Rolling mill intermediate roll alternating motion off-line detection platform

An off-line detection and intermediate roll technology, applied in the field of metallurgical steel rolling machinery, can solve the problems of limited space, difficult maintenance and debugging, rolling mill shutdown, etc., to ensure accuracy and stability, shorten roll change maintenance cycle, improve accuracy and stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

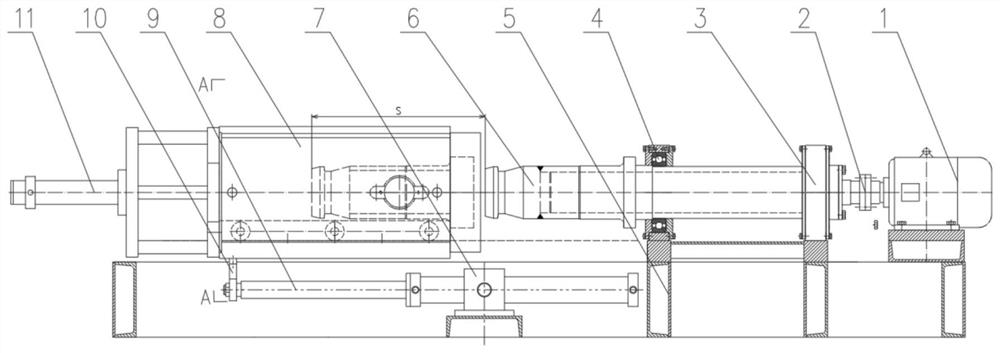

