Ball screw pair pre-tightening force measurement and control system and method with self-sensing function

A ball screw pair, measurement and control system technology, applied to piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, generators/motors, etc. Complex problems, to achieve the effect of precise preload output control, improve transmission accuracy, running accuracy and processing quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0036] A ball screw pair preload measurement and control system with self-sensing function, including a preload device and a measurement and control device, wherein:

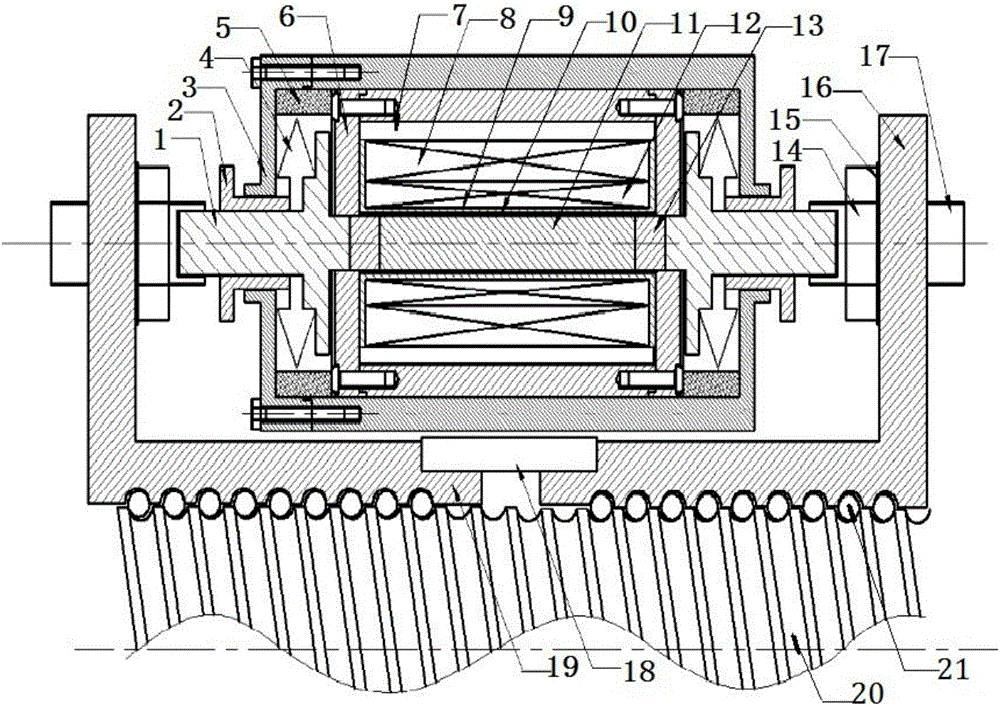

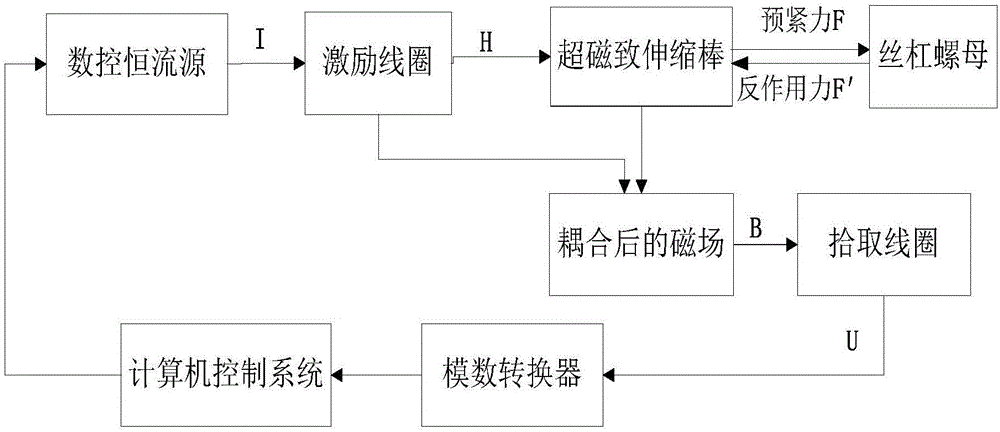

[0037] Such as figure 1 The schematic diagram of the structure of the pretensioning device shown, the pretensioning device is a symmetrical structure with double-ended output, including a giant magnetostrictive rod 11, and the giant magnetostrictive rod 11 is installed in the center of the bobbin 9, and the bobbin 9 The outer side is wound with a pickup coil 12 and an excitation coil 8, the outer side of the excitation coil 8 is provided with a permanent magnet 7, and the two ends of the giant magnetostrictive rod 11 are respectively connected to the yoke 6 through two magnetic blocks 13. The magnetostrictive rod 11 and the magnetically conductive blocks 13 at both ends are covered with a shaft sleeve 10, and each magnetically conductive block 13 is equipped with an output ejector rod 1, and the output ejector r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com