RGV body

A car body and wheel technology, applied in the field of RGV car body, can solve problems such as misalignment, achieve the effects of reducing equipment quality, compressing upper space occupation, and reducing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

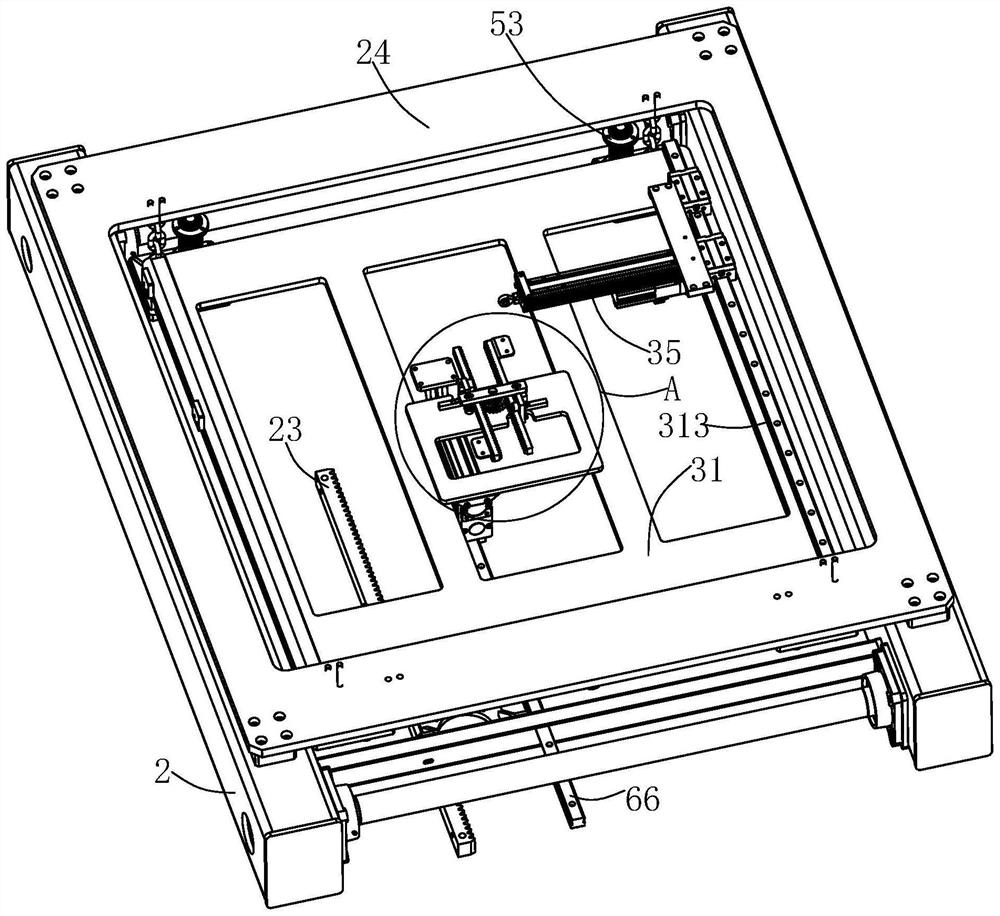

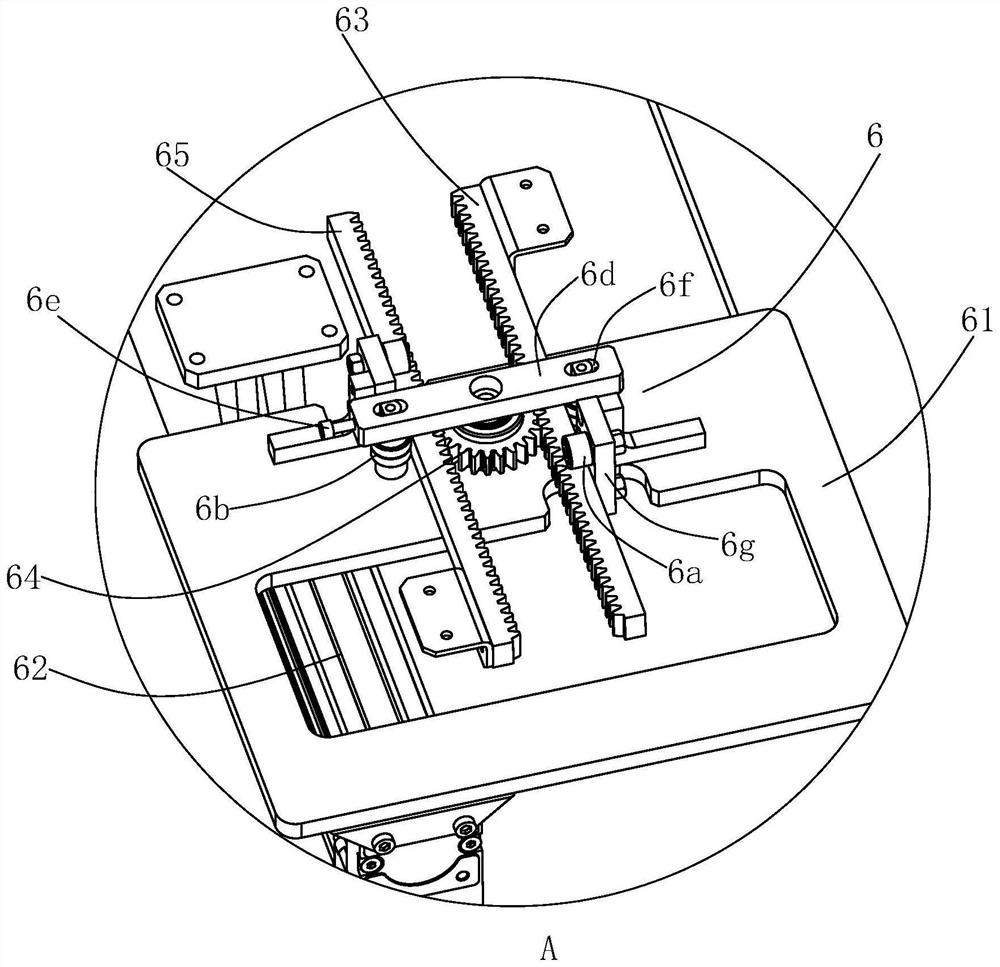

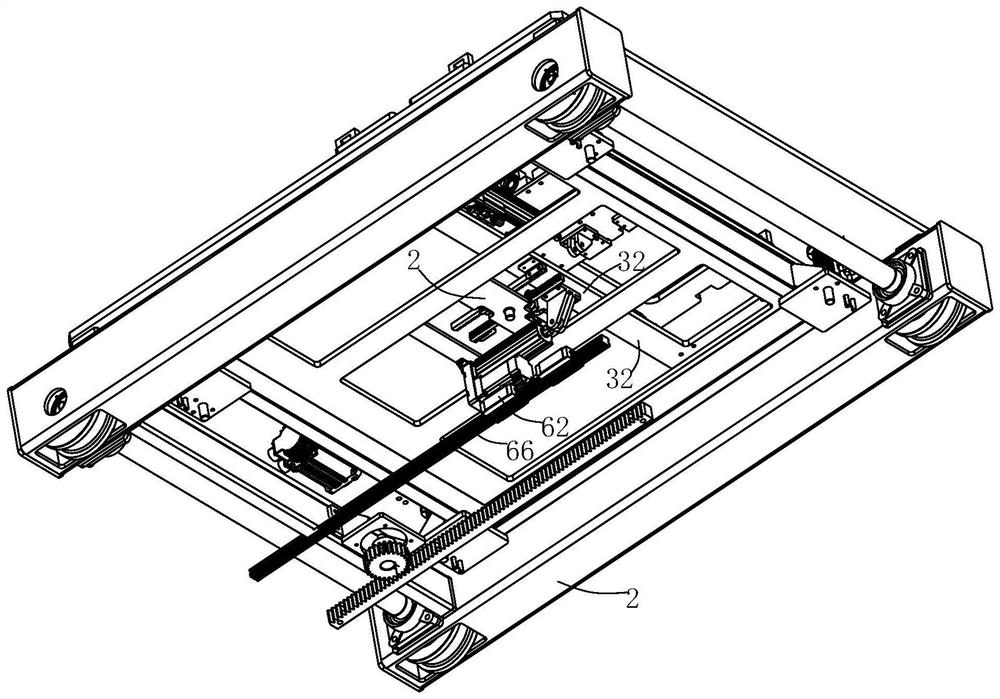

[0048] An RGV car body, the lower part of which is a foundation track 1 for the RGV to run, and the foundation track 1 is an I-shaped steel rail. Wheels are respectively installed at the four corners of the bottom of the RGV, and the vehicle body and the foundation track 1 are in rolling contact with the wheels, and the vehicle body slides on the foundation track 1 . The car body includes a car frame 2. As a driving method for the RGV car body, a traveling drive motor 21 is installed on the front end of the car frame 2, and a traveling gear 22 is installed on the output shaft of the traveling driving motor 21. The traveling gear 22 is connected to the The guide rack 23 on the foundation engages to form the drive to the car body.

[0049] The vehicle frame 2 is a rectangular frame, and its upper part is an upper connection frame 24. The upper connection frame 24 is also a rectangular frame, and is separated from the vehicle frame 2 by a certain height. The upper connection fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com