Patents

Literature

150results about How to "Guaranteed running accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

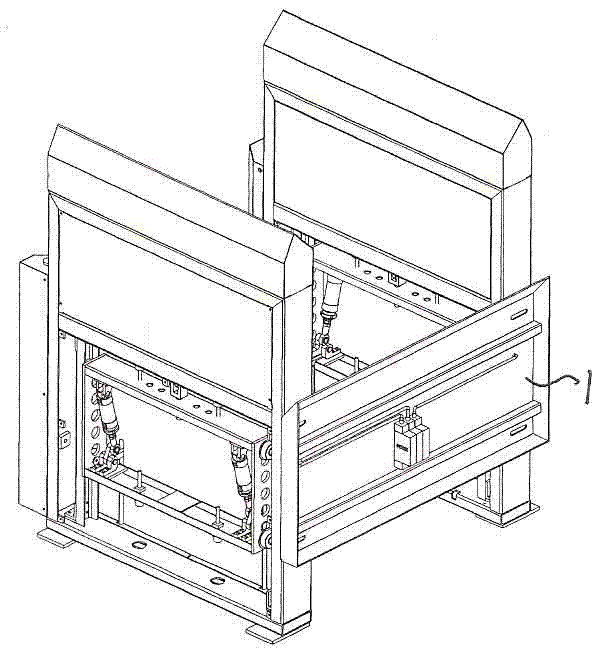

Automatic pallet machine

ActiveCN102730422ASave human effortReduce manufacturing costStacking articlesDe-stacking articlesElectrical controlEngineering

The invention discloses an automatic pallet machine, comprising a left lifting mechanism and a right lifting mechanism. Guiding apparatuses are arranged in the front of the left and right lifting mechanisms, and rear support plates are arranged at the back of the left and the right lifting mechanisms, wherein the rear support plate is used to connect the left lifting mechanism and the right lifting mechanism and restrict the pallet in place. The machine provided in the invention has the following advantages that: the structure of the machine is reasonable, forward operation can be adopted for task of pallet removing, and reverse operation can be used for pallet stacking and pallet settling in a warehouse; the mechanical structure of the machine is simple and portable, the operation is convenient and easy to learn, and the machine occupies a small area; and positioning precision is greatly improved by adopting electrical control. According to the above advantages, the product can greatly minimize manpower of enterprise and reach a final purpose that reduces production cost of the enterprise. The machine provided in the invention is suitable for splitting of various pallets, and the machine can be widely applied in industries of daily chemicals, medicine, foodstuff, beverage, warehouse and the like.

Owner:NANTONG UNIVERSAL MACHINERY

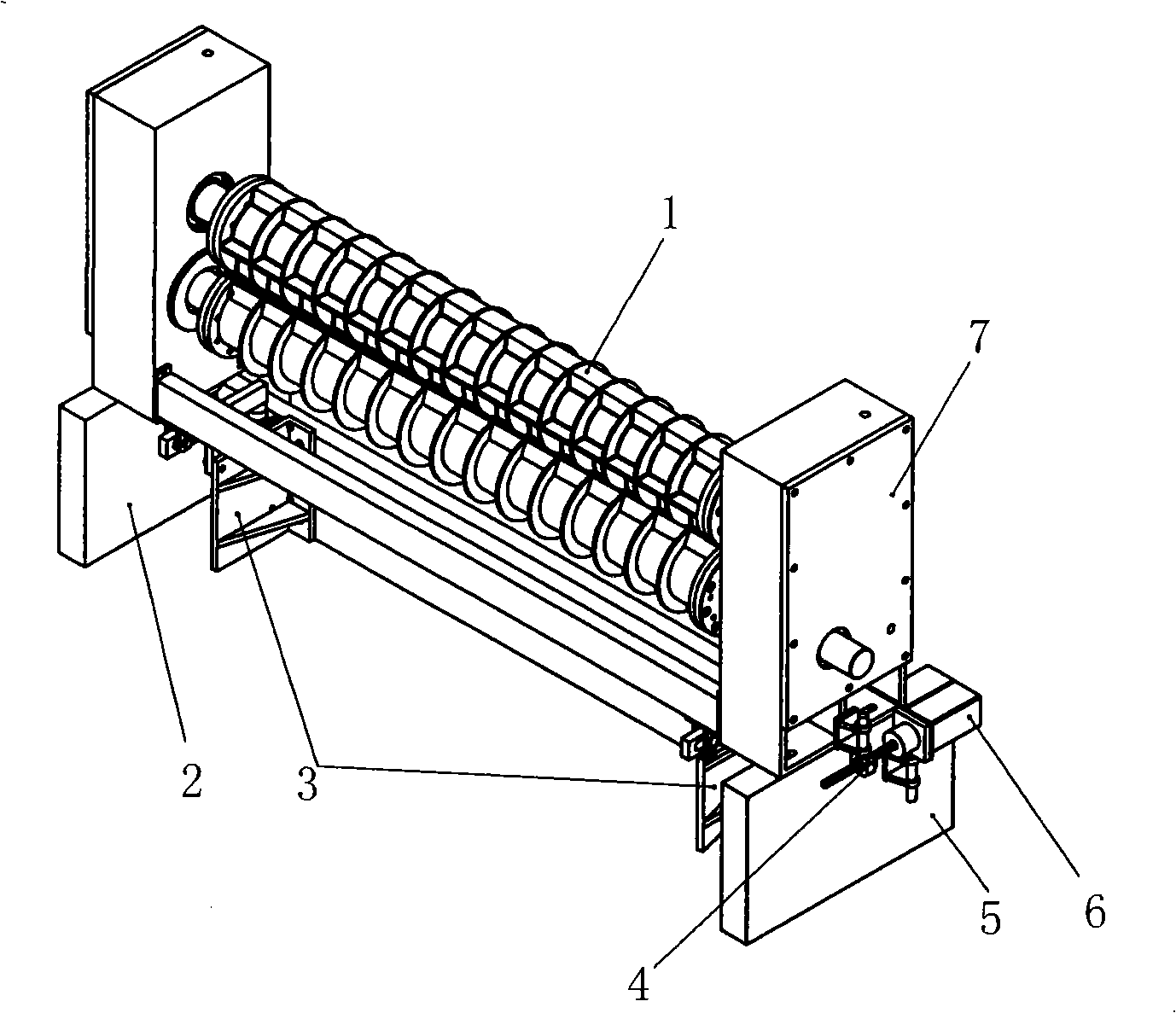

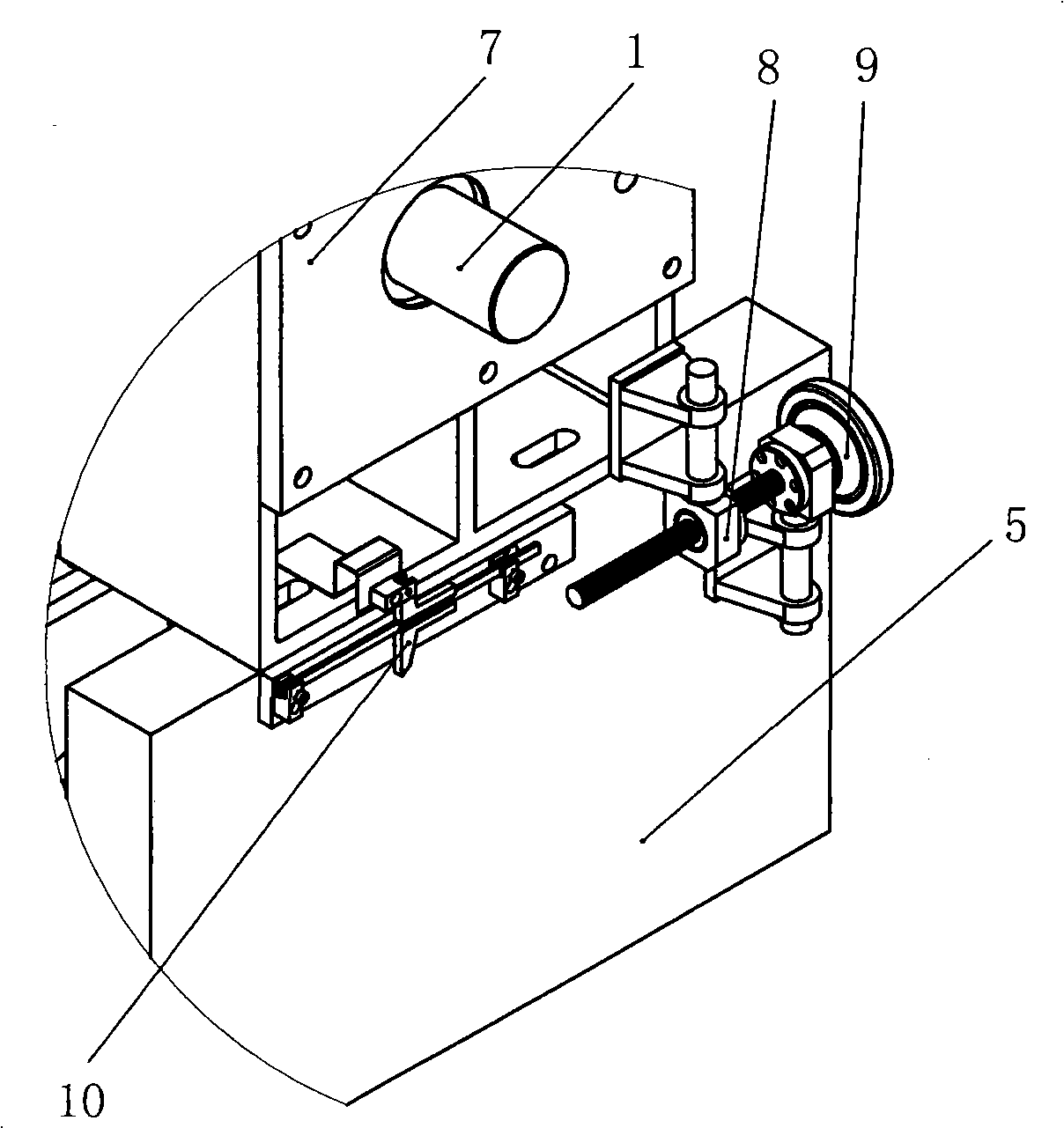

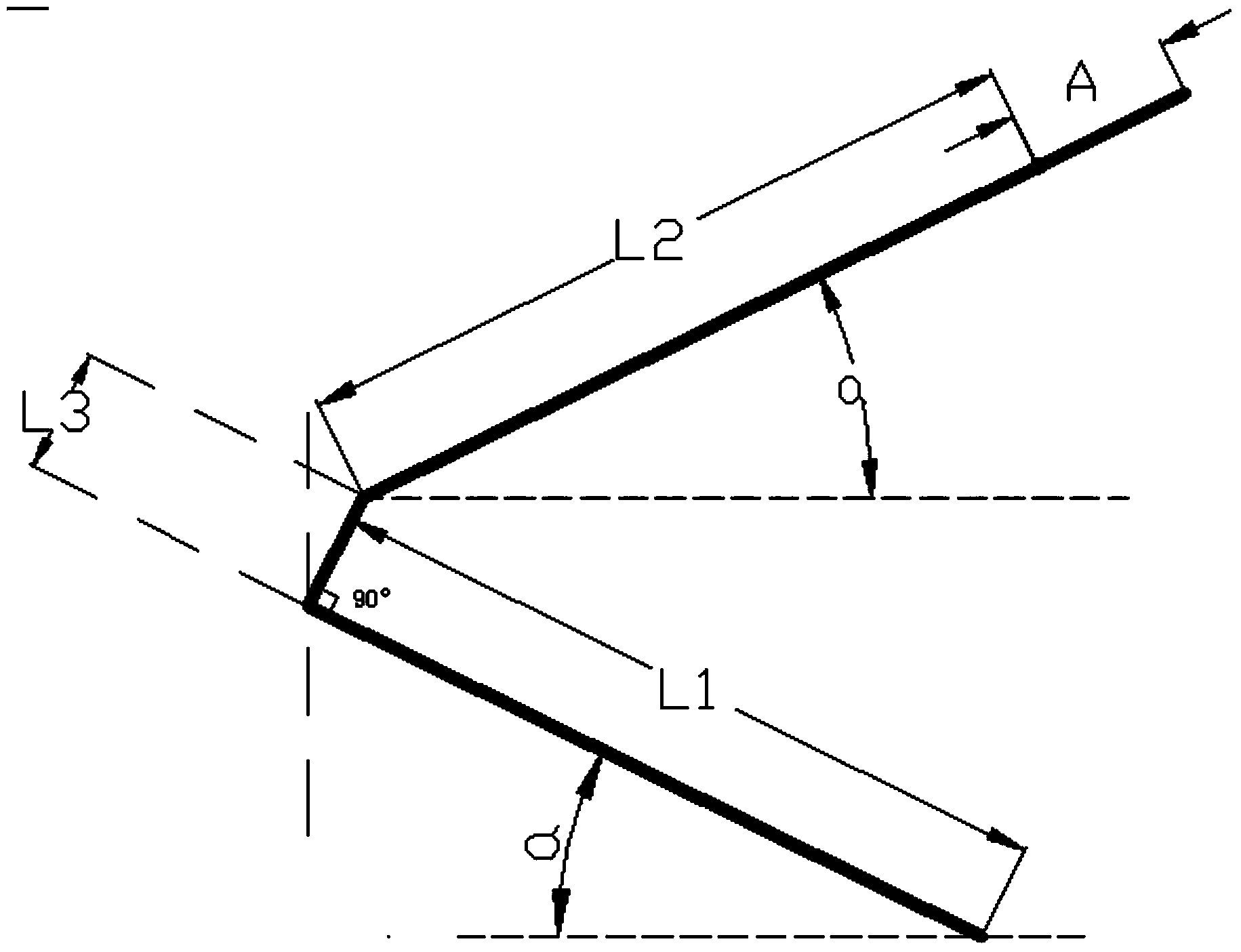

Transversely cutting device of paper cutter with double flying knives and method for adjusting length and squareness of cut paper

InactiveCN101537645AGuaranteed squarenessSmall transmission powerMetal working apparatusPulp and paper industryElectric motor

The invention provides a transversely cutting device of a paper cutter with double flying knives and a method for adjusting the length and the squareness of cut paper. The transversely cutting device comprises stands and a double-rotary knife roll, wherein both ends of the double-rotary knife roll are arranged on the stands by bearing supports, one bearing support is articulated with the stand at one side by a rotating axle, a knife roll adjusting mechanism is arranged on the stand at the other side, and a revolving knife hold-down mechanism is arranged on a connecting plate between the stand at one side and the stand at the other side, and articulated with the bearing supports by adjustable post rods and connecting pieces. The positions of the adjustable post rods are adjusted, which enables the bearing supports at both ends of the knife roll, the stand at both sides to be compressed or loosened. The speed ratio of the peripheral speed of the knife roll to the running line speed of paper is adjusted for adjusting the length of the cut paper. When cutting the paper, the knife roll rotates at a uniform speed all the time. A method that the angle between an axial line of the knife roll and the running direction of the paper is adjusted is adopted to ensure the cutting squareness. The invention can greatly decrease the installed capacity of an electric motor of the transversely cutting device and lower the complexity and the cost of manufacture.

Owner:李秉江

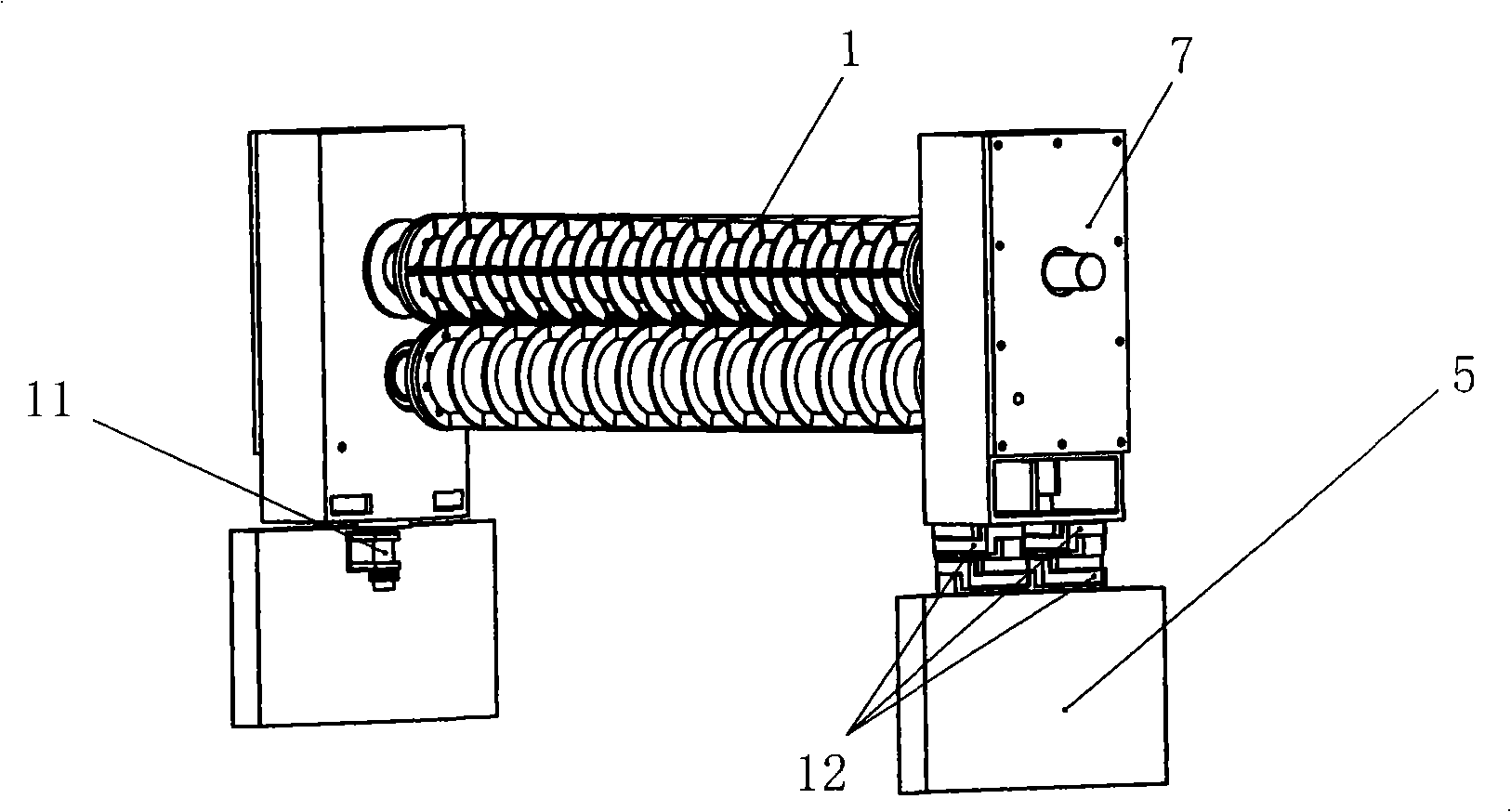

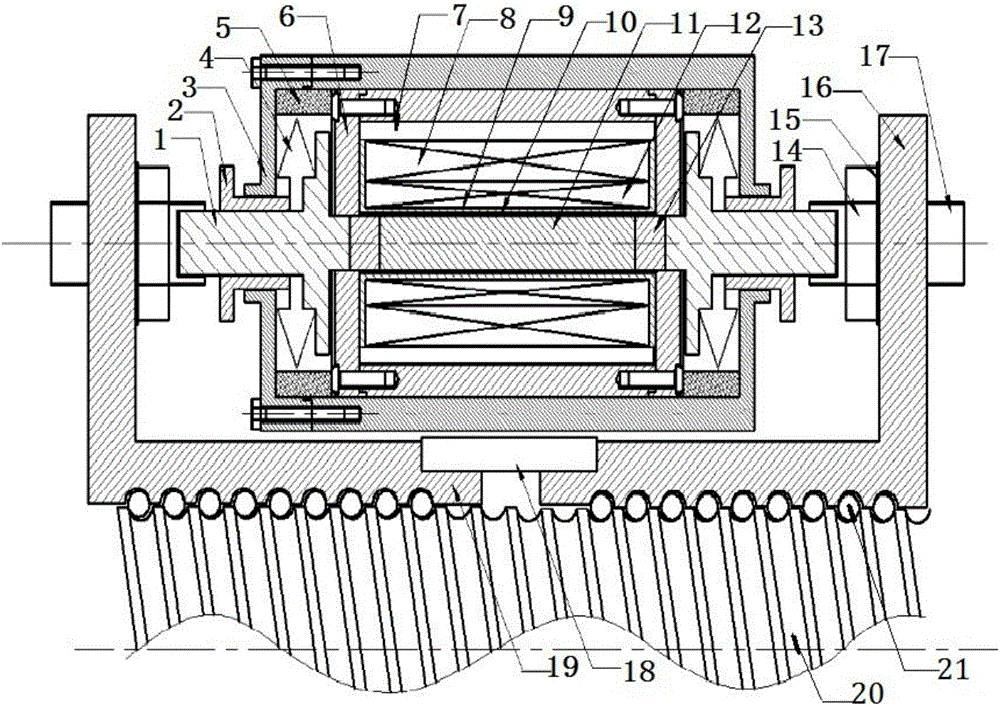

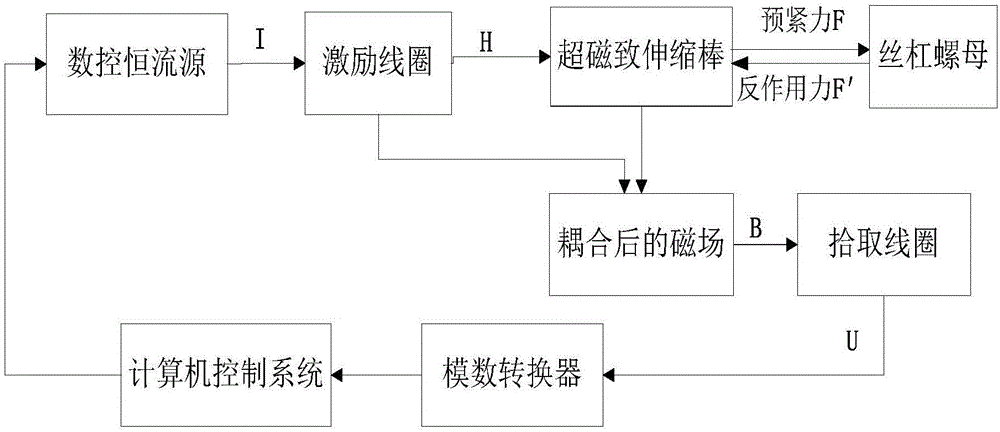

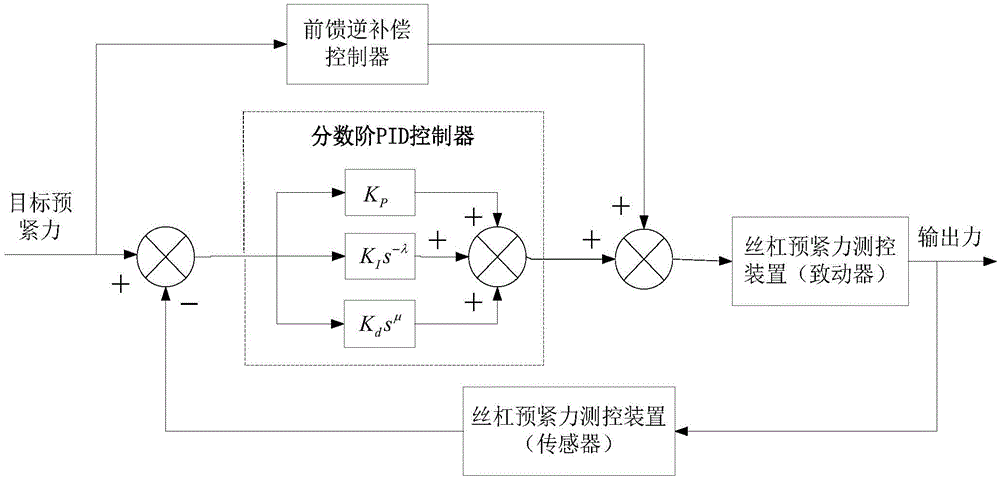

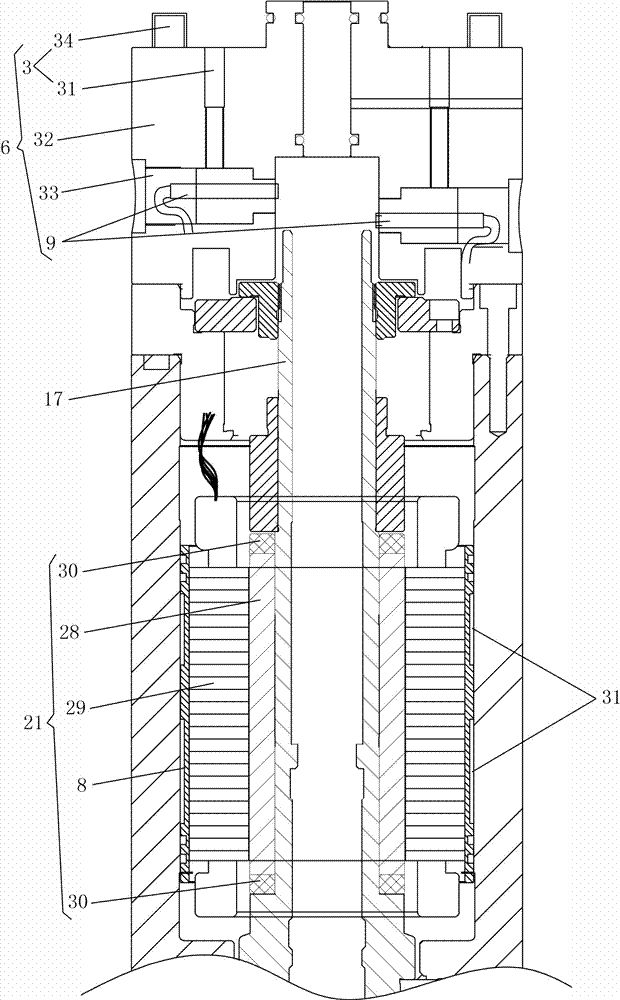

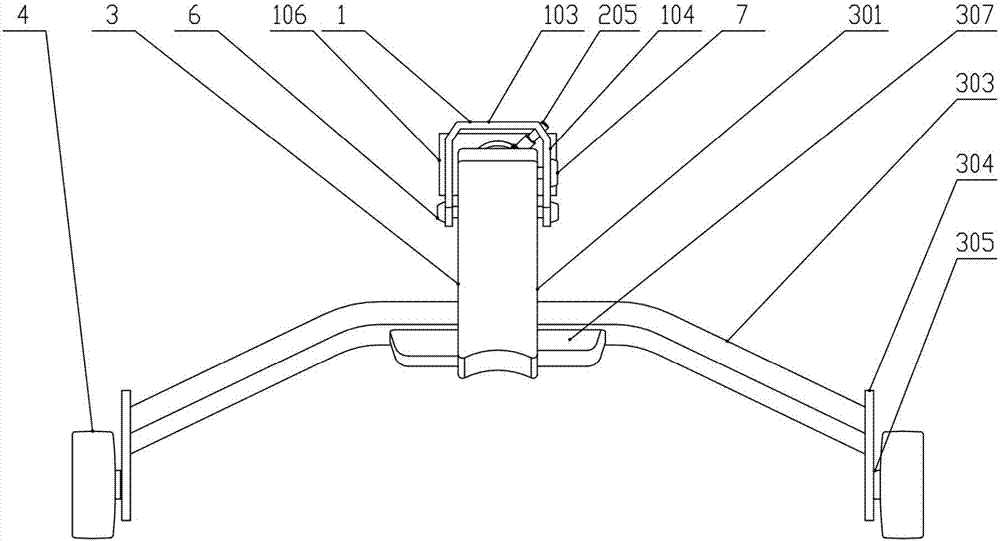

Ball screw pair pre-tightening force measurement and control system and method with self-sensing function

ActiveCN106230308ARealize self-awarenessEliminate disturbance effectsPiezoelectric/electrostriction/magnetostriction machinesNumerical controlMagnetostrictive actuator

The invention discloses a ball screw pair pre-tightening force measurement and control system and method with a self-sensing function. The system comprises a pre-tightening device and a measurement and control device, a giant magnetostrictive material is used as the core, the functions of an actuator and a sensor are realized by using the normal inverse effect of the material, a permanent magnet provides a bias magnetic field for a giant magnetostrictive bar, one coil is used as an exciting coil for providing a driving magnetic field for the giant magnetostrictive actuator of the measurement and control device, the magnitude of pre-tightening force output by the actuator is controlled by changing the current of the exciting coil, and the other coil is used as a pick-up coil for realizing the self-sensing function of ball screw pair pre-tightening force by acquiring a magnetic field change caused by a pre-tightening force change. The system and the method can realize self-sensing of the ball screw pair pre-tightening force and automatic and accurate control of the pre-tightening force, and improve the transmission precision of the ball screw pair, so that the running precision and the machining quality of a numerically-controlled machine tool are guaranteed.

