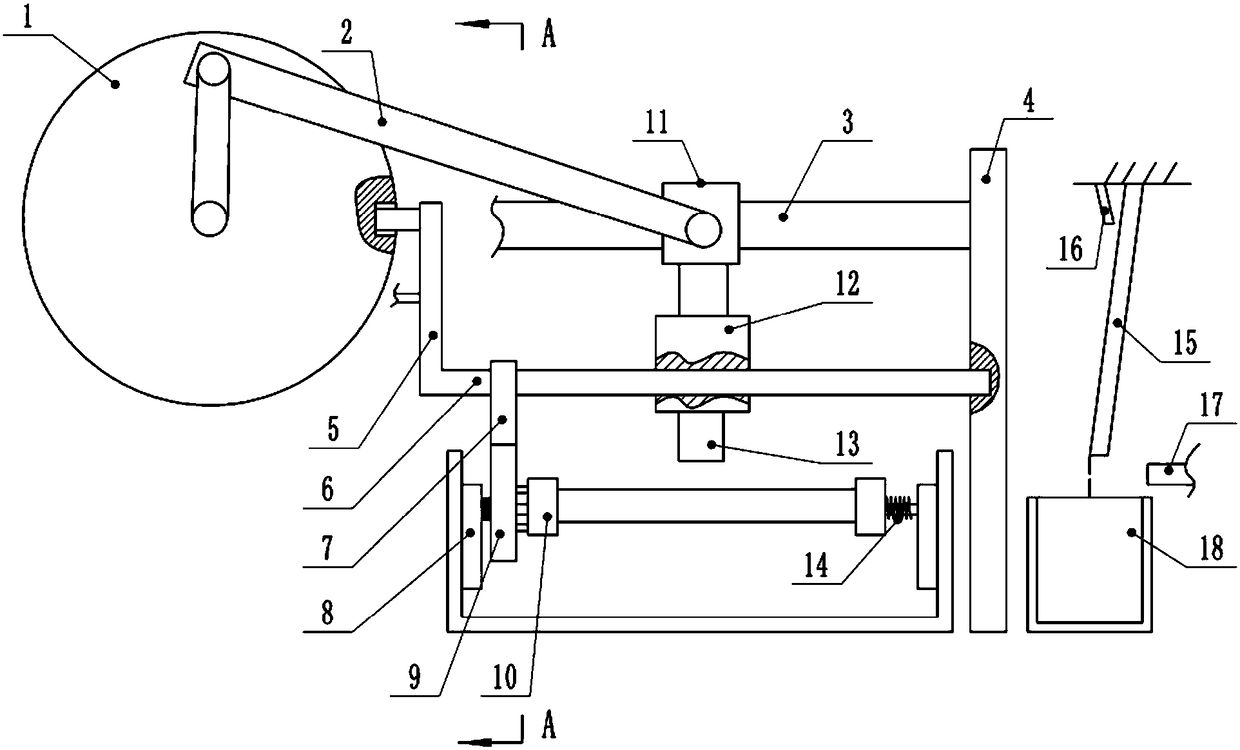

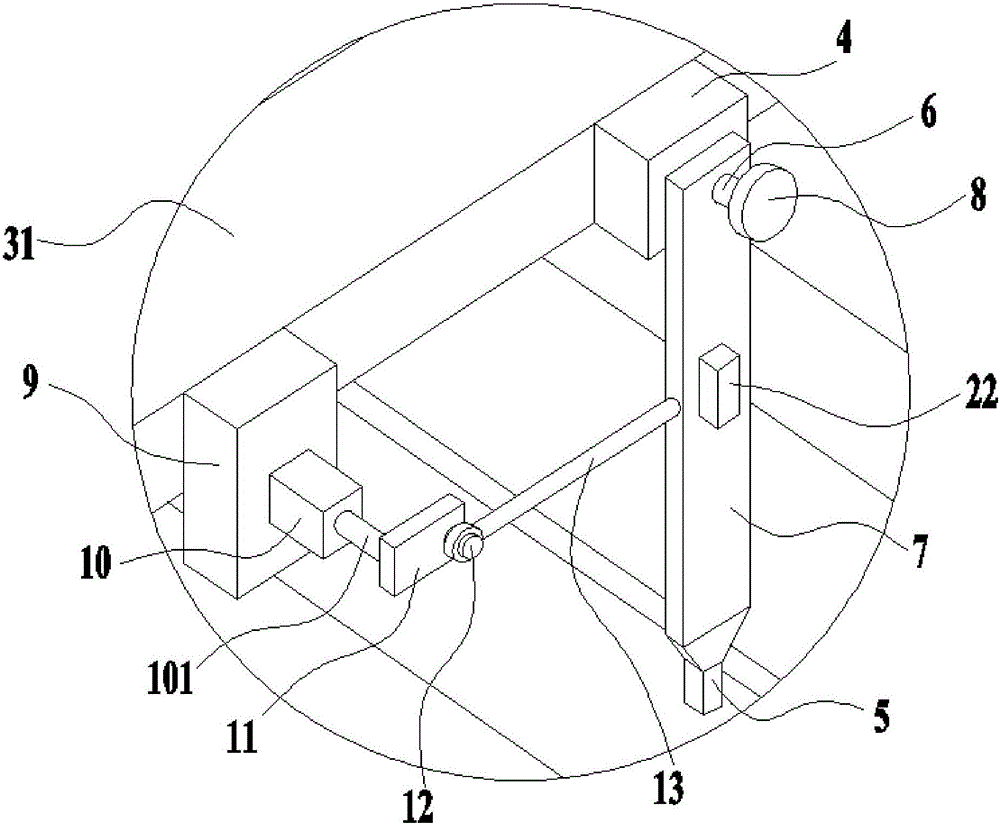

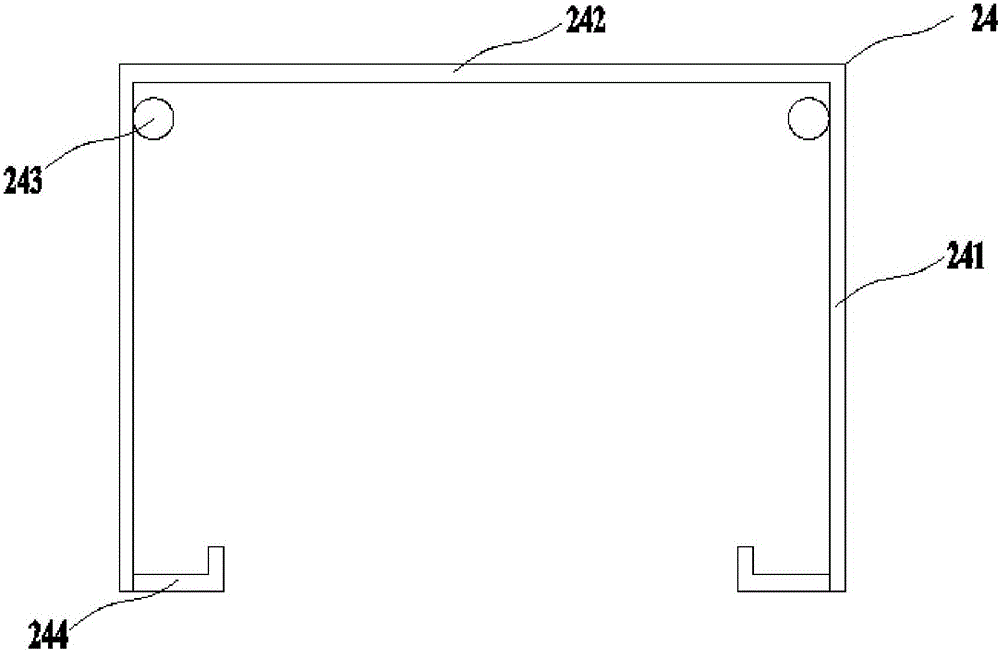

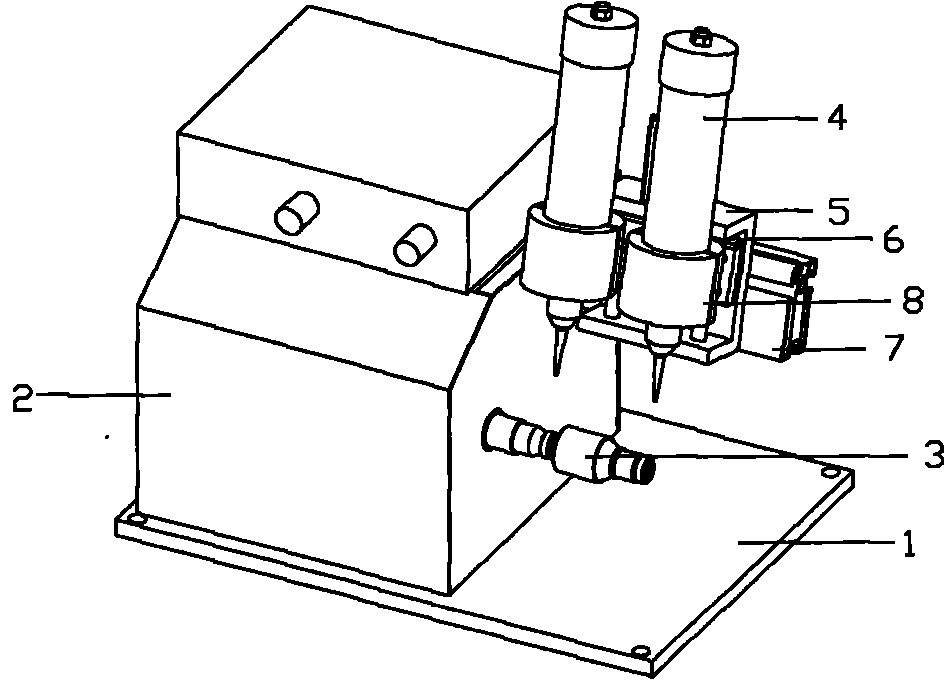

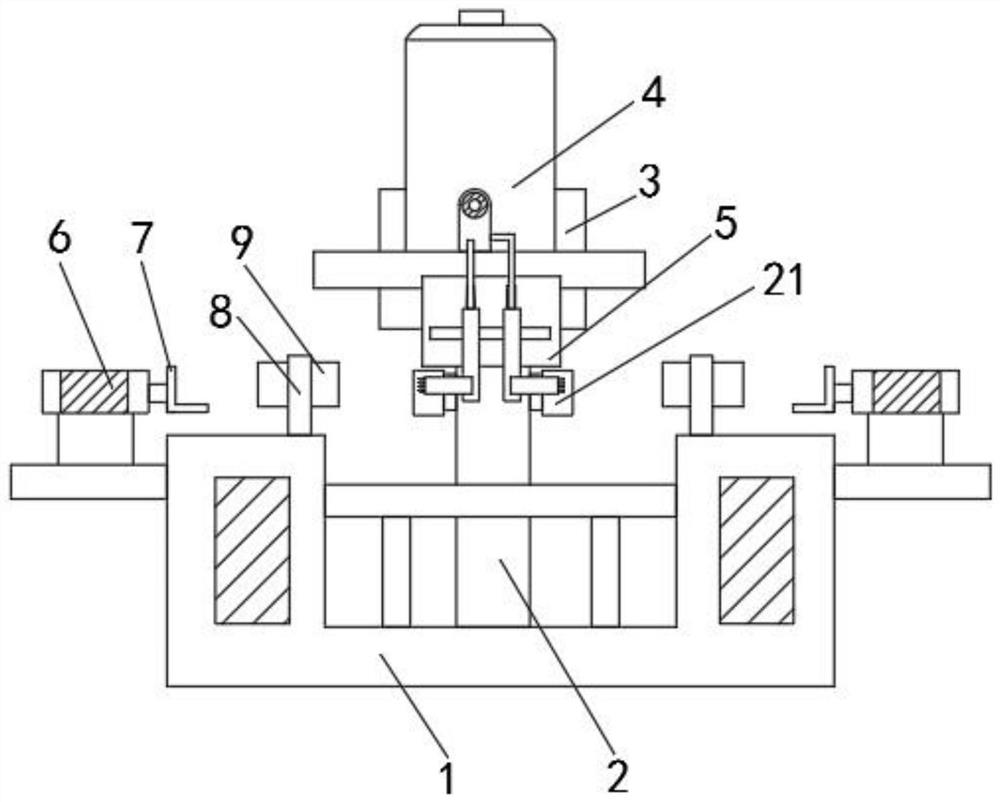

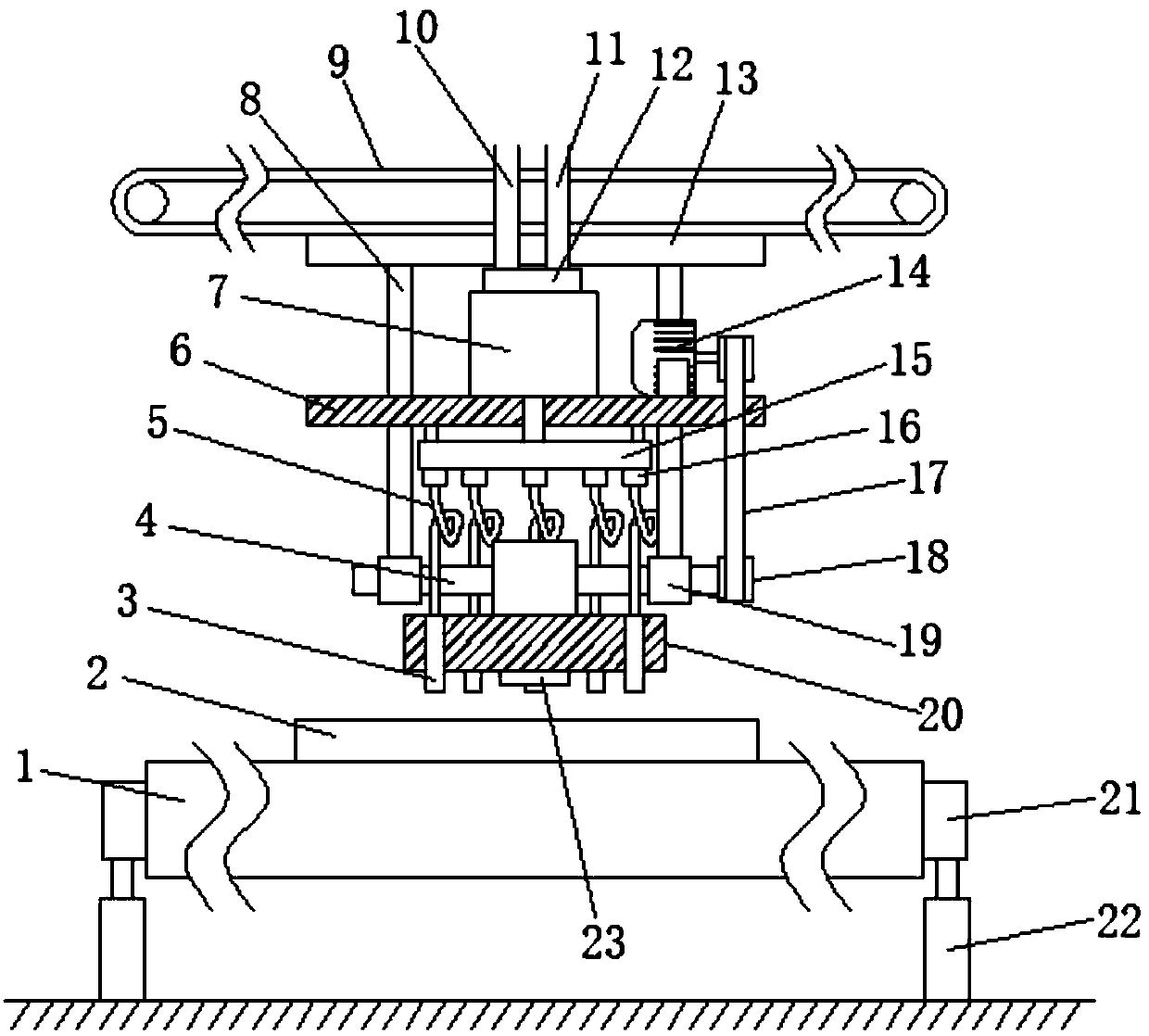

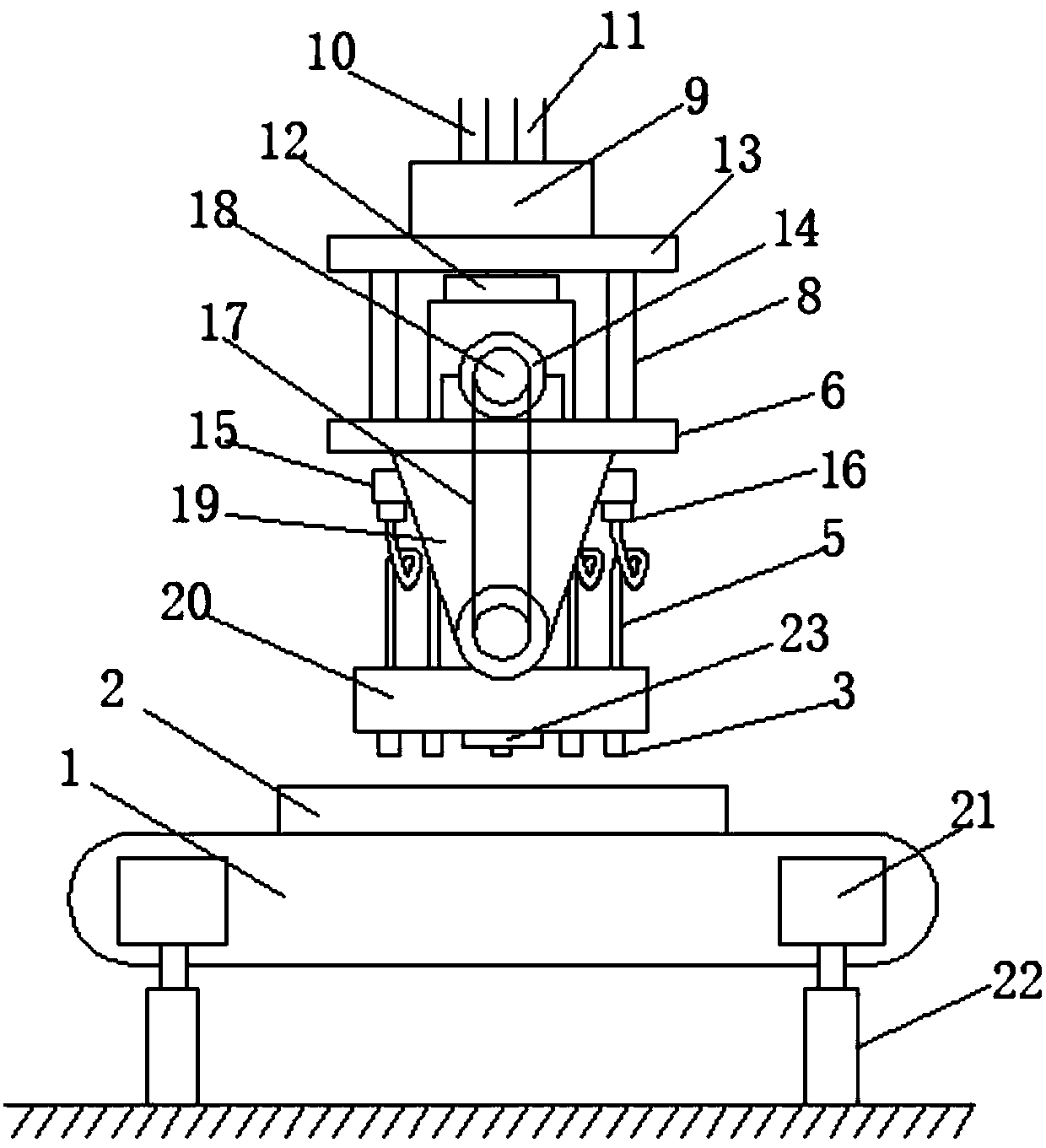

Glue spraying device

The invention belongs to the technical field of spraying equipment, and particularly relates to a glue spraying device. The glue spraying device comprises a conveying mechanism and a glue spraying part. The conveying mechanism is provided with a plurality of clamping mechanisms; the glue spraying part comprises a reciprocating movement mechanism, a reciprocating swinging mechanism and a glue spraying gun; the reciprocating movement mechanism is a slider-crank mechanism; an installation mechanism is hinged onto a slide block; the reciprocating swinging mechanism comprises a cylinder and a swinging rod; the swinging rod is hinged onto the rack; a curve sliding chute is formed in the curve surface of the cylinder; the upper end of the swinging rod is slidably connected into the curve slidingchute; the cylinder rotates to drive the swinging rod to swing in a reciprocating way through the curve sliding chute; a driving rod is fixed to the lower end of the swinging rod and is parallel to asliding rod; the installation mechanism is slidably connected onto the driving rod; a wabbler mechanism is arranged between the driving rod and the clamping mechanism; and the driving rod swings in areciprocating way so as to drive the clamping mechanism to rotate through the wabbler mechanism. When the glue spraying device provided by the scheme is used for spraying a glue, the glue spraying guncan move front and back in a reciprocating way and swinging left and right in a reciprocating way, and a workpiece can further rotate in a reciprocating way, so that a glue spraying effect is good, and the glue spraying efficiency is high.

