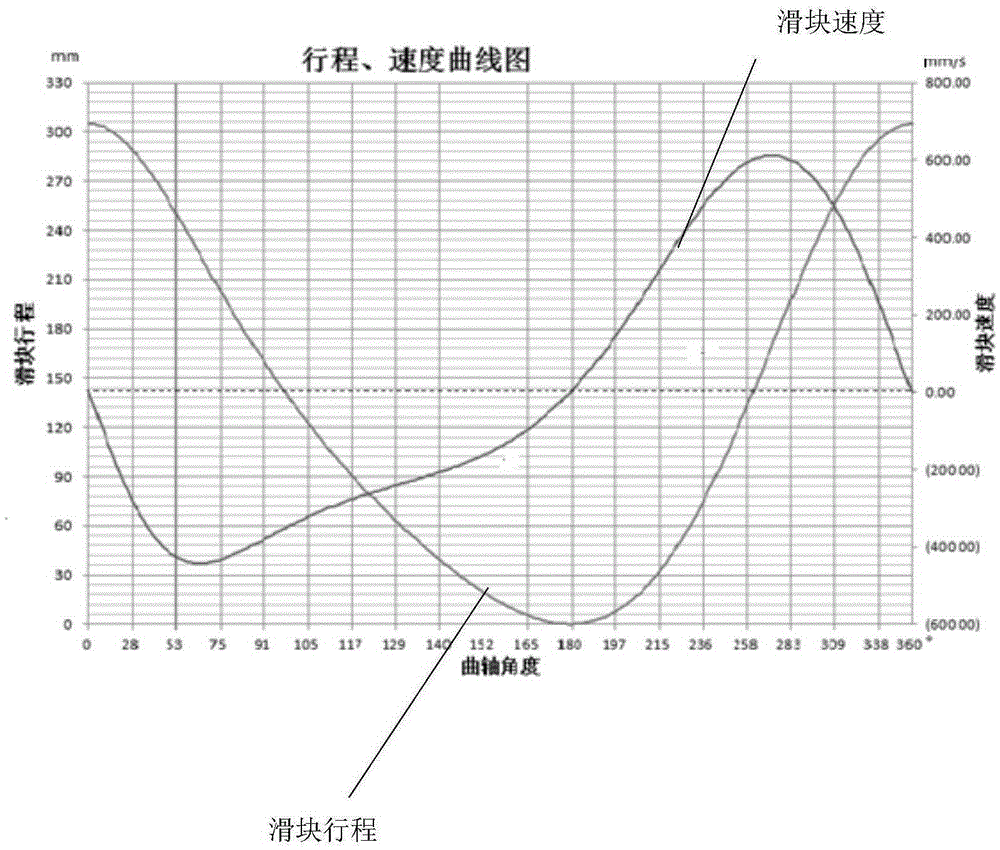

Double-point eccentric gear type multi-linkage mechanism for punch press

An eccentric gear, multi-link technology, applied in punching machines, presses, manufacturing tools, etc., can solve problems such as high speed, and achieve the effects of low production cost, guaranteed punching efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