Owner:SHANDONG UNIV

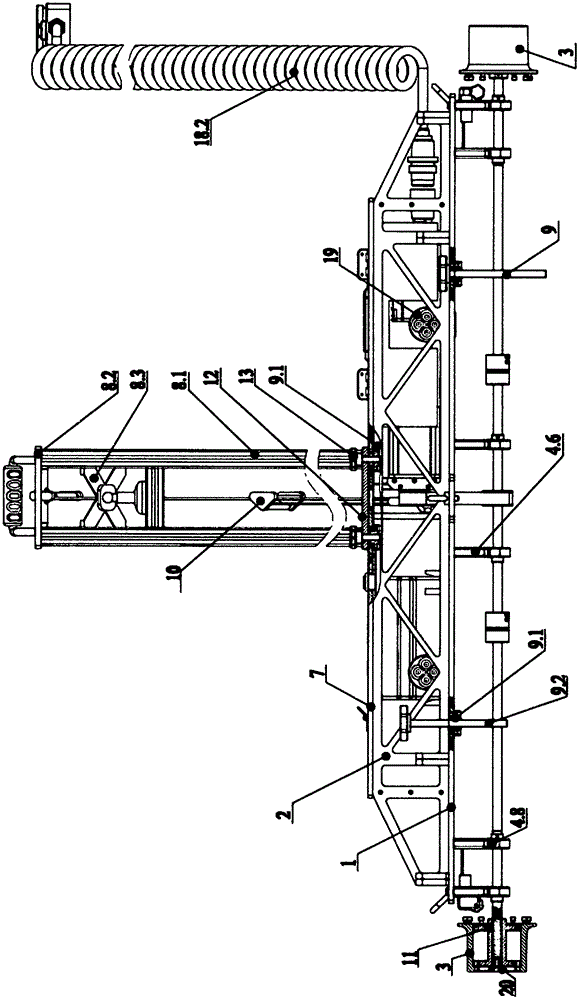

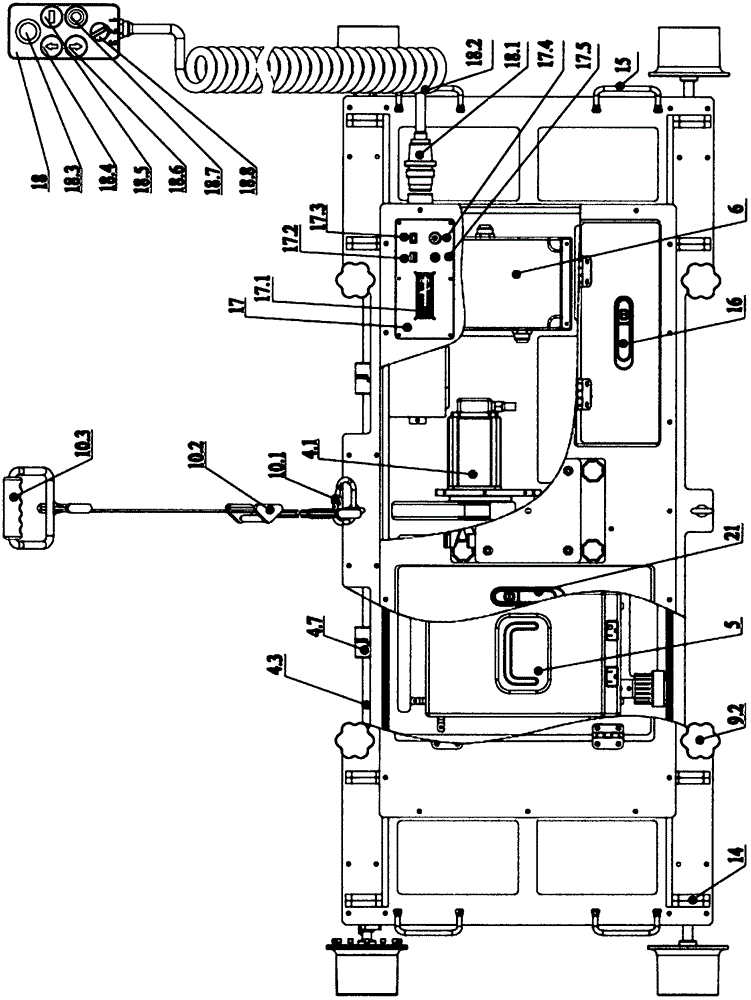

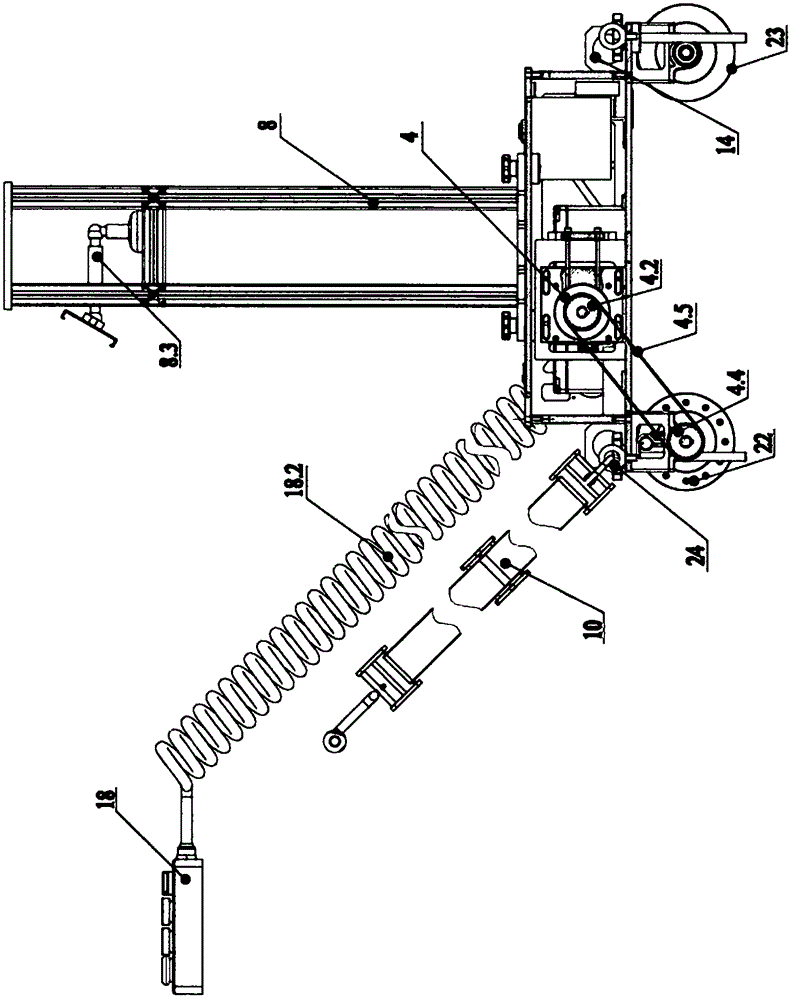

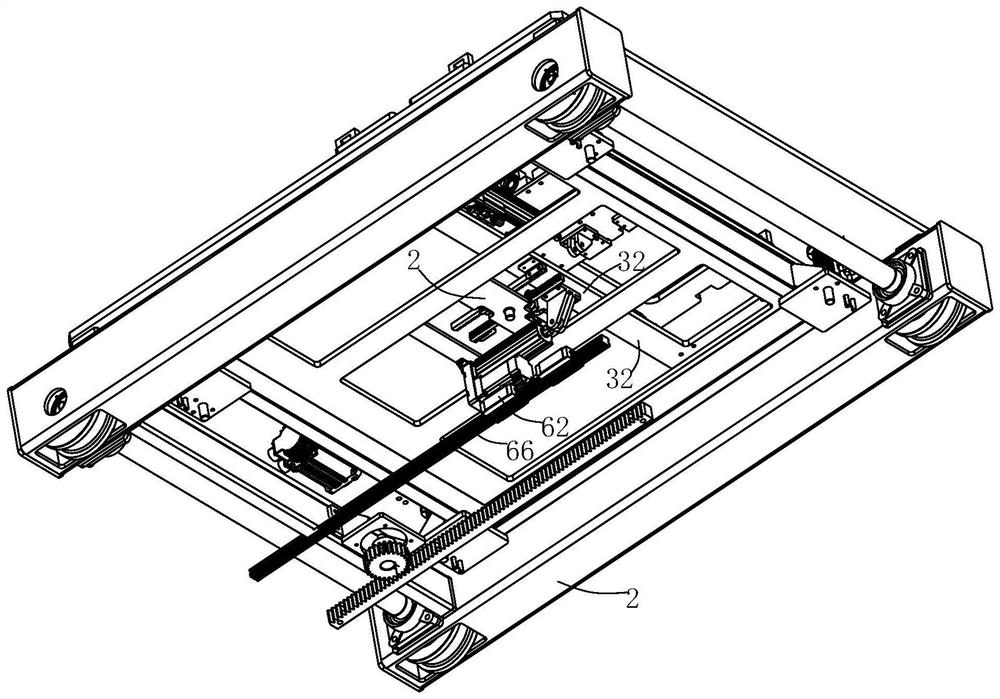

Portable full-automatic rail and tunnel movable inspection vehicle

ActiveCN106080626AEasy to handleHigh degree of automationRailway inspection trolleysDrive shaftControl system

The invention discloses a portable full-automatic rail and tunnel movable inspection vehicle. The portable full-automatic rail and tunnel movable inspection vehicle is characterized in that the inspection vehicle comprises a chassis (1), a side plate (2), vehicle wheels (3), transmission mechanisms (4) controlling the vehicle wheels (3) to operate, an integrated power supply system (5) and an integrated control system (6) controlling the inspection vehicle to operate. A detachable instrument installation platform (8) used for holding instruments is arranged on an installation plate (7). The chassis (1) is provided with an adjustable support device (9). An insulation sleeve (11) is arranged between each vehicle wheel (3) and a transmission shaft driving the vehicle wheel (3) to operate. According to the inspection vehicle, vehicle automation technology and geographic information survey equipment are combined and applied to the field of geographic information surveys of subway rails and tunnels to achieve high efficiency and high precision of geographic information data collection, and huge convenience is brought to subsequent data processing. The inspection vehicle is high in automation degree, convenient to operate and high in measurement precision.

Owner:武汉月恒自动化设备有限公司

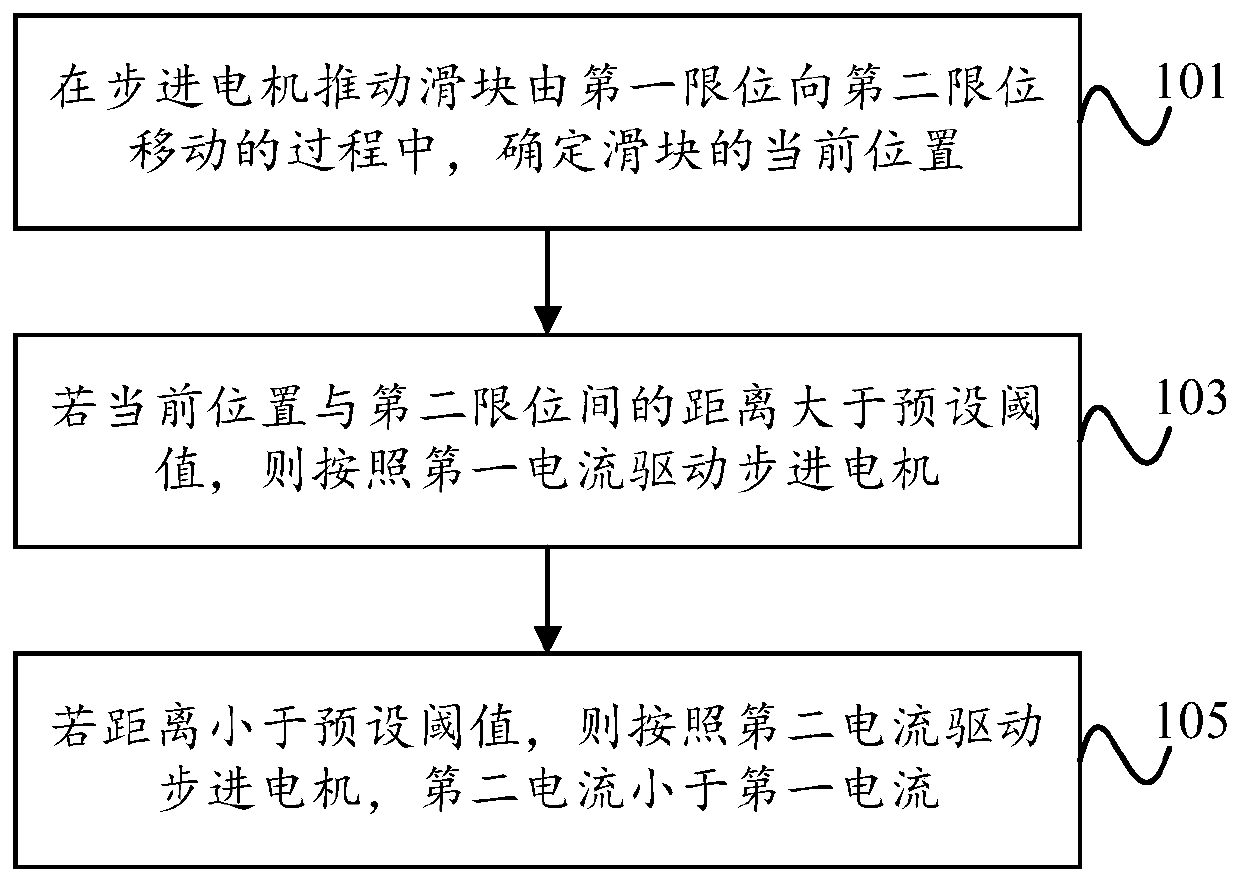

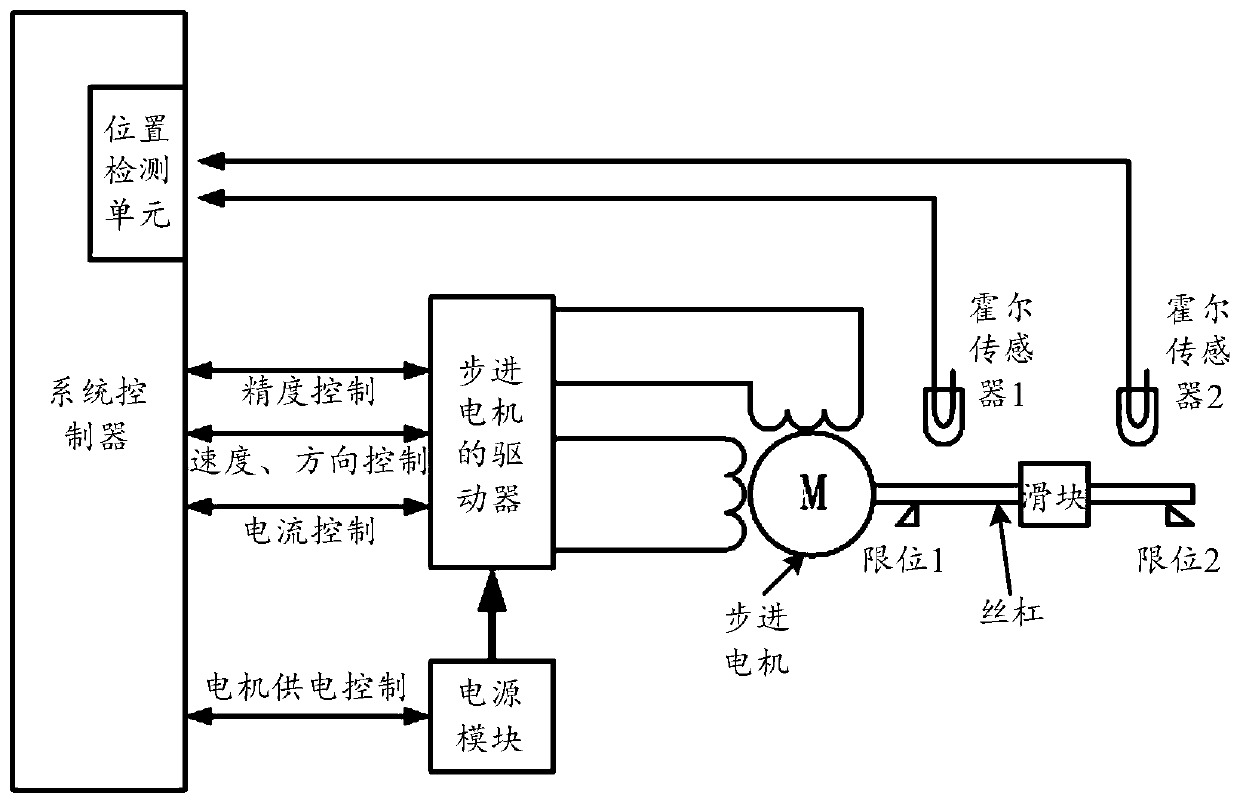

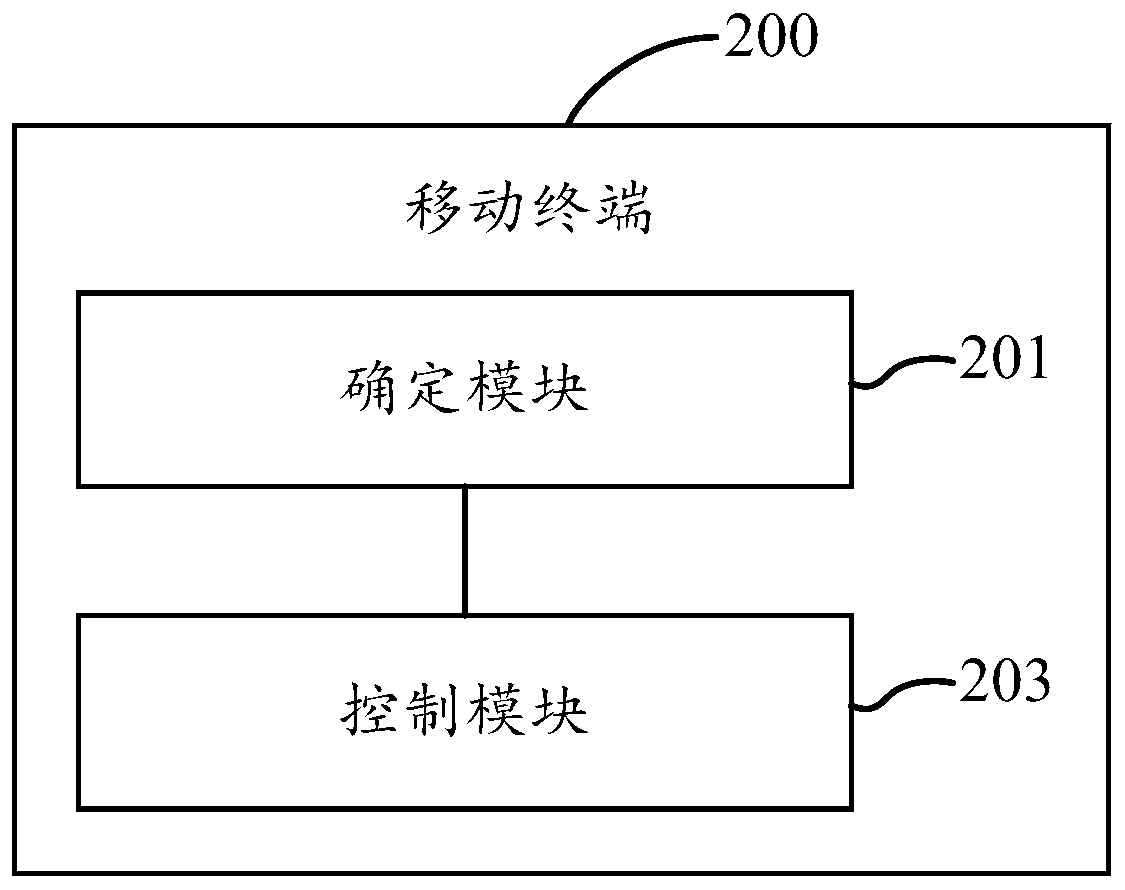

Control method for stepping motor, and mobile terminal

ActiveCN109981009AReduce output torqueGuaranteed service lifeElectric motor controlDynamo-electric converter controlEngineeringElectrical and Electronics engineering

The embodiment of the invention discloses a control method for a stepping motor, and a mobile terminal. The method comprises the following steps: in a process that the stepping motor pushes a slidingblock to move to a second limitation position from a first limitation position, determining the current position of the sliding block; if a distance between the current position and the second limitation position is greater than a preset threshold value, according to a first current, driving the stepping motor; and if the distance is smaller than the preset threshold value, according to a second current, driving the stepping motor, wherein the second current is smaller than the first current. By use of the embodiment of the invention, noise generated between a lead screw and the sliding blockcan be reduced or avoided, the service life and the operation accuracy of the stepping motor are guaranteed, and meanwhile, user experience is improved.

Owner:VIVO MOBILE COMM CO LTD

Low-temperature storage transfer device and operation method thereof

The invention discloses a low-temperature storage transfer device and an operation method thereof. The low-temperature storage transfer device is used for conveying a transfer pot from the external environment to a refrigeration house and comprises a sealing component and a transmission component, wherein the sealing component comprises an inner door and an outer door; the inner door is provided with an inner lifting mechanism, the outer door is provided with an outer lifting mechanism, and a sealable buffer area is formed between the inner door and the outer door; the inner door is communicated with the refrigeration house, and the outer door is communicated with the external environment; the transmission component comprises an outer transmission mechanism and an inner transmission mechanism; the outer transmission mechanism is used for conveying the transfer pot from the external environment to the buffer area, and the inner transmission mechanism is used for conveying the transfer pot from buffer area to the refrigeration house. The low-temperature storage transfer device can ensure that a biological sample cannot be exposed in the normal-temperature environment after the transfer pot is uncapped, thereby reducing sample damage. The buffer area can prevent the inner part of the transfer pot from frosting, and the success rate of automatically storing and taking pipes is increased.

Owner:SHANGHAI ORIGINCELL BIOLOGICAL CRYO EQUIP CO LTD

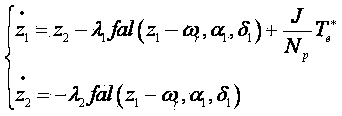

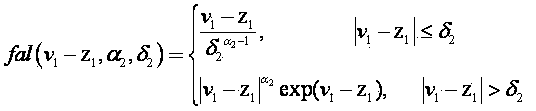

Method for controlling rotor-side converter of doubly fed induction generator (DFIG)

ActiveCN103746628AHigh control precisionSolve the difficulty of debuggingElectronic commutation motor controlVector control systemsVoltage vectorSelf excited induction generator

The invention discloses a method for controlling a rotor-side converter of a doubly fed induction generator (DFIG). A vector control system consists of a torque inner ring control module, a voltage space vector modulation module, a rotating speed measurement module, a maximum wind energy capturing module and a first-order auto disturbance rejection controller (ADRC); a given DFIG rotor rotating speed output by the maximum wind energy capturing module and an actual DFIG rotor rotating speed measured by the rotating speed measurement module are sent into the ADRC; given reactive power, given stator flux linkage and expected electromagnetic torque output by the ADRC are sent into the torque inner ring control module; the rotor-side converter is controlled through the voltage space vector modulation module according to a rotor voltage vector modulation signal output by the torque inner ring control module. According to the method, parameters of the ADRC are optimized on line, so that the problem of large difficulty in debugging of the parameters of the ADRC is solved, the control accuracy of the ADRC is improved, and the operation stability of a power generation system is further ensured.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

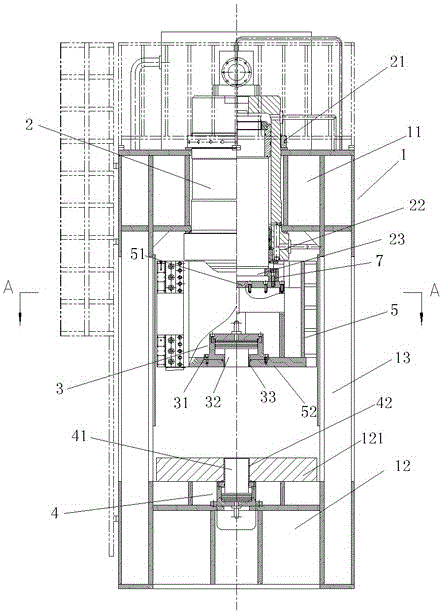

Mode locking mechanism of electric plastic injection machine

The invention discloses a mould locking device for an electric injection molding machine, which comprises a front moulding plate, a middle moulding plate and a back moulding plate which are arranged sequentially from front to back in parallel, wherein four pull rods are arranged between the front moulding plate and the back moulding plate, and the front ends of the pull rods are fixedly connected with the front moulding plate. The tail ends of the pull rods are connected with a mould locking piston, and an outer ring of the mould locking piston is glidingly matched with a mould locking oil cylinder which is fixedly connected with the back moulding plate. The back moulding plate is matched with at least one set of hydraulic jacks, and controls the movement of the mould locking piston. A mould moving motor which is matched on the back moulding plate is connected with a mould moving roll ball screw rod which is positioned in the center of the back moulding plate by driving. The front end of the mould moving roll ball screw rod is fixedly connected with the back end of the middle moulding plate through a main shaft, wherein the back end of the middle moulding plate adopts a horn-shaped structure, and the middle stressing and force transferring effect is uniform. The back moulding plate is provided with a mould adjusting component, a mould locking component and a quick mould moving component integrally, and the structure is compact. The mould moving roll ball screw rod and the main shaft adopt a thread pitch multi-head roll ball screw rod structure, and the mould moving speed is high.

Owner:NINGBO HAIXING MACHINERY MFG

Preparation method of low-noise grease lubricant for miniature bearing with high precision and density

The invention discloses a preparation method of a low-noise grease lubricant for a miniature bearing with high precision and density. The preparation method comprises the following steps of: carrying out ultrafiltration on raw materials and adding all raw materials into a saponification kettle to carry out saponification; and after saponifying, carrying out filtering, high-pressure homogenizing and high-reflux shearing pressure in sequence. The preparation method has the advantages of simpler production process, fewer procedures, lower production cost and improved production efficiency; meanwhile, the grain diameter of mechanical impurities in the grease lubricant is smaller than that of the grease lubricant in the prior art and the vibration decibel value of the bearing is lower than that of the grease lubricant in the prior art, so that the operation precision of the miniature bearing is guaranteed, and the vibration and abrasion are reduced; the vibration decibel value of the bearing is lower than 40, the grain diameter of mechanical impurities in the grease lubricant is smaller than 10 microns, and the work penetration of the grease lubricant is 310-340, 0.1 mm.