Owner:陕西华强涂装技术有限公司

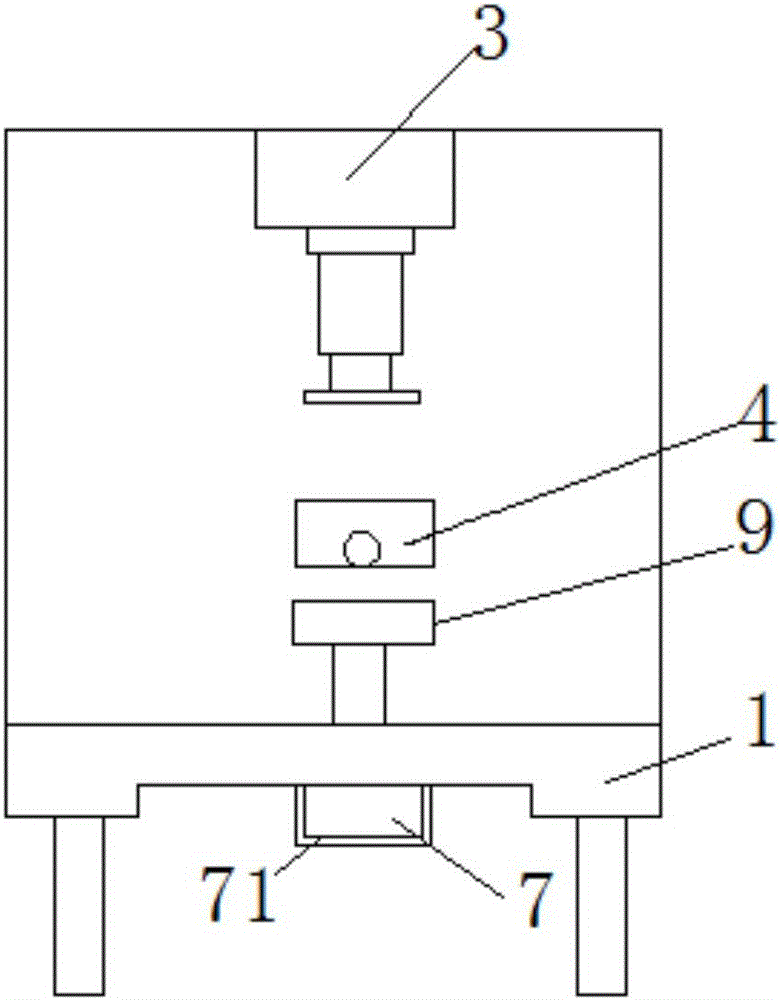

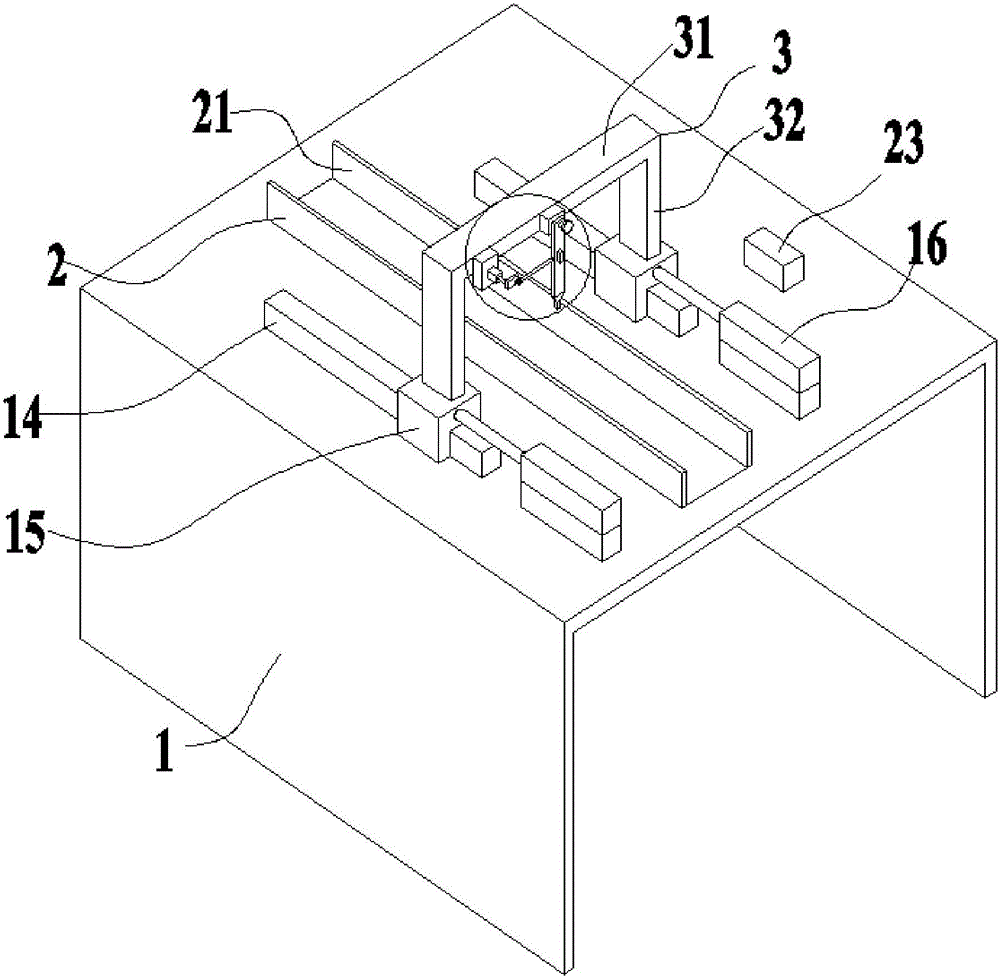

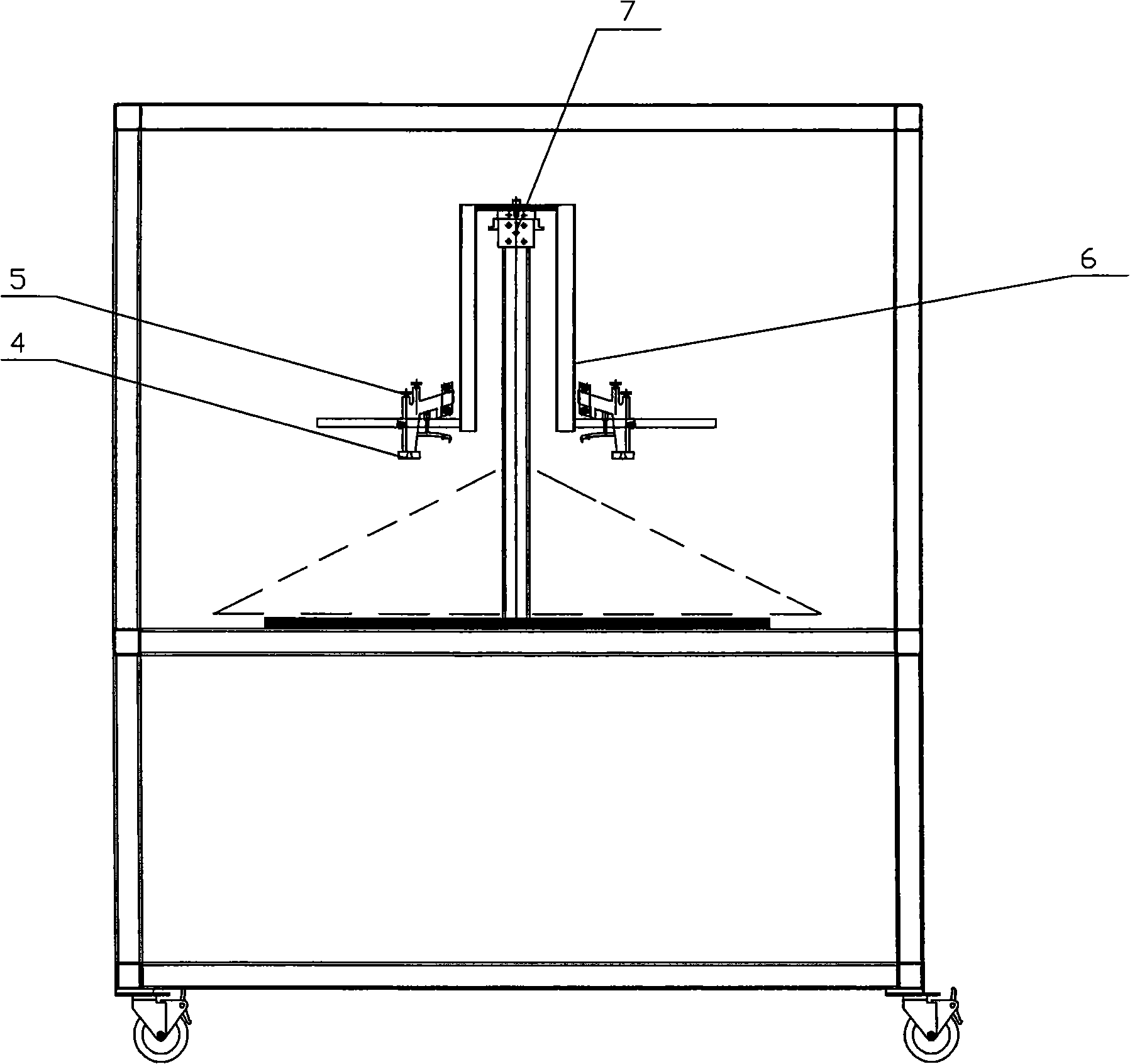

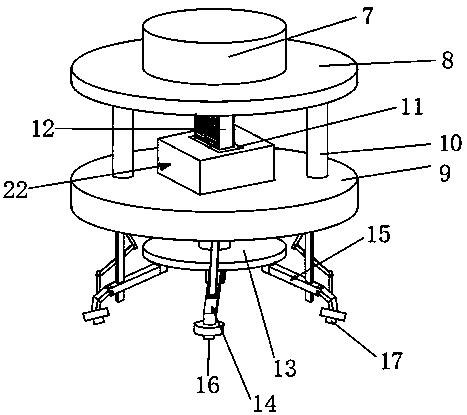

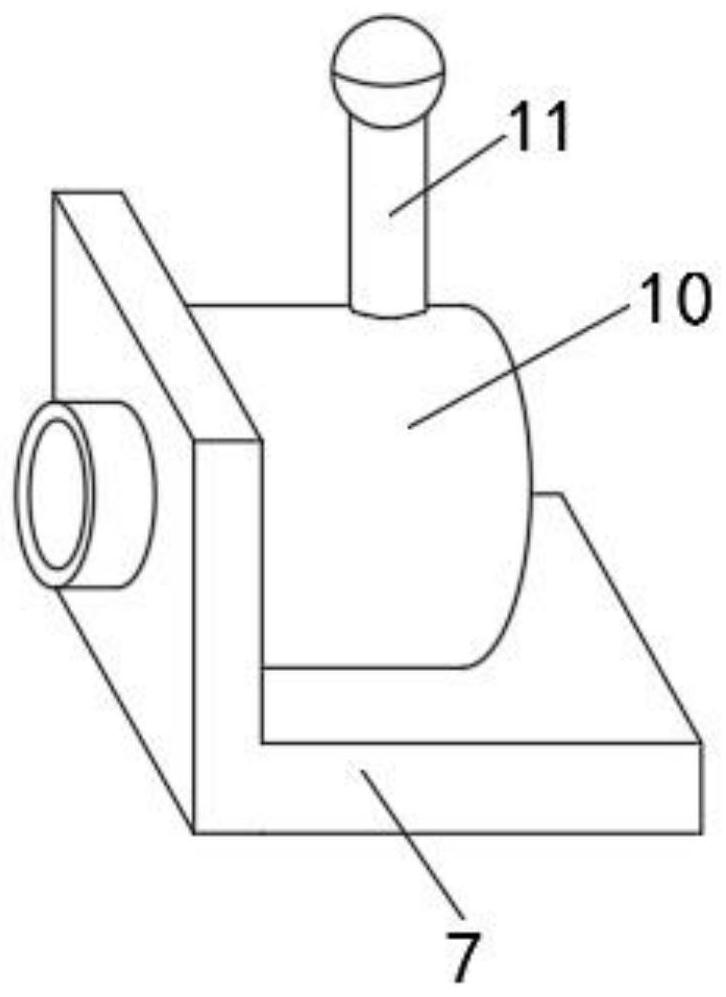

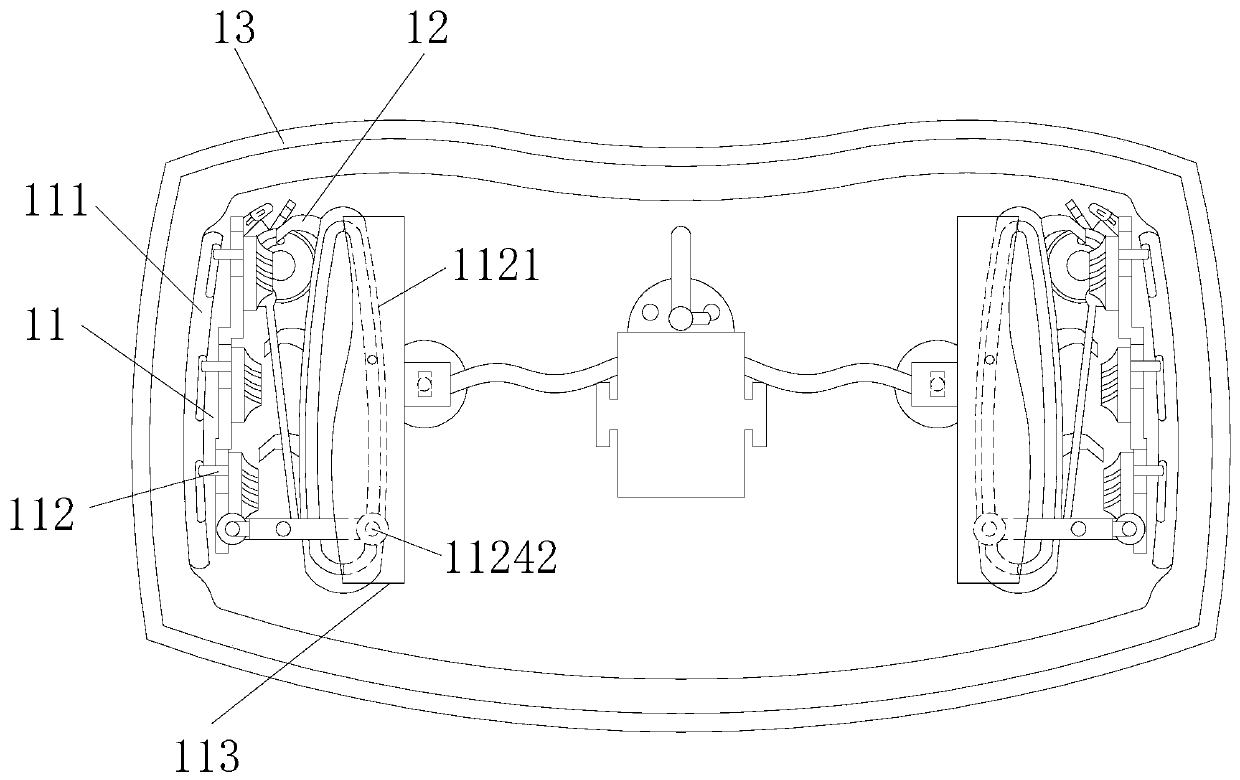

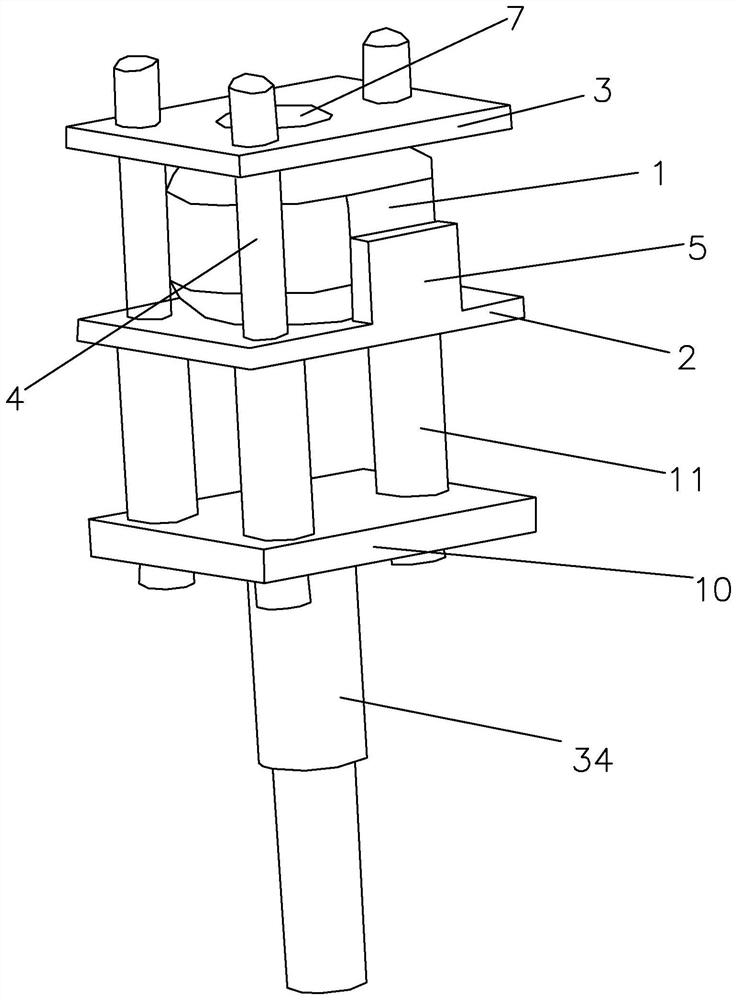

Rotary clamping device of shoe sole glue sprayer

InactiveCN105795606AEasy to useAvoid stayingSpraying apparatusShoe gluingEngineeringAtmospheric pressure

The invention discloses a rotary clamping device of a shoe sole glue sprayer. The device comprises a worktable plate, a side plate and a connection rod. A flange bearing is embedded in the bottom face of one end of the connection rod. A shaft in the flange bearing is fixedly connected with the upper end of a pneumatic cylinder, a piston rod is inserted in the pneumatic cylinder, one end of the piston rod is connected with a first clamping piece, a motor is arranged at the bottom end of the worktable plate, an upright column is inserted in the middle of the worktable plate, the bottom end of the upright column is connected with the motor through a shaft, and a second clamping piece is fixed to the upper end of the upright column. The rotary clamping device of the shoe sole glue sprayer is simple in structure, the pneumatic cylinder is additionally arranged so that resources can be saved and gas can be injected at any time to make the piston rod move up and down, and accordingly work efficiency of gluing is improved. The first clamping piece and the second clamping piece are driven by the motor, the flange bearing and the upright column to rotate, so that a shoe sole can be glued during rotation unlike some traditional glue sprayers. The clamping device rotates to reduce the load of the motor, and the gluing speed is increased.

Owner:WENZHOU JUNA SHOES IND CO LTD

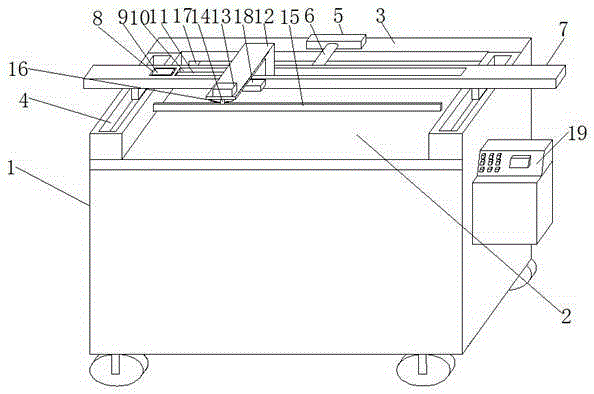

Automatic induction glue spraying device for brake shoe

The invention discloses an automatic induction glue spraying device for a brake shoe. The automatic induction glue spraying device comprises a rack platform. A guide rail is arranged on the rack platform. A portal frame is arranged above the guide rail in a spanning manner. A spraying head fixing seat is arranged on one side of a top beam of the portal frame. A glue spraying head capable of swinging back and forth in the direction perpendicular to the guide rail is arranged on the spraying head fixing seat. The portal frame is provided with a driving device used for driving the glue spraying head to swing back and forth in the direction perpendicular to the guide rail. Glue spraying can be conducted on the outer circumferential face of the brake shoe stably and evenly, the glue spraying head can move forwards and backwards in the direction of the guide rail, and the glue spraying position is convenient to adjust.

Owner:湖北新亿通机车配件有限公司

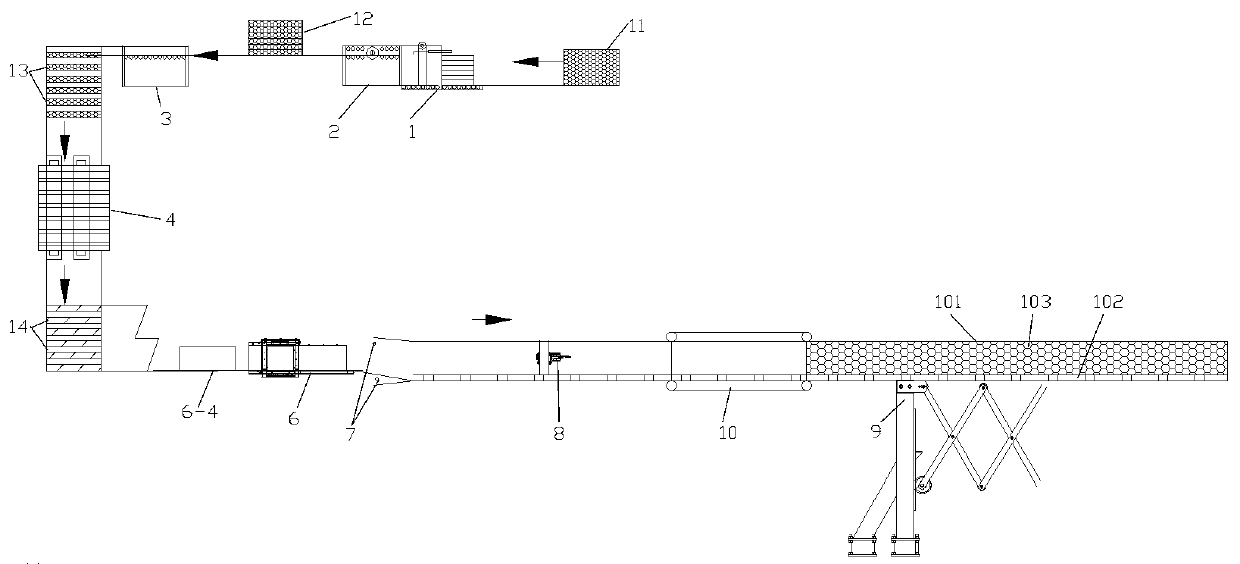

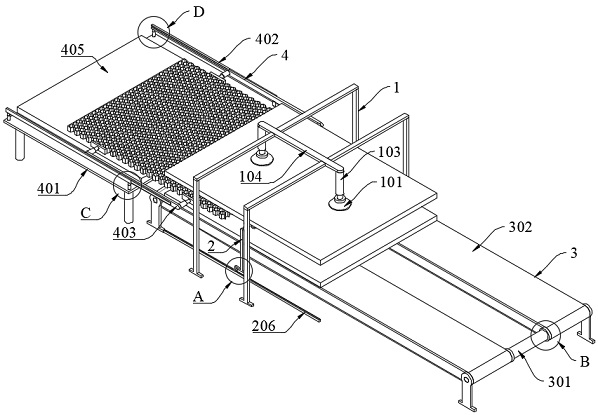

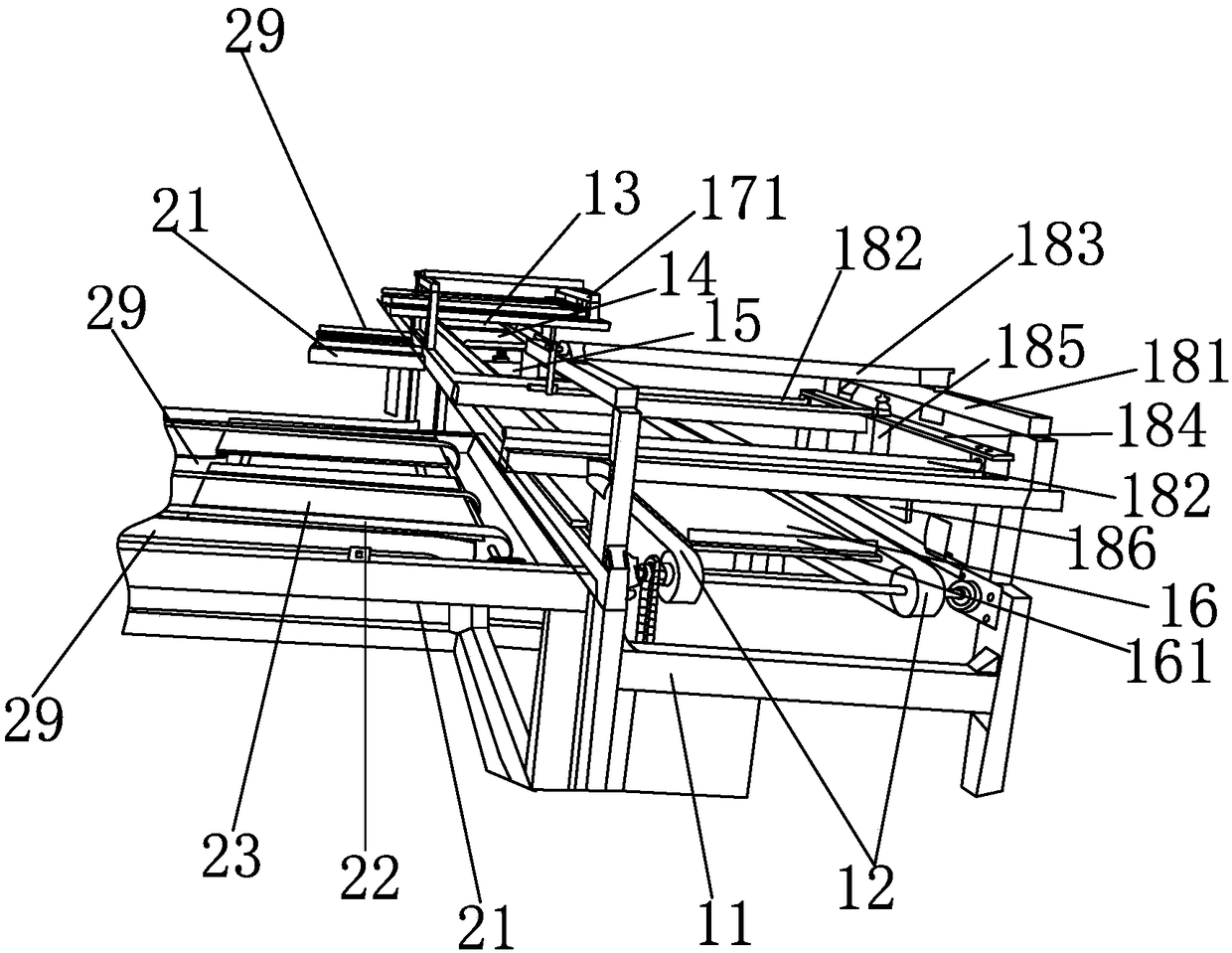

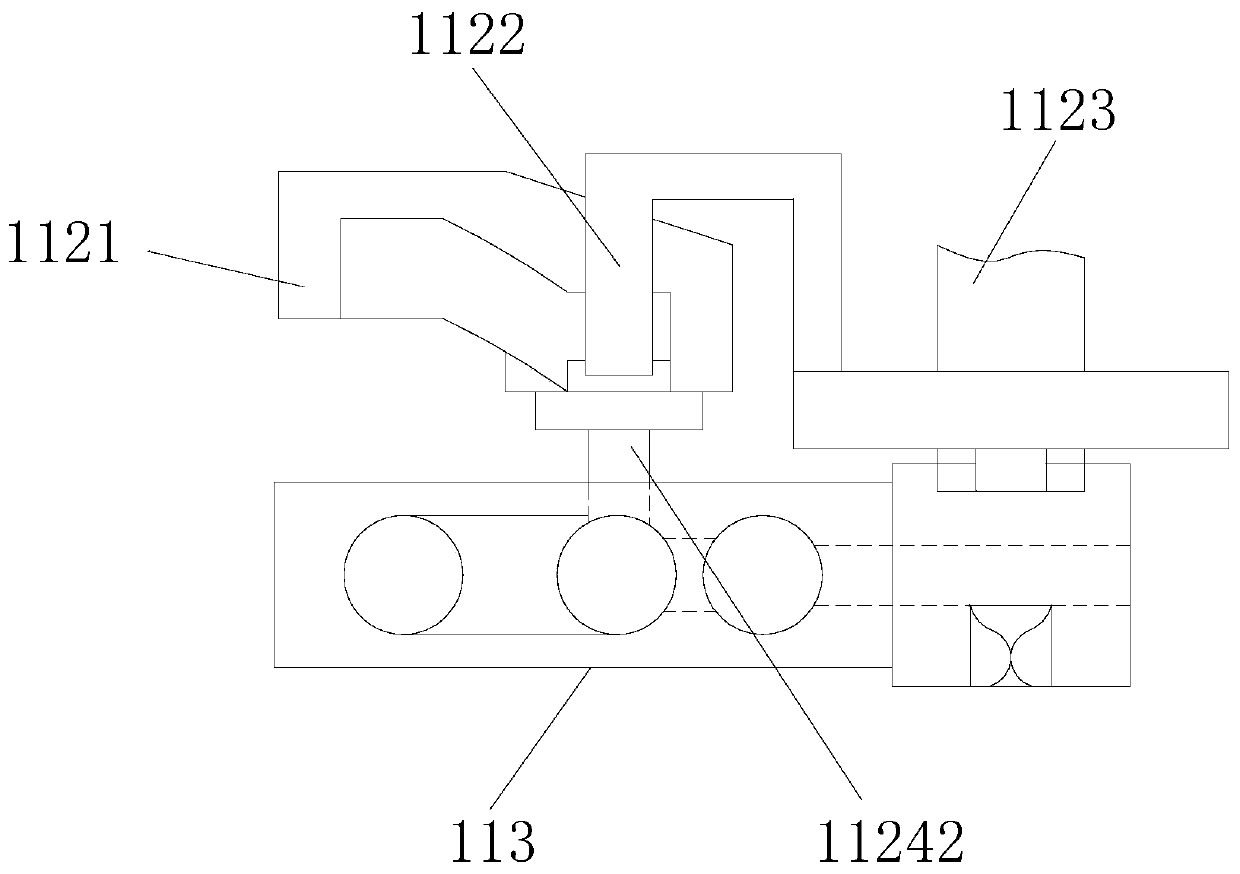

Production line of light composite wallboard

PendingCN111468328ARealize feeding automationNo pollution in the processLamination ancillary operationsSpraying apparatusProduction lineThermal insulation

The invention discloses a production line of a light composite wallboard. The production line comprises a rock wool cutting device, a steel board glue spraying device and a composite board forming device. The rock wool cutting device is used for cutting to-be-slit rock wool blocks into slit rock wool blocks and conveying the rock wool blocks to the composite board forming device. The a steel boardglue spraying device is used for spraying glue to the inner end faces of steel boards and conveying the steel boards to the composite board forming device. The composite board forming device is usedfor attaching and carrying out aftertreatment on the steel boards and inner sandwich layers. The rock wool cutting device comprises a feeding lifting mechanism, a rock wool block cutting mechanism, arock wool strip separating mechanism and a rock wool strip conveying mechanism. The composite board forming device receives output rock wool strips from the rock wool cutting device and output color steel boards of the steel board glue spraying mechanism at the same time, and a distribution mechanism, a crawler belt heating machine and a slitting mechanism are sequentially arranged in the conveying direction of a conveying belt. Fire resistance, thermal insulation properties and other indexes of composite boards produced through the production line are all improved.

