Inductance type wireless ball rod instrument

A wireless ball, inductive technology, used in instruments, measuring/indicating equipment, program control, etc., can solve the problems of high machining accuracy and assembly requirements of parts, unadjustable relative positions, and high costs, achieving high measurement efficiency and reliable guidance. , the effect of satisfying accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with the accompanying drawings.

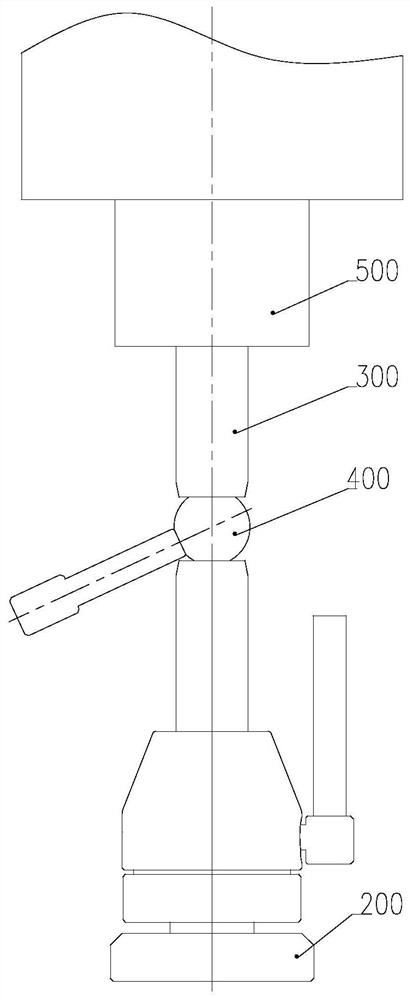

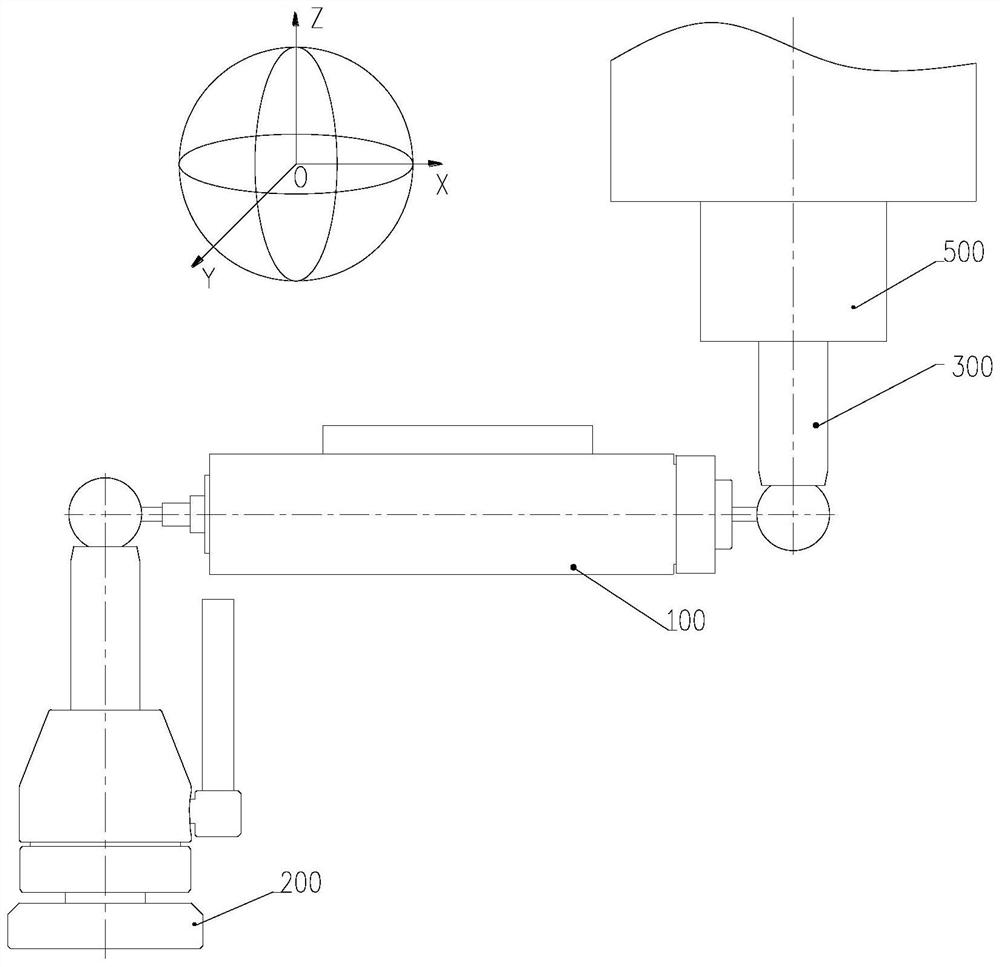

[0045] like figure 1 and figure 2 As shown, an inductive wireless ballbar is mainly composed of four parts: a ballbar host 100 , a center support assembly 200 , a center cup assembly 300 and a setting ball assembly 400 .

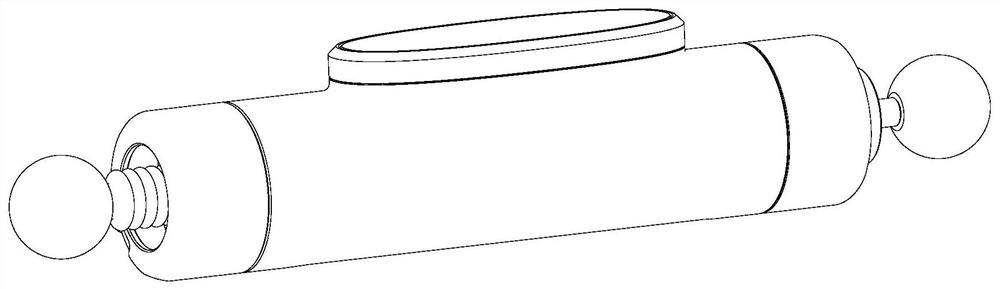

[0046] like Figure 3 to Figure 6 As shown, the ballbar host 100 includes: a first measuring ball 1, a measuring rod 2, a measuring head body 3, a guide sleeve 4, a ballbar body 5, a circuit board cover 6, a circuit board 7, and a magnetic core sleeve rod 8 , Battery positive guide 9, battery 10, battery end cap 11, second measuring ball 12, measuring ball connecting rod 13, shrapnel 14, battery negative shrapnel 15, magnetic core 16, coil 17, return spring 18, pin 19.

[0047] like Figure 7 to Figure 10 As shown, the central support assembly 200 includes: a measuring ball support block 20, a magnet 21, a movable support rod 22, an elastic claw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com