Owner:AMER TECH CO LTD

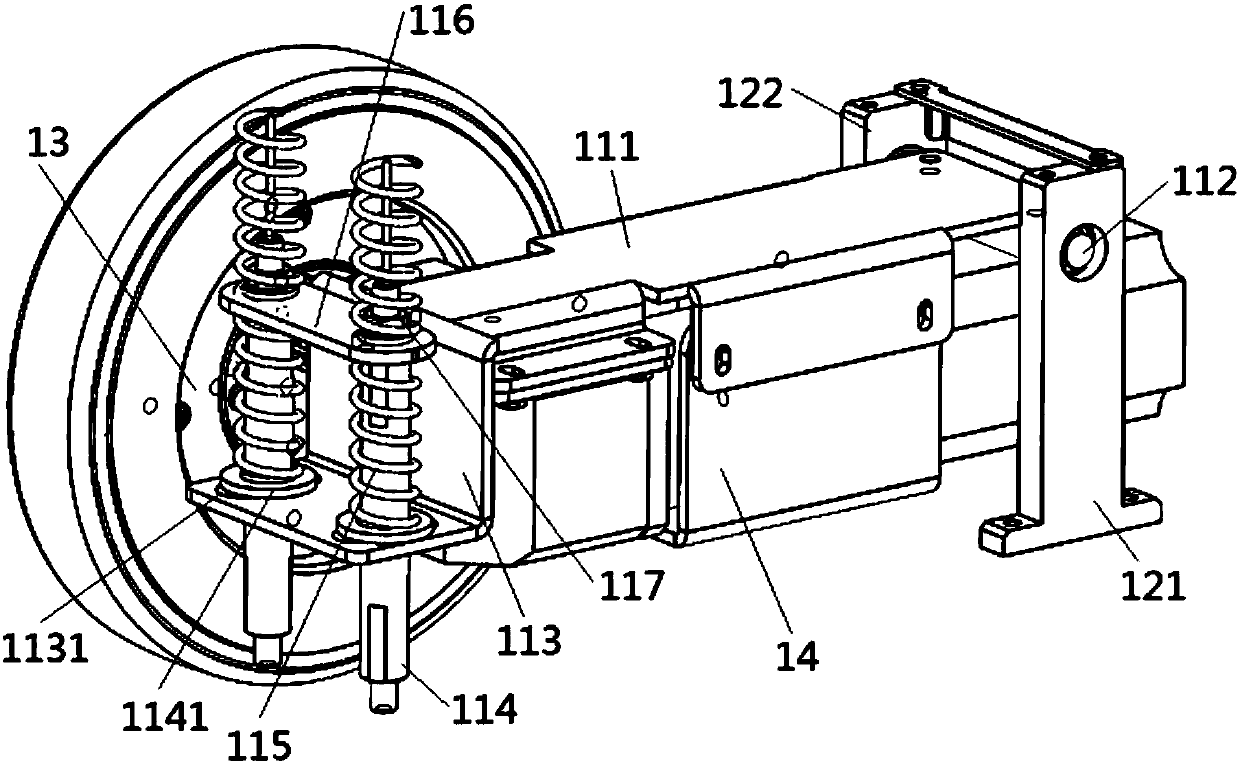

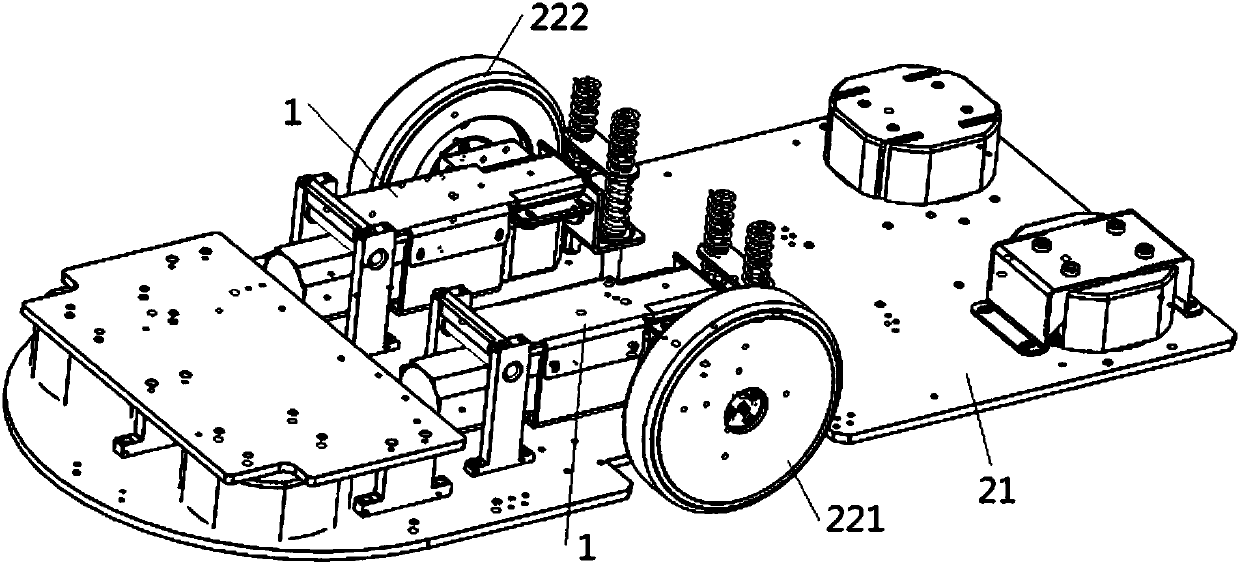

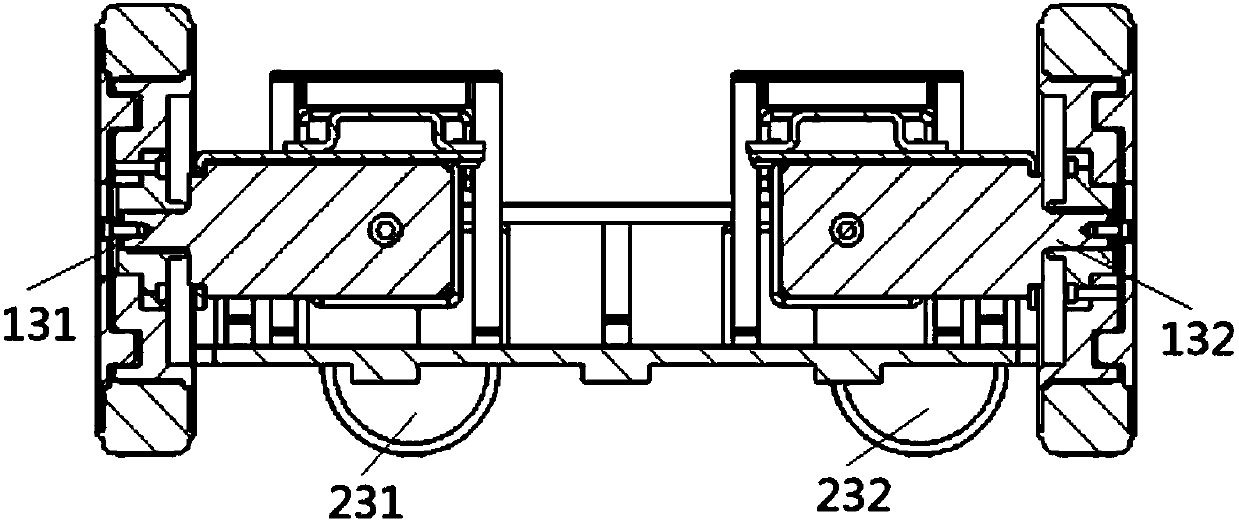

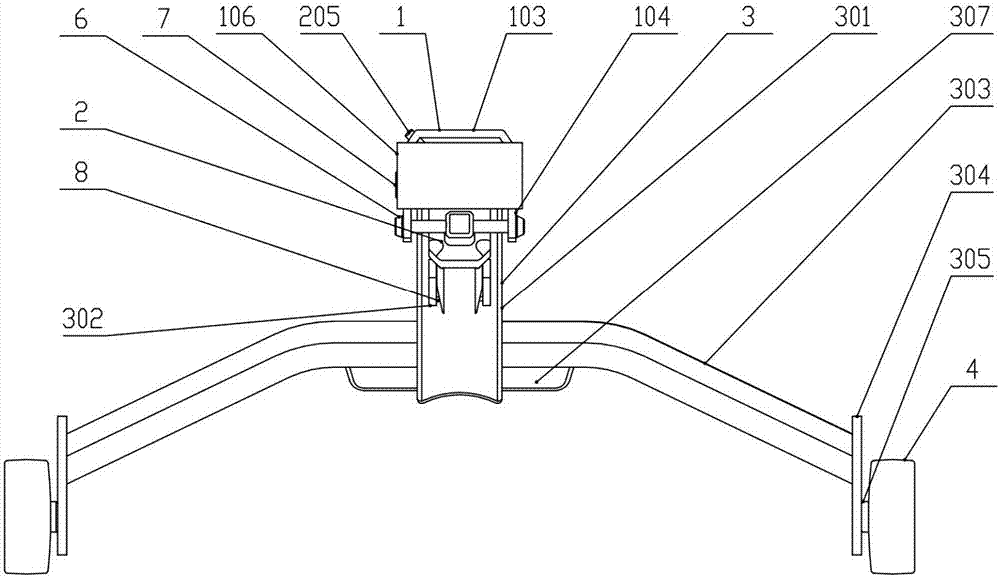

AGV and suspension structure thereof

PendingCN107914532AGuaranteed running accuracyGuaranteed stabilityResilient suspensionsVehiclesDrive wheelSuspension (vehicle)

The invention discloses an AGV and a suspension structure thereof. The suspension structure comprises a suspension mechanism and a supporting mechanism, wherein the suspension mechanism is connected with a hub assembly of a driving wheel; the supporting mechanism is connected with a vehicle body of the AGV; and the suspension mechanism is rotatably arranged on the supporting mechanism, so that thesuspension mechanism can drive the hub assembly to carry out curvilinear motion around the supporting mechanism. The road grabbing ability of driving wheels is improved, the circumstance that the driving wheels are suspended is avoided, and therefore, slipping of the driving wheels is prevented effectively; preferably, the circumstance that the vehicle body is inclined and the like is further avoided effectively; and therefore, the stability of a chassis of the AGV in a heavy-load starting and stopping process is ensured, and the running precision of the AGV is ensured.

Owner:SHANGHAI MROBOT TECH CO LTD

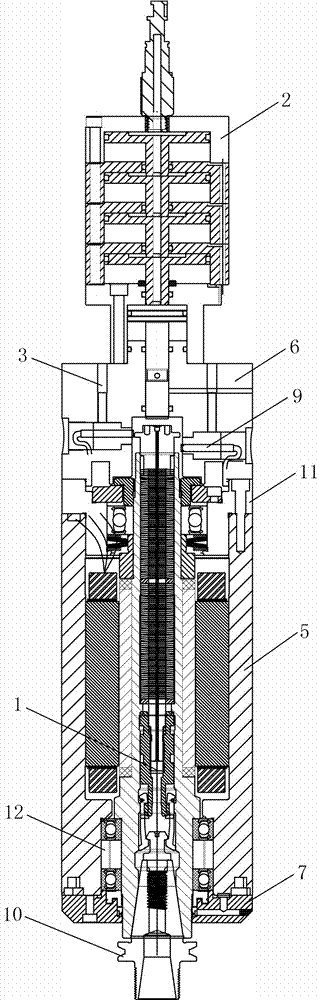

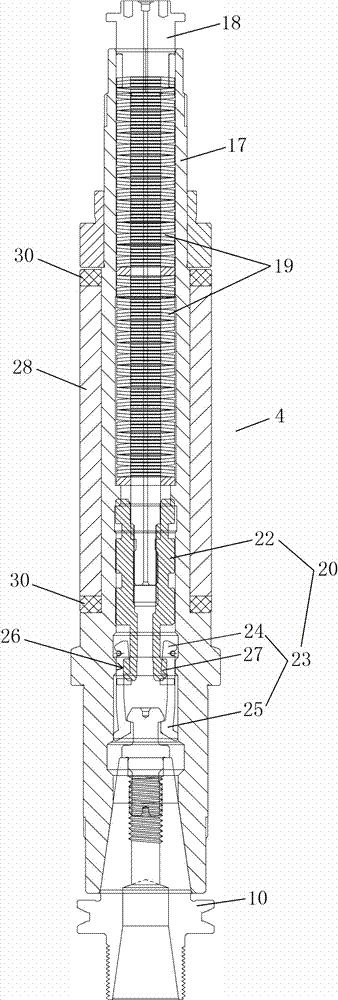

Electric spindle capable of realizing automatic tool changing and provided with build-in shank

PendingCN107042420AImprove structural strengthRealize automatic tool changeFeeding apparatusMaintainance and safety accessoriesBall bearingStator coil

The invention relates to an electric spindle capable of realizing automatic tool changing and provided with a build-in shank. A spindle body is provided with a cooling mechanism and comprises a spindle box, a back seat and a dust cover; spindle assemblies are press-fitted in the spindle box; the back seat and the dust cover are arranged at two ends of the spindle box; the spindle assemblies are fixedly mounted in the spindle box through cooling copper sleeves; a detection device and a control device are arranged on the back seat; one end of each spindle assembly is in transmission connection with a driving device; and the other end of each spindle assembly is detachably connected with an external device. The electric spindle has the beneficial effects as follows: a stator coil outer sleeve is changed from a steel piece into a brass casting, a circulating water-cooling channel is added in the casting outer sleeve, the temperature is prevented from increasing too fast, the operation precision of the spindle is kept, a clamping jaw and the shank are organically combined, meanwhile, a built-in encoder connected with a control center is configured, functions of automatic tool changing, instant accurate stop and the like are realized, a rotor magnetic piece is in short-circuited connection through an end copper ring, the consumption is reduced, a steel angular contact ball bearing is replaced with a ceramic ball bearing, the friction and the heat are reduced, and the life is prolonged.

Owner:岳阳市显隆电机有限公司

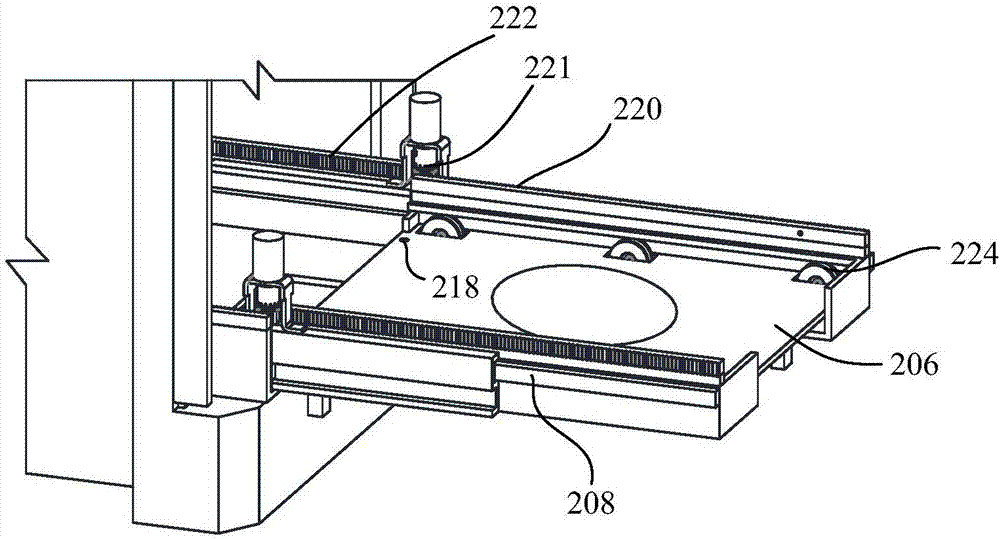

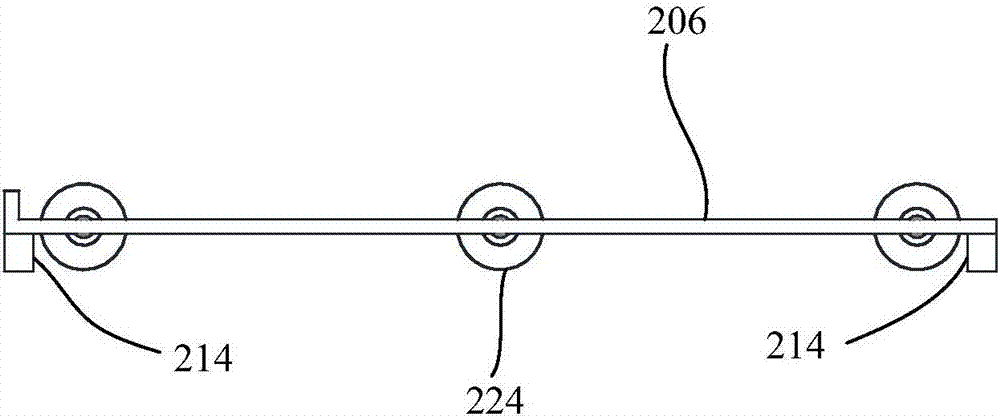

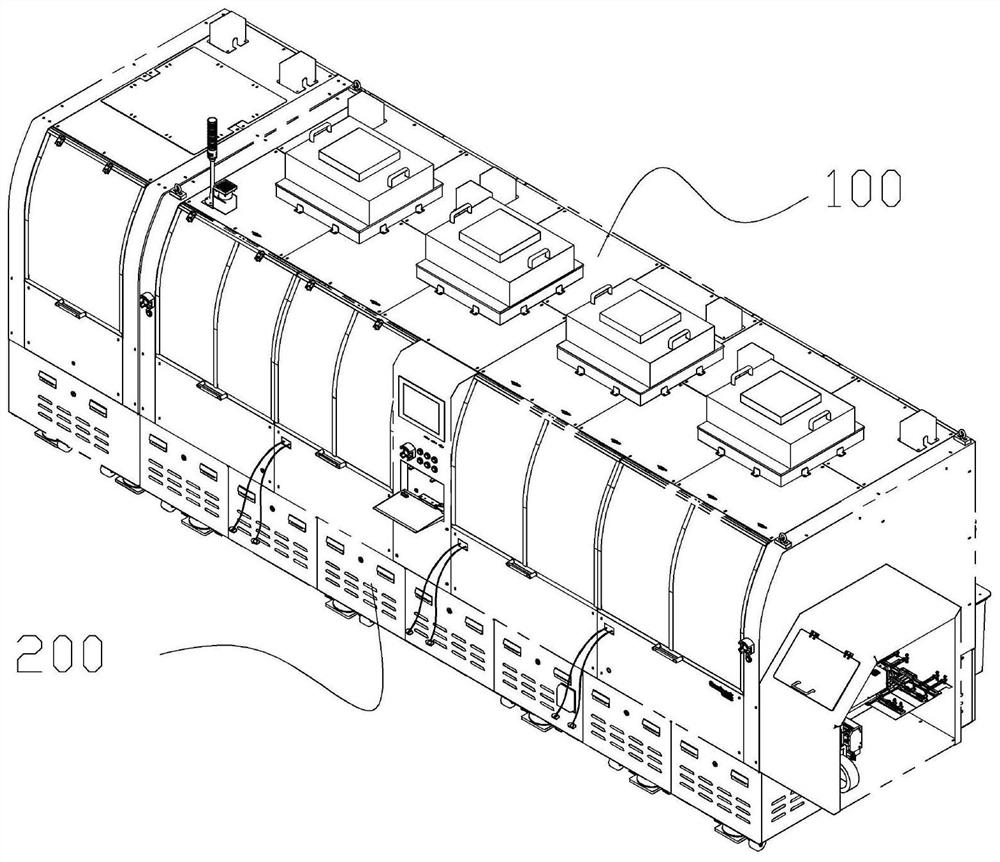

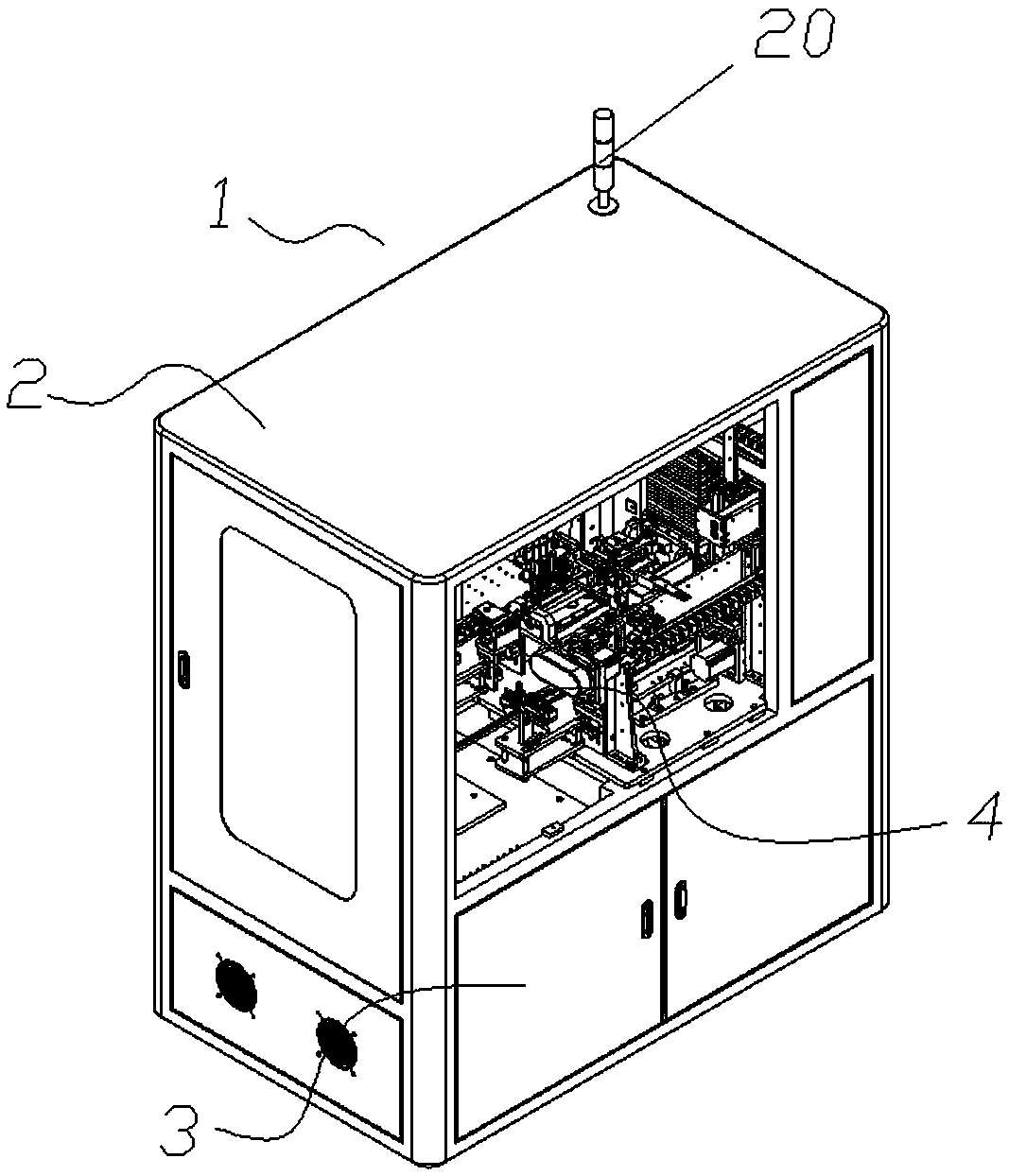

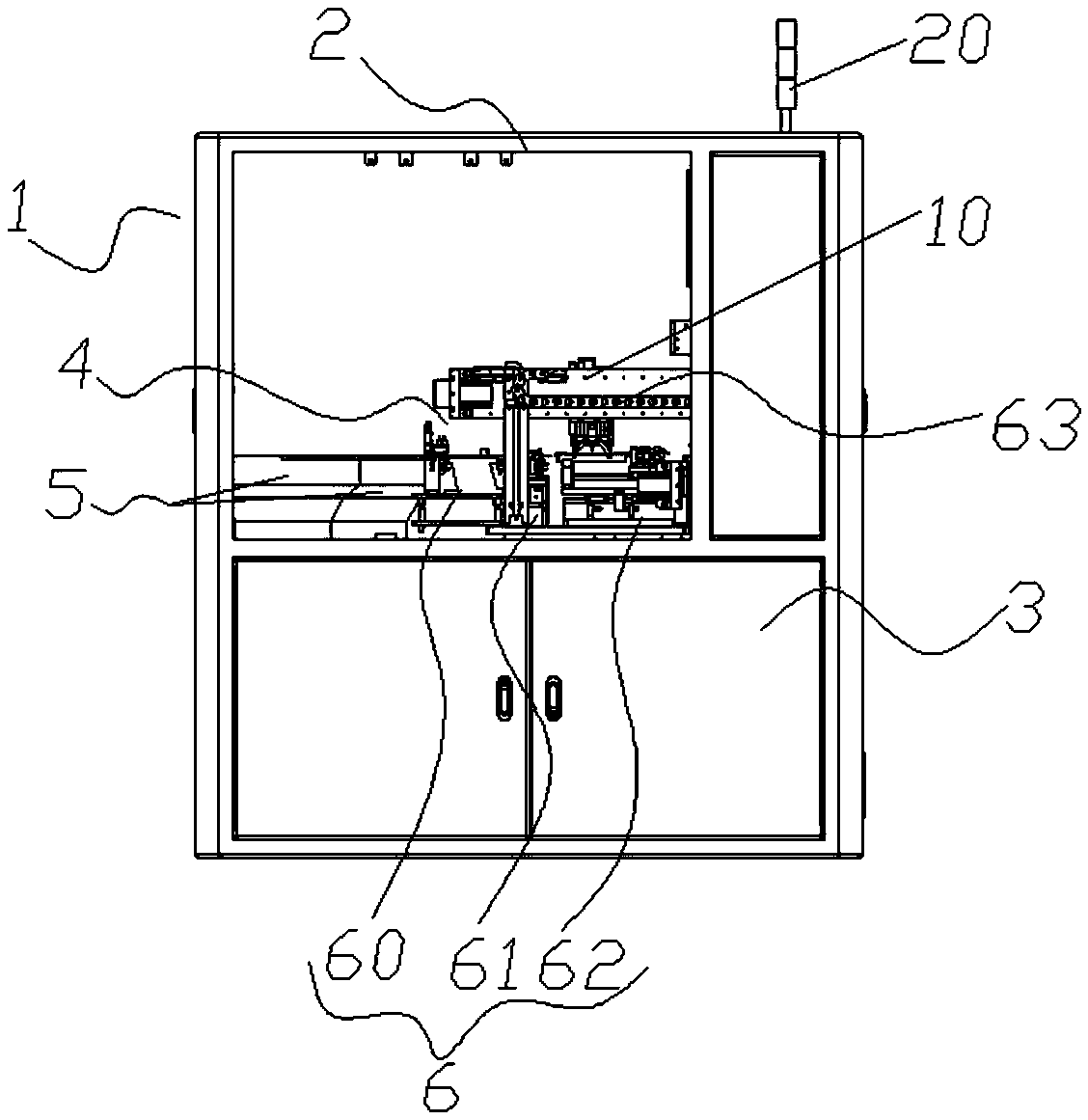

Full-automatic FOG binding equipment

PendingCN112462540ASimple structureEasy to useCharge manipulationNon-linear opticsAgricultural scienceRobot hand

The invention discloses full-automatic FOG binding equipment which comprises an upper rack and a lower rack, the upper rack and the lower rack are connected to form an equipment machine body, and thefull-automatic FOG binding equipment comprises a switching manipulator, a switching platform mechanism, an attaching platform mechanism, an attaching pressure head device, a pre-pressing platform mechanism, an FPC feeding manipulator, an FPC pre-pressing device, a main pressing platform mechanism, an FPC main pressing device and a carrying manipulator; the switching manipulator, the switching platform mechanism, the attaching platform mechanism, the attaching pressure head device and the pre-pressing platform mechanism, and the FPC feeding manipulator, the FPC pre-pressing device, the main pressing platform mechanism and the FPC main pressing device are sequentially connected in the equipment body. According to the full-automatic FOG binding equipment, through cooperative arrangement of the switching manipulator, the switching platform mechanism, the attaching platform mechanism, the attaching pressure head device, the pre-pressing platform mechanism, the FPC feeding manipulator, the FPC pre-pressing device, the main pressing platform mechanism, the FPC main pressing device and the carrying manipulator, automatic production of accurately mounting an FPC on a glass substrate is realized.

Owner:浙江鼎晶科技有限公司

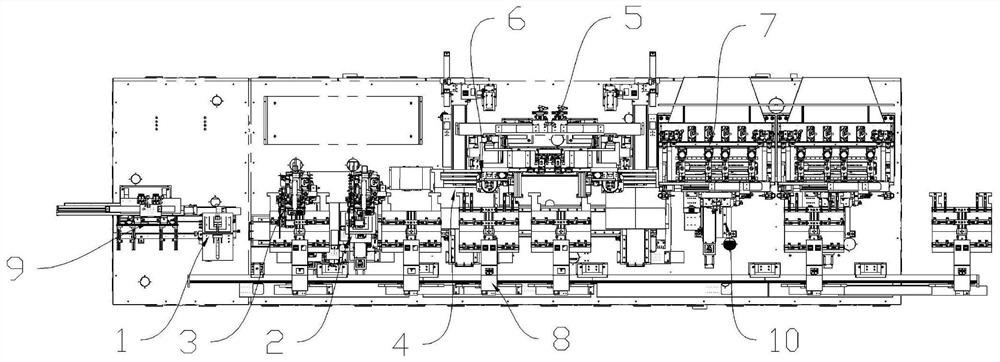

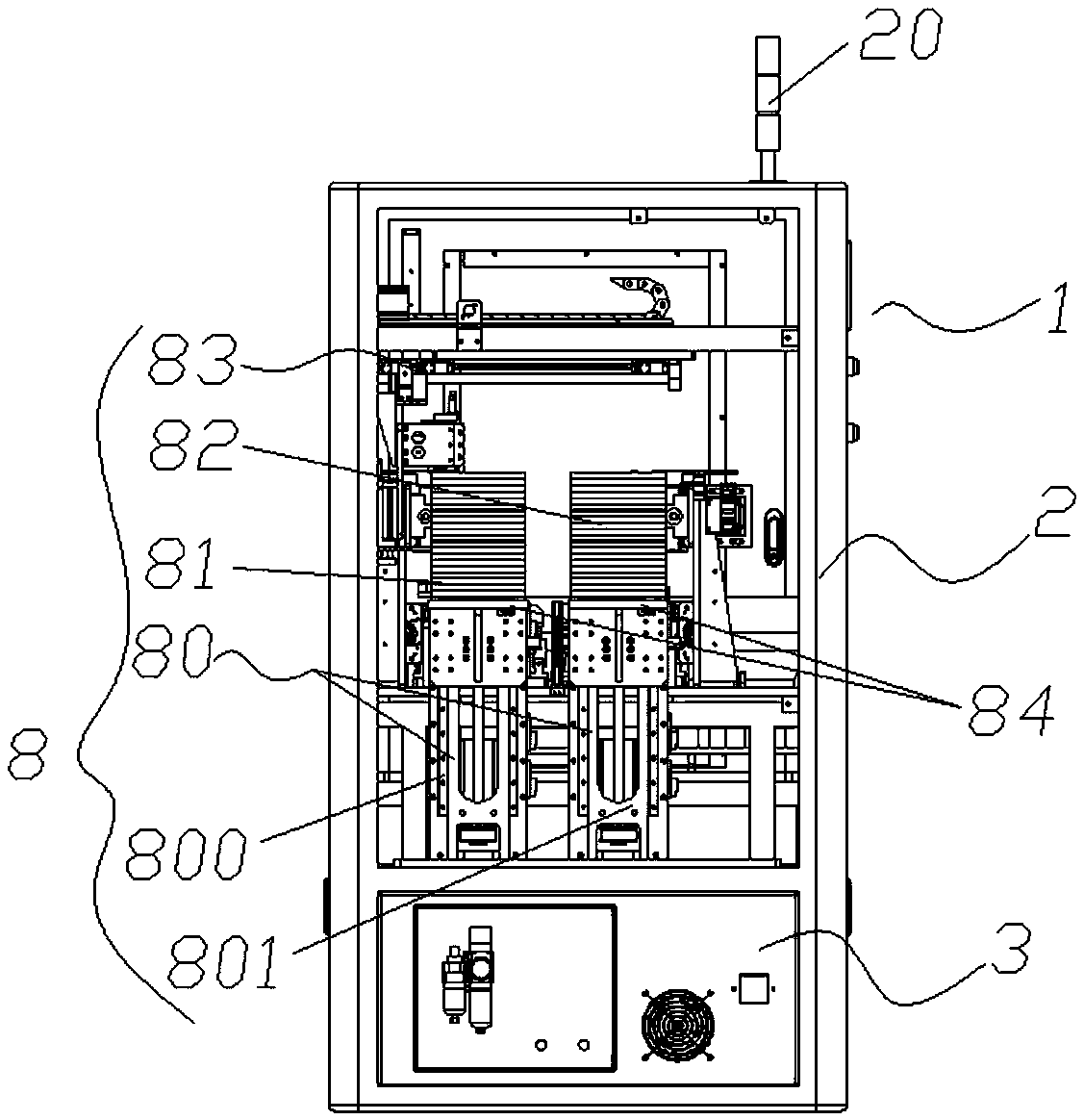

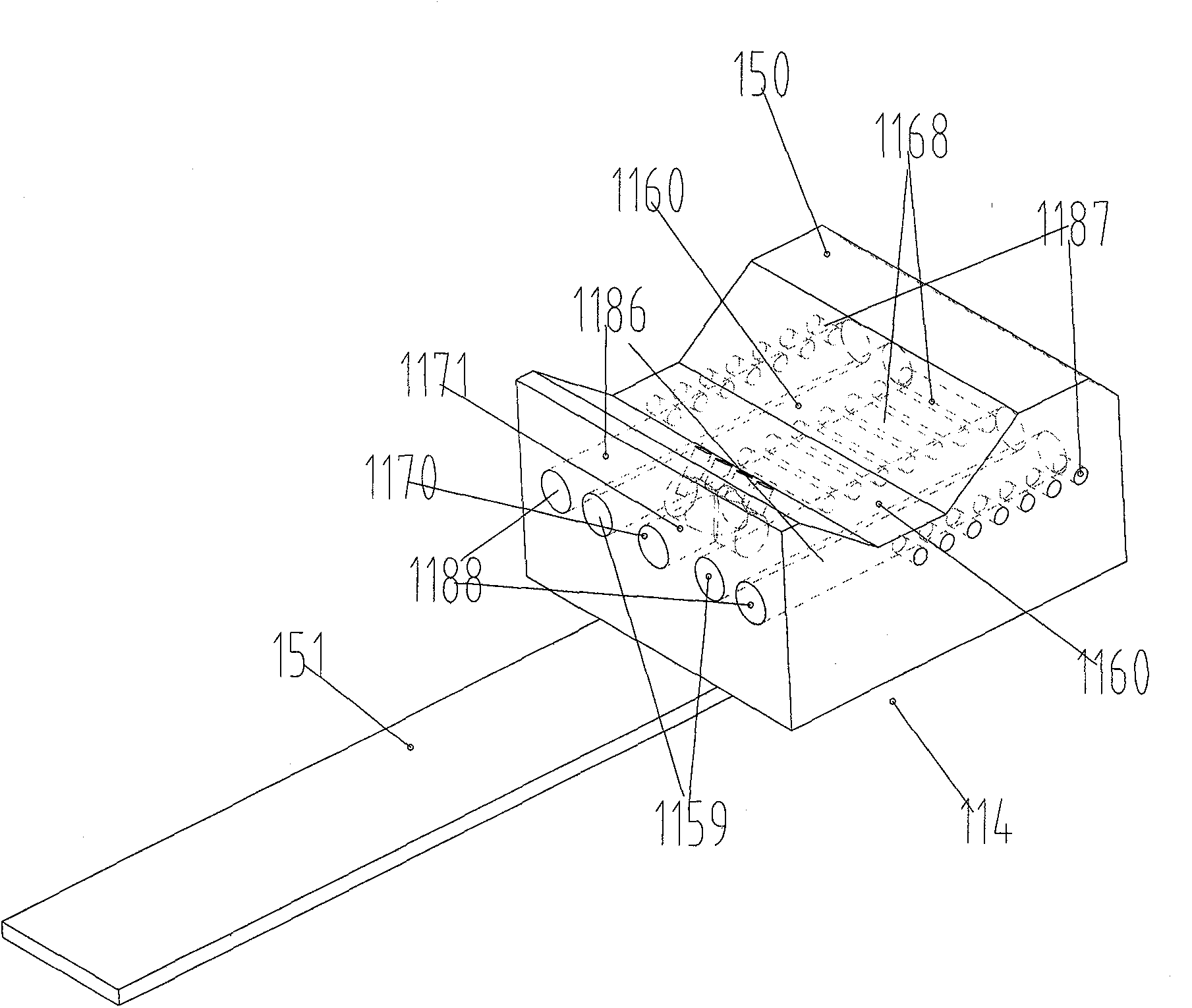

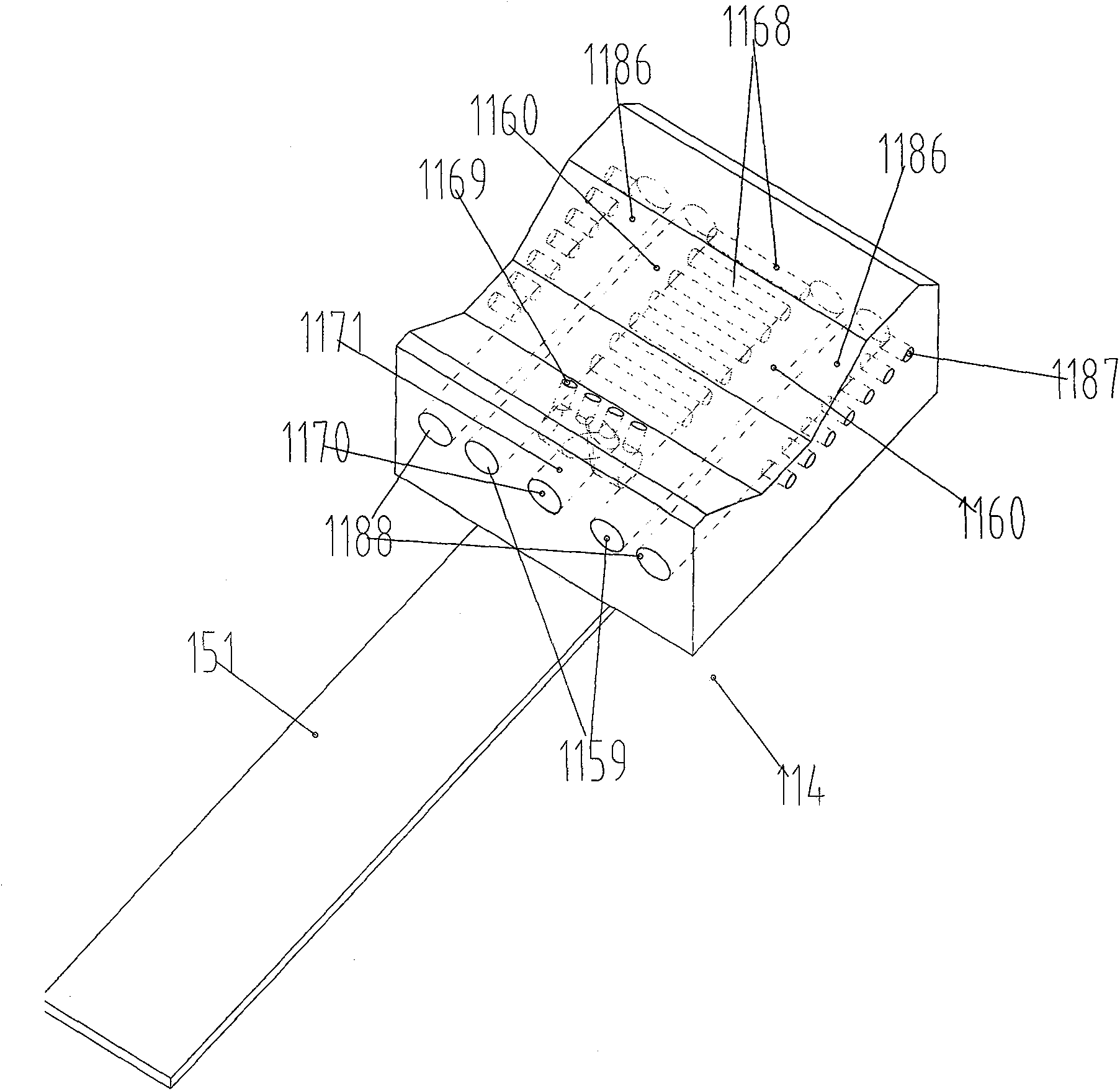

Automatic bead stringing equipment and automatic bead stringing method of stainless steel watchband parts

PendingCN109531138AImprove production and processing efficiencyImprove subsequent grinding qualityAssembly machinesAutomatic processingManipulator

The invention discloses automatic bead stringing equipment of stainless steel watchband parts. The automatic bead stringing equipment comprises a machine frame, a control cabinet and two groups of processing stations; each of the two processing stations comprises a sequencing vibration disc, a rapid positioning threading device, a placing device and a feeding and discharging device, wherein each of the sequencing vibration disc, the rapid positioning threading device, the placing device and the feeding and discharging device is provided with a detection sensor; and each rapid positioning threading device comprises a feeding mechanism, a material clamping mechanism, a silk yarn placing mechanism, a carrying mechanical arm and a fixing support, wherein the carrying mechanical arm is arrangedon the fixing support. The invention further discloses an automatic bead stringing method. According to the equipment and the method, two processing stations are arranged, the production processing efficiency is improved, full automatic processing such as automatic feeding, stringing, positioning and discharging of a processing part and a silk yarn can be realized through the sequencing vibrationdiscs, the rapid positioning threading devices, the placing devices and the feeding and discharging devices, the labor intensity and the cost are reduced, the production efficiency is improved, the stringing quality is guaranteed, and the subsequent grinding quality is improved.

Owner:盈利时表业(东莞)有限公司

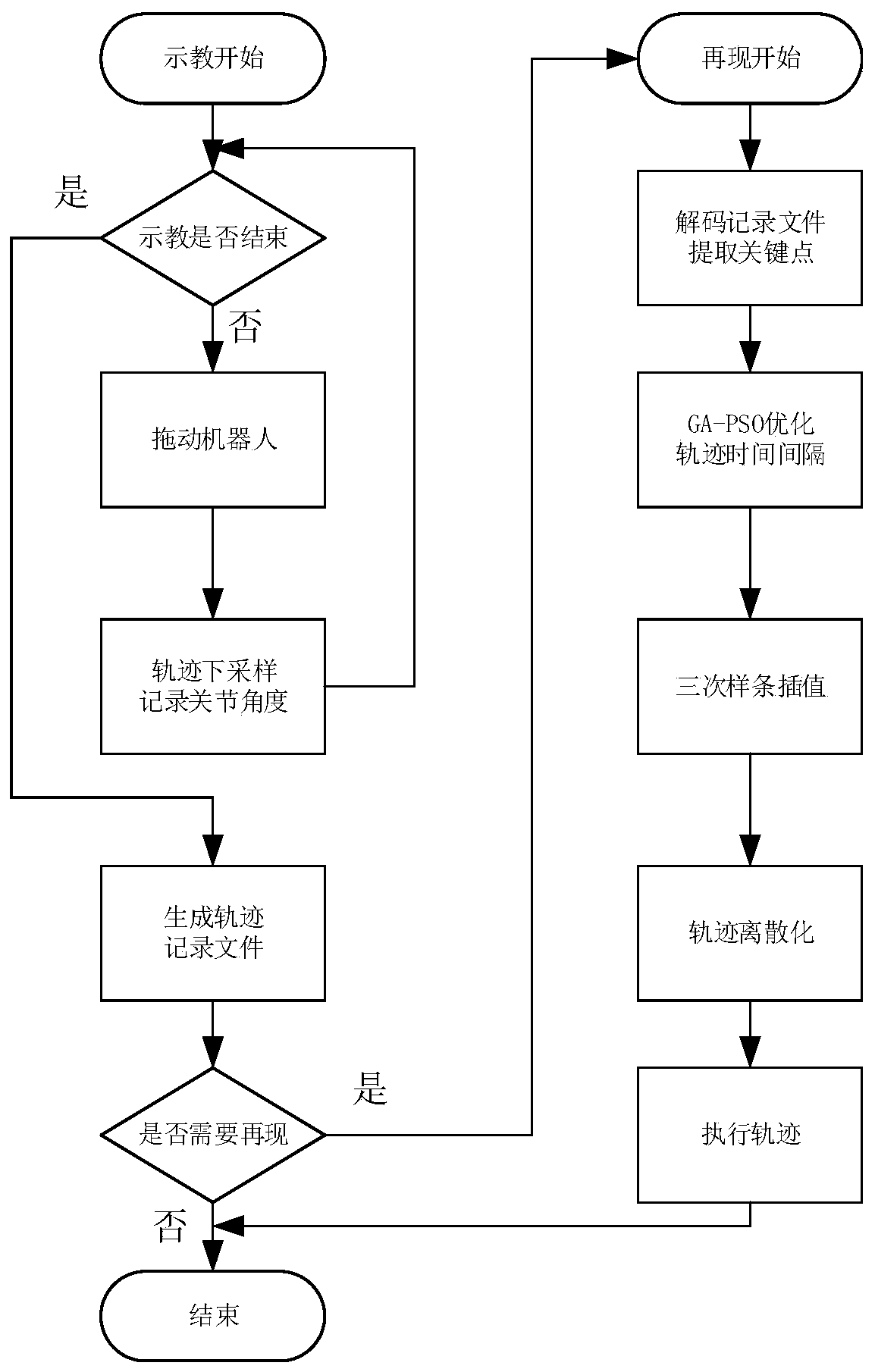

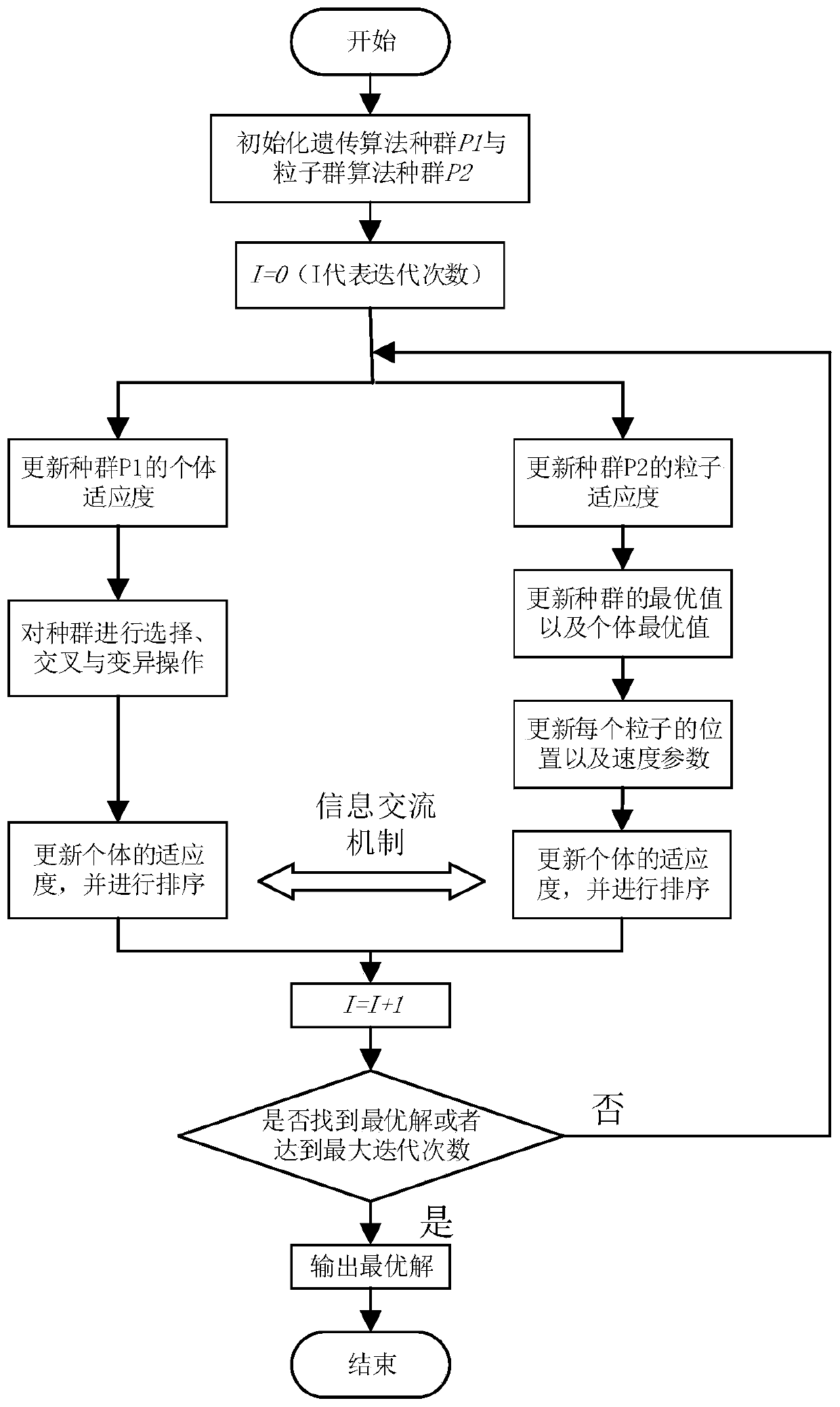

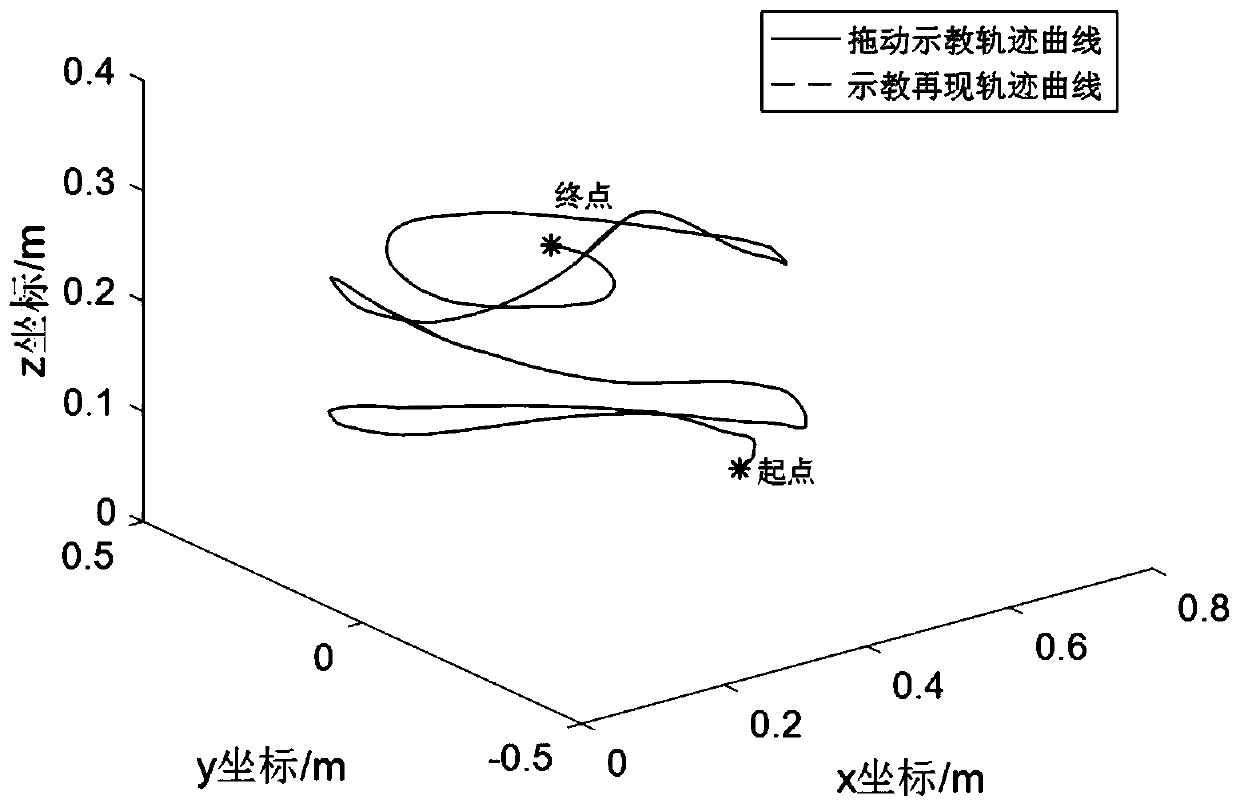

Teaching regenerated trajectory optimizing method based on GA-PSO

ActiveCN109895103AEfficient removalEliminate high frequency jitterProgramme-controlled manipulatorSimulationTrajectory optimization

The invention relates to a teaching regenerated trajectory optimizing method based on GA-PSO. The method comprises the steps that 1), when direct teaching is conducted, sampling is conducted on the trajectory of a robot according to a set sampling period, and the angular value of each joint of the robot is recorded in real time; 2), a GA-PSO algorithm is adopted as an optimization algorithm to obtain the optimal trajectory point time interval sequence; 3), spline interpolation is conducted three times according to the optimized time interval sequence and corresponding sampling trajectory pointto obtain an optimized teaching trajectory; 4), when teaching trajectory regeneration is conducted, the optimized teaching trajectory is discretized according to the controlling period to be transmitted to the robot controller, and the whole teaching trajectory is completely regenerated. Compared with the prior art, the method has the advantages of redundant trajectory information removing, stable operation, halt and abrupt acceleration nonexistence and the like.

Owner:TONGJI UNIV

Low-noise lubricating grease and preparation method and application thereof

ActiveCN103627476AReasonable formulaImprove work efficiencyLubricant compositionLow noiseBenzoic acid

The invention discloses low-noise lubricating grease and a preparation method and application thereof. The invention adopts the technical scheme as follows: the low-noise lubricating grease is prepared from the raw materials in parts by weight: 65-85 parts of base oil, 10-15 parts of C12-C22 hydroxy fatty acid, 2-8 parts of lithium hydroxide (LiOH.H2O), 1-5 parts of boric acid, m parts of dimethyl terephthalate (m is greater than or equal to 0, but smaller than or equal to 1), n parts of benzoic acid (n is greater than or equal to 0, but smaller than or equal to 2), 1-3 parts of antioxidant and 1-3 parts of sulfosalicylic acid. The invention further discloses the preparation method of the low-noise lubricating grease and application of the low-noise lubricating grease to high-precision miniature mechanical bearings. The low-noise lubricating grease is reasonable in formulation, and relatively high in production efficiency; after the low-noise lubricating grease is ground by a grinder, which is a patented product of the Company, the particle sizes of mechanical impurities in the low-noise lubricating grease are controlled to be smaller than those of mechanical impurities in the exhibiting lubricating grease, and the vibrating decibel value of a bearing lubricated by the low-noise lubricating grease is lower than that of a bearing lubricated by the exhibiting lubricating grease, thus ensuring the running accuracy of the miniature bearing and reducing vibration and abrasion; the vibrating decibel value of the bearing is lower than 40 decibels; and the particle sizes of the mechanical impurities in the low-noise lubricating grease are smaller than 2 microns.

Owner:XINXIANG HENGXING TECH CO LTD

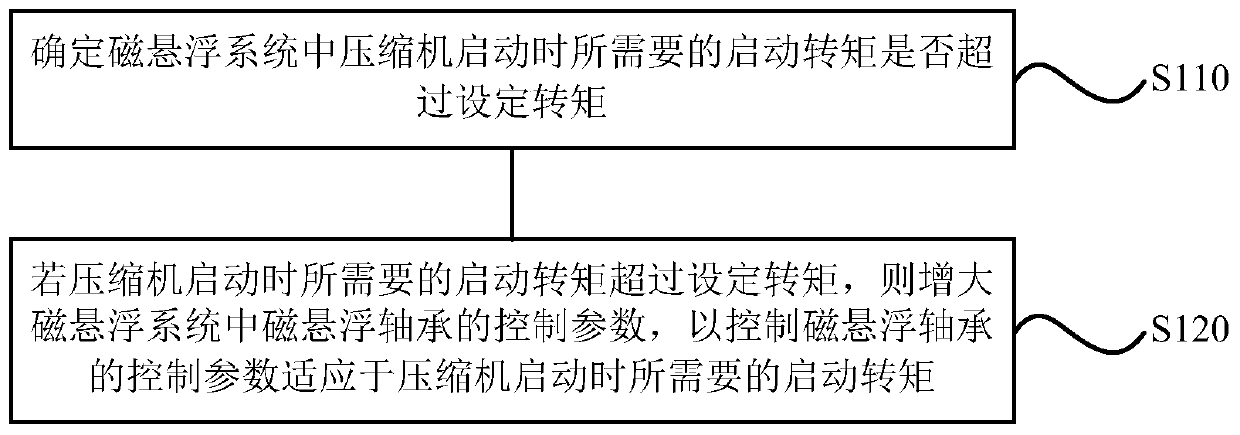

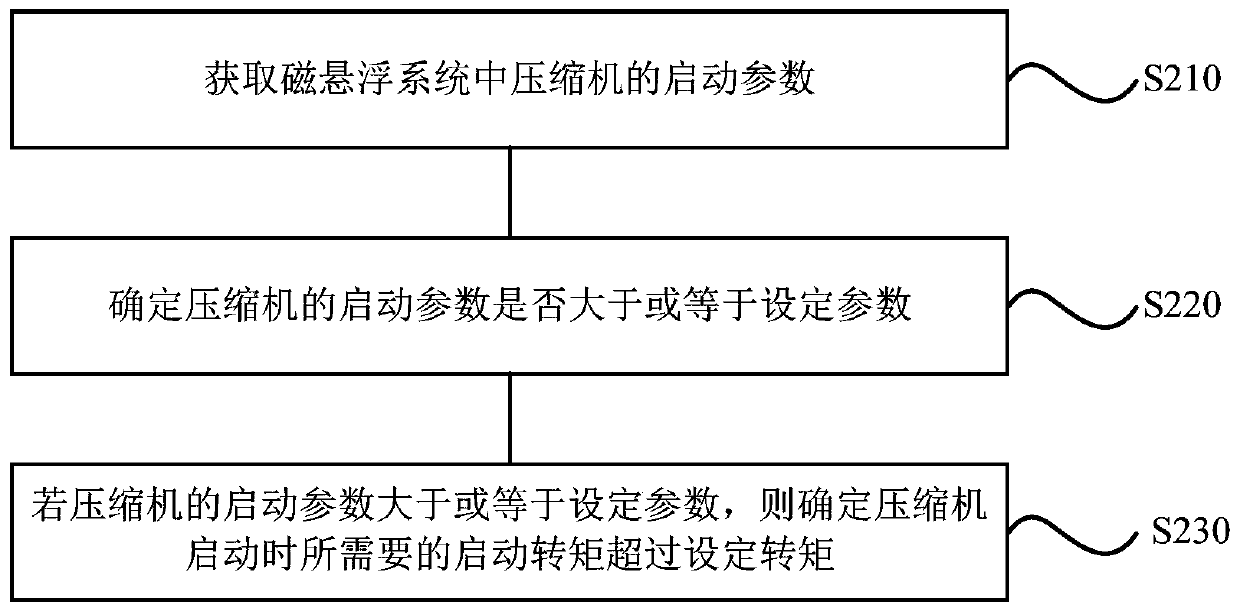

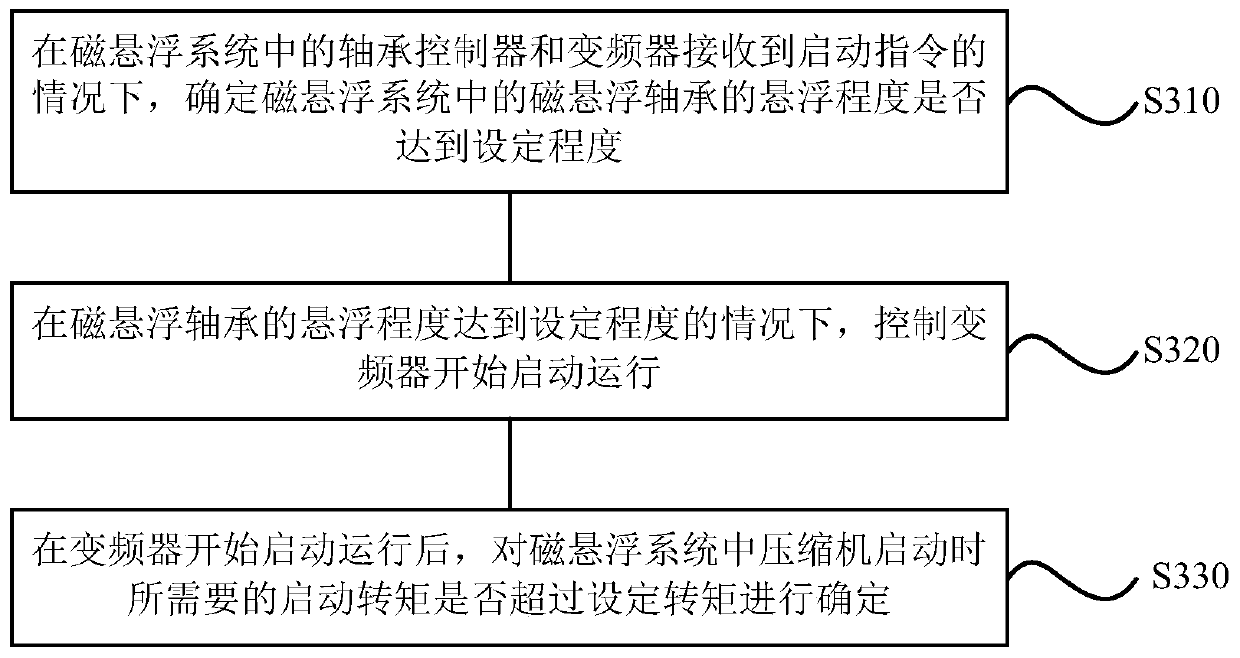

Magnetic levitation bearing control method and device, storage medium, and magnetic levitation system

ActiveCN110939654AGuaranteed control accuracyReliable startRotary/oscillating piston combinations for elastic fluidsShaftsEngineeringMechanical engineering

The invention discloses a magnetic levitation bearing control method and device, a storage medium, and a magnetic levitation system. The method comprises the following steps of determining whether thestarting torque required when a compressor in the magnetic levitation system is started exceeds preset torque or not; and if the starting torque required when the compressor is started exceeds the preset torque, increasing control parameters of the magnetic levitation system to control the control parameters of a magnetic levitation bearing to be adapted to the starting torque required when the compressor is started. According to the scheme disclosed by the invention, the problem that the starting torque is variable to affect the starting reliability can be solved so as to achieve the effectof improving the starting reliability.

Owner:GREE ELECTRIC APPLIANCES INC

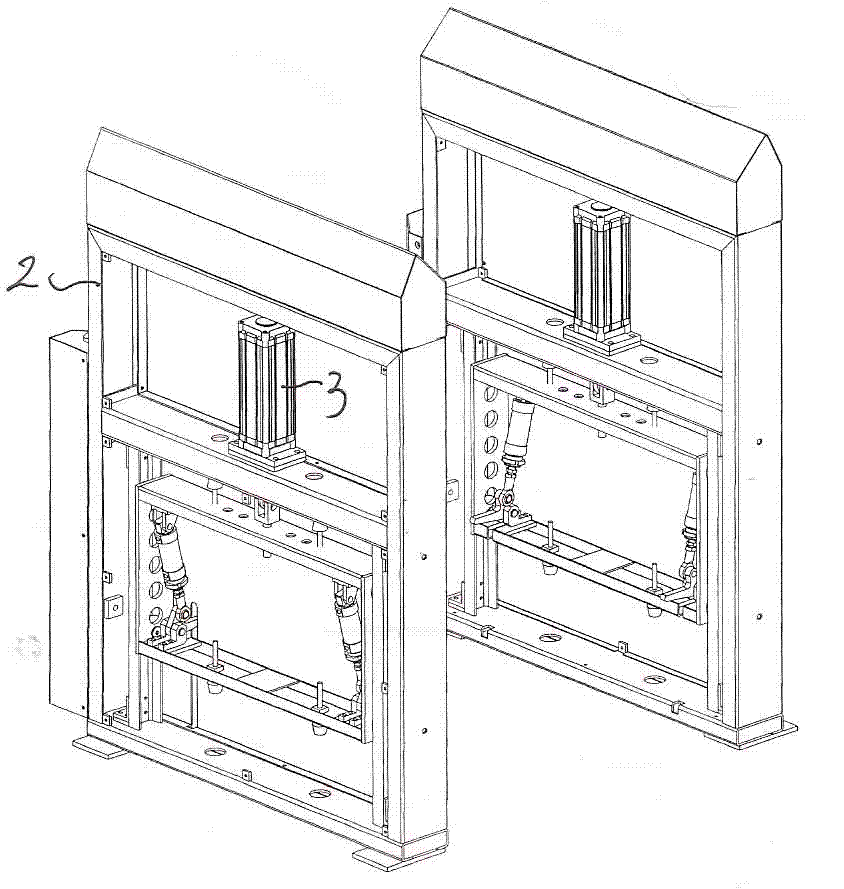

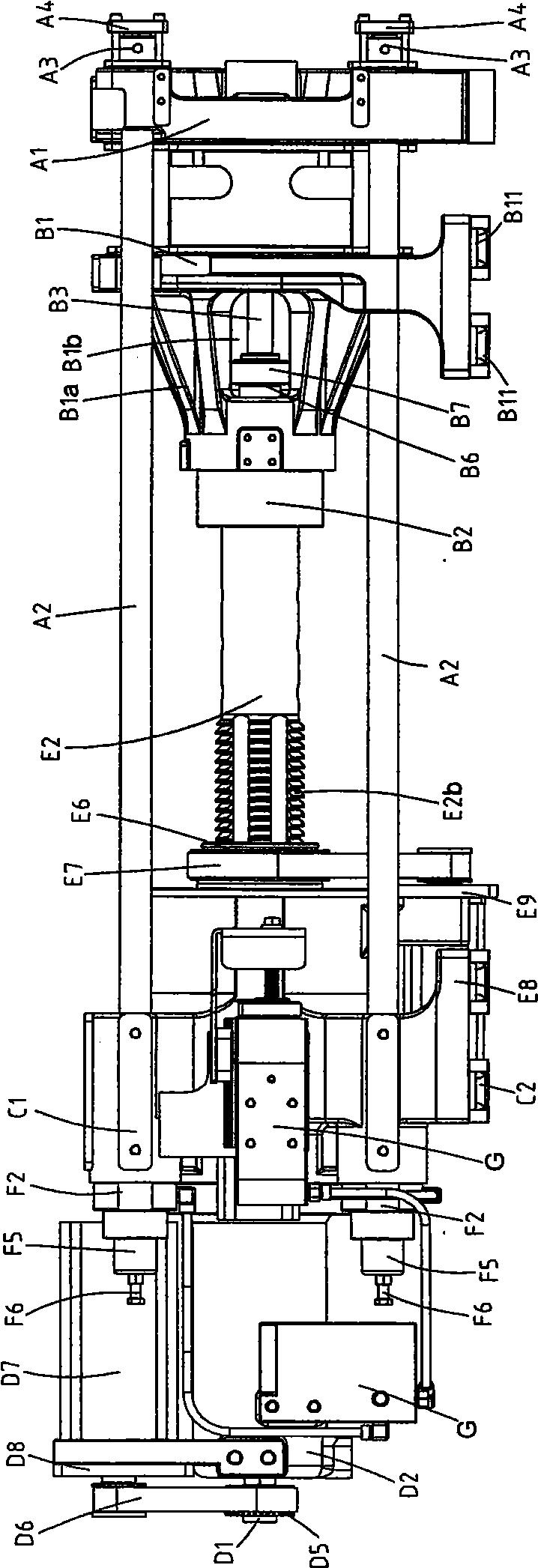

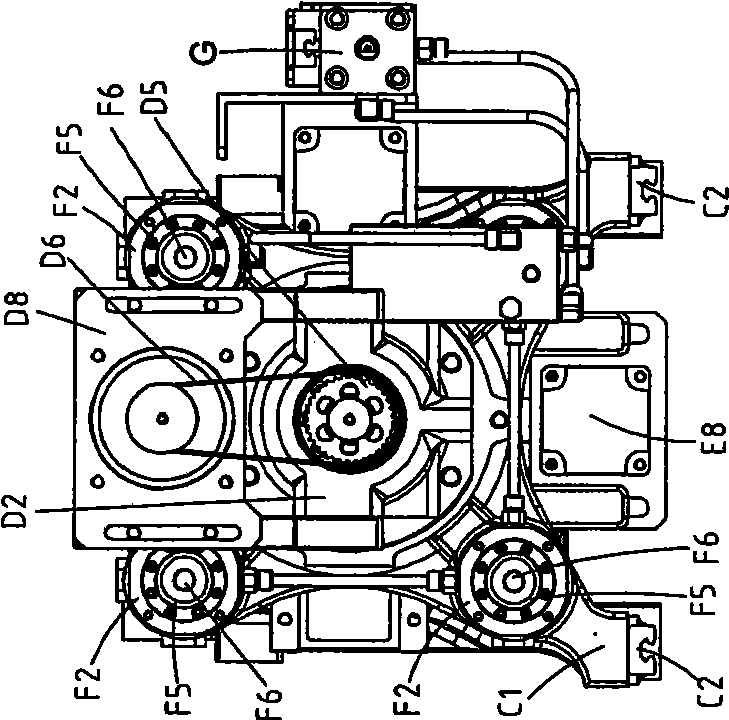

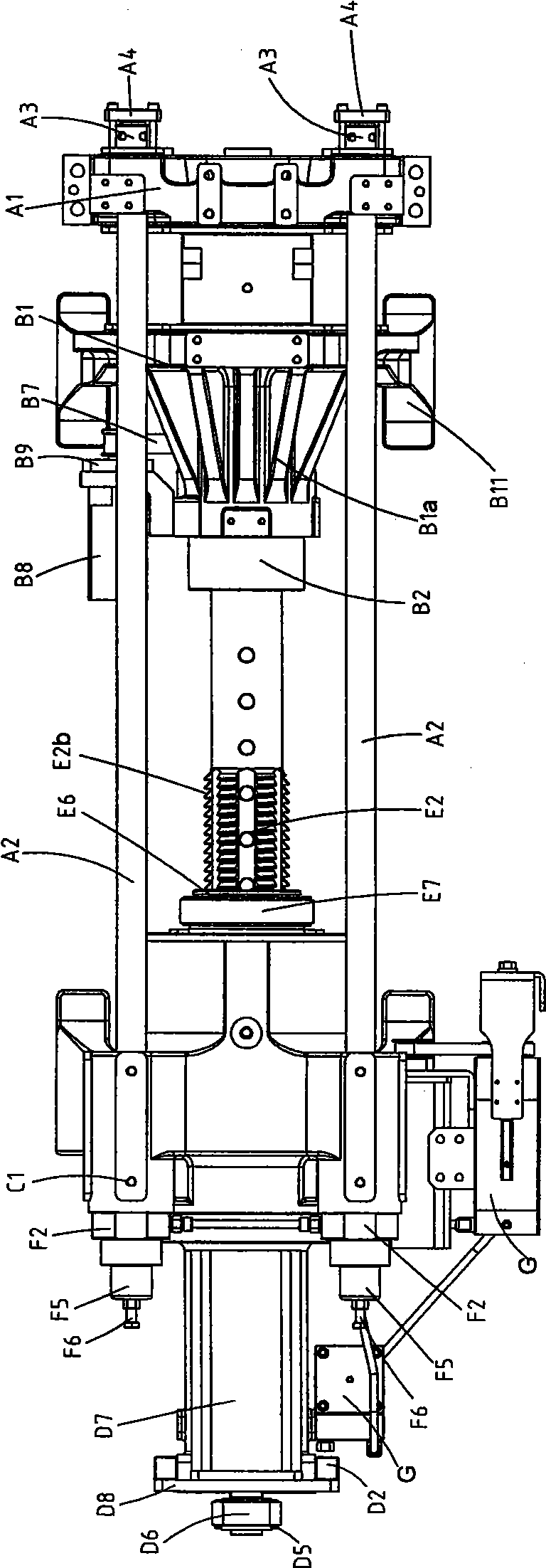

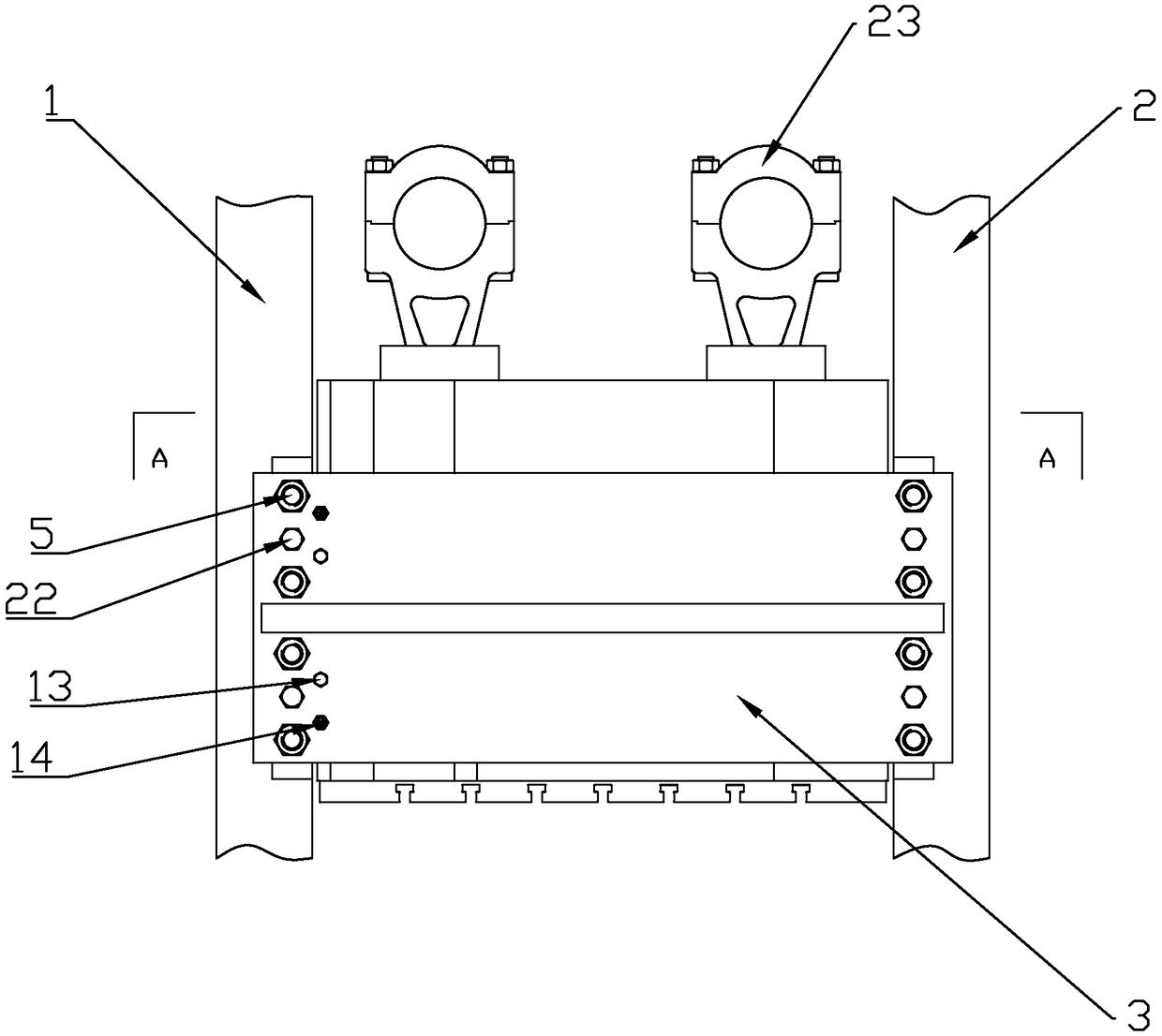

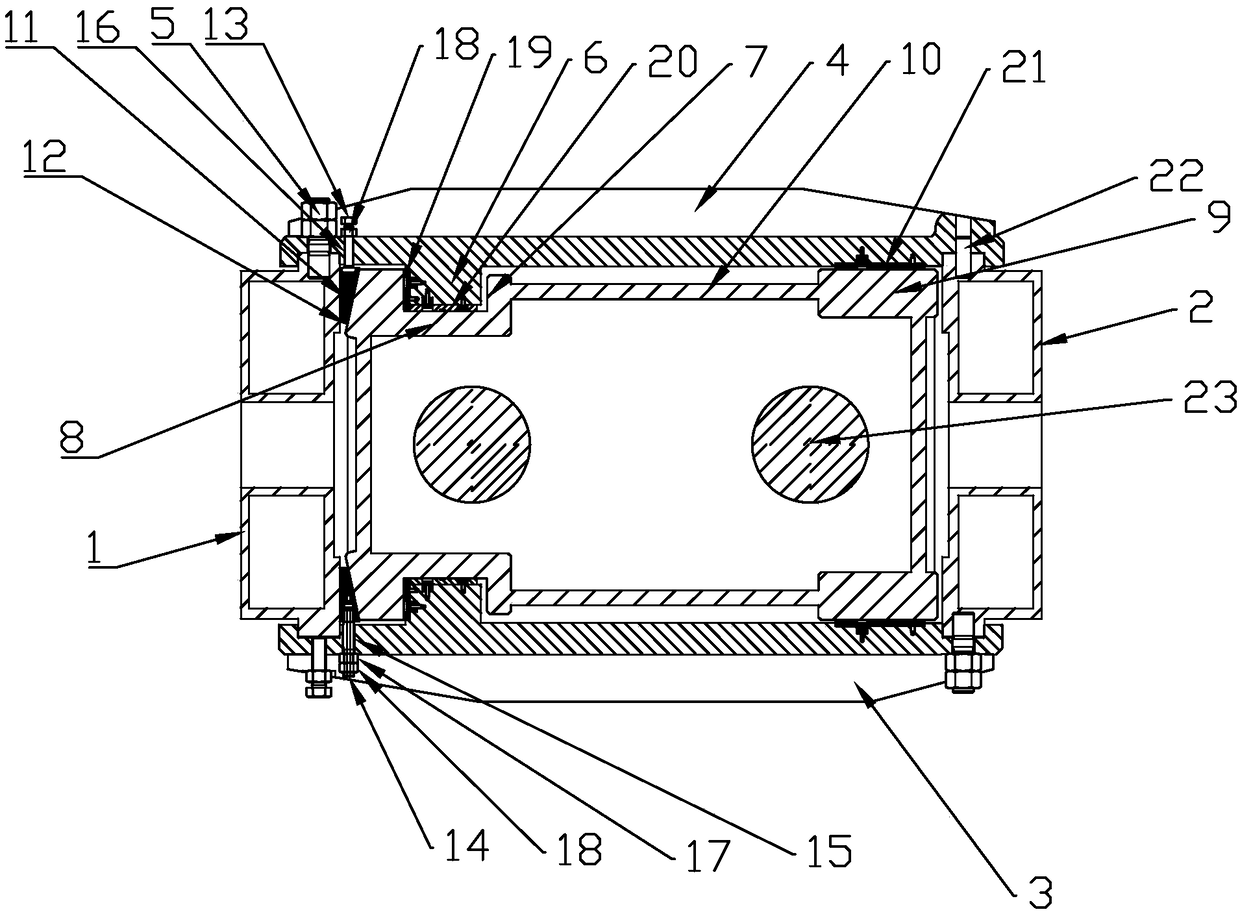

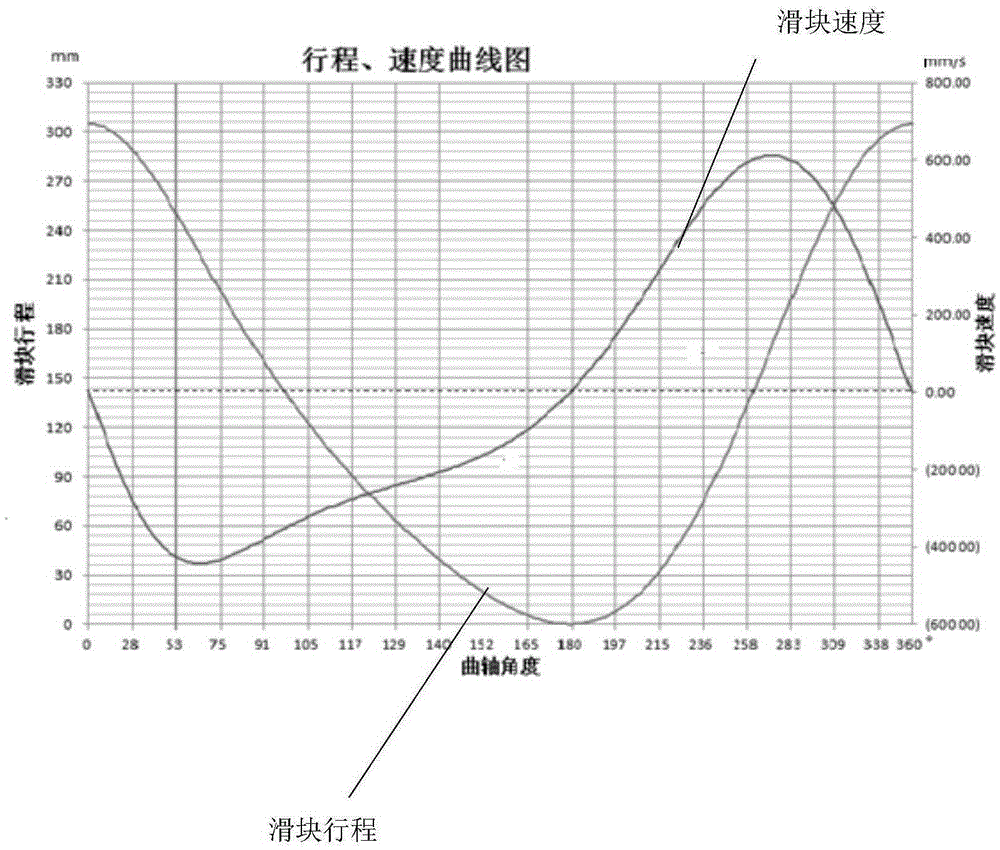

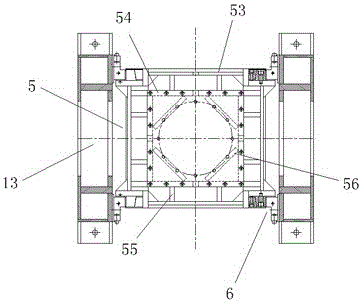

Sliding block guide and precision adjustment structure applied to hot blanking press machine

PendingCN108906968ARestricted degrees of freedomGuaranteed running accuracyShaping toolsPressesEngineeringDegrees of freedom

The invention provides a sliding block guide and precision adjustment structure applied to a hot blanking press machine. The sliding block guide and precision adjustment structure comprises a left stand column, a right stand column, a front guide plate and a rear guide plate, wherein the left stand column and the right stand column are located at the left and right ends of a sliding block correspondingly, and front guide plate and the rear guide plate are located on the front and rear sides of the sliding block correspondingly. The front guide plate and the rear guide plate are connected withthe left stand column and the right stand column through guide plate adjusting bolts, two protruding blocks are symmetrically and vertically arranged at the left ends of the inner side walls of the front guide plate and the rear guide plate, and grooves corresponding to the protruding blocks are formed in the sliding block. The sliding block is slidably connected with the left stand column and thegrooves are slidably connected with the left side surfaces and the bottom surfaces of the protruding blocks, and the sliding block and the right stand column are arranged at intervals. By adopting the sliding block guide and precision adjustment structure, the sliding block guide and precision adjustment structure applied to the hot blanking press machine is reasonable in design, the degree of freedom of the sliding block in the nonmoving direction is limited, the running accuracy of the sliding block is guaranteed; the sliding block guide and precision adjustment structure applied to the hotblanking press machine can effectively prevent the sliding block from jamming in a guide rail gap after heating expansion, prolong the service life of mould and meet the market requirements.

Owner:SHANDONG JINCHEN MACHINERY CORP LTD LTD

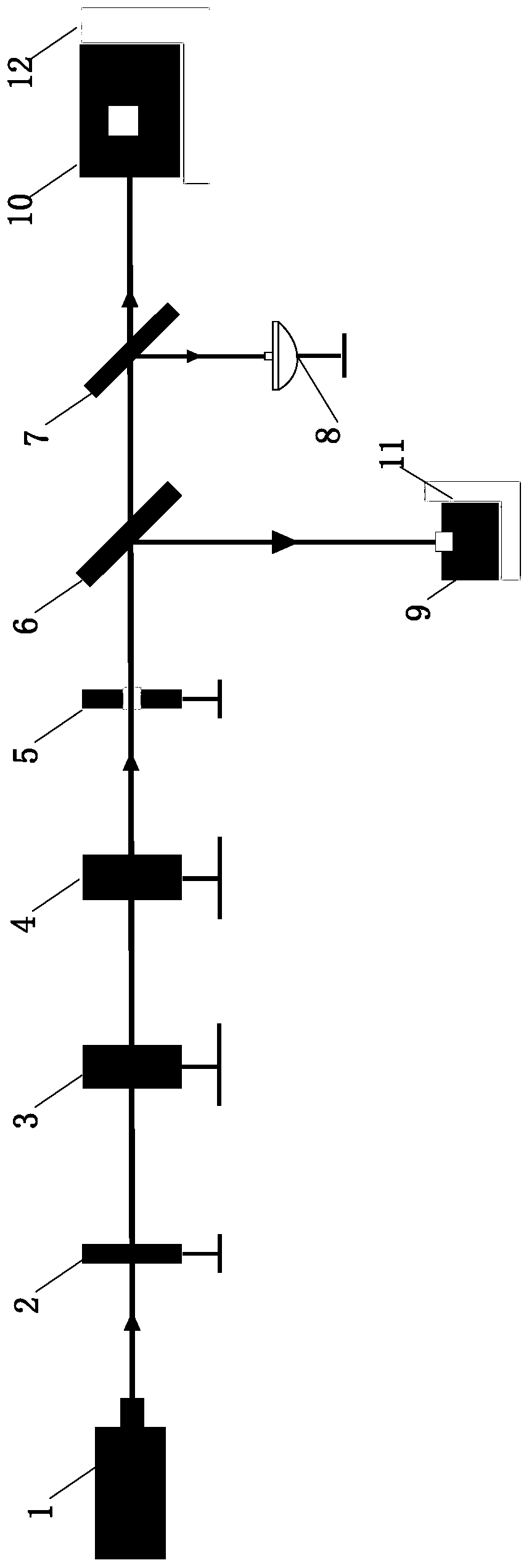

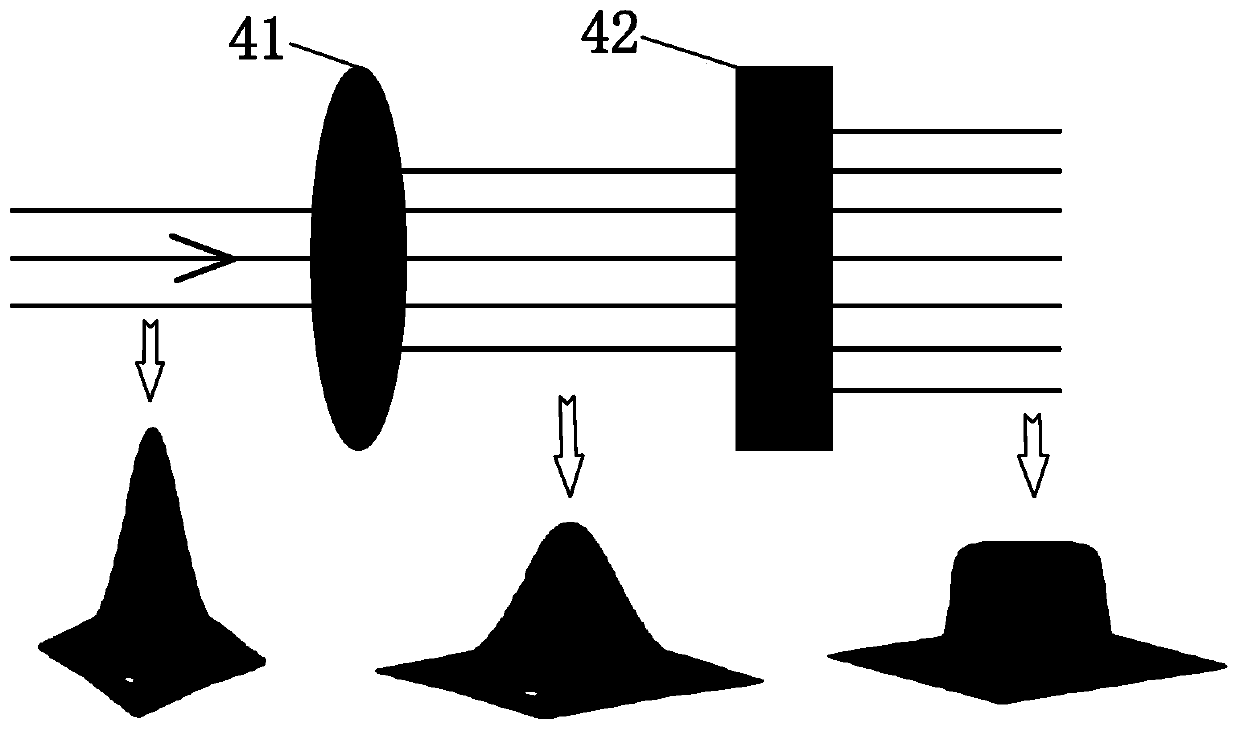

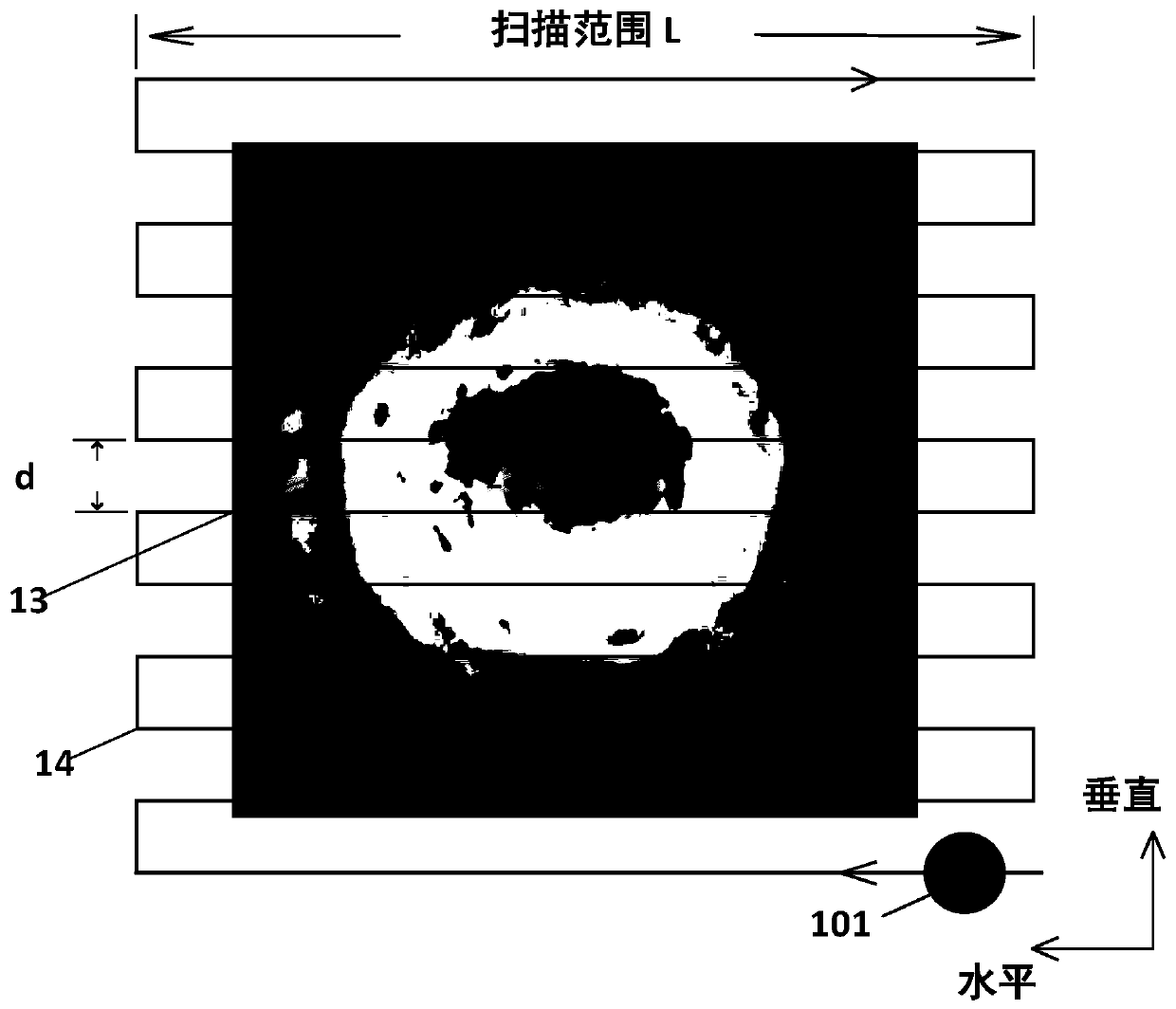

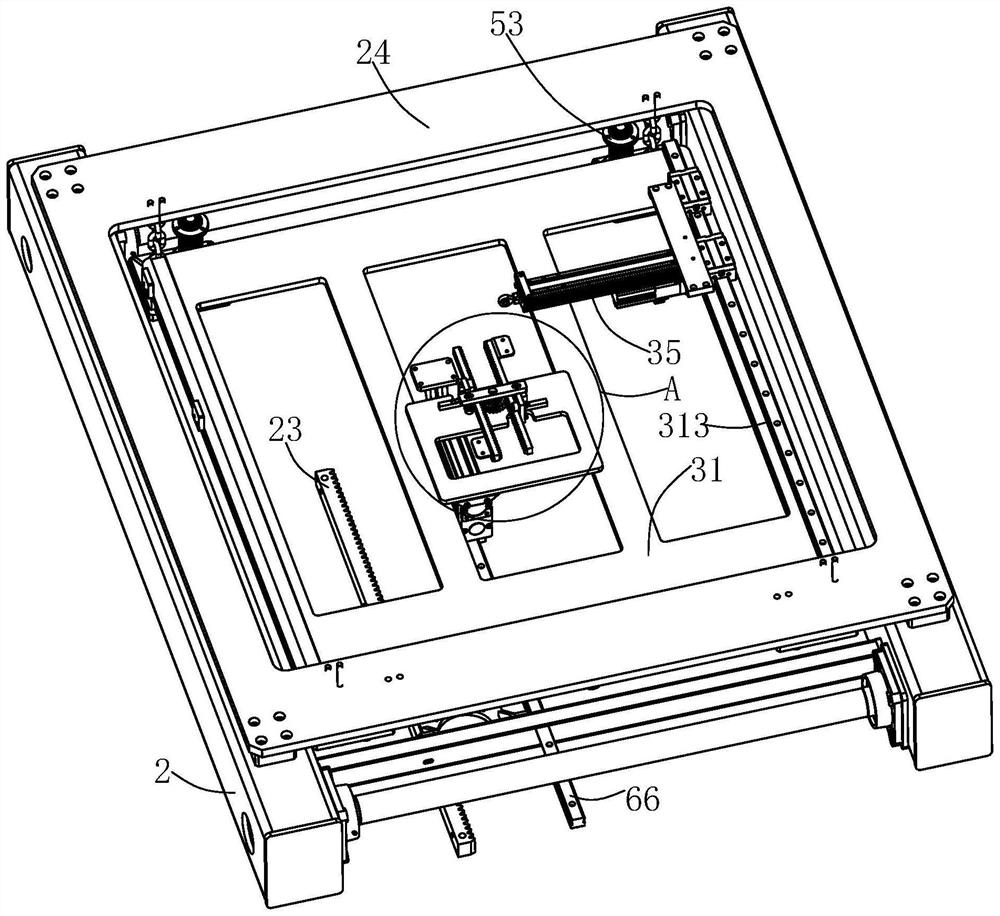

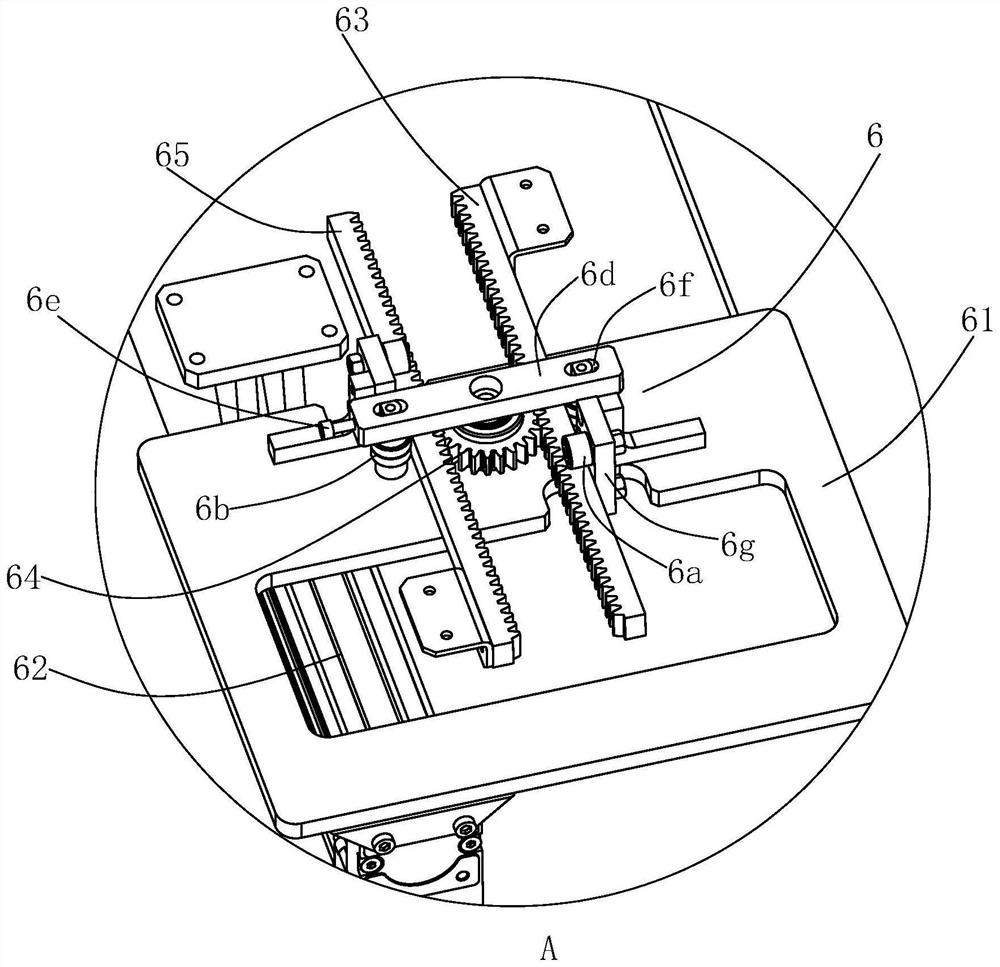

Detector array target calibration system and method

ActiveCN110296756AGuaranteed straightnessGuaranteed running accuracyPhotometryDetector arrayOptical path

The invention relates to a detector array target calibration system and method. The system comprises a light spot acquisition device, a first spectroscope, a second spectroscope, a power meter, a calibration detector module, and a to-be-calibrated detector array target, wherein the calibration detector module and the to-be-calibrated detector array target are in the same distance to the first spectroscope; light spots output by the light spot acquisition device are transmitted to the calibration detector module and the detector array target respectively after passing through the first spectroscope, the second spectroscope arranged on an optical path is used for emitting a beam of light to the power meter; and a first two-dimensional scanning platform and a second two-dimensional scanning platform enable the corresponding calibration detector module and the detector array target to perform full-coverage scanning of a set path on a plane directly facing the light spots. According to thesystem in the invention, the calibration detector module is matched with the power meter so as to obtain the real power density of a calibration light source output by the light spot acquisition device, and the two-dimensional scanning platforms are arranged, so that the straightness and running precision during full-coverage scanning of the calibration detector module and the detector array target on the set path are ensured.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

RGV body

PendingCN114162539AAccurate Floating GrabQuick resetCharging stationsVehicular energy storageVehicle frameIn vehicle

The invention relates to an RGV body, and belongs to the technical field of tracking conveying vehicles. The RGV body runs on the foundation track and comprises a vehicle frame and a multi-stage platform installed in the vehicle frame in a floating mode. The floating installation mode is achieved through a flexible chain connected between the vehicle frame and the multi-stage platform. The multi-stage platform is suspended by a flexible chain, so that floating fit between the multi-stage platform and the vehicle frame is realized; the vehicle body further comprises an aligning mechanism, and the aligning mechanism is located between the multi-stage platform and the vehicle frame to achieve aligning or resetting of the multi-stage platform relative to the vehicle frame. After the multi-stage platform grabs and unlocks a vehicle chassis and a battery locking mechanism on the chassis in a matched mode, the flexible chain enables the multi-stage platform to swing laterally through lateral swing to adapt to matching of the positioning cone and the conical groove, and accurate floating grabbing of a vehicle-mounted battery is facilitated. After the vehicle-mounted battery is grabbed, an aligning mechanism is installed between the multi-stage platform and the upper connecting frame, and the multi-stage platform is assisted in rapidly and accurately aligning or resetting.

Owner:泽清新能源科技有限公司

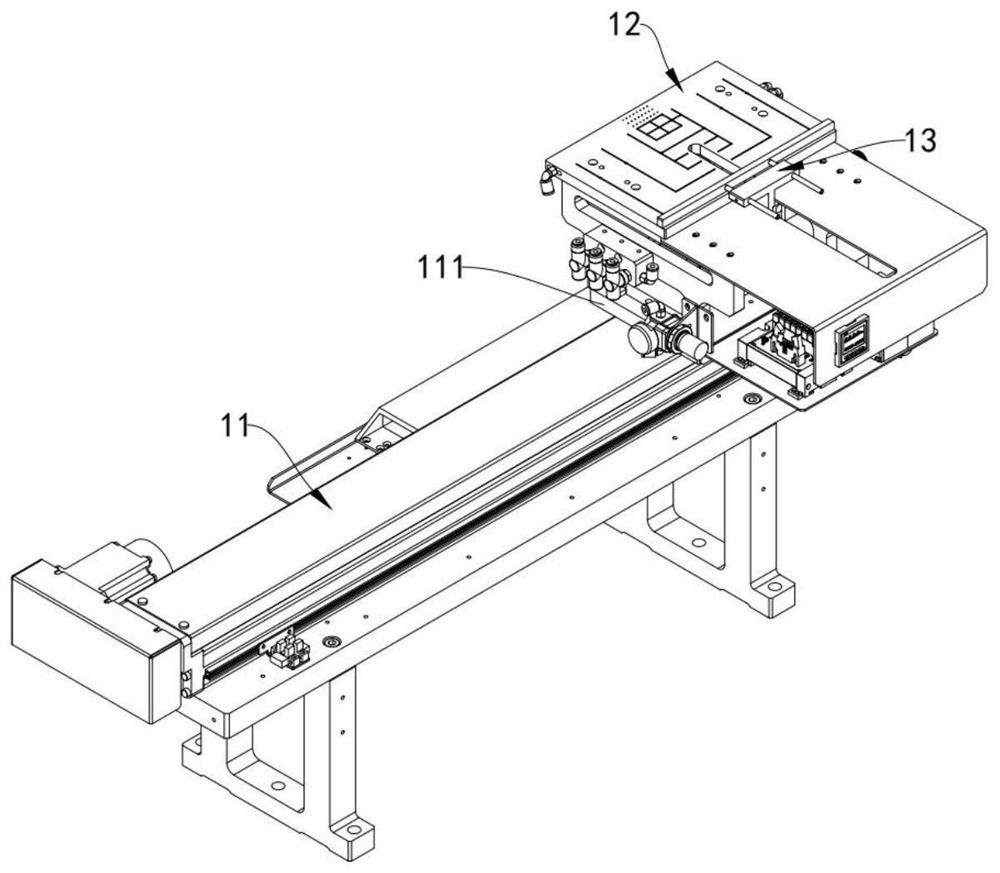

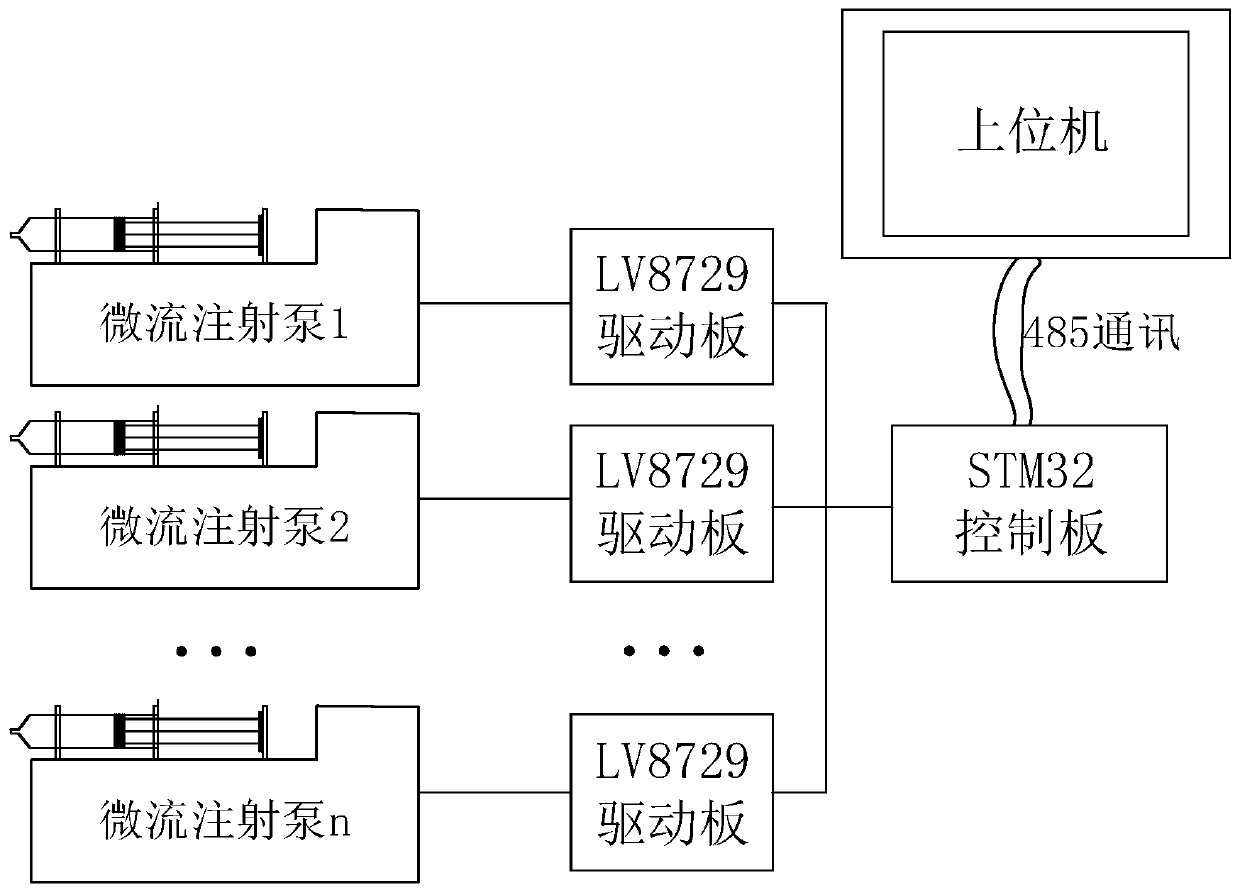

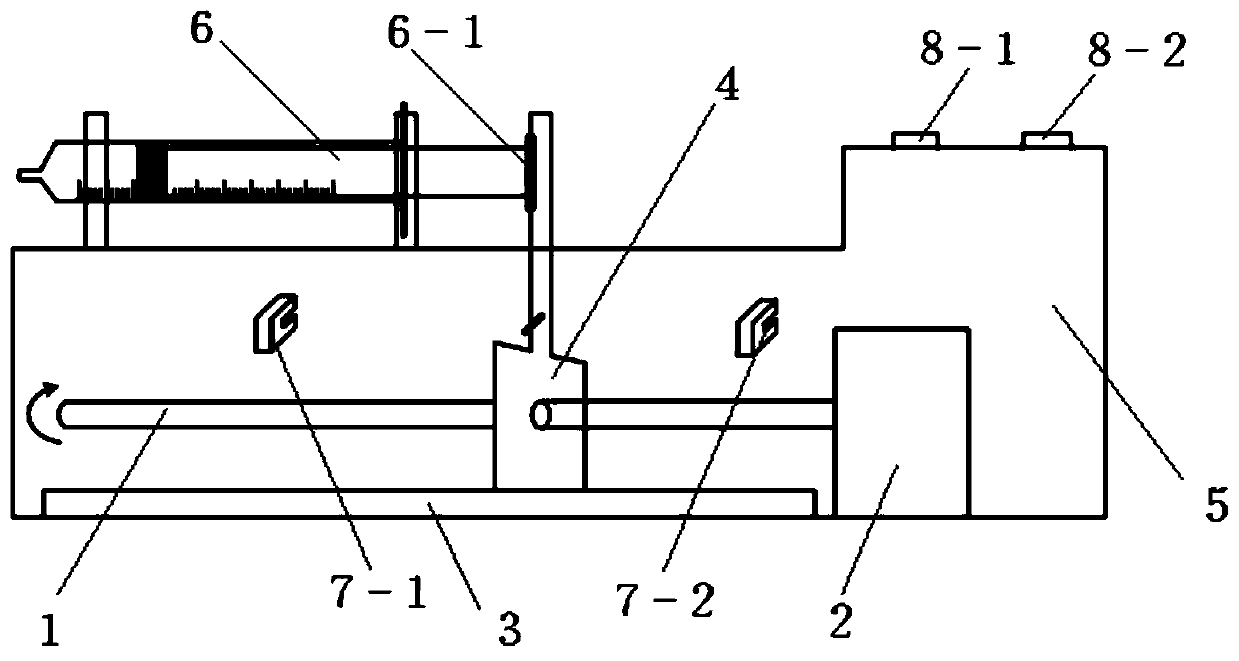

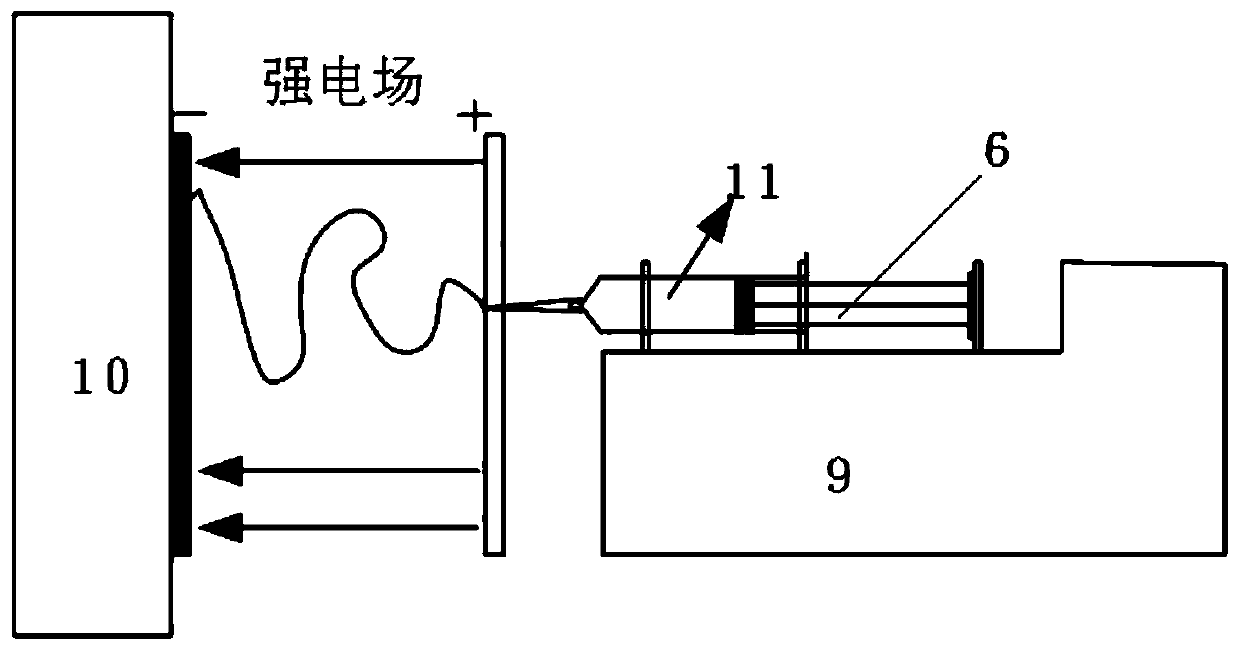

Micro-flow injection pump system for electrostatic spinning

PendingCN110578664AHigh precisionWide range of injection speedsPositive displacement pump componentsPump controlElectrospinningMultiple injection

The invention discloses a micro-flow injection pump system for electrostatic spinning. The injection pump system comprises an injection pump, drive plates, a control panel and an upper computer, wherein the upper computer communicates with the control board mutually; the control board is separately connected to multiple micro-flow injection pumps through multiple drive plates; the core of the injection pump is a step motor which rotates to drive a slide table to move left and right; an injector is fixedly arranged on the slide table; the drive plate supports high-subdivision drive operation ofthe step motor; the control board receives the instruction of the upper computer through a 485 serial port, and controls the injection pump to act; the upper computer is a high-definition display screen which displays solution injection amount and solution injection progress in real time in addition to setting system operation parameter; and the micro-flow pump system supports one upper computerto simultaneously control multiple injection pumps. The micro-flow injection pump system is high in operation precision, is convenient in operation, and achieves injection speed range of 0.1 mL / h to 50 mL / h.

Owner:镇江博慧自动化技术研究院有限公司

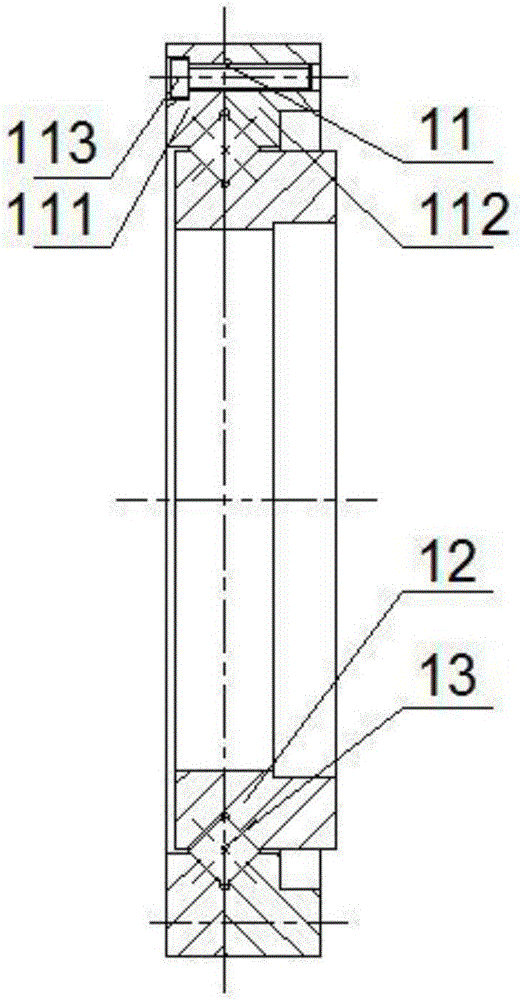

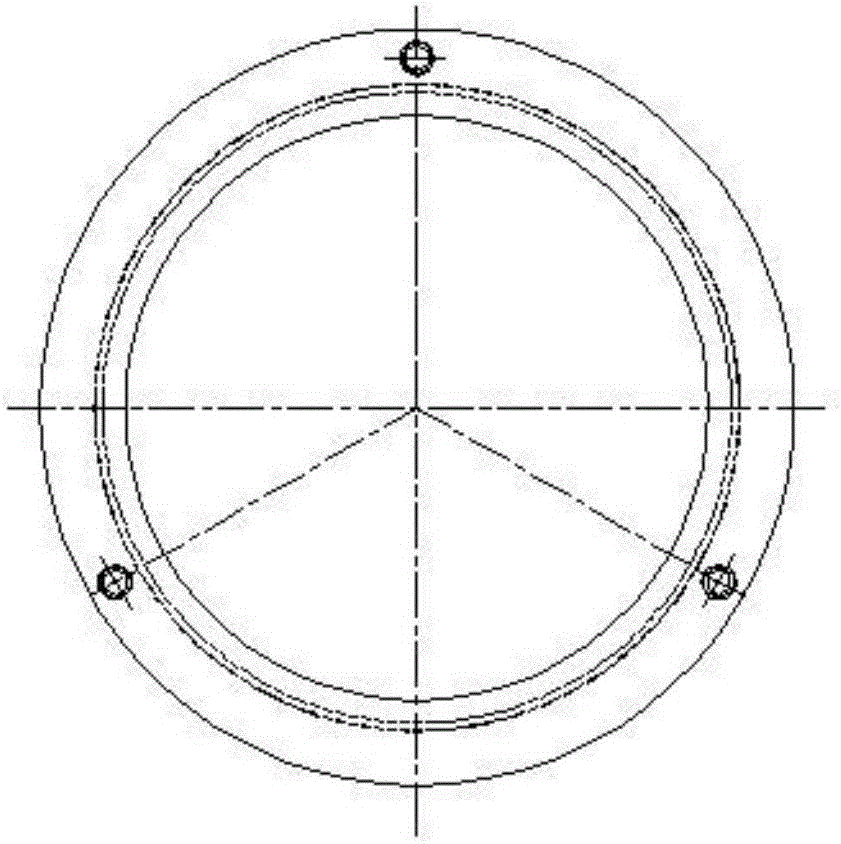

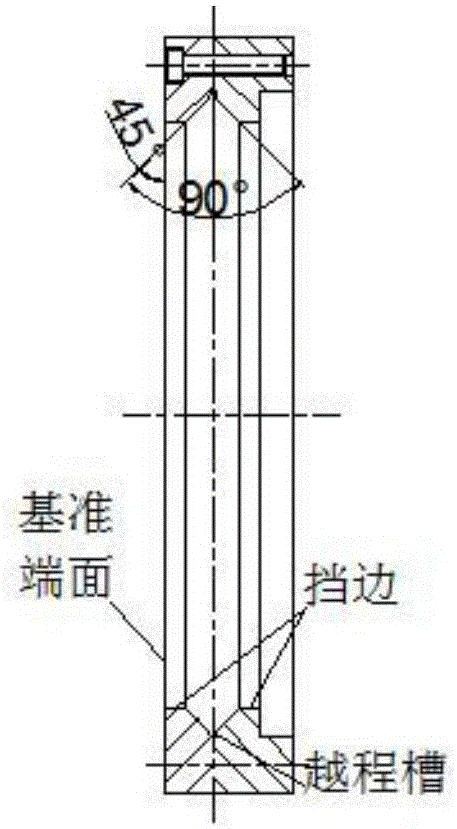

Crossed roller bearing with roller path with convexity and manufacturing method thereof

ActiveCN106195015AReduce startReduce frictionRolling contact bearingsBearing componentsMachined surfaceEngineering

The invention provides a crossed roller bearing with a roller path with convexity and a manufacturing method thereof. The crossed roller bearing with the roller path with convexity is characterized in that the V-shaped roller path of the crossed roller bearing has the convexity; a convex shape comprises a straight line, an arc-shaped quadratic curve and a logarithmic curve; and the V-shaped roller path with the convexity is formed in a crush grinding mode or a precision hard turning mode, or the V-shaped roller path with the convexity and other important finish machining surfaces of a loop are sequentially formed in a precision hard turning mode during one-time clamping positioning. According to the crossed roller bearing, machined according to the design, with the roller path with the convexity, compared with a grinding-formed crossed roller bearing with a roller path without convexity, the fringe effect of a roller-roller path contact pair is greatly reduced or completely avoided, the contact state between the outer circle face and the end face of a roller, and the roller path is improved, the bearing operating friction power consumption is reduced, the temperature rise is decreased, and the deflection-resisting capability of the bearing is improved; and accordingly, the operating precision, the bearing capability and the operating reliability of the bearing are improved, the service life of the bearing is prolonged, and very important practical engineering significance is achieved.

Owner:SHANGHAI F&S BEARING TECH

Logistics two-wheel automobile electric lifting and descending auxiliary support

InactiveCN106882289ASolve the problem of easy vehicle overturningSolve the flipped problemCycle standsElectricityLogistics management

The invention discloses a logistics two-wheel automobile electric lifting and descending auxiliary support. The support comprises a mounting base, a support body and an electric telescopic driver, the two ends of the mounting base are provided with a first through hole and a second through hole respectively, the first through hole is fixed to a first hinge shaft, the second through hole is fixed to a second hinge shaft, one end of the electric telescopic driver is hinged to the first hinge shaft, one end of the support body is hinged to the second hinge shaft, the support body is fixed to a third hinge shaft, the other end of the electric telescopic driver is hinged to the third hinge shaft, the other end of the support body is further connected to a roller, and the electric telescopic driver is electrically connected to a controller, and can linearly telescope to drive the support body to rotate to thus make the roller lift and descend. The logistics two-wheel automobile electric lifting and descending auxiliary support has one-key electric lifting and descending support, after an automobile stops, the automobile can move in a short distance, and a better safe support effect is achieved.

Owner:昆山纽斯步工业设计有限公司

Rotary joint for water-cooled roller

InactiveCN105805458AExtended service lifeClose contactAdjustable jointsMechanical engineeringFixed joint

The invention provides a rotary joint for a water-cooled roller. The rotary joint comprises a fixed joint, a fixed casing, a rotary casing, a bearing, a bearing block, a sliding seat, a fixed sealing ring and a rotary sealing ring, wherein the fixed joint is connected with one end of the fixed casing; the other end of the fixed casing is connected with the bearing block; the bearing is arranged between the bearing block and the rotary casing and is positioned and connected through a retainer ring; the sliding seat is fixed on the inner wall of the fixed casing through an adjusting bolt; two ends of a spring are propped against the fixed casing and the sliding seat respectively; the fixed sealing ring is embedded in an end surface of the sliding seat; the rotary sealing ring is embedded in an end surface of the rotary casing; the fixed sealing ring corresponds to the rotary sealing ring; and a water outlet is formed in the bottom of the fixed casing. The operating accuracy of the rotary joint can be guaranteed, and the service life of the rotary joint is prolonged.

Owner:武汉钢铁有限公司

Low-noise lubricating grease and preparation method and application thereof

ActiveCN104087395AReasonable formulaImprove work efficiencyLubricant compositionLow noiseLithium hydroxide

The invention discloses a low-noise lubricating grease and a preparation method and application thereof. According to the technical scheme, the low-noise lubricating grease is characterized by being prepared from the following raw materials in parts by weight: 65-85 parts of base oil, 10-15 parts of C12-C22 hydroxy fatty acid, 3-9 parts of lithium hydroxide, 2-7 parts of boric acid and 4-8 parts of multi-effect additives. The invention also discloses the preparation method of the low-noise lubricating grease and an application of the low-noise lubricating grease in a high-accuracy micro mechanical bearing. The low-noise lubricating grease disclosed by the invention is reasonable in formula and high in production efficiency. According to the low-noise lubricating grease and the application thereof disclosed by the invention, the low-noise lubricating grease is ground by using a patent product grinding machine (a patent number: ZL201220281084.7) of the company, the particle diameters of mechanical impurities contained in the lubricating grease are controlled to be smaller than that of the prior art, the vibration decibel value of the micro mechanical bearing is less than that of the lubricating grease in the prior art, the operation accuracy of the micro mechanical bearing is ensured, the vibration and the abrasion are reduced, the vibration decibel value of the micro mechanical bearing is less than 40, and the mechanical impurities contained in the lubricating grease are smaller than 2 micrometers.

Owner:XINXIANG HENGXING TECH CO LTD

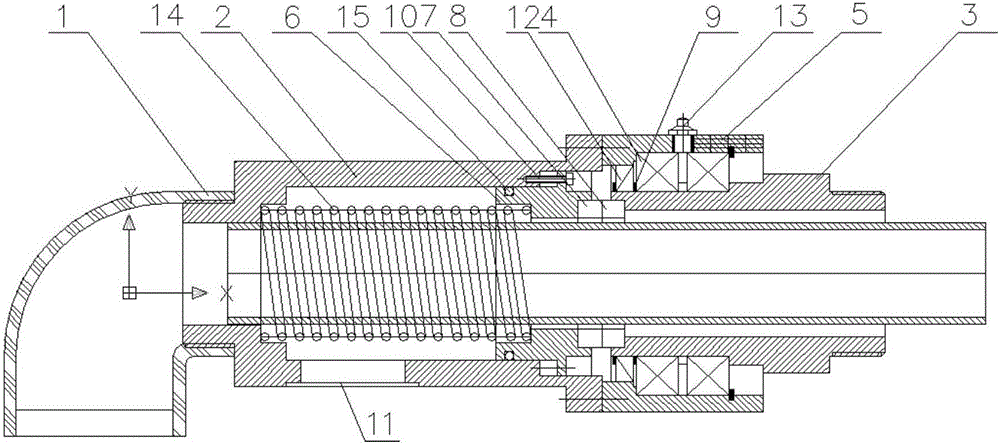

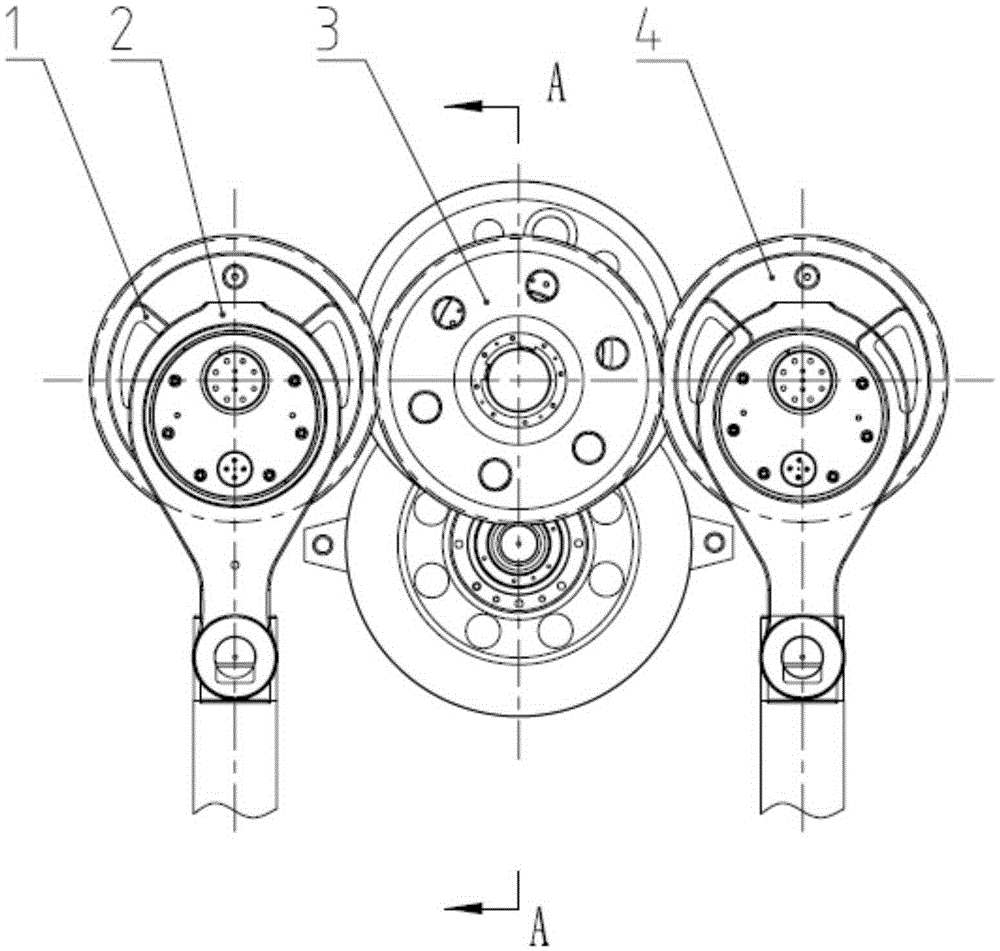

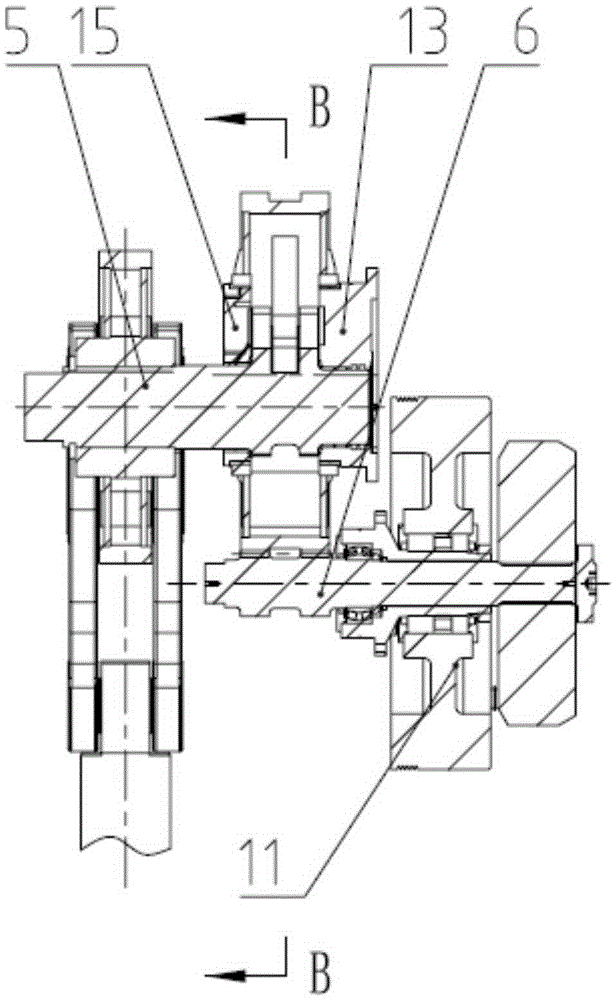

Double-point eccentric gear type multi-linkage mechanism for punch press

The invention relates to a double-point eccentric gear type multi-linkage mechanism for a punch press. A rotary shaft connected with a big intermediate gear is installed on one side of the big intermediate gear. A connecting pin which is perpendicular to the end face of the big intermediate gear is installed on the portion, close to an outer ring, of the interior of the big intermediate gear. The middle of the connecting pin is connected with one end of a rocker. The other end of the rocker is connected with a transmission shaft which is installed in the middle eccentric position of the interior of the big intermediate gear. One end of the transmission shaft vertically penetrates through the middle of the front end face of the big intermediate gear, and an intermediate gear is installed at the end. A left eccentric gear and a right eccentric gear which are engaged with the intermediate gear are symmetrically installed on the two sides of the intermediate gear. Connecting rods are installed on the front end face of the left eccentric gear and the front end face of the right eccentric gear. Guide columns are installed at the lower ends of the connecting rods. The double-point eccentric gear type multi-linkage mechanism for the punch press has the characteristics that the structure is simple, the production cost is low, the punching speed during punching can be effectively decreased, rapid returning is guaranteed, and the punching efficiency of the punch press is guaranteed.

Owner:NINGBO BOXIN MACHINERY

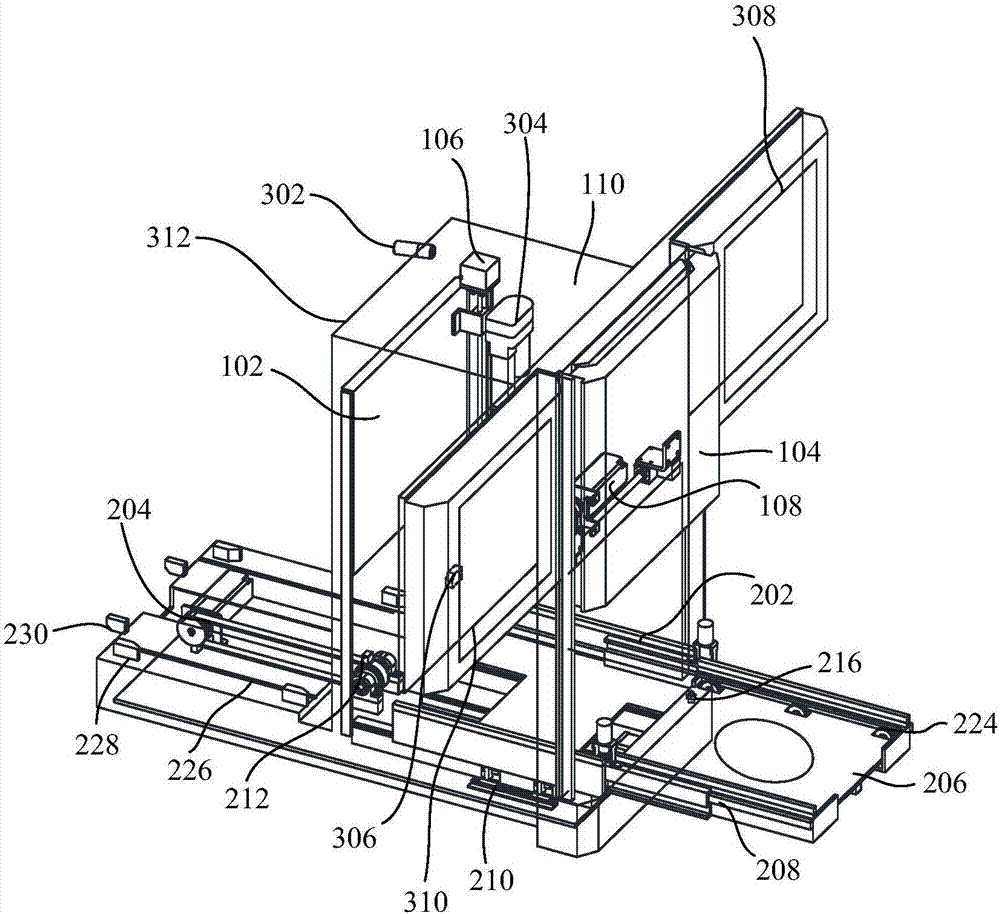

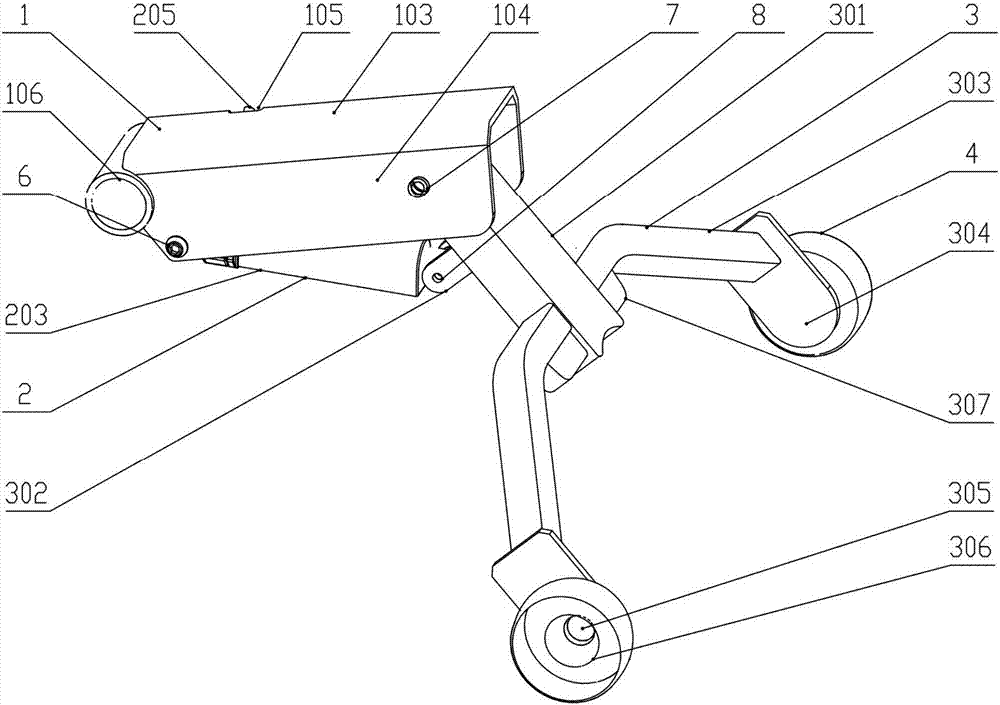

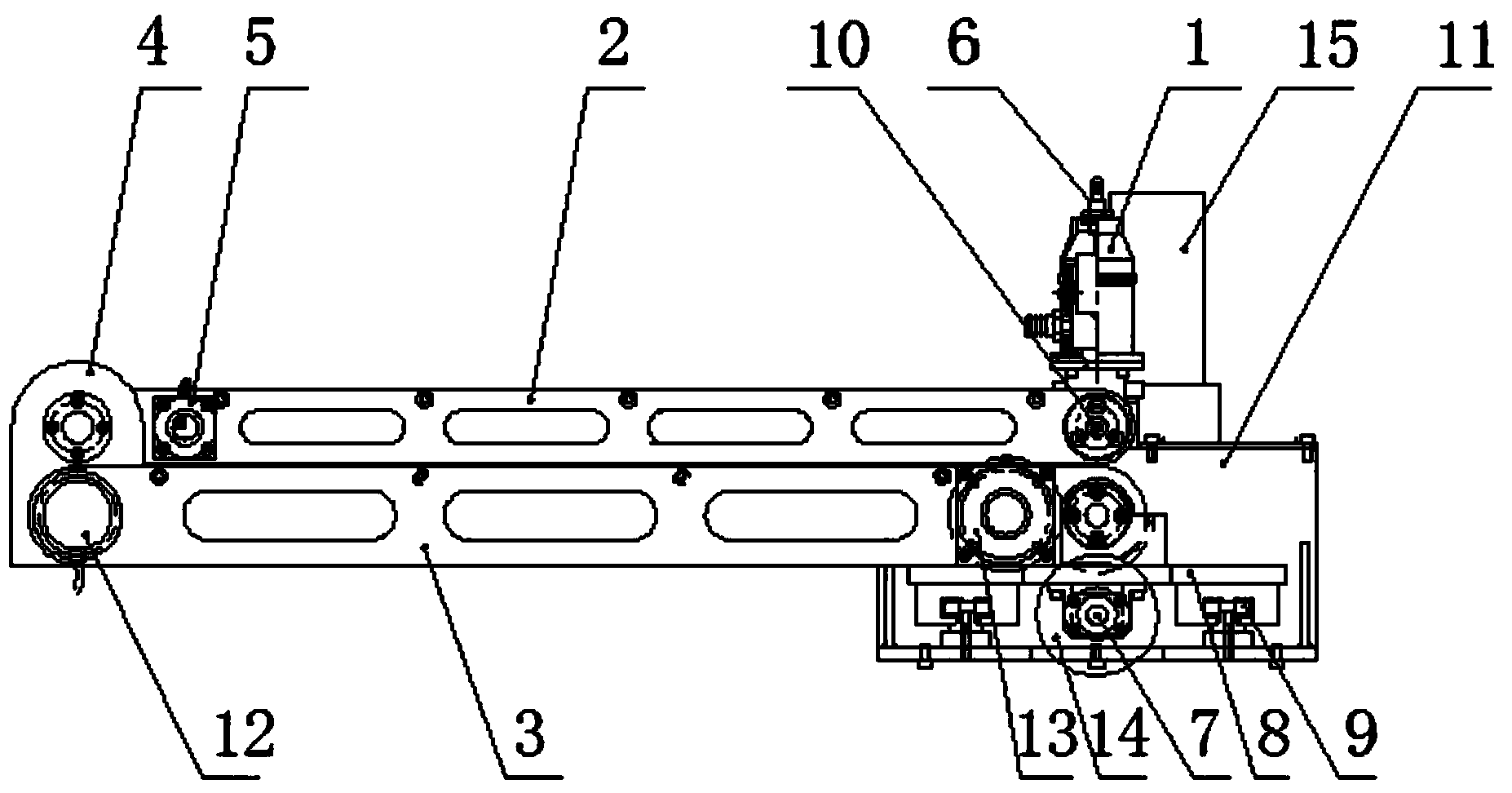

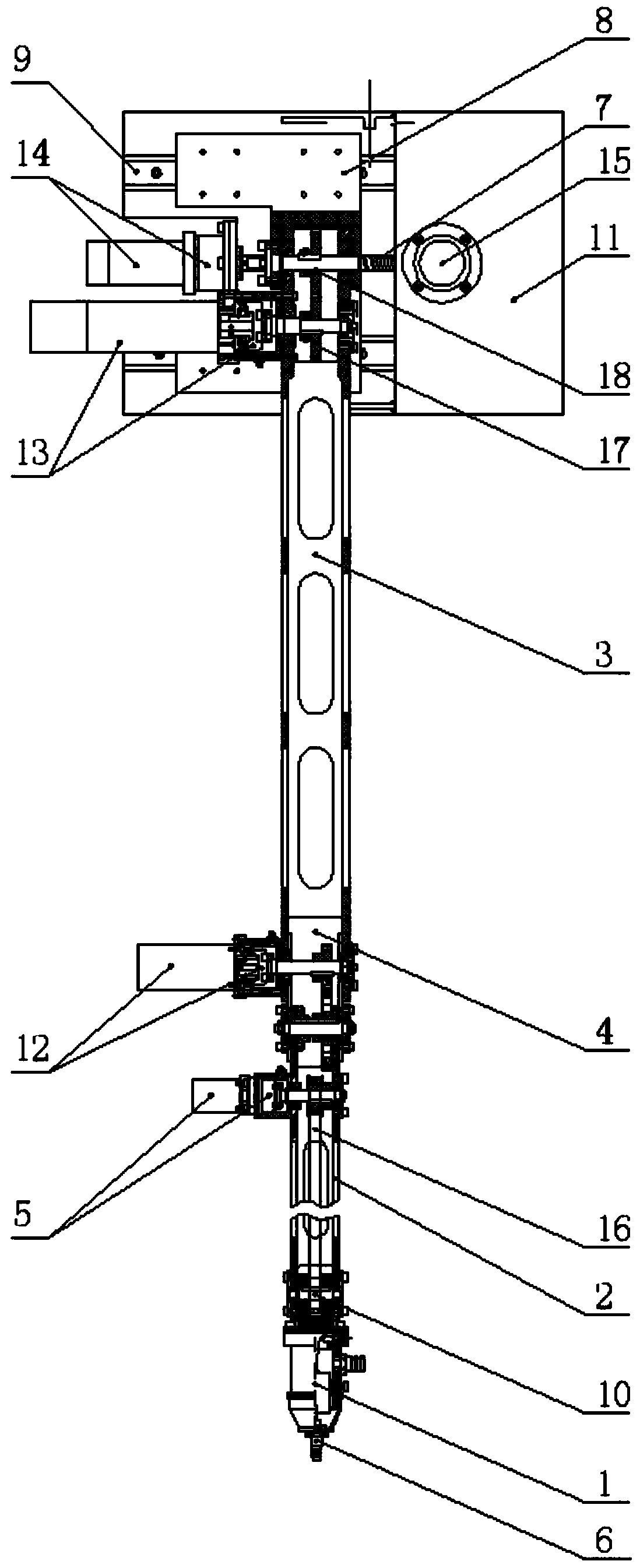

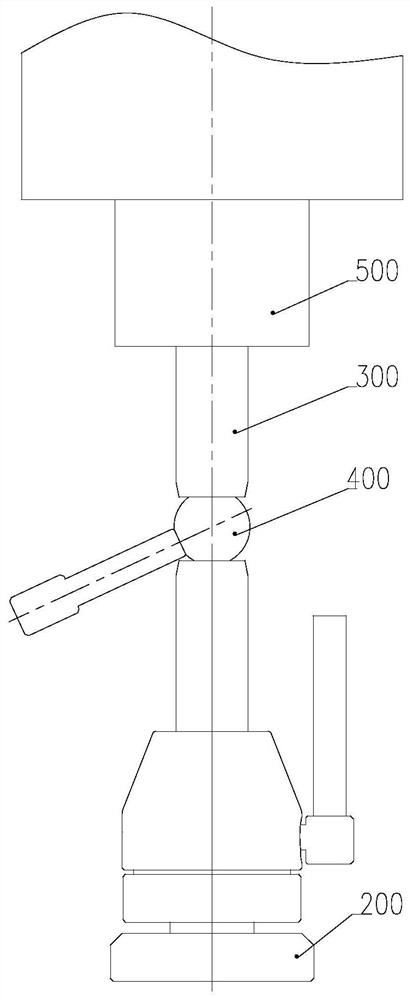

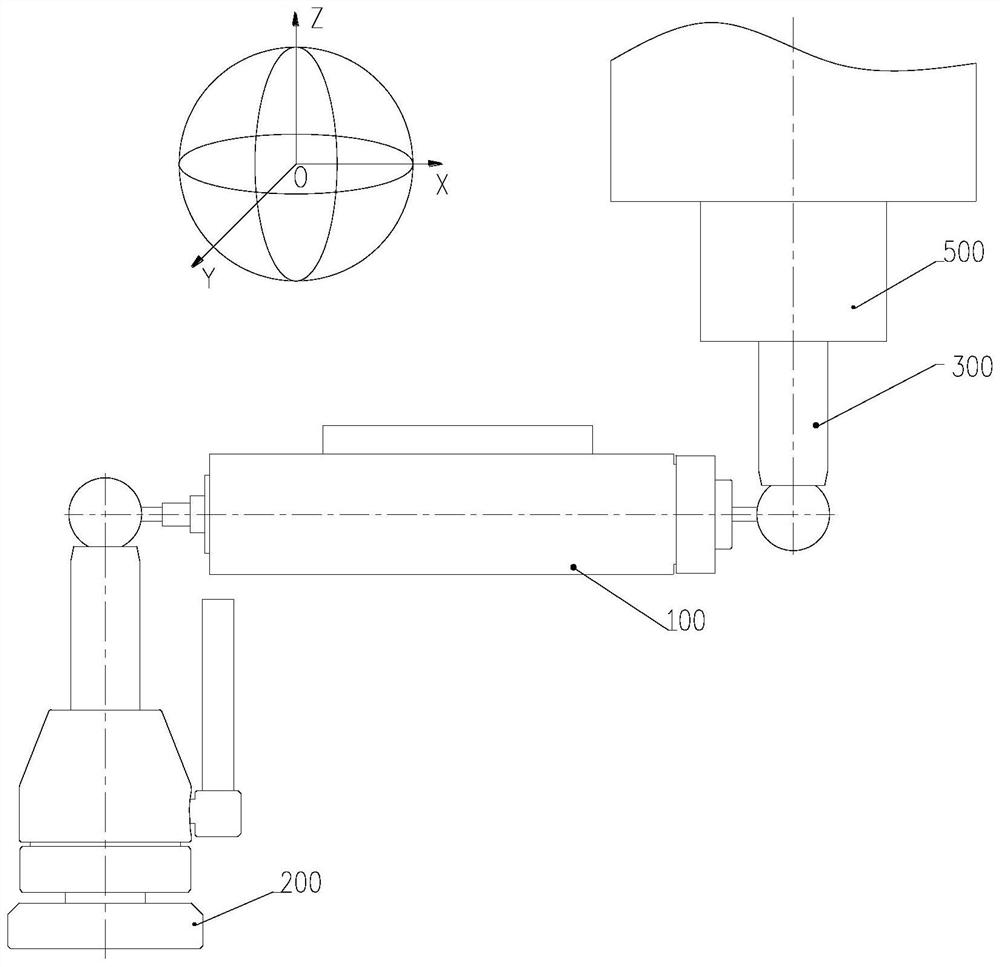

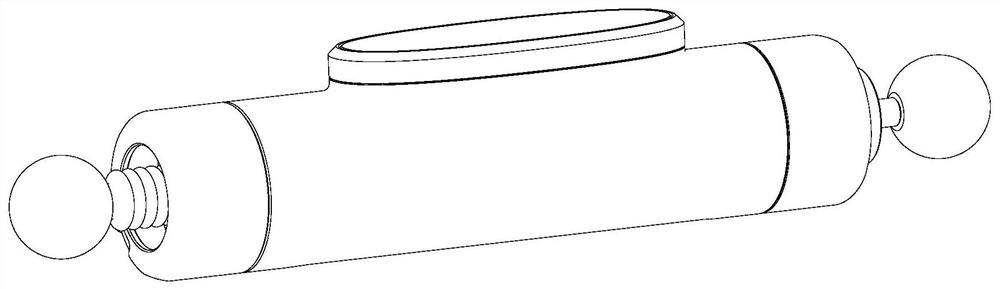

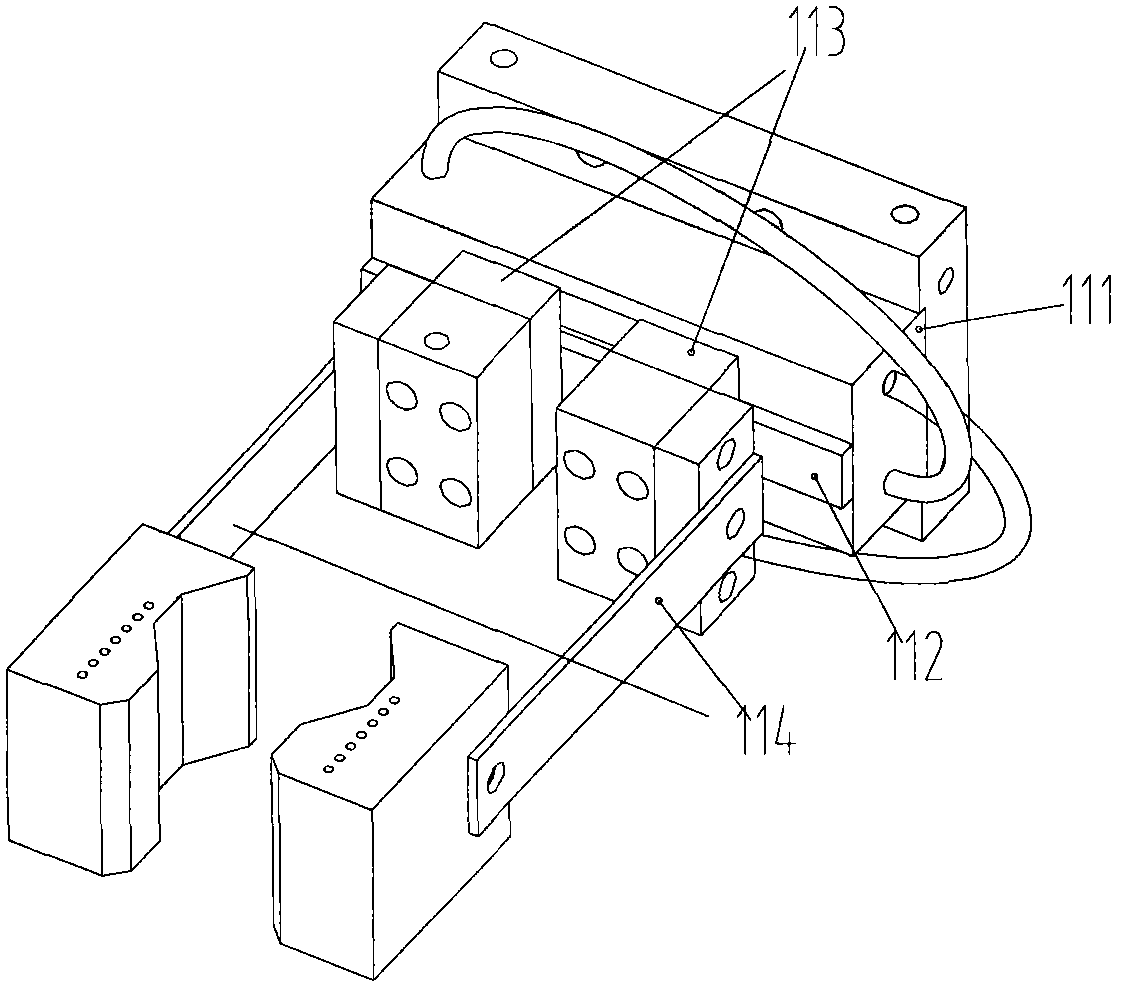

Manipulator and composite material large-scale shell automatic profile modeling system

ActiveCN103934819ARun accuratelyGuaranteed running accuracyProgramme-controlled manipulatorSimulationMotion controller

The invention relates to a manipulator and a composite material large-scale shell automatic profile modeling system. The system is formed by the manipulator, a motion controller, a sensor and an industrial computer. The sensor is mounted at the top end of a probe of the manipulator, the industrial computer is connected with the motion controller, the motion controller respectively controls five servo motors of the manipulator, and the sensor is connected with the motion controller. When the sensor on the manipulator is in contact with a shell, the motion controller records positional information of the five servo motors of the manipulator and transmits the positional information to the industrial computer, fitting is carried out on the corresponding positional information through the industrial computer so that corresponding curves can be formed, and the appearance contour of the composite material large-scale shell is formed. The system can automatically conduct profile modeling of the contour curve of the shell, fitting is carried out on all collected point coordinates to form the corresponding curves, motion trails are generated, and the manipulator can operate along the surface of the shell.

Owner:WUHAN ZHONGKE INNOVATION TECH

Inductance type wireless ball rod instrument

PendingCN111638681AGuaranteed running accuracyWon't turnProgramme controlComputer controlControl engineeringMechanical engineering

The invention provides an inductance type wireless ball rod instrument. The inductance type wireless ball rod instrument is mainly composed of a ball rod instrument main machine, a center support assembly, a center cup assembly and a set ball assembly. The ball rod instrument main machine comprises an inductance measuring head assembly, a battery assembly, a circuit board assembly and a ball rod instrument main body. A wireless measuring system composed of the ball rod instrument main machine, the center support assembly and the center cup assembly is used for comprehensively detecting the precision of a CNC machine tool motion shaft. The instrument is simple to operate, high in precision, low in cost and capable of quickly detecting the precision of the CNC machine tool motion axis.

Owner:CHOTEST TECH INC

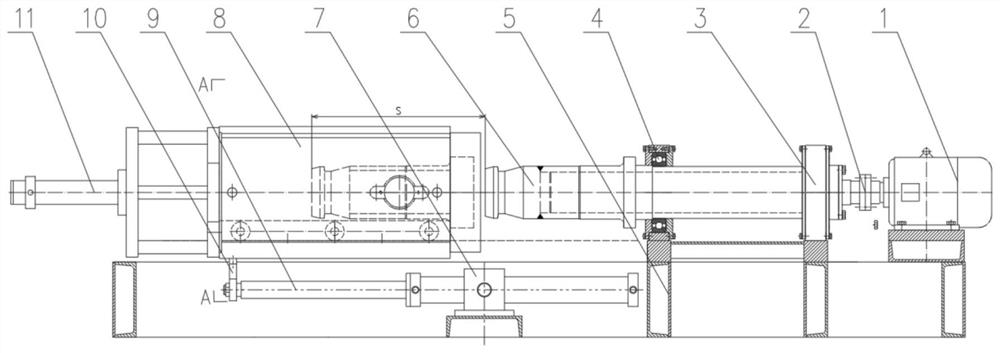

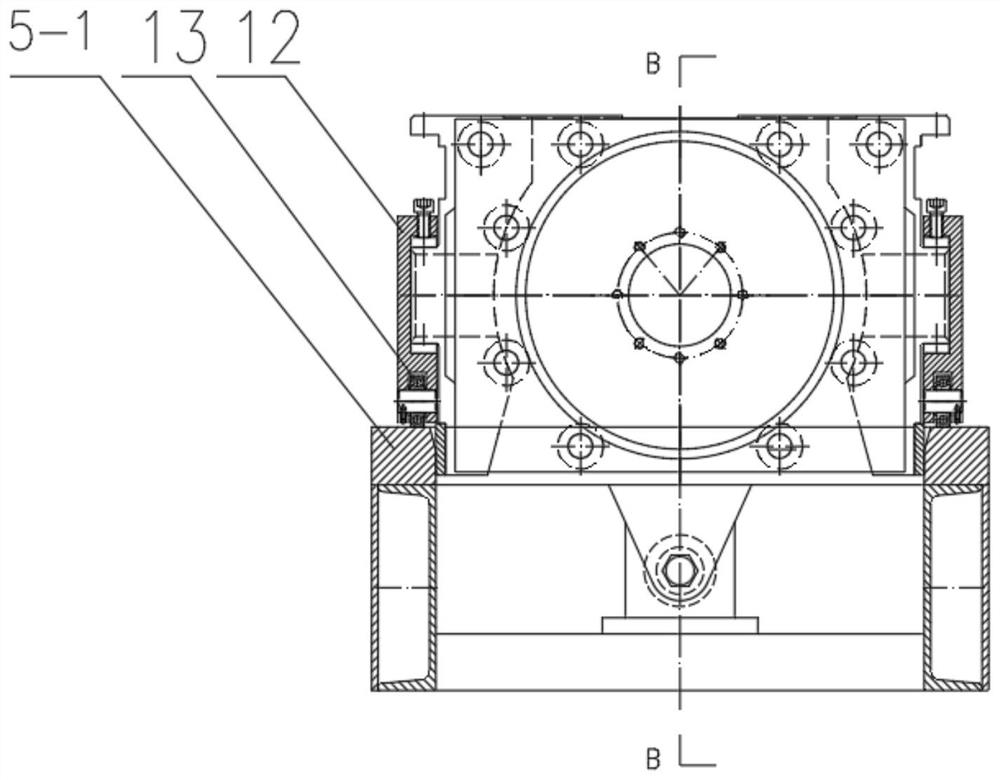

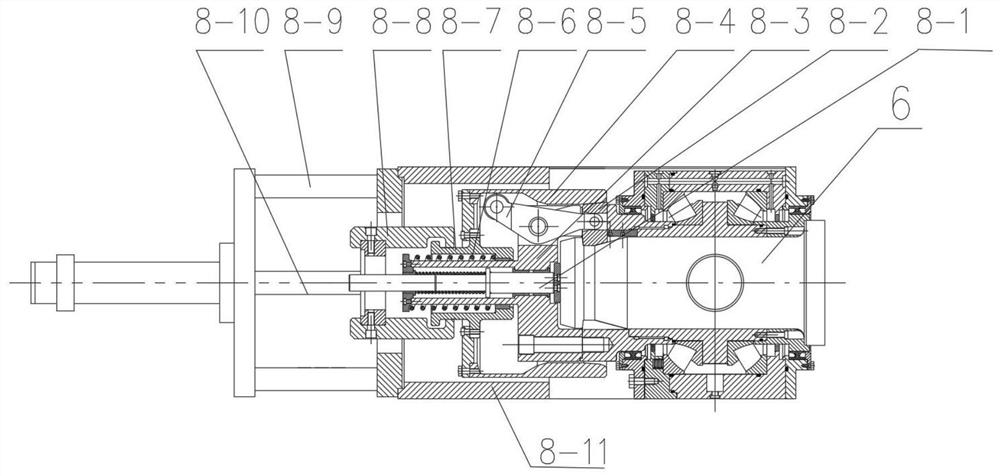

Rolling mill intermediate roll alternating motion off-line detection platform

PendingCN111644471AHigh precisionImprove stabilityMeasuring devicesRolling safety devicesCouplingControl engineering

The invention discloses a rolling mill intermediate roll alternating motion off-line detection platform. The platform comprises a base, a motor, an imitated intermediate roll, a translation oil cylinder, a intermediate roll coupling device and a coupling oil cylinder, wherein the motor, the imitated intermediate roll, the translation oil cylinder, the intermediate roll coupling device and the coupling oil cylinder are mounted on the base, a motor shaft of the motor is connected with one end of the imitated intermediate roll through a coupler, the other end of the imitated middle shaft is connected with the output end of the intermediate roll coupling device, the input end of the intermediate roll coupling device is connected with a piston rod of the coupling oil cylinder, the motor shaft and the intimated intermediate roll are coxially arranged, the axis directions of the motor shaft and the intimated intermediate roll are consistent with the driving direction of the coupling oil cylinder, the bottom of the intermediate roll coupling device is connected with a piston rod of the translation oil cylinder through a connecting support, and the translation oil cylinder is mounted on a machine base through an oil cylinder supporting base. According to the platform, the intermediate roll coupling device and a fitting intermediate roll are combined according to actual working conditions of a rolling mill, equipment faults are pre-judged in advance by simulating disassembly and assembly and rolling operation of the intermediate roll, and the online running precision and stability ofthe intermediate roll are improved.

Owner:武汉钢铁有限公司

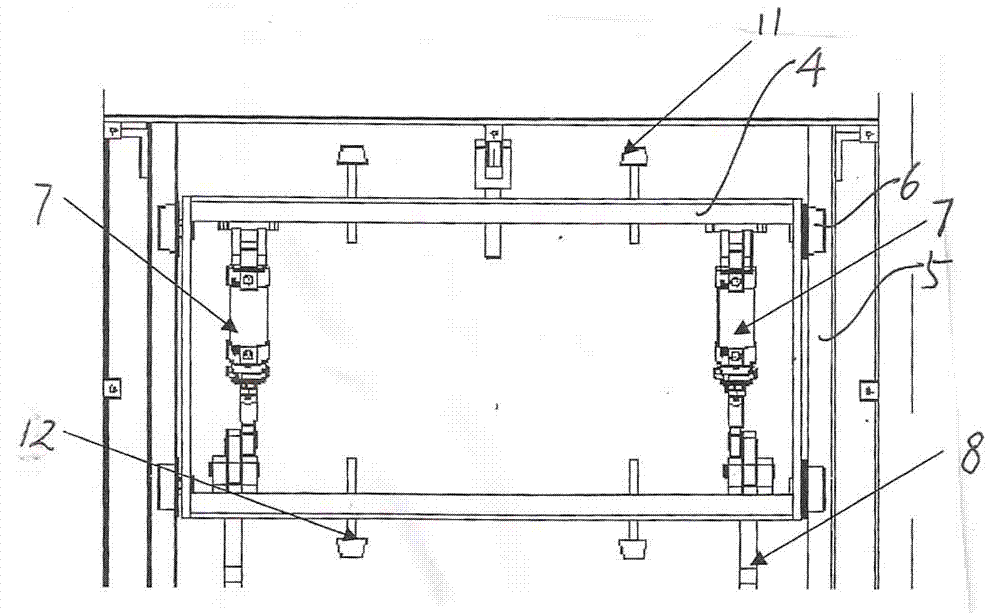

Hydraulic machine for fine blanking of sheet metal

InactiveCN106142626AEliminate out-of-sync defectsGuaranteed running accuracyPress ramBack pressureSurface smoothness

The invention discloses a hydraulic machine for fine blanking of sheet metal. The hydraulic machine comprises a machine body, a main oil cylinder, a back-pressure cylinder, a gear ring cylinder and a sliding block, wherein the gear ring cylinder is arranged in a lower workbench of the machine body; the upper end of a piston rod of the gear ring cylinder is supported in a lower guide sleeve; the lower guide sleeve is fixed in a central hole of a workbench plate; the main oil cylinder perpendicularly downward penetrates through an upper cross beam and is fixed at the center of the upper cross beam; the head part of a piston rod of the main oil cylinder is fixed on the upper side of the sliding block; the back-pressure cylinder is positioned in the sliding block; the lower side of the back-pressure cylinder is fixed inside the lower part of the sliding block; the lower end of a piston rod of the back-pressure cylinder is supported in an upper guide sleeve; and the upper guide sleeve is fixed in a central hole of the lower side of the sliding block. The hydraulic machine disclosed by the invention is simple in structure and has the advantages that the defect of desynchrony of a multi-cylinder system is overcome, the rigidity of the machine body is greatly improved, the running precision of the sliding block is guaranteed, and the requirement for utilization of a high-precision fine blanking die is met; meanwhile, the forming rate of blanked parts is improved and the material waste cost is reduced; and the flatness, the surface smoothness and the size precision of the blanked parts are improved.

Owner:WORLD PRECISE MACHINERY CO LTD CHINA

Compound forging manipulator

ActiveCN103878285AIncrease temperatureReduce the temperatureProgramme-controlled manipulatorForging/hammering/pressing machinesForging manipulatorRoom temperature

The invention relates to industrial automation device, in particular to an automation manipulator. The compound forging manipulator comprises a gripper and a finger. The gripper comprises a finger body, a guide rail, pistons, a plunger pin and sliders. The finger is fixedly connected to the sliders and comprises a finger tip and a bridge, one end of the bridge is fixedly connected to the sliders while the other end of the same is fixedly connected with the finger, and a clamping face is arranged on the finger. When a workpiece is impacted or bumped, affections of impact on the gripper can be avoided or reduced due to an elastic function of the finger. Graphite can be sprayed to a die while the workpiece is gripped simultaneously, so that production efficiency is improved; liquid fed into an inlet flows out of an outlet via a channel, heat accumulated through the fingers is taken away by the flowing liquid, temperature of the fingers can be greatly reduced, and the finger can be kept at constant temperature under working conditions; meanwhile, the high-temperature workpiece is subjected to quenching treatment.

Owner:ZHEJIANG WEILI METALFORMING MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com