Owner:XUCHANG SUPERELEVATOR ELECTRICAL & MECHANICAL EQUIP

Gluing equipment

InactiveCN101786066ASpray glue evenlyPrecise glue sprayLiquid surface applicatorsSpraying apparatusFixed frameEngineering

The invention relates to gluing equipment. The gluing equipment comprises at lest one automatic glue-spraying gun and a drive device, wherein the drive device is used for driving a workpiece fixed on a fixing frame to rotate and fixedly provided with a rail corresponding to the fixing frame; an automatic glue-spraying gun is arranged on the rail in a sliding mode; and the gluing equipment also comprises a movement controller which can make the glue-spraying gun realize automatical coating along gluing paths of different workpieces. Because the gluing equipment adopts the sliding design, under an action of the controller, the automatic glue-spraying gun can automatically, uniformly and accurately spray the glue on the workpieces of different shapes.

Owner:SUZHOU INDAL PARK TAIGE ELECTRONICS SCI &TECH

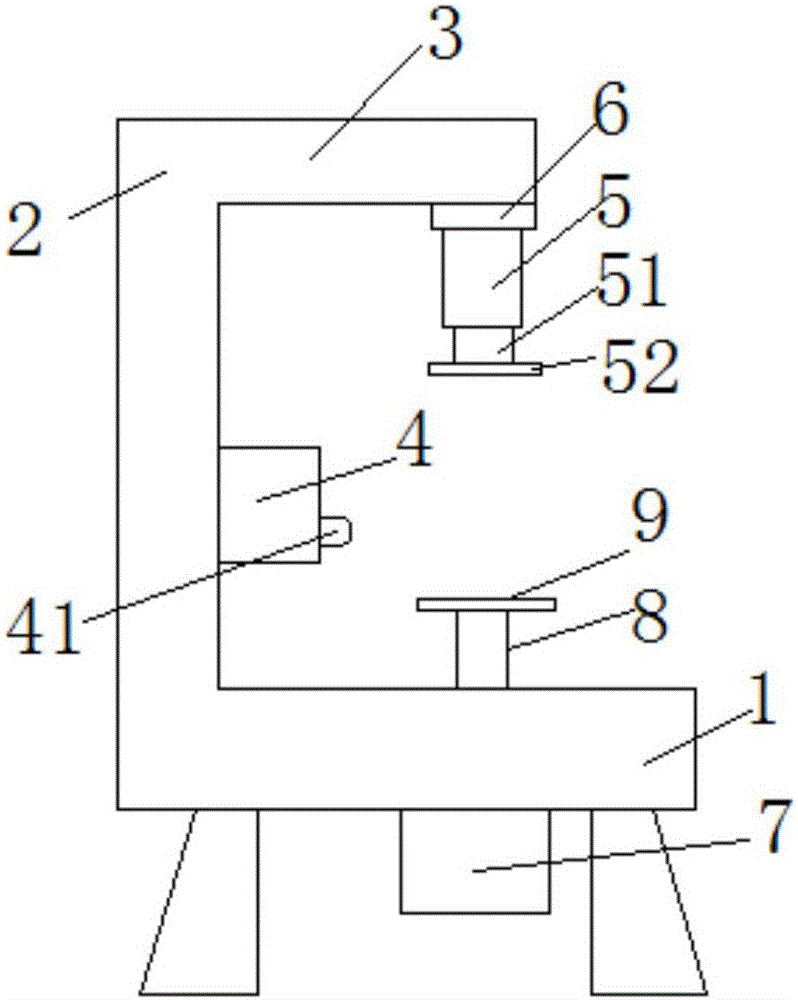

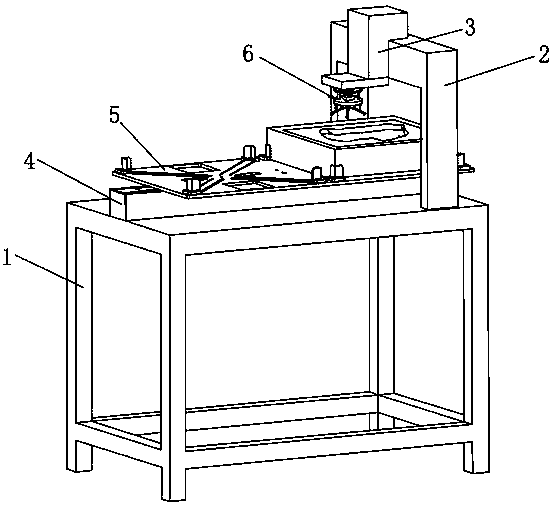

High-uniformity glue sprayer

InactiveCN105413922AAchieve forward and backward movementAchieve left and right movementSpraying apparatusDrive shaftEngineering

The invention discloses a high-uniformity glue sprayer. The high-uniformity glue sprayer comprises a glue sprayer body. A workbench is arranged at the top of the glue sprayer body. A protection cover is arranged on the surface of the workbench. First sliding grooves are formed in the surface of the protection cover and are symmetrically arranged. A first motor is arranged on the surface of the protection cover and connected with one side of a cross beam through a first transmission shaft. The bottom of the cross beam is clamped in the two first sliding grooves through protruding blocks respectively, and the cross beam can slide in the first sliding grooves. A motor storage groove and a second sliding groove are formed in the surface of the cross beam. A second motor is arranged in the motor storage groove and connected with a glue gun through a second transmission shaft. A third motor is arranged on the surface of the glue gun. According to the high-uniformity glue sprayer, the forward and backward movement of the glue gun can be achieved through the first motor, and leftward and rightward movement of the glue gun can be achieved through the second motor.

Owner:无锡万能胶粘剂有限公司

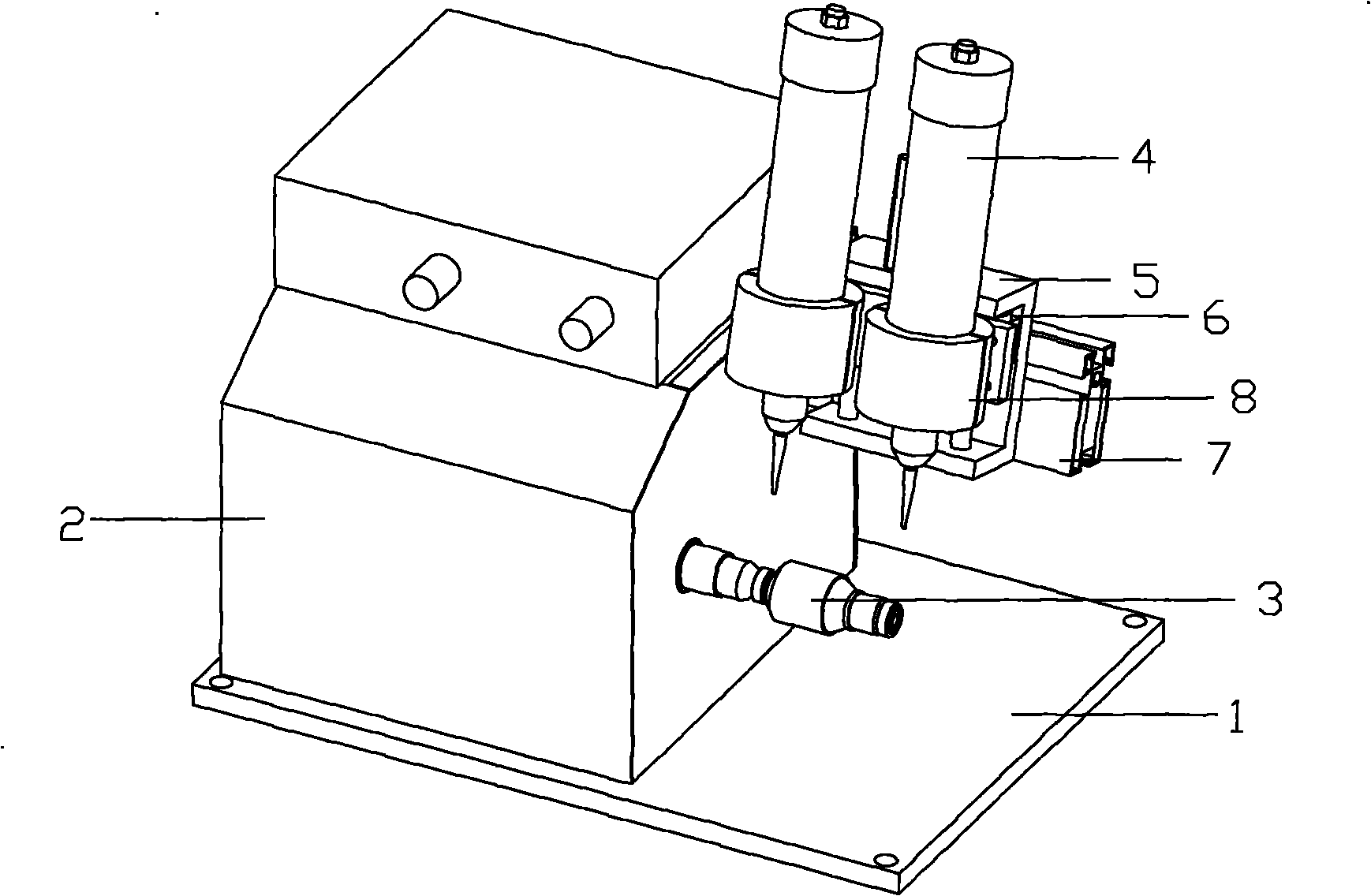

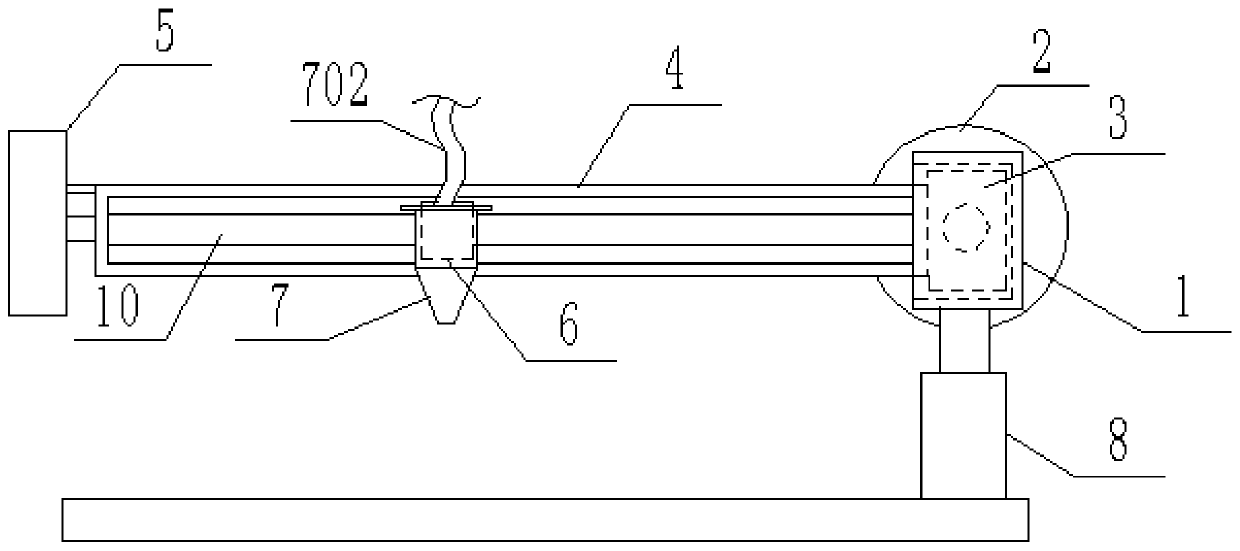

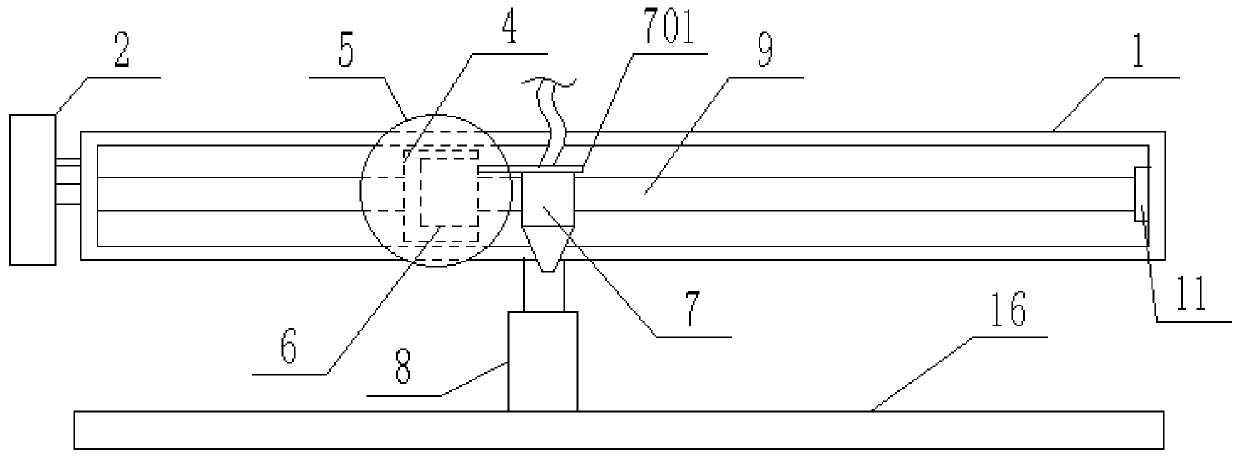

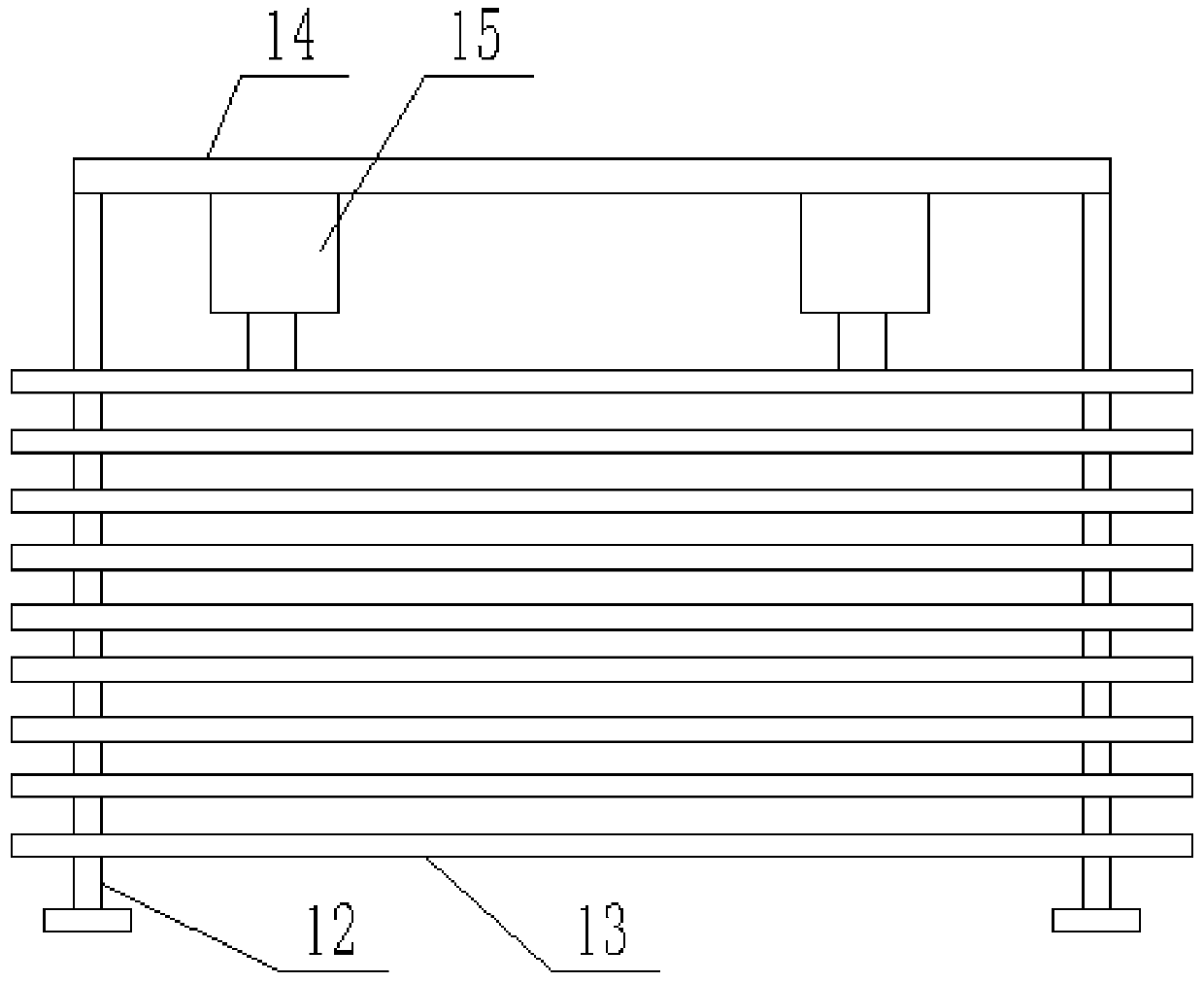

Automatic glue-spraying mechanism of vehicle noise insulation pad

InactiveCN101322963ASpray glue evenlyPrecise positioningLiquid surface applicatorsSpraying apparatusFiberEngineering

The invention relates to an automatic glue spraying mechanism of automobile sound insulating pad, which belongs to the technical field of mechanical structure. The automatic gel spraying mechanism is characterized in that a gel barrel is put on the base of a glue spraying room, a retaining board and a glue jetting rod are arranged in the glue spraying room, a locating block is arranged on the retaining plate and a glue jetting device is arranged at the glue jetting rod; the glue jetting device consists of a nozzle, a pneumatic glue gun, a connecting rod support of the glue gun and a non-rod cylinder; the nozzle is arranged at the pneumatic glue gun which is arranged at the connecting rod support of the glue gun; the connecting rod support of glue gun is arranged at the non-rod cylinder. With the non-rod cylinder serving as a power source, the automatic glue spraying mechanism realizes automatic glue spraying by driving the glue gun to reciprocate by the connecting rod support; therefore, the automatic glue spraying mechanism can adapt to a plurality of products, has high automation degree, ensures that the glue is uniformly sprayed on the surface of the fiber plate of the sound insulating pad with working pieces accurately located and can improve the production efficiency, lower the labor intensity of workers, save the manufacturing cost of products and improve the product quality.

Owner:刘明春

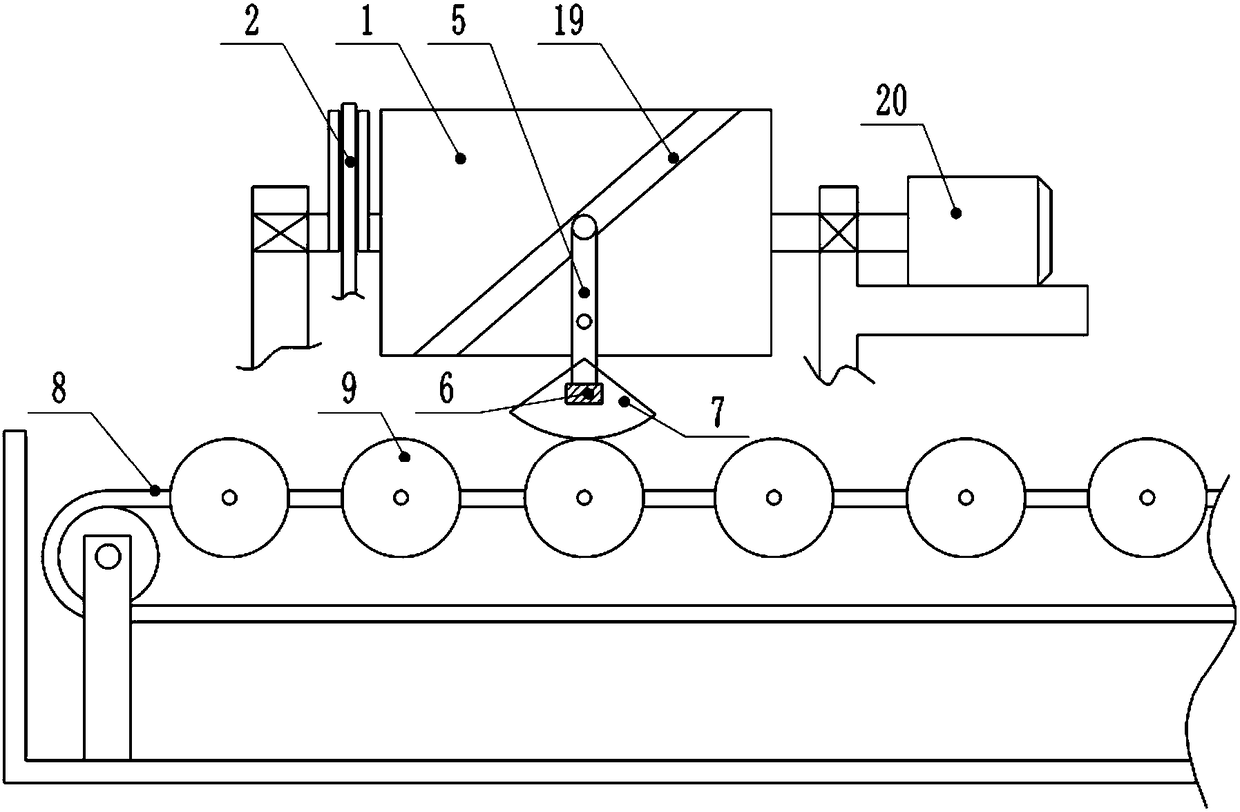

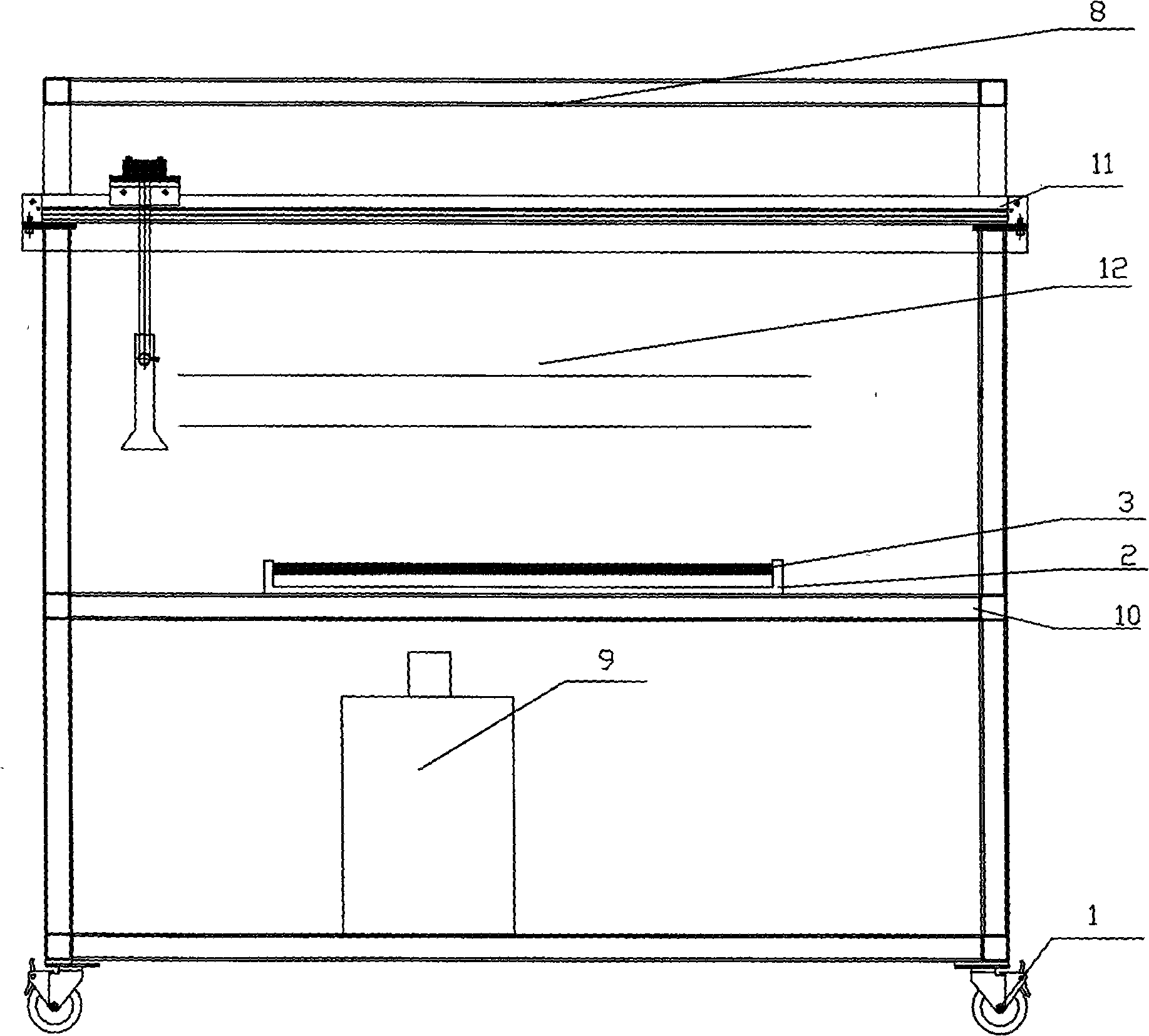

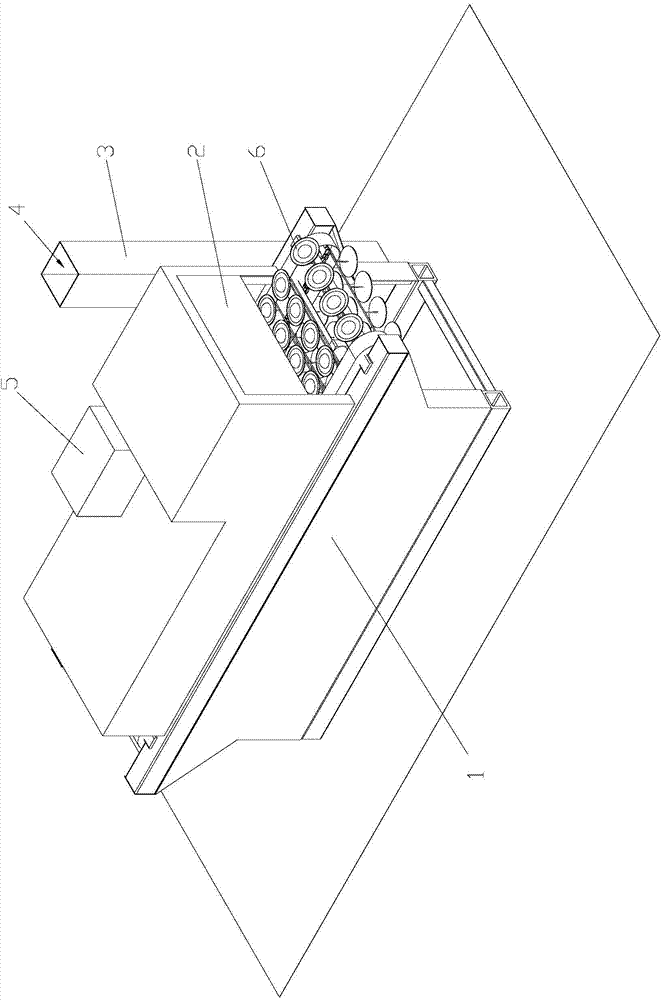

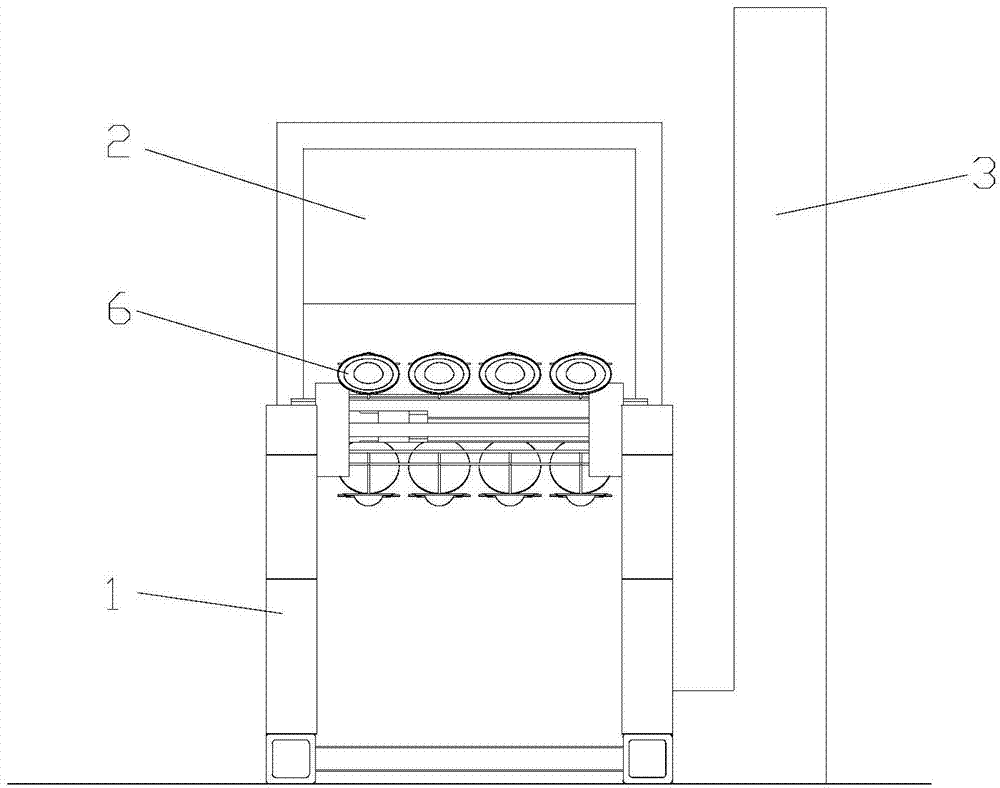

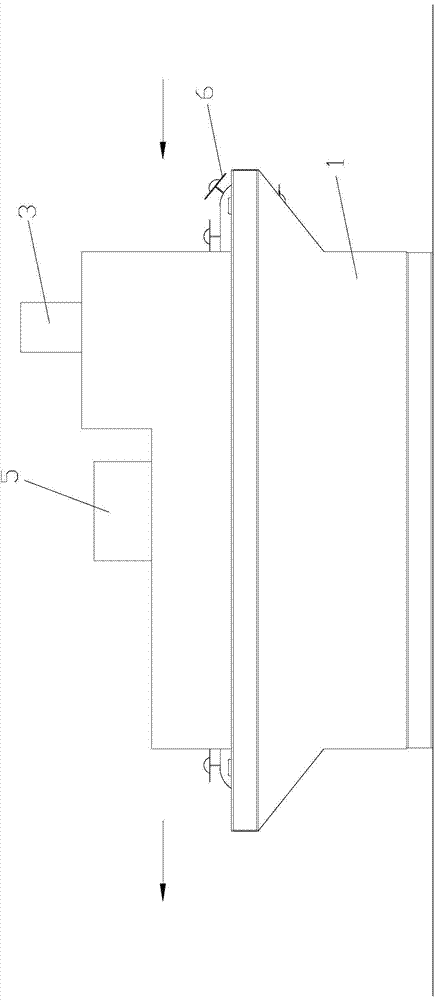

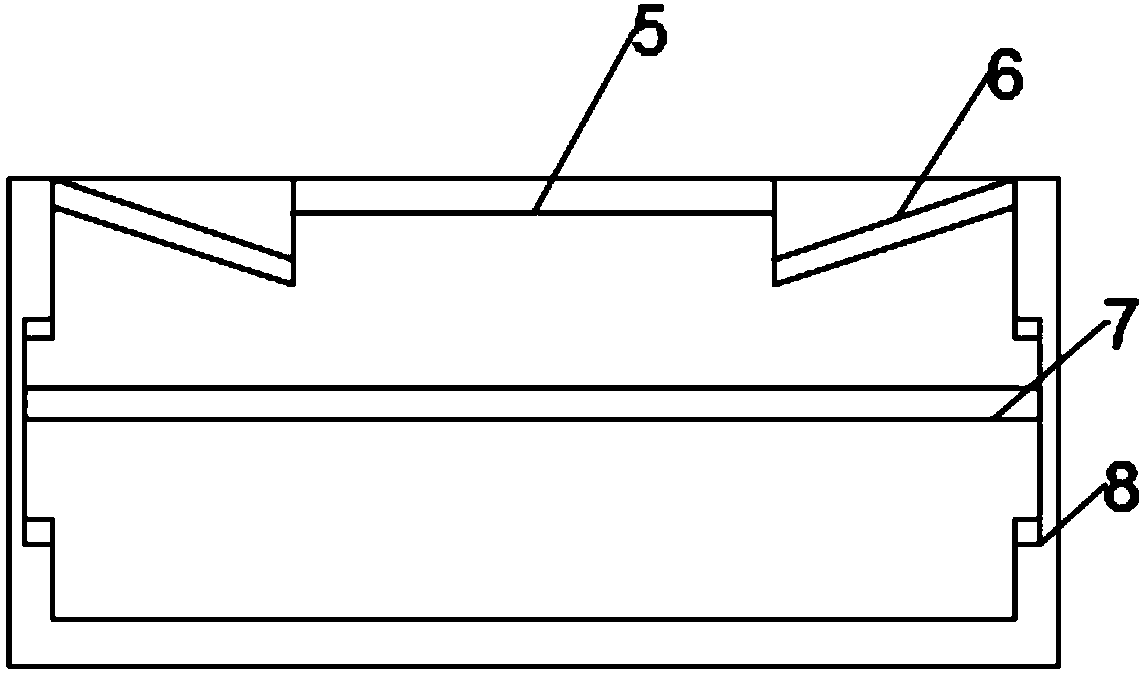

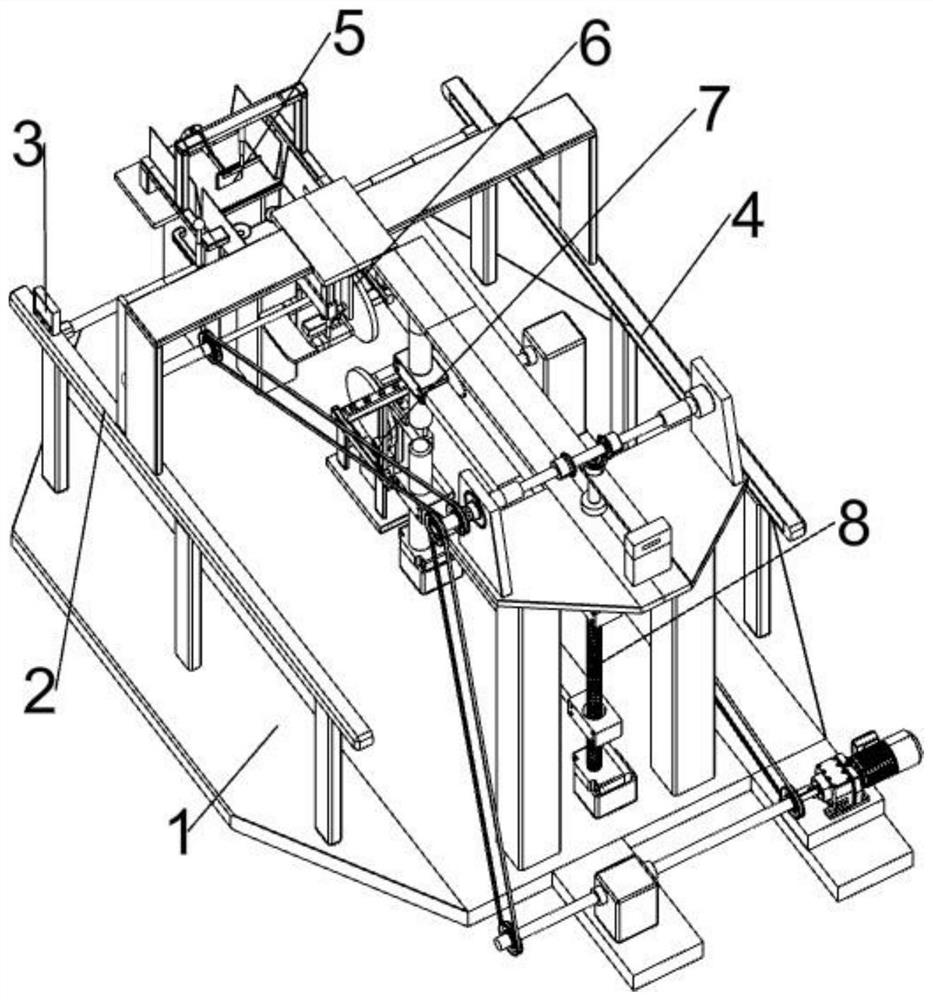

Vertical cotton glue sprayer

ActiveCN103506236AIncrease productivityImprove qualityLiquid spraying apparatusNon-woven fabricsSprayerEngineering

The invention provides a vertical cotton glue sprayer. The vertical cotton glue sprayer comprises a box body and a chain conveying device, wherein an inlet and an outlet are respectively formed in the front end and the back end of the box body, an automatic glue spray device is arranged above the front of an inner chamber of the box body, the chain conveying device penetrates the inner chamber of the box body from the inlet of the box body, penetrates out of the box body from the outlet, and comprises a chain, a gear for driving the chain and a reducing motor for driving the gear; a plurality of vertical cotton bearing devices are arranged on the chain at intervals. According to the vertical cotton glue sprayer, the chain conveying device and the automatic glue spray device are adopted to replace manual operation to form the flow production and greatly improve the production efficiency; the automatic glue spray device is free from influence of manual operation, the spraying of glue is more uniform, and the product quality is improved; the glue spray process is performed in the inner chamber of the box body, so that the influence on the production workshop environment is greatly reduced, and a workshop is cleaner.

Owner:苏州爱美纤维科技有限公司

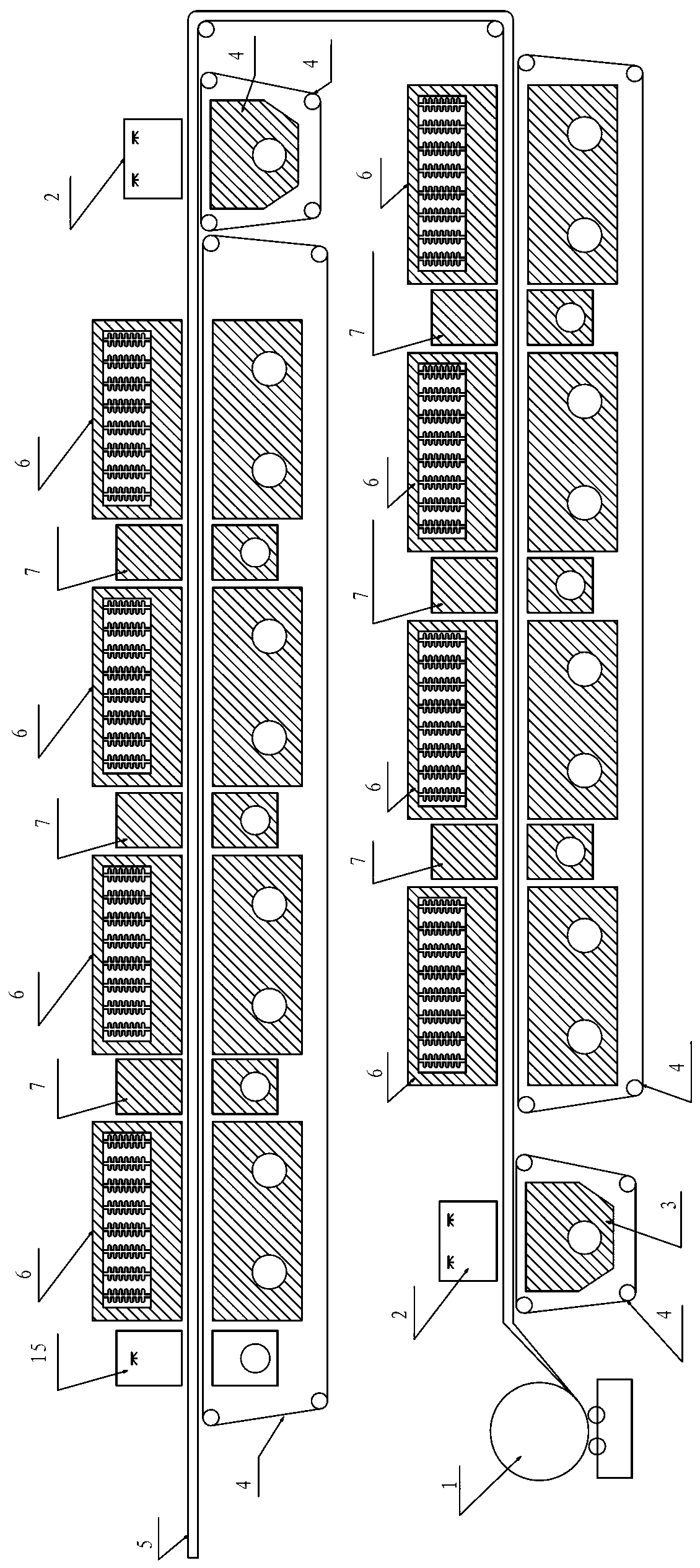

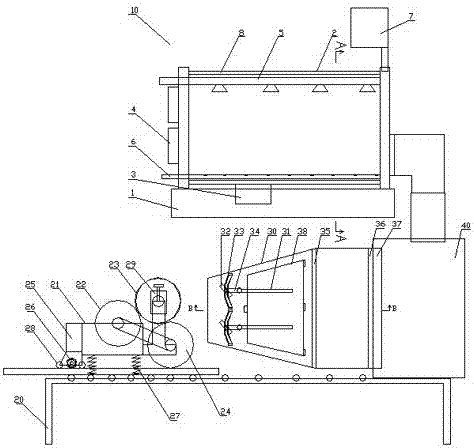

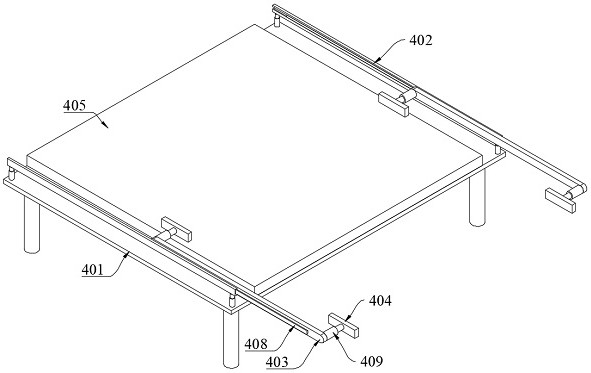

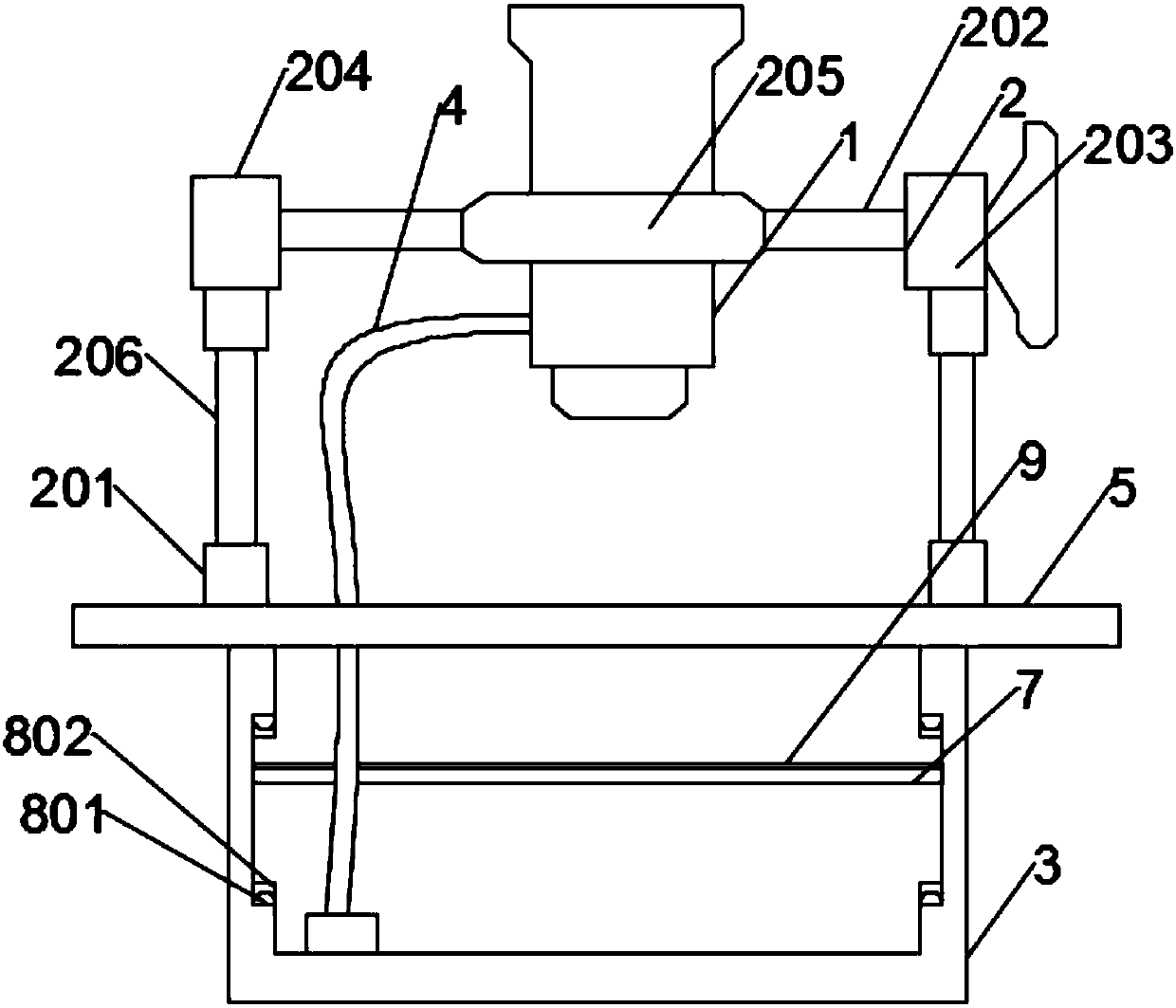

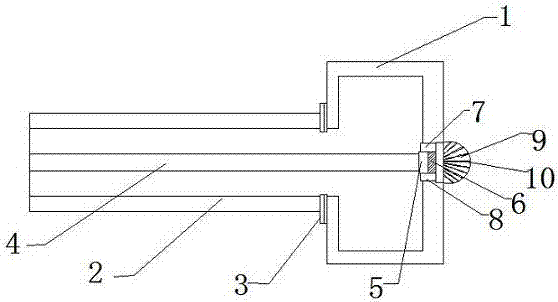

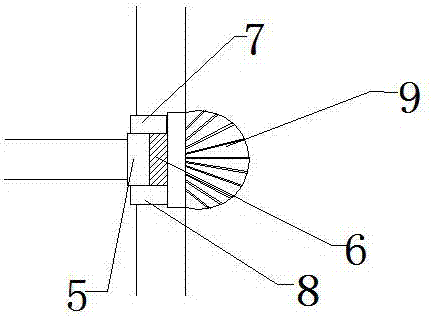

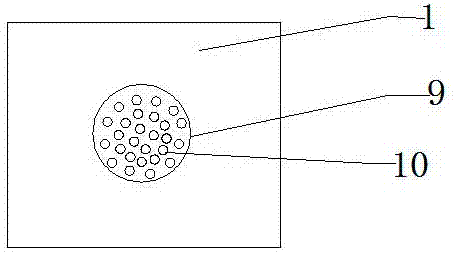

Straw powder glue mixing and paving system

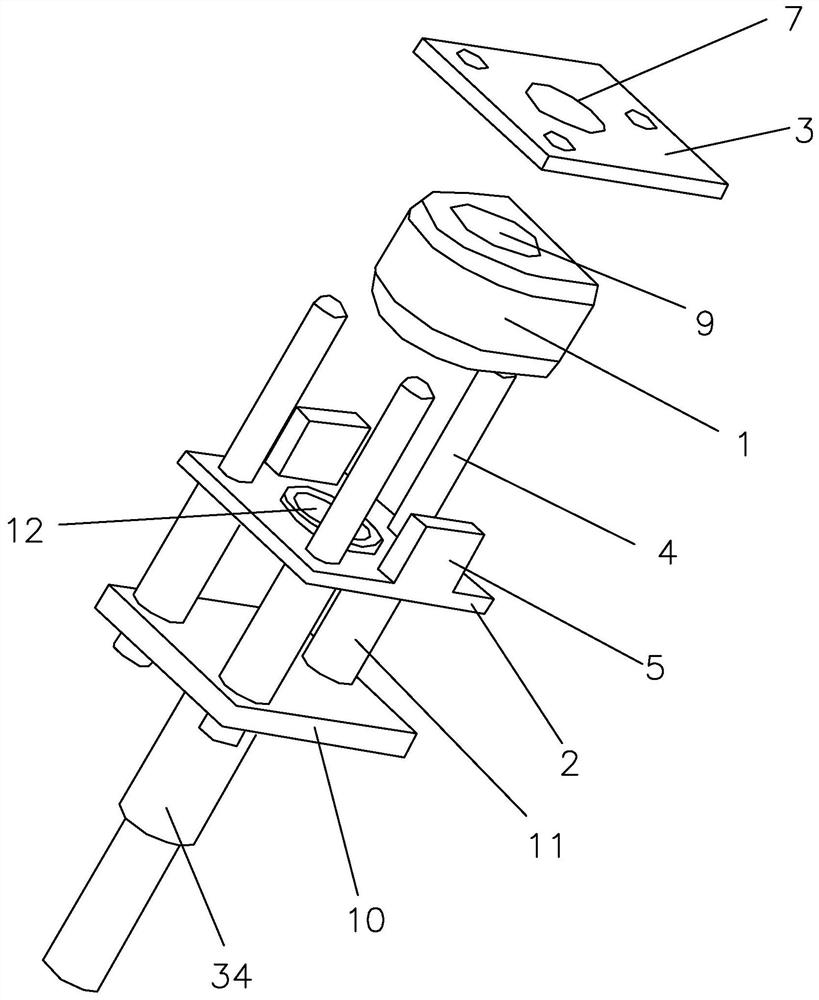

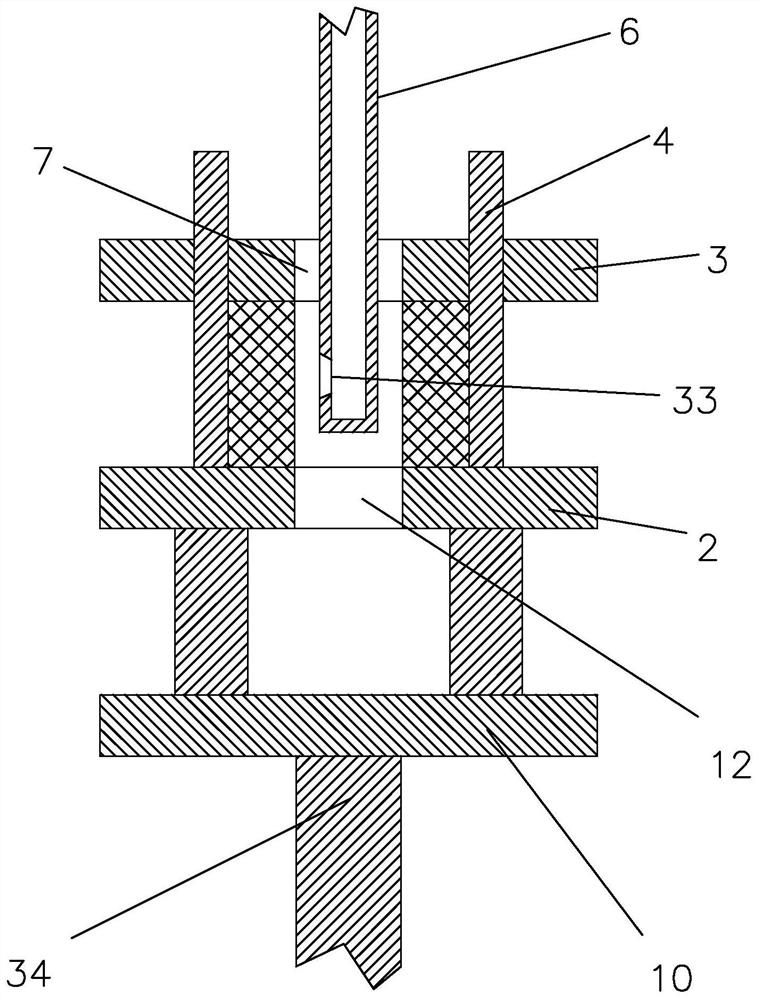

The invention discloses a straw powder glue mixing and paving system which comprises an atomizing glue mixing machine (10) and a paving machine (40). The bottom of the paving machine (40) is provided with a supporting plate conveying roller bed (20). The atomizing glue mixing machine (10) comprises a machine frame (1), a barrel body (2), a barrel body driving motor (3), a fan (4), a glue spraying pipe (5), a set of air pipes (6) and a cyclone separator (7). The supporting plate conveying roller bed (20) is provided with a supporting plate base coating device. The supporting plate base coating device comprises a base coating assembly and a cleaning assembly. The paving machine (40) is provided with a paving machine airflow adjusting device. The straw powder glue mixing and paving system has the advantages that glue spraying is uniform, a supporting plate is cleaned through a dust collector and a cleaning roller brush before smearing of a die release agent, the die release agent is made uniform through a set of rollers to be smeared to the supporting plate, smearing is uniform, the working efficiency is high, the airflow direction and balance in an airflow channel are adjusted through a flow guide assembly, and powder paving is uniform.

Owner:湖北凯利板业有限公司

Corrosion-resistant sound absorption and insulation aluminum honeycomb plate profiling device

PendingCN112721401ASpray glue evenlyImprove efficiencyLaminationLamination apparatusCorrosion resistantEngineering

The invention provides a corrosion-resistant sound absorption and insulation aluminum honeycomb plate profiling device, which comprises: a profiling mechanism comprising an upper suction cup and a lower suction cup which are vertically arranged; a gluing mechanism comprising a glue conveying pipe, wherein the glue conveying pipe is communicated with a plurality of pairs of nozzles arranged up and down, and the moving direction of the gluing mechanism is perpendicular to the direction of the glue conveying pipe; a panel conveying mechanism comprising a pair of conveying rollers, wherein the two ends of each conveying roller are sleeved with horizontally-arranged conveying belts; and an aluminum honeycomb plate conveying mechanism comprising a containing table, wherein a pair of sliding rails are arranged on the two sides of the containing table, the sliding rails are parallel to the conveying belt, sliding rods capable of horizontally moving are arranged on the sliding rails in a clamped mode, the two ends of each sliding rod are connected with clamping blocks, and the clamping blocks can horizontally move in the direction perpendicular to the sliding rods. According to the invention, the automatic glue spraying process is achieved, glue spraying is uniform, the efficiency is high, up-down position positioning can be achieved when the two sealing plates are sucked by the upper suction cup and the lower suction cup, the profiling precision is improved, the subsequent edge cutting process is not needed, the product production cost is reduced, and due to the fact that the profiling time is short, the performance of an adhesive can be kept, and the bonding effect is improved.

Owner:SICHUAN WUHUAN PETROCHEM EQUIP CO LTD

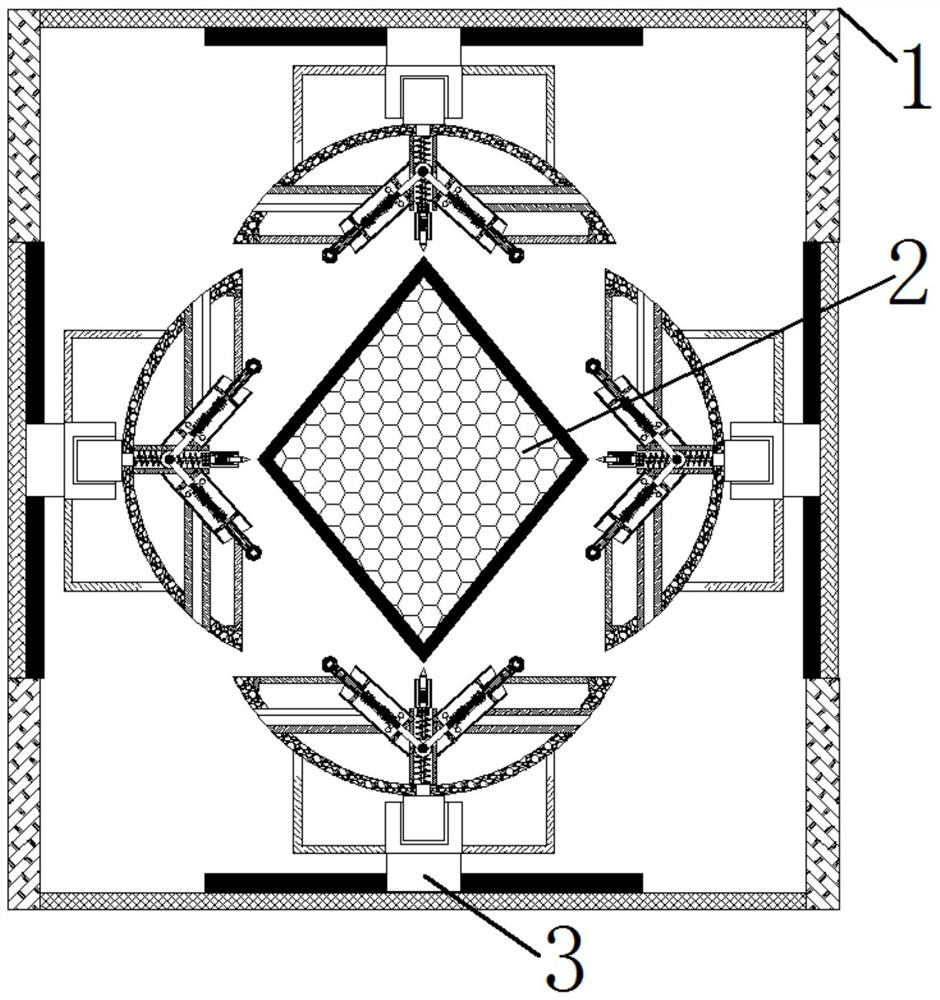

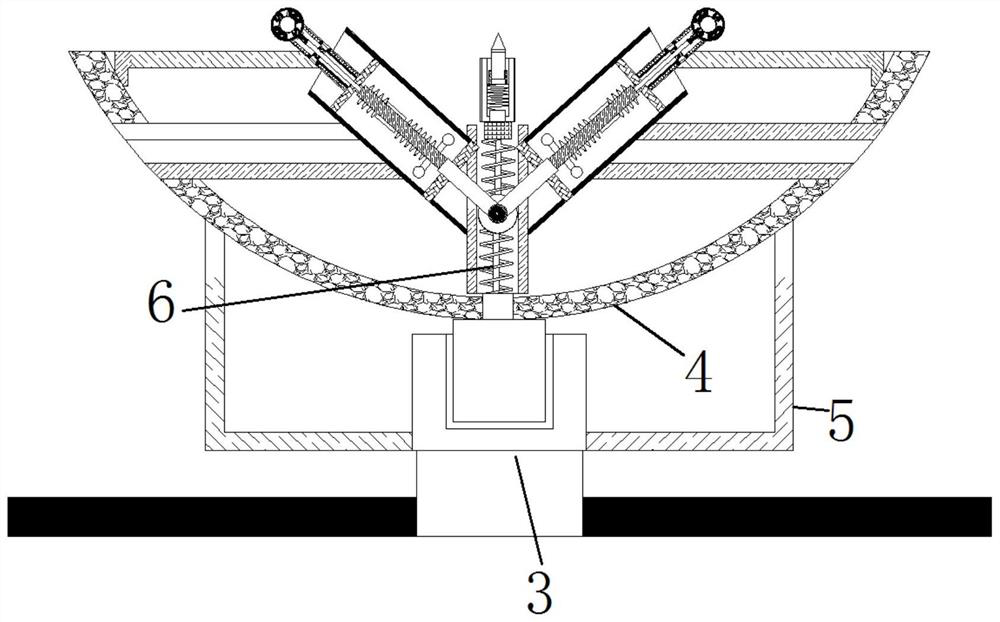

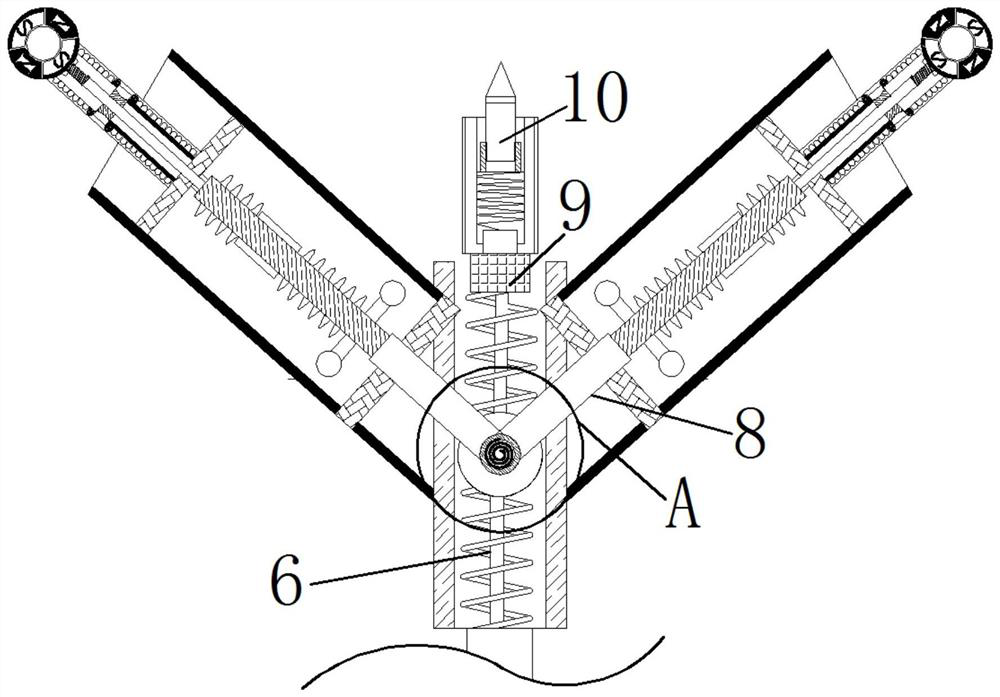

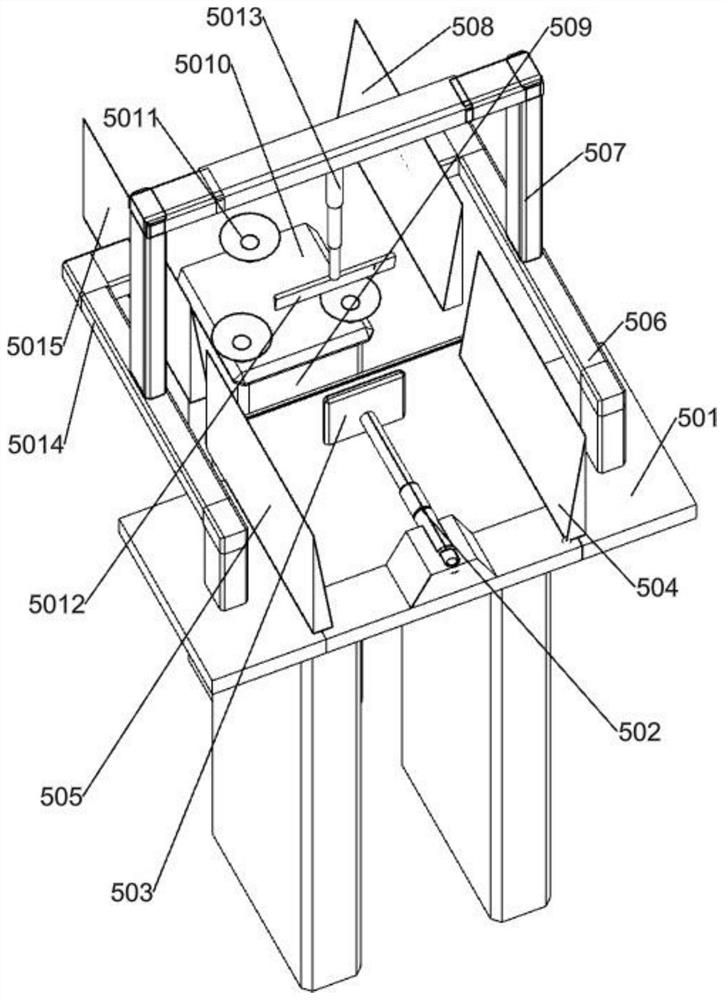

Multi-head glue spraying device for sand mold casting

The invention discloses a multi-head glue spraying device for sand mold casting. The multi-head glue spraying device for sand mold casting comprises a rack, a portal frame is arranged on the rack, a sliding block is arranged on the portal frame, a linear conveying sliding table is arranged on the rack, a multi-head glue spraying mechanism is arranged at the bottom of the sliding block, the multi-head glue spraying mechanism comprises a rotating seat which is arranged at the bottom of the sliding block, an upper base plate is arranged at the bottom of the rotating seat, a lower base plate is arranged below the upper base plate, a plurality of positioning rods are arranged between the upper base plate and the lower base plate; and a vertically-downward stroke sleeve is arranged in the middleof the lower base plate, a movable rod is arranged in the stroke sleeve, a lifting disc is arranged at the bottom of the movable rod, a plurality of first linkage frames and second linkage frames arearranged between upper base plates of the lifting disc, first atomization glue spraying heads are arranged on the first linkage frames, and second atomization glue spraying heads are arranged on thesecond linkage frames. According to the multi-head glue spraying device for sand mold casting, spraying an inner cavity of a sand mold is carried out through the multi-head glue spraying mechanism, and the multi-head glue spraying device has the characteristics of being wide in spraying face and uniform in spraying.

Owner:INST OF LASER & OPTOELECTRONICS INTELLIGENT MFG WENZHOU UNIV

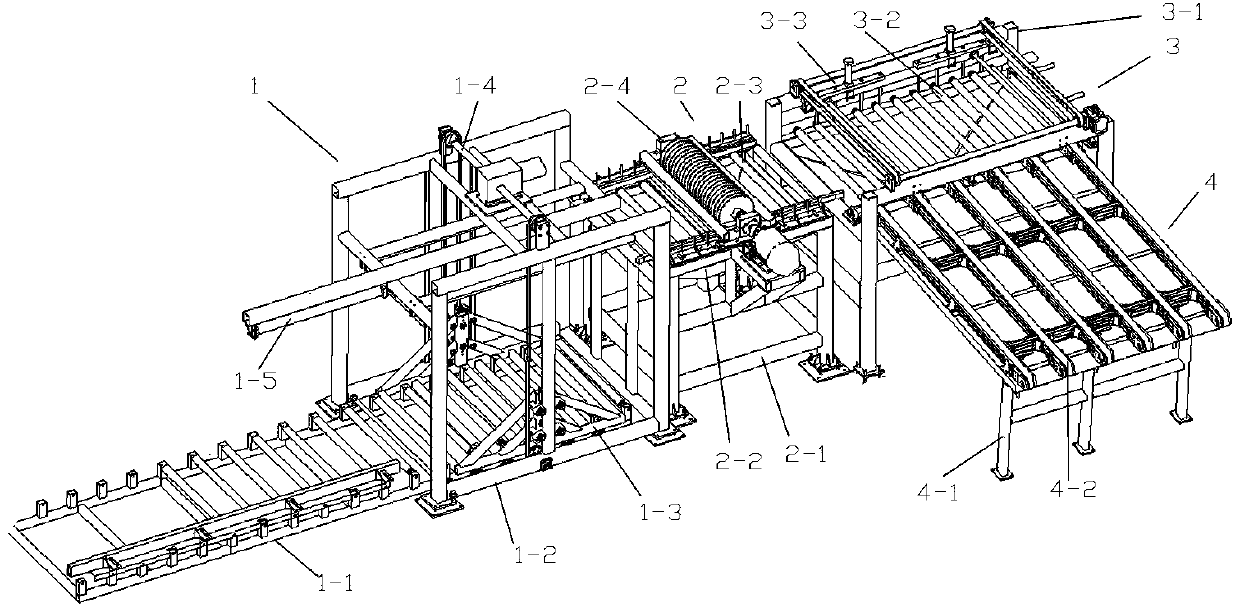

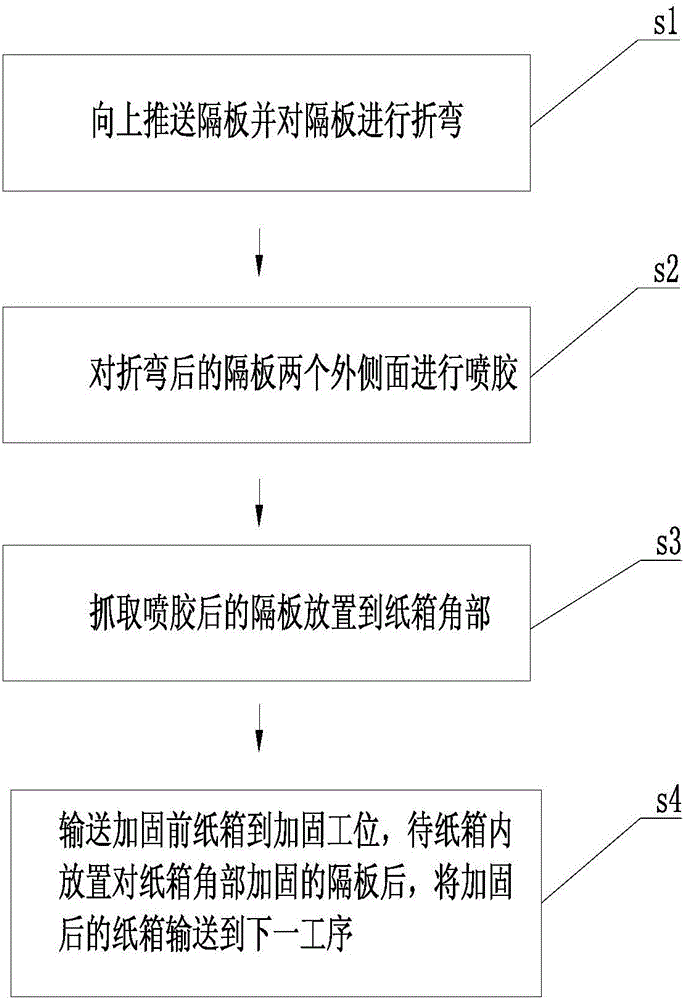

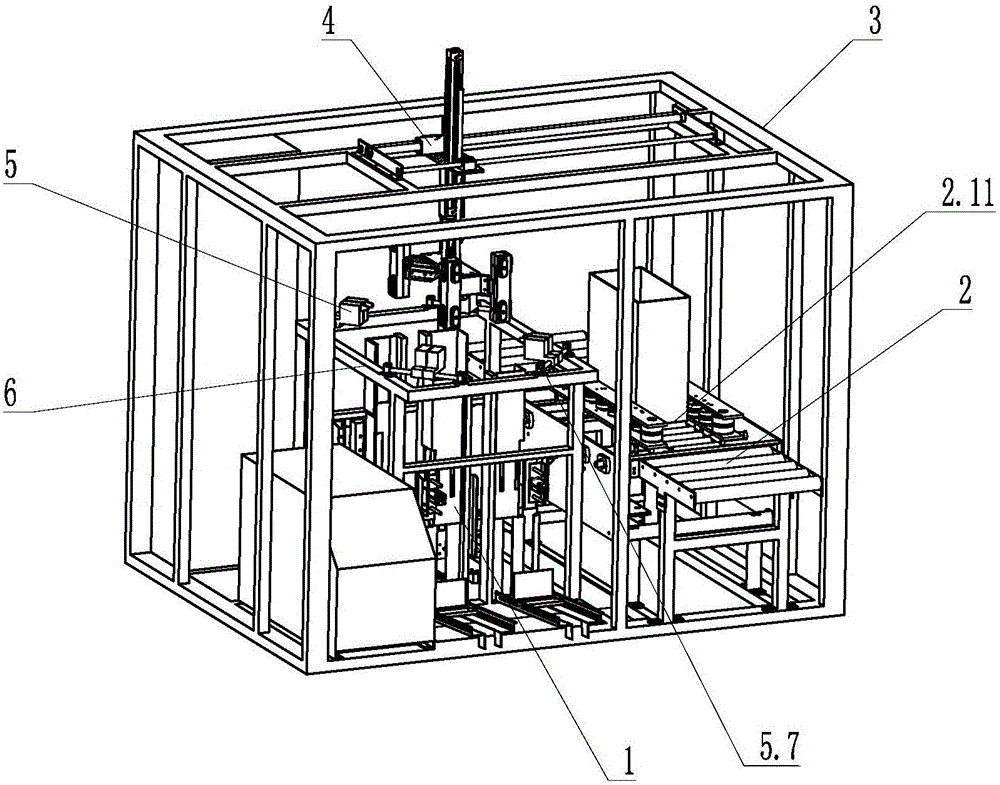

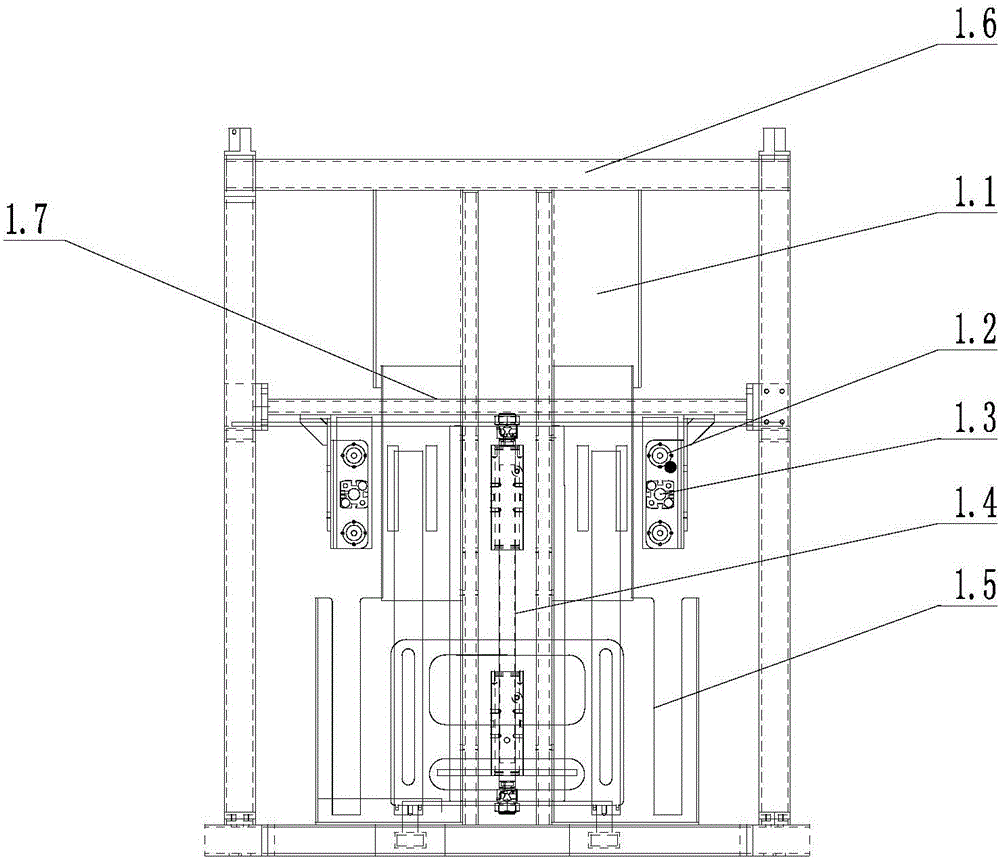

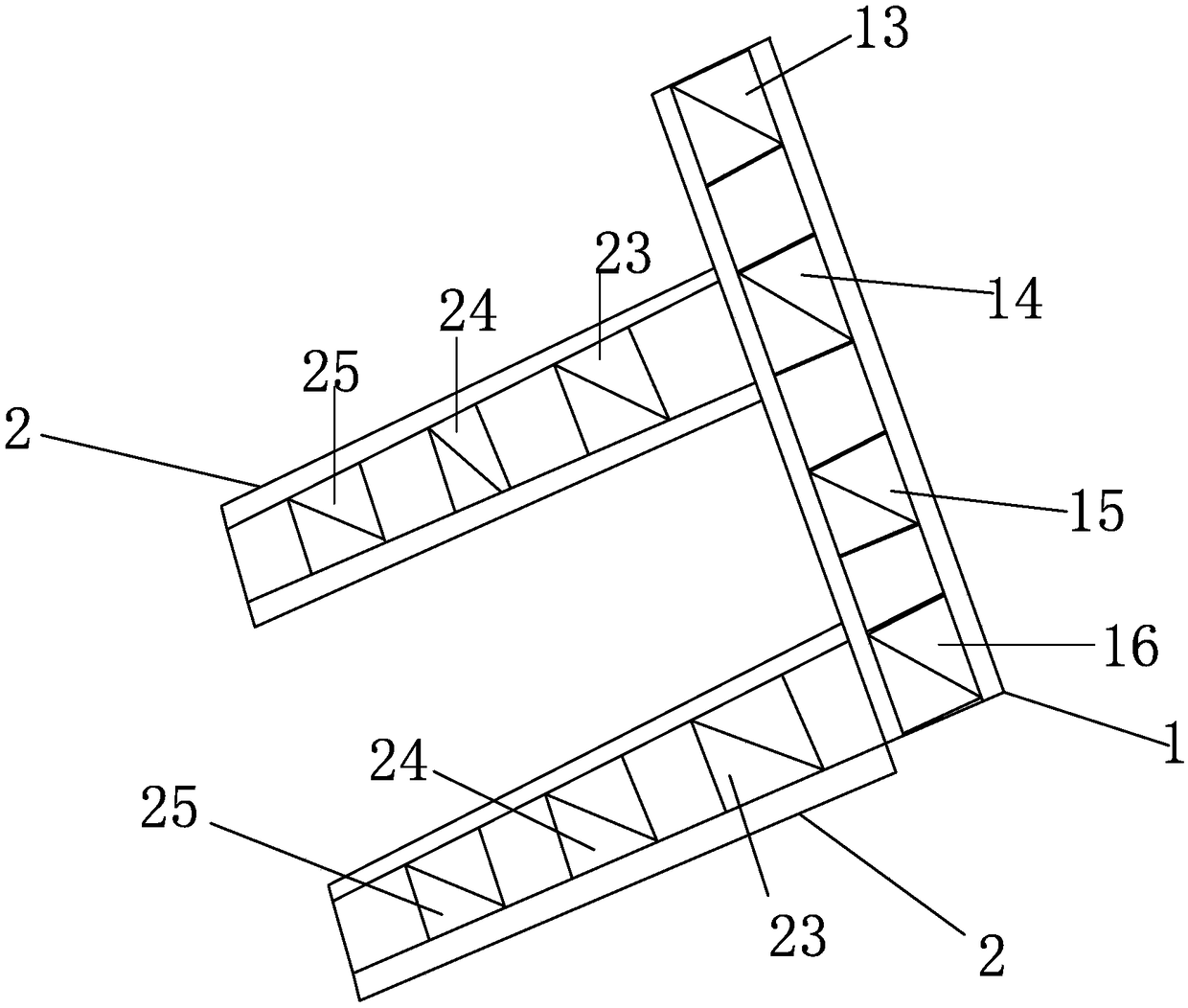

Method and device for reinforcing corners of corner-plate type carton

ActiveCN105856628ARealize automated productionImprove work efficiencyBox making operationsPaper-makingCartonEngineering

The invention relates to a method and a device for reinforcing corners of a corner-plate type carton, and belongs to the technical field of carton package. The device comprises a separator charging structure, wherein a separator glue-spray device is arranged at the top end of a separator charging device; a carton delivery device is arranged on one side of the separator charging device; a separator grasping placement device is arranged at the upper part of the separator charging device. According to the method and device for reinforcing corners of a corner-plate type carton, corners of a carton can be reinforced by means of automatic charging and bending, automatic glue spraying and automatic grasping placement on separators, automatic production is realized, and the working efficiency is greatly improved; the requirement for reinforcing a carton can be met by only reinforcing corners, so that the cost is low.

Owner:SHINVA MEDICAL INSTR CO LTD

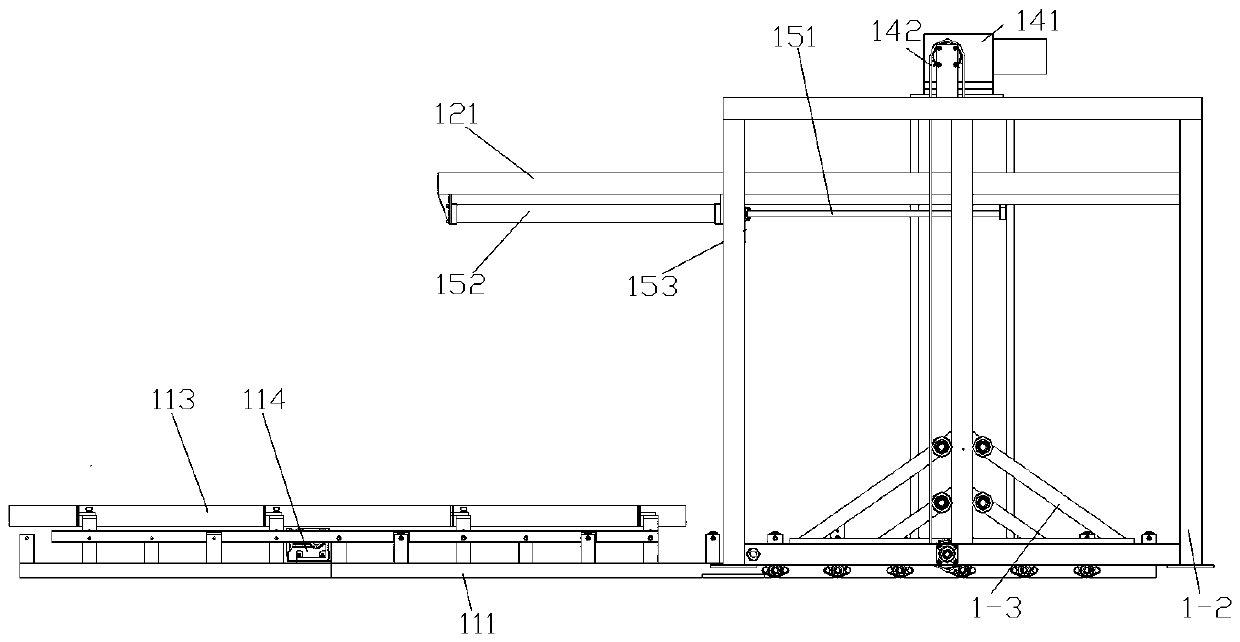

Production equipment for sticking non-woven fabric to aluminous gusset plate

PendingCN109109437AIncrease productivitySpray glue evenlyCeilingsLaminationGusset plateHigh intensity

The invention discloses production equipment for sticking non-woven fabric to an aluminous gusset plate. The production equipment comprises a main conveying line for conveying aluminous gusset plates,two or more sub-conveying lines arranged beside the main conveying line, wherein the aluminous gusset plates are distributed and conveyed by the main conveying line into the sub-conveying lines through a first push plate platform and a second push plate platform; a first middle transition platform enables the middles of the aluminous gusset plates to stop for transition, and the aluminous gussetplates are conveyed into the sub-conveying lines by shunting; the sub-conveying lines pass through a second middle transition platform to reach a fabric sticking platform and a smoothing fabric sticking platform; thus, a plurality of lines run at the same time, the production efficiency is high, and the production equipment is suitable for production with relatively high intensity. Through conveying by a fabric conveying mechanism, glue spraying on the fabric and then conveying to the fabric sticking mechanism, the glue spraying way is relatively uniform, less glue is left on the fabric, and influence on the production equipment is avoided; moreover, the conveying and sticking way is relatively convenient and realizes a good sticking effect.

Owner:韶关龙督装饰材料有限公司

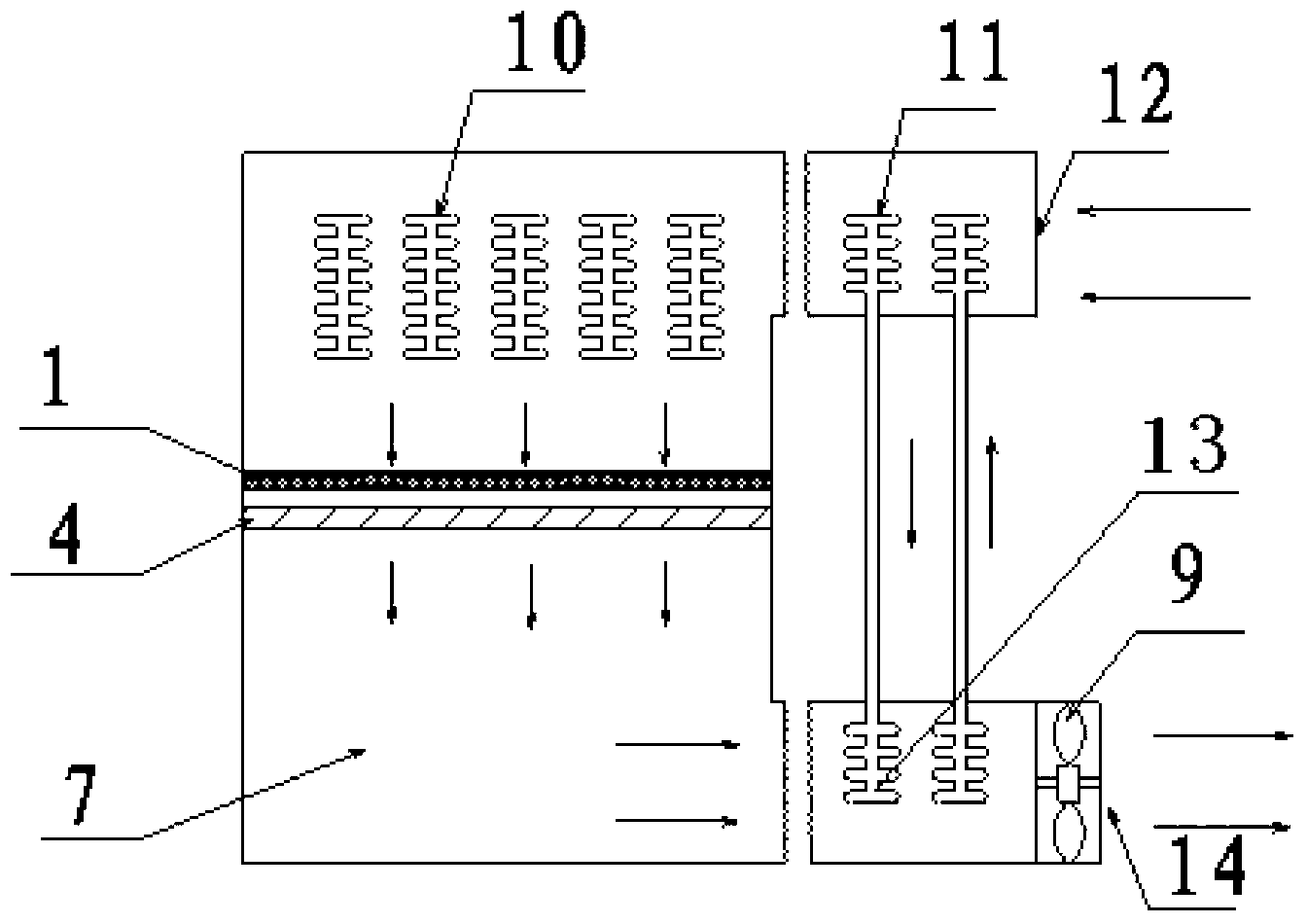

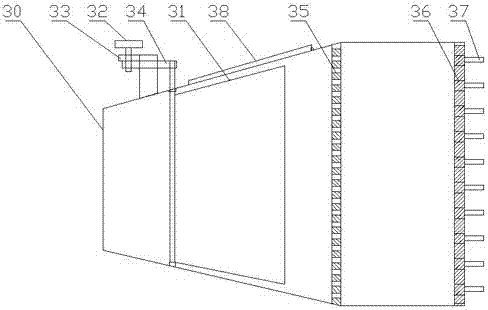

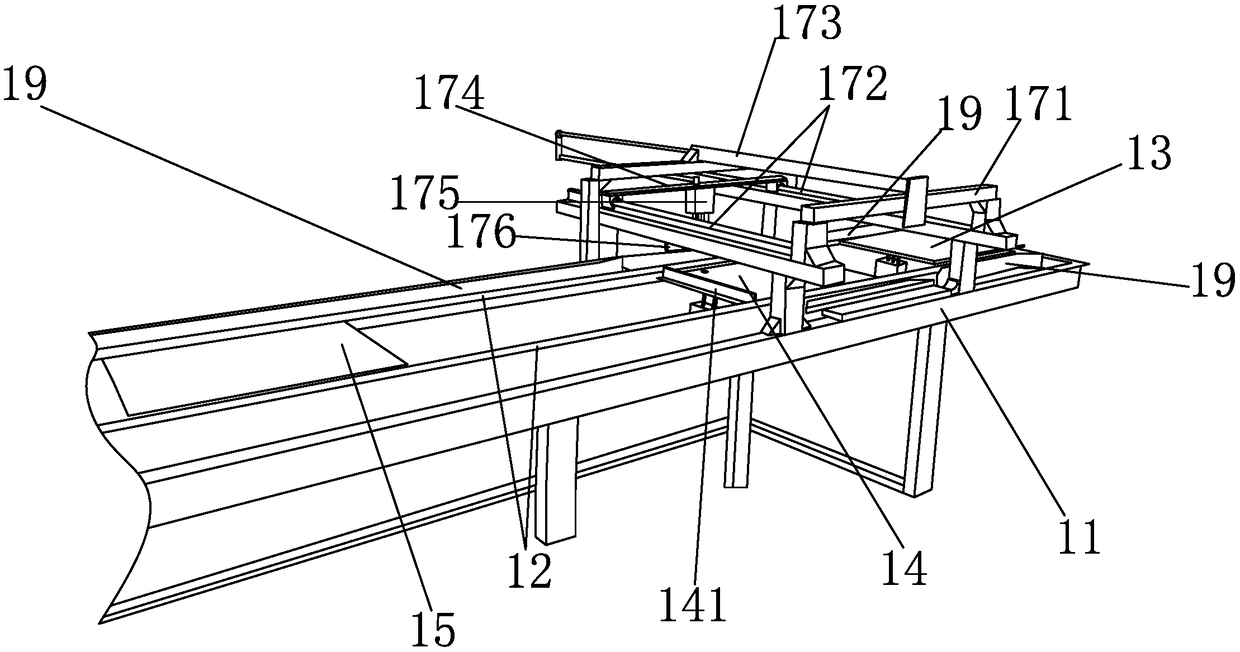

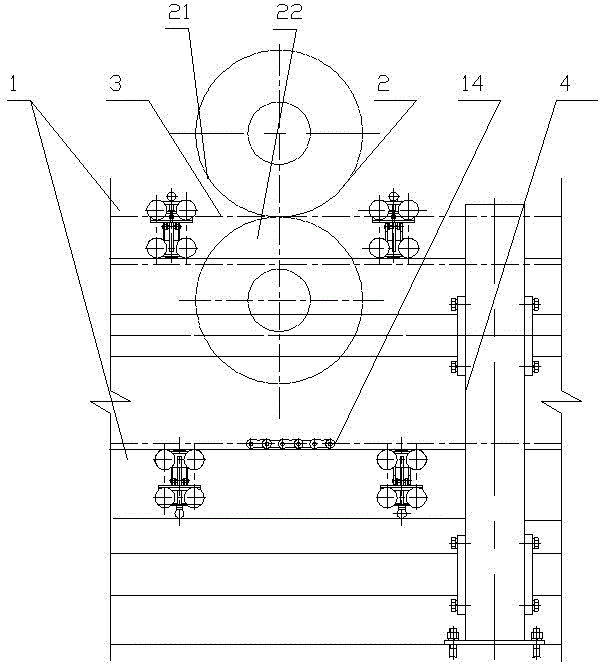

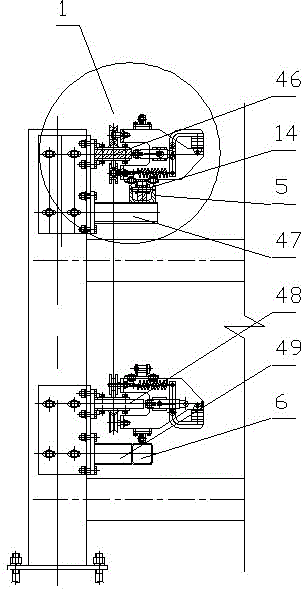

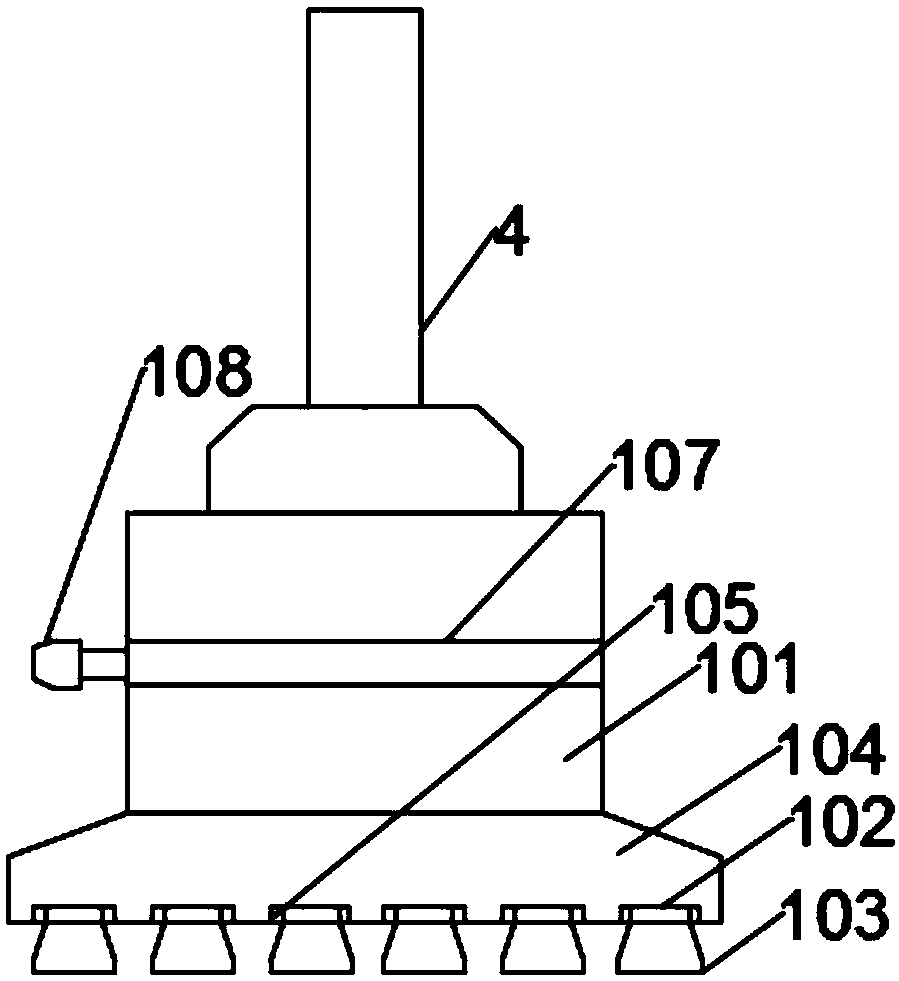

Continuous melamine-formaldehyde resin veneer rubber coating, dipping, drying and conveying device

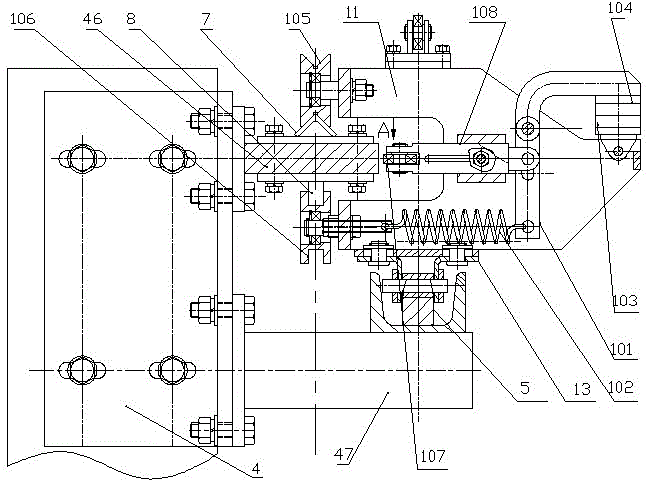

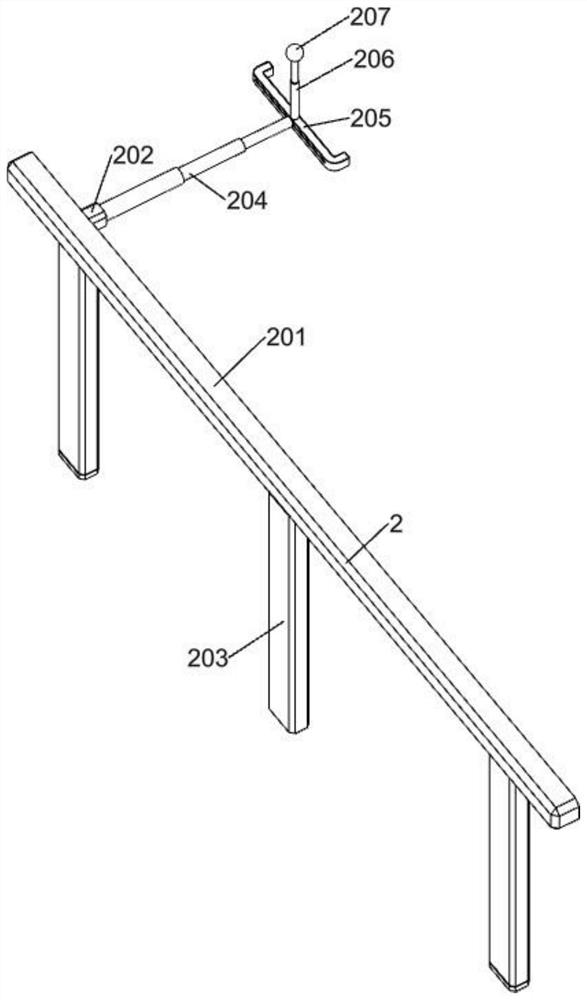

InactiveCN104972537AGuaranteed accuracyGuaranteed running accuracyWood treatment detailsLaminationEngineeringCantilever

The invention discloses a continuous melamine-formaldehyde resin veneer rubber coating, dipping, drying and conveying device which comprises a rubber coating and dipping device and a chain transmission device. The continuous melamine-formaldehyde resin veneer rubber coating, dipping, drying and conveying device is characterized by further comprising a rack 4; the upper portion of the rack 4 is provided with a first short suspension arm 46 and a first long suspension arm 47, and the lower portion of the rack 4 is provided with a second short suspension arm 48 and a second long suspension arm 49; the upper surface of the first short suspension arm 46 is fixedly connected with a V-shaped guide rail 7, and the lower surface of the first short suspension arm 46 is fixedly connected with a rectangular guide rail 8; the upper surface of the first long suspension arm 47 is fixedly connected with a chain supporting rail 5; the upper surface of the second short suspension arm 48 is fixedly connected with a rectangular guide rail 8, and the lower surface of the second short suspension arm 48 is fixedly connected with a V-shaped guide rail 7; the upper surface of the second long suspension arm 49 is fixedly connected with a feeding device supporting rail 6; feeding devices 1 are arranged on the upper portion or the lower portion of the rack 4 respectively; the bottom face of the feeding device 1 arranged on the upper portion of the rack 4 is fixedly connected with a chain 14, and the side face of the feeding device 1 is in contact with the V-shaped guide rail 7 and the rectangular guide rail 8; rubber applying devices 9 are arranged at the positions of an upper rubber roll 21 and a lower rubber roll 22 to be fixedly connected with the rack 4, and a rubber amount adjusting device 2 is fixedly connected to the rack 4.

Owner:BEIHUA UNIV

Uniform glue discharging device of glue gun

Owner:TANGSHAN LANDSKY TECH

Pipeline gluing fixing device and using method thereof

InactiveCN111878492AEffectively fixedAvoid fixationEdge grinding machinesGrinding drivesLever pressingRetainer (device)

The invention discloses a pipeline gluing fixing device, which comprises a supporting underframe, a bearing frame is mounted in the middle of the top of the supporting underframe, a fixing frame is mounted in the middle of the rear end of the supporting underframe, a glue conveying tank is mounted at the top of the fixing frame, a glue feeding plate is mounted at the position, close to bottom, ofthe front end of the glue conveying tank, polishing parts are mounted on the two sides of the fixing frame correspondingly, air cylinders are mounted on the two sides of the supporting underframe correspondingly, push plates are mounted at the opposite ends of the two sets of air cylinders correspondingly, two sets of fixing rods are mounted at the top of the supporting underframe, limiting cylinders are mounted on the inner sides of the fixing rods, a guiding cylinder is mounted on one side of each push plate, a pressing rod is mounted in the mode of penetrating through the top of each guiding cylinder, and each guiding cylinder is internally provided with two sets of oppositely-arranged arc-shaped sheets. An end opening of a pipeline can be polished, meanwhile, a good limiting function is achieved, uniform distribution of glue can be further maintained when the pipeline is glued, and thus the fixing effect is improved.

Owner:钱佳钰

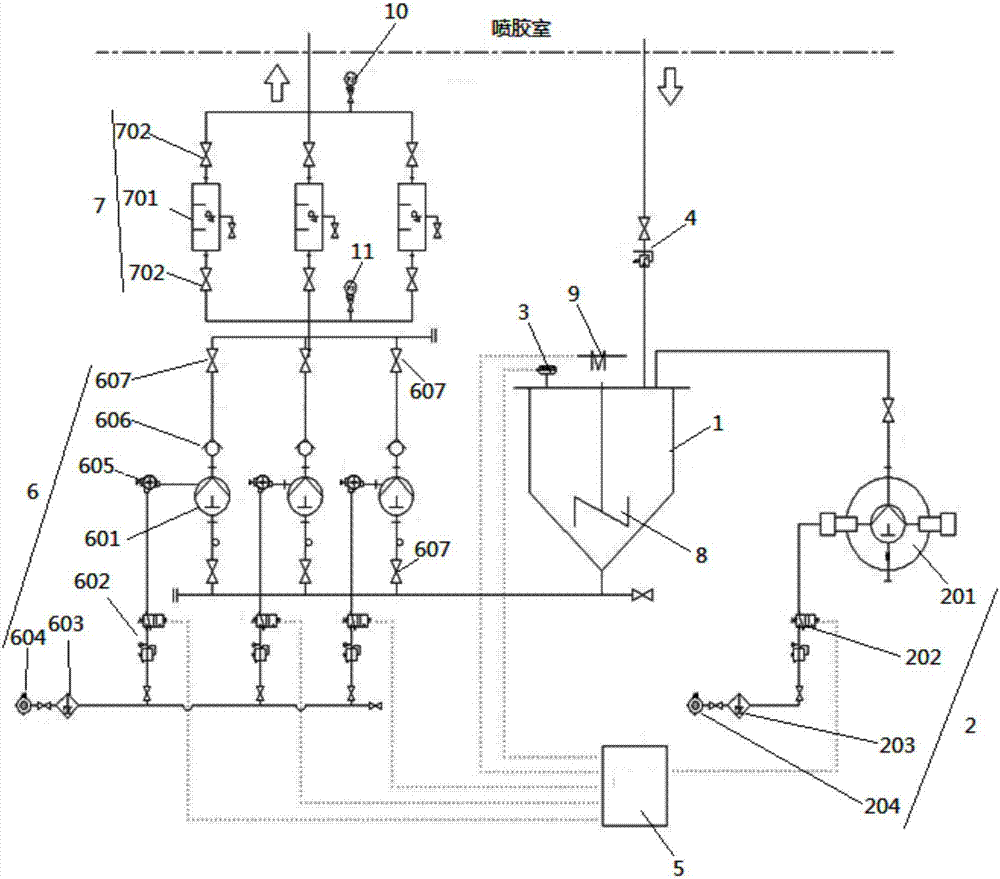

Novel glue supply system for automobile plant

ActiveCN106881219AEasy to manageAvoid the problem of frequent replacement of glue barrelsSpraying apparatusElectricityPulp and paper industry

The invention discloses a novel glue supply system for an automobile plant. The novel glue supply system comprises a transferring glue tank, a charging pump, a liquid level meter, a backpressure valve, a controller, a glue supply pump and a filter unit; a material inlet of the charging pump is communicated with a glue barrel for supplying, an outlet of the charging pump is communicated with the transferring glue tank, and the charging pump is used to pump a glue material in the glue barrel into the transferring glue tank; the transferring glue tank is communicated with the glue supply pump, the glue supply pump is communicated with the filter unit and is used to pump the glue material in the transferring glue tank into the filter unit; the filter unit is communicated with a glue supply pipe coiled in a glue spraying chamber; an inlet of the backpressure valve is communicated with the glue supply pipe, and an outlet of the backpressure valve is communicated with the transferring glue tank; the liquid level meter is mounted in the transferring glue tank and is used to detect a liquid level height of the glue material in the transferring glue tank; and the controller is electrically connected to the liquid level meter and the charging pump. The novel glue supply system can ensure that glue supply pressures of respective glue guns are equal, such that uniform glue spraying is ensured and unified management on the glue barrel is facilitated.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Glue spraying device for packing box glue spreader

ActiveCN107694835AIncrease the areaReduce too muchLiquid surface applicatorsCoatingsEngineeringHOLDING CHAMBER

The invention discloses a glue spraying device for a packing box glue spreader. The glue spraying device comprises a glue spraying head, an adjusting frame and a glue supply barrel. The glue sprayinghead and the glue supply barrel are connected together through an adjusting frame. The glue spraying head is connected with the glue supply barrel through a glue spraying hose to spray glue. A placingplate is arranged at the top end of the glue supply barrel. The adjusting frame and the placing plate are installed together fixedly. The adjusting frame comprises an adjusting rod and two fixed struts. A connecting seat is arranged at the top end of the fixed strut at one end. The adjusting rod penetrates through the connecting seat. An installing seat is arranged on the surface of the adjustingrod. The glue spraying head is installed on the installing seat and comprises a glue holding chamber, glue outlets and spreading heads. A glue outlet plate is arranged at the bottom end of the glue holding chamber. The glue outlets are evenly formed in the surface of the glue outlet plate. The spreading heads is installed in the glue outlets. A plurality of conical mouths are arranged in the spreading heads. Overall glue spreading can be conducted fast, glue spreading is uniform, reasonable glue spreading adjustment can be conducted for different packing boxes, work efficiency of the glue spreader is improved, and the glue spraying device is worth popularization.

Owner:LINQUAN YATAI PACKING

Paper carton adhesive tape sealing device based on magnetic attraction principle

InactiveCN111761873ASpray glue evenlyProblems affecting normal useBox making operationsPaper-makingPhysicsEngineering

The invention relates to the technical field of paper cartons and discloses a paper carton adhesive tape sealing device based on the magnetic attraction principle. The paper carton adhesive tape sealing device comprises a device body. A paper carton body is placed in the device body. Drive devices are arranged in the device body. The outside of each drive device is movably connected with a supporting frame. The outside of each drive device is movably connected with a drive spring. A drive shaft center is movably installed in each drive spring. The outside of each drive shaft center is movablyconnected with a shaft rod. The end, far away from the corresponding drive spring, of each drive block is movably connected with an adhesive spraying head. According to the paper carton adhesive tapesealing device, every two groups of electromagnets are relatively close to each other based on the magnetic attraction principle and motion of a mechanical structure to be attracted together and simultaneously clamp one corner just finishing adhesive spray of the paper carton body, external pressure is provided during adhesion, so that paper angle beads of the paper carton body are enough firmly stuck, and then the problem that debonding happens and causes the paper carton to crack, so that normal use of the paper carton is influenced is avoided.

Owner:李新

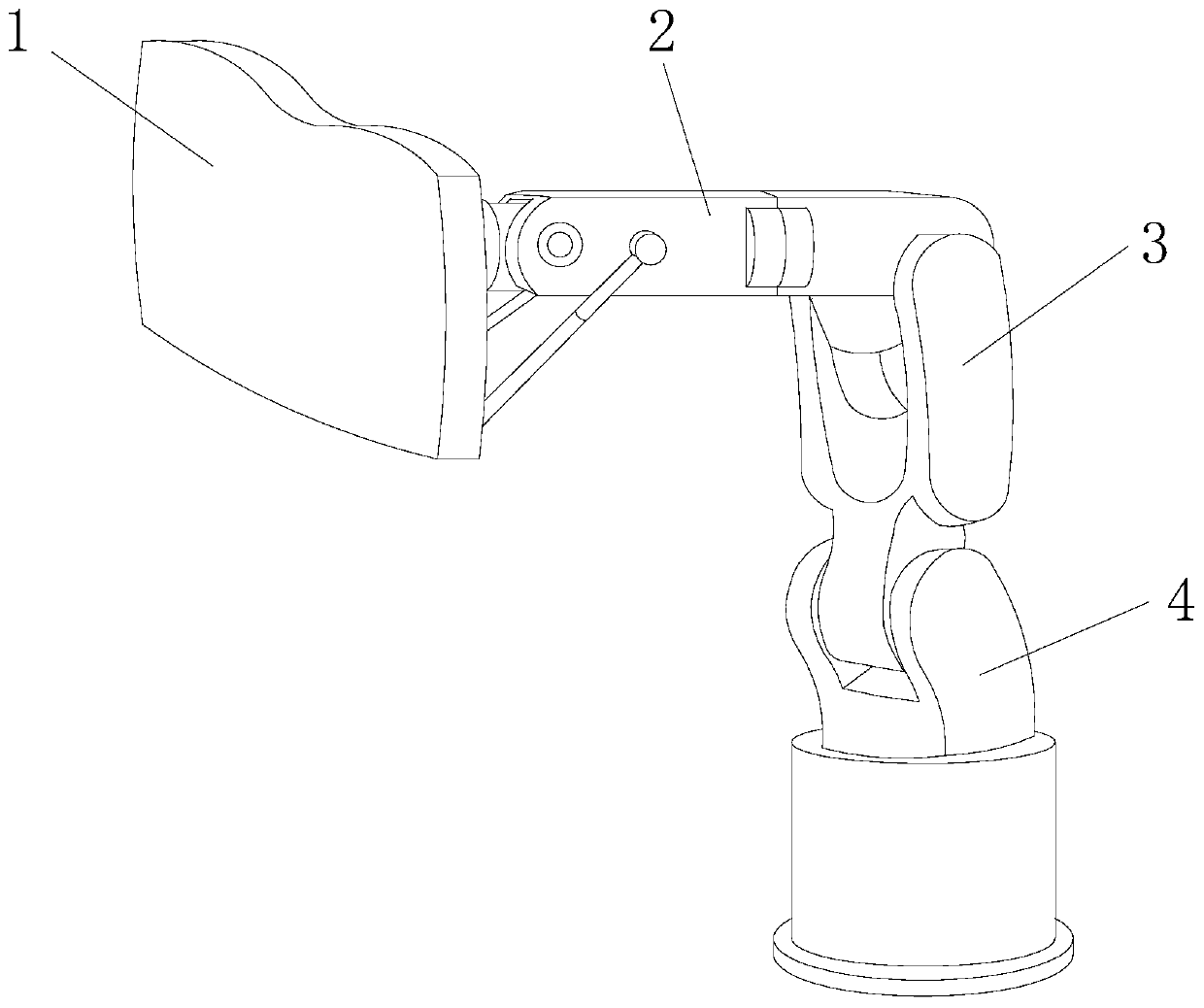

Lateral pushing buckling groove device of automobile glass gluing equipment

InactiveCN109926270ASpray glue evenlyGlue tight and firmLiquid surface applicatorsCoatingsRocker armEngineering

The invention discloses a lateral pushing buckling groove device of automobile glass gluing equipment. The device structurally comprises a lateral pushing buckling groove device, a spraying machine arm, an oscillating arm and a base. According to the device, air is charged into a plurality of bending pipe sections in an air throttling bar through an outer air pipe, so that a fixed pendulum is pushed to drive a convex coating shaft to move in an arc shape along a folding rail plate; a constant-speed-moving arc plate is extruded from bottom to top to upwards press neutral silicone adhesive whichis downwards sprayed and accumulated, and the neutral silicone adhesive accumulated at the lower end is conveyed to the upper part; and meanwhile, a movable tapered plate is inwards pulled by a rolling ball rod through a folding frame plate; when a hook head is extruded through the fixed pendulum, the movable tapered plate is driven to return and is blown and rotated through a moon arc shaped channel, and the constant-speed-moving arc plate is driven to level. Therefore, the upper parts and the lower parts of two sides of a front glue-interlayered windshield of the automobile can be uniformlyglued; the circumstances that the upper end is not firmly glued and the accumulated neutral silicone adhesive at the lower end is not perfect can be avoided; the front windshield of the automobile and corners of an automobile frame are tightly firmly glued; and the natural silicone adhesive at the corners of the front windshield of the automobile is capable of normally damping.

Owner:赵子花

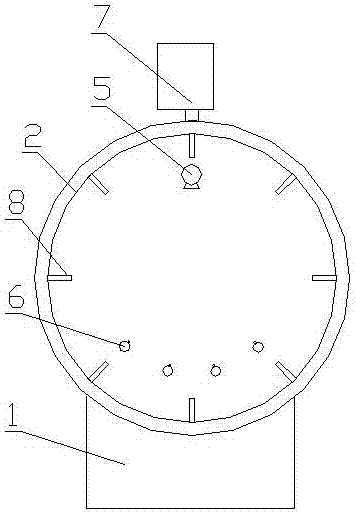

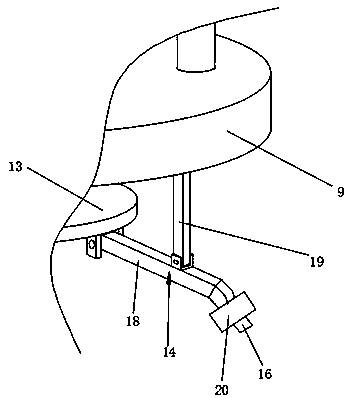

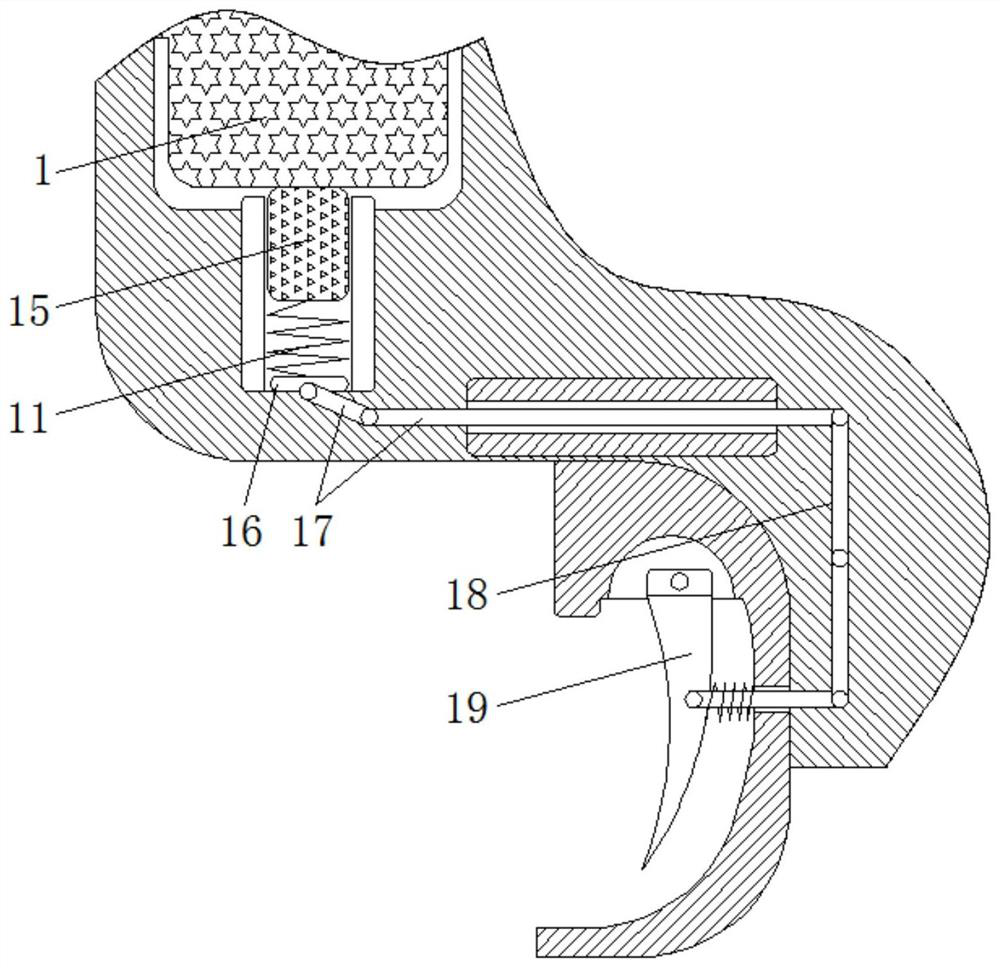

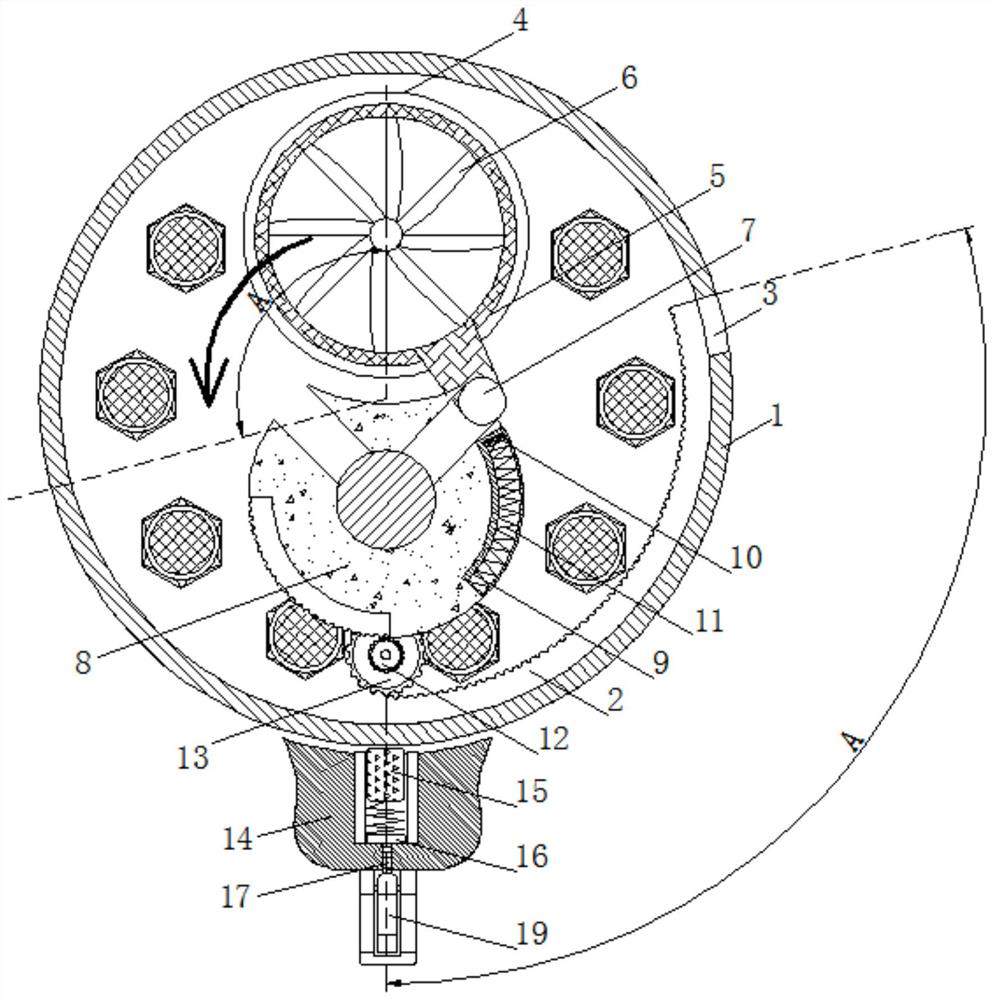

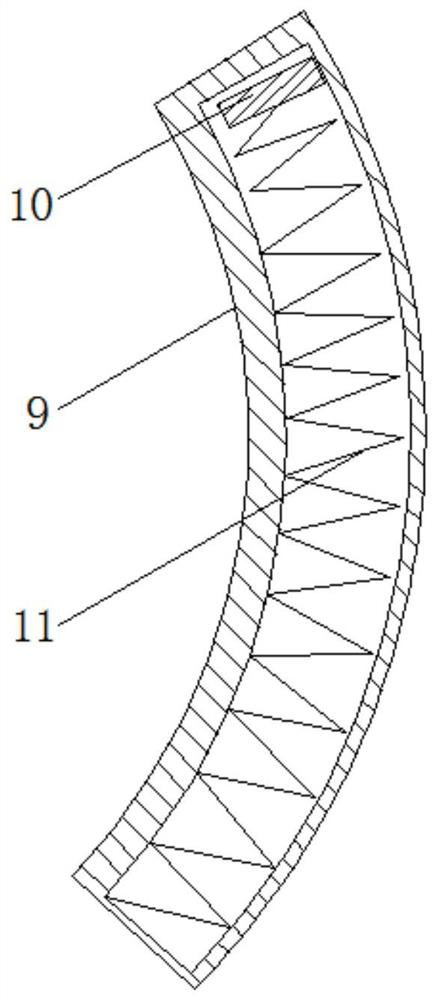

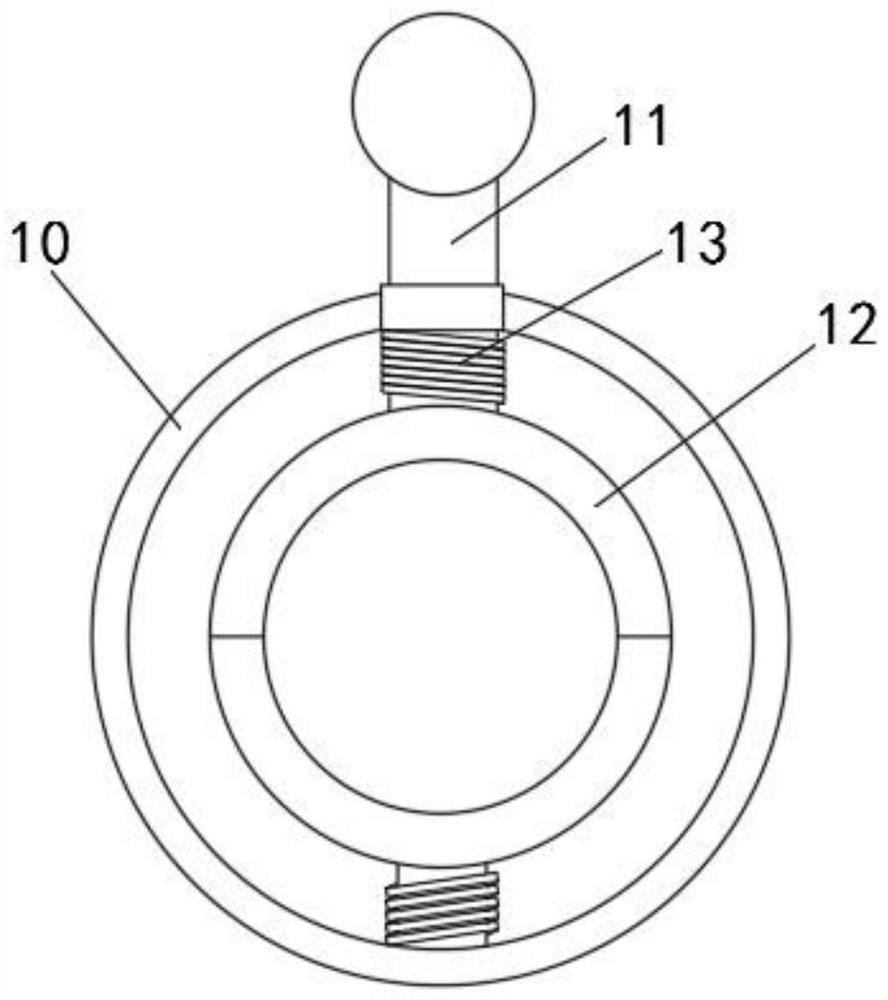

A glue spraying structure for a rock wool centrifuge

InactiveCN105152526BAvoid wear and tearAvoid compromising fiber qualityGlass making apparatusFiberCentrifugation

The invention provides a glue spraying structure for a rock wool centrifuge, which includes a centrifugal roller and a centrifugal shaft. The centrifugal roller and the centrifugal shaft are connected by a flange. There is an anti-vibration washer at the position, and a sealing ring is provided at the end of the spray pipe, and a first fixed block and a second fixed block for fixing the anti-vibration washer and the sealing ring are arranged at the position where the anti-vibration washer and the sealing ring are in contact, and the spray pipe The glue spraying port is connected with the hemispherical glue spraying head set in the center of the outer side of the centrifugal roller. The inner and outer layers of the anti-shock gasket are made of wear-resistant silica gel, and the middle is made of rubber. A small tube, several small tubes are connected to the nozzles arranged on the hemispherical glue spray head, and the glue spray pipe, small tube, and hemispherical glue spray head are all stainless steel. The invention has simple structure and reasonable design, not only can effectively support and prevent the vibration of the glue spraying pipe, but also can make the glue spray evenly and improve the fiber quality.

Owner:GUANGDE SKD ROCKWOOL MFG

Method for manufacturing reconstituted tobacco substrate by using dry method of paper making

ActiveCN103222676BMake a qualitative leapNo significant emissionsTobacco preparationVacuum pumpingFiber

A method for manufacturing a reconstituted tobacco substrate by using a dry method of paper making comprises the following steps: after tobacco stems, plant fiber materials become short fibers by crushing and fiber dissolving, the short fibers are conveyed to forming head boxes to be broken up by wind, and the broken-up materials are evenly laid and adsorbed on a forming net of the dry method of paper making by the vacuumizing effect of an air suction device below the forming net to form a fiber film; an adhesive is added into the fiber film in a spraying manner, wherein a manner combining spraying through mist spray with vacuum suction on the back face of the spraying is adopted; and finally the reconstituted tobacco substrate with a dimensional lattice structure is obtained by oven-drying. Antistatic ropes are laid between the upper part of the forming net and the forming head boxes or between the forming net and openings of vacuum boxes, and / or antistatic nets are laid between the forming net and the openings of the vacuum boxes. According to the invention, dry method of paper making is firstly used successfully to manufacture the reconstituted tobacco substrate which has better wet strength, a stronger tensile capacity, a high load-carrying capacity, a high filling value and an excellent processing capability.

Owner:CHINA TOBACCO HUNAN INDAL CORP

Special plywood processing device

InactiveCN111687961ASpray glue evenlyPrecise positioningCane mechanical workingWood veneer joiningWood veneerAdhesive

The invention relates to special adhesives, in particular to a special plywood processing device in order to solve the technical problems. The special plywood processing device comprises a working main base plate, a first clamping and moving mechanism, a real-time control screen, a second clamping and moving mechanism, an interval feeding mechanism, a first glue spraying mechanism, a second glue spraying mechanism and a locating and pressurization laminating mechanism. The left side of the top end of the working main base plate is connected with the first clamping and moving mechanism. The right side of the top end of the working main base plate is connected with the second clamping and moving mechanism. The special plywood processing device realizes automatic shifting, locating and feeding of bamboo sheets, implements uniform glue spraying on the front and back surfaces of the bamboo sheets during unidirectional movement of the bamboo sheets without manually touching the glue coatingsurfaces. Glue layers on glue spraying surfaces are flat and uniform. The special plywood processing device can accurately locate the bamboo sheets after glue spraying and achieves the accurate locating and laminating effect on double-face wood veneers.

Owner:贵港市泓源木业有限公司

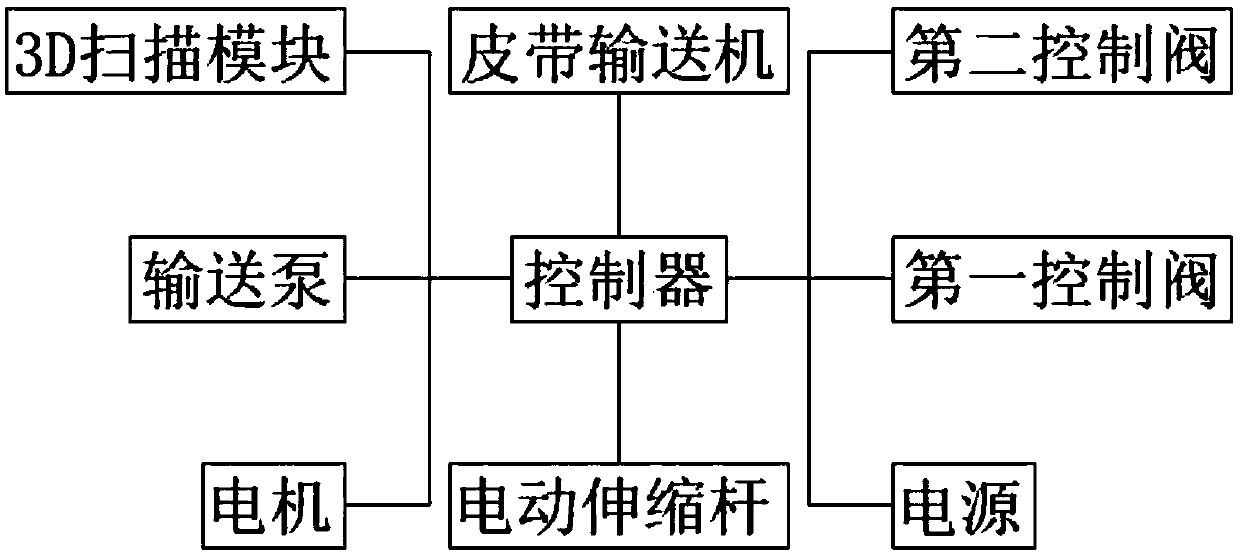

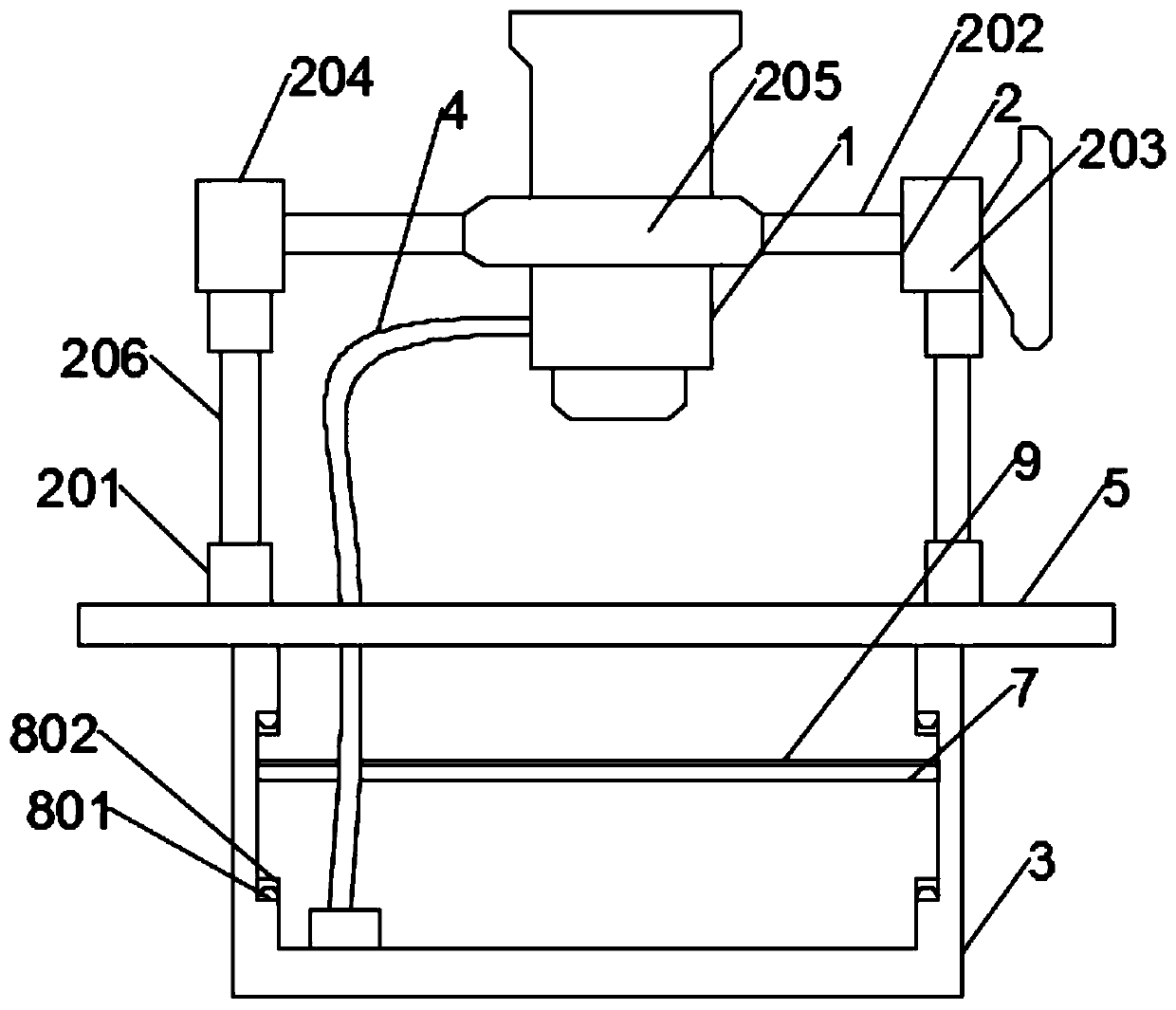

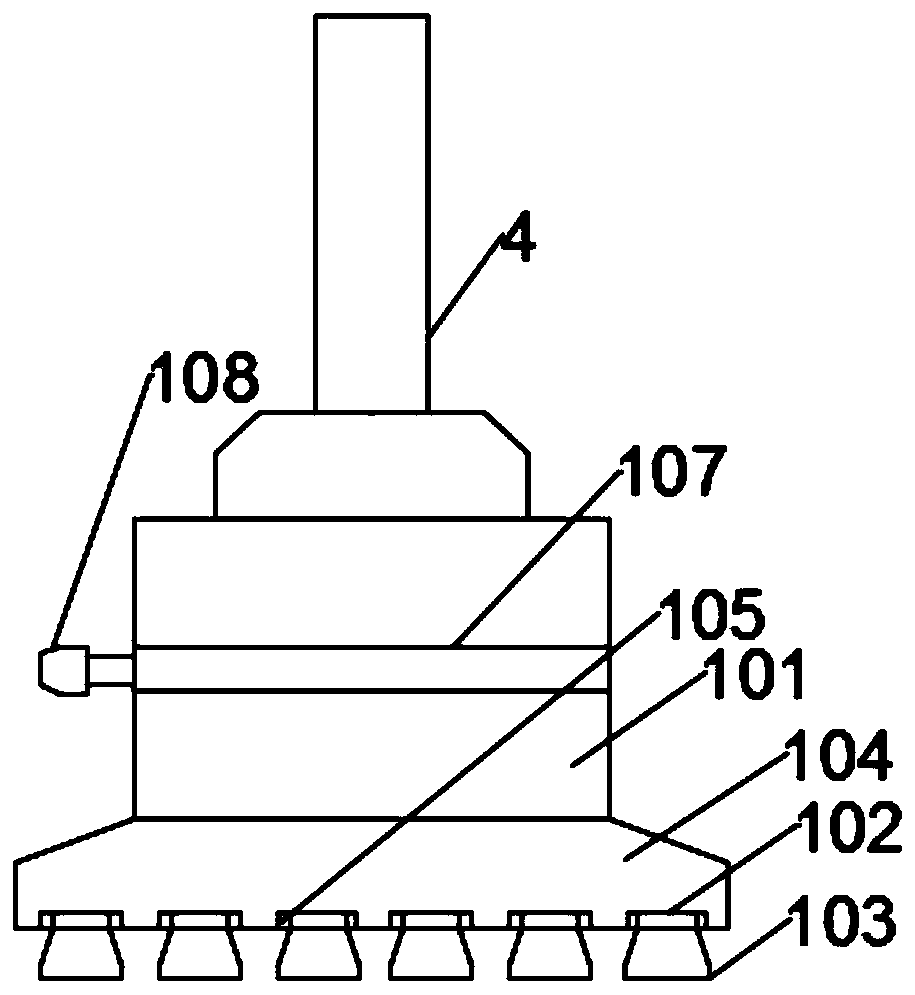

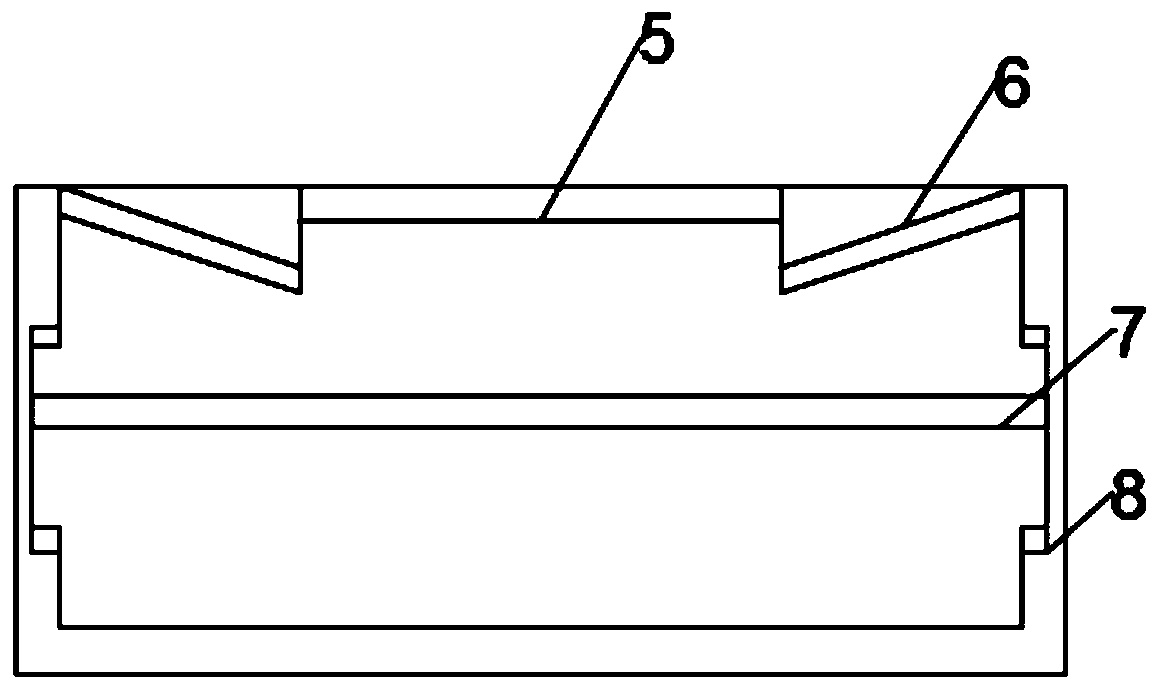

Automatic glue spraying system

The invention relates to the technical field of glue spraying systems, in particular to an automatic glue spraying system, which comprises a first belt conveyor arranged horizontally, wherein a translation mechanism driving a mounting plate to move in a direction perpendicular to the conveying direction of the first belt conveyor is arranged above the first belt conveyor; the mounting plate is arranged horizontally; a storage box is fixed on the mounting plate; a rotation mechanism for rotating the mounting plate along an axis in the horizontal direction is arranged at the bottom of the mounting plate; a D scanning module is arranged in the middle of the bottom surface of the mounting plate; a plurality of nozzles are arranged on the mounting plate; and the specifications of the nozzles are different. The system avoids the waste caused by manual glue spraying, and saves the glue. Compared with mechanical roll coating, this technology has the advantages of being able to spray workpieceswith different shapes, roll coating can only be aimed at planar shapes or fixed shapes, and one rotary drum corresponds to one shape.

Owner:江山花木匠家居有限公司

A glue spraying device of a packing box glue coating machine

ActiveCN107694835BIncrease the areaSpray glue evenlyLiquid surface applicatorsCoatingsEngineeringHOLDING CHAMBER

The invention discloses a glue spraying device for a packing box glue spreader. The glue spraying device comprises a glue spraying head, an adjusting frame and a glue supply barrel. The glue sprayinghead and the glue supply barrel are connected together through an adjusting frame. The glue spraying head is connected with the glue supply barrel through a glue spraying hose to spray glue. A placingplate is arranged at the top end of the glue supply barrel. The adjusting frame and the placing plate are installed together fixedly. The adjusting frame comprises an adjusting rod and two fixed struts. A connecting seat is arranged at the top end of the fixed strut at one end. The adjusting rod penetrates through the connecting seat. An installing seat is arranged on the surface of the adjustingrod. The glue spraying head is installed on the installing seat and comprises a glue holding chamber, glue outlets and spreading heads. A glue outlet plate is arranged at the bottom end of the glue holding chamber. The glue outlets are evenly formed in the surface of the glue outlet plate. The spreading heads is installed in the glue outlets. A plurality of conical mouths are arranged in the spreading heads. Overall glue spreading can be conducted fast, glue spreading is uniform, reasonable glue spreading adjustment can be conducted for different packing boxes, work efficiency of the glue spreader is improved, and the glue spraying device is worth popularization.

Owner:LINQUAN YATAI PACKING

Laminating machine and method for processing paperboard laminating

The invention discloses a novel paper mounting machine and a paper board paper mounting processing method. The novel paper pasting machine comprises a glue spraying mechanism and a pressing mechanism;the glue spraying mechanism comprises a first track, a second track, a bottom plate and a controller, wherein the second track and the first track are perpendicular to each other and located on the same plane; the first track is internally provided with a first screw rod which is parallel to the first track, and the first screw rod and the first track are located on the same plane; and one end ofthe first screw rod is rotationally connected to one end of the first track through a bearing, a first motor is arranged at the other end of the first track, and an output shaft of the first motor isin driving connection with the other end of the first screw rod. According to the novel paper mounting machine and the paper board paper mounting processing method, the technical problems that the pressed colored paper and paperboard are warped or unfirmly bonded can be solved.

Owner:津市中南新鲁包装印刷有限公司

Auxiliary tooling for glue spraying of stabilizer bar bushing

The invention discloses an auxiliary tooling for spraying glue on a stabilizer bar bushing, which relates to the technical field of bushing processing equipment; it includes a fixing mechanism for fixing the bushing and a rotating mechanism for rotating the fixing mechanism; the fixing mechanism includes a The bottom plate supporting the lower side of the bushing, the cover set on the upper side of the bushing so as to realize the upper and lower limit of the bushing, and several lower ends fixed on the bottom plate for abutting against the side of the bushing so as to realize the limit of the bushing Guide posts, a number of limit plates fixed on the bottom plate against the opposite sides of the bush to prevent relative rotation of the bush and the bottom plate, and a glue gun on the cover plate for inserting glue guns to spray glue inside the bush The through hole of the fixed mechanism coincides with the axis of the hole on the bushing used to pass through the stabilizer bar, the guide column passes through the cover plate and is slidably connected with the cover plate, and the lower end of the glue gun is equipped with a device for spraying mist The glue outlet of the glue. The method of rotary spraying is adopted to make the glue spraying more uniform under the action of centrifugal force.

Owner:ZHEJIANG MEILI AUTOMOBILE SPRING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com