Continuous melamine-formaldehyde resin veneer rubber coating, dipping, drying and conveying device

A technology of formaldehyde resin and melamine, applied in the direction of coating impregnation, wood impregnation, lamination device, etc., can solve the problems of high processing cost and serious pollution, and achieve the effect of ensuring precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawings and examples.

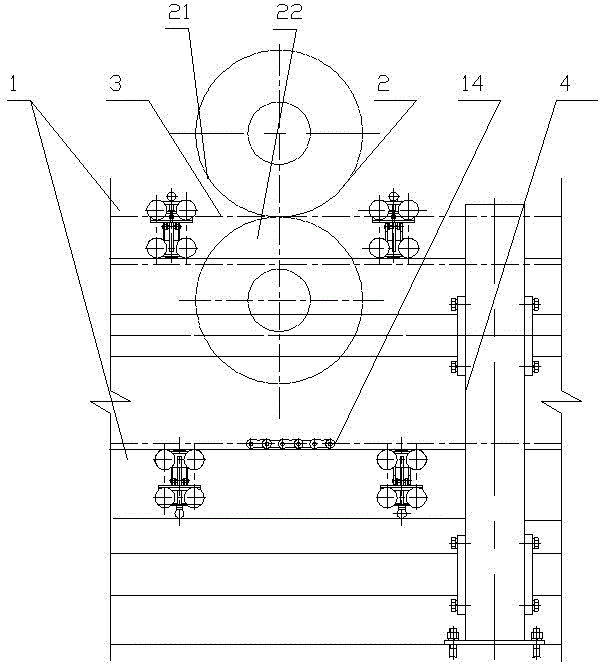

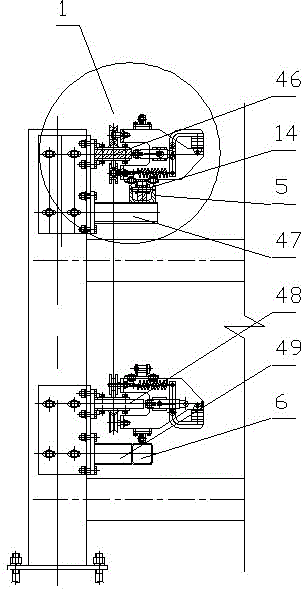

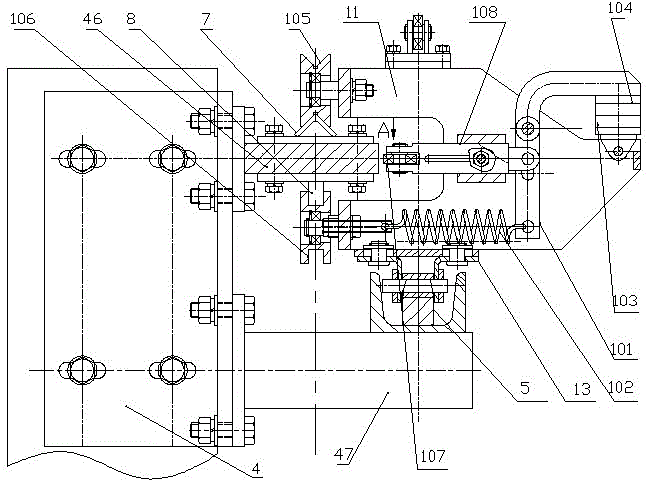

[0025] see Figure 1 to Figure 7, a kind of continuous melamine formaldehyde resin veneer gluing impregnation drying conveying device of the present invention, it comprises gluing impregnating device, chain transmission device, and described gluing impregnating device comprises opposite upper rubber roller 21 and lower rubber roller 22, also It includes a frame 4, a feeding device 1 for veneer clamping and conveying, a glue releasing device 9, and a glue amount adjusting device 2. The upper part of the frame 4 is sequentially provided with a first short cantilever 46 and a first long cantilever from top to bottom. 47, the bottom of the frame 4 is provided with the second short cantilever 48 and the second long cantilever 49 successively from top to bottom. The end of the cantilever 46, the front end and the rear end of the chain drive are fixedly connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com