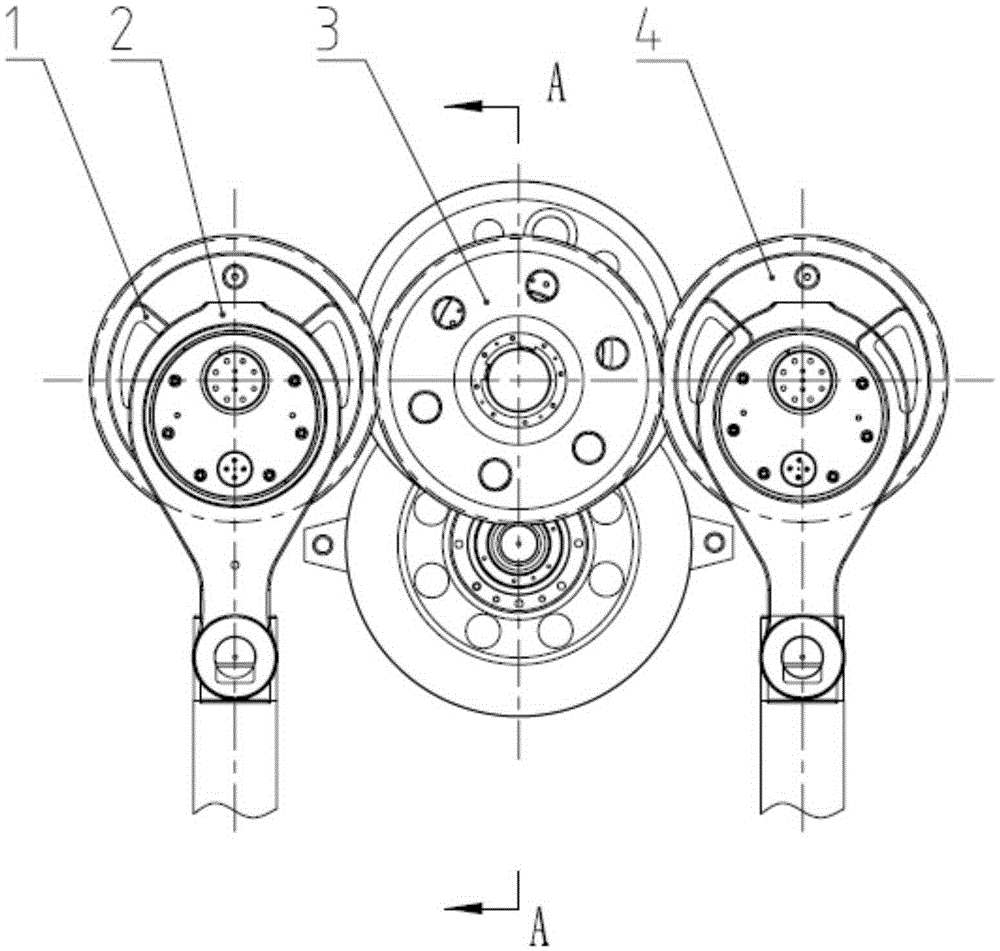

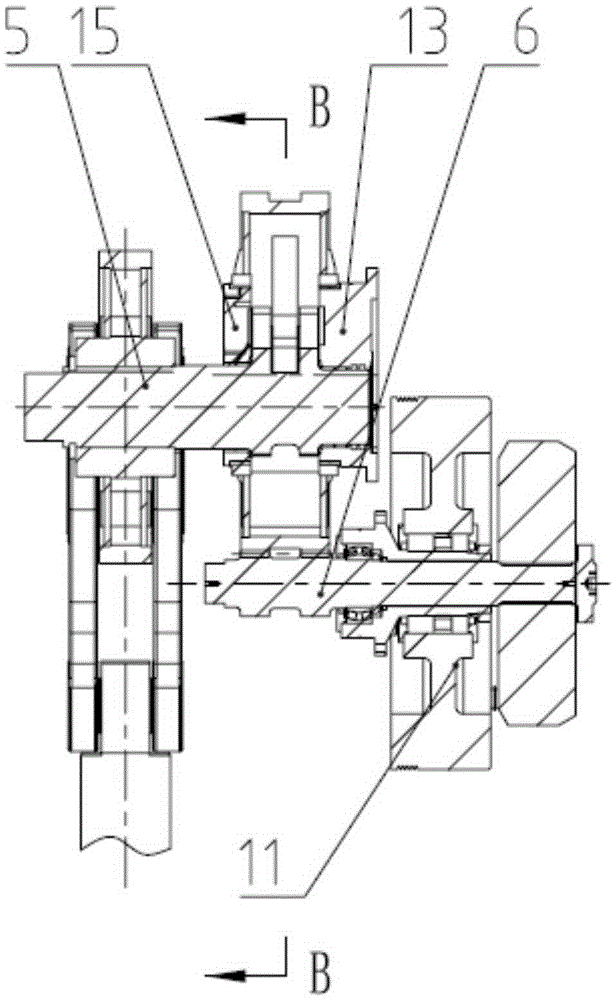

[0030] When starting the whole mechanism, firstly, the motor drives the transmission gear 11, the transmission gear 11 drives the rotating shaft 6, the rotation of the rotating shaft 6 makes the middle large gear 9 rotate, and the rotation of the middle large gear 9 drives the connecting pin 7 to rotate around the center of the central large gear 9 , the connecting pin 7 drives the rocking bar 8 to rotate again, because the other end of the rocking bar 8 is fixedly connected with the transmission shaft 5, so the rocking bar 8 rotates around the transmission shaft 5, and the transmission shaft 5 will rotate with the rotation of the rocking bar 8, and the transmission The rotation of the shaft 5 drives the rotation of the intermediate gear 3, the rotation of the intermediate gear 3 drives the rotation of the left eccentric gear 1 and the right eccentric gear 4, the rotation of the left eccentric gear 1 and the right eccentric gear 4 drives the two connecting rods 2 to move up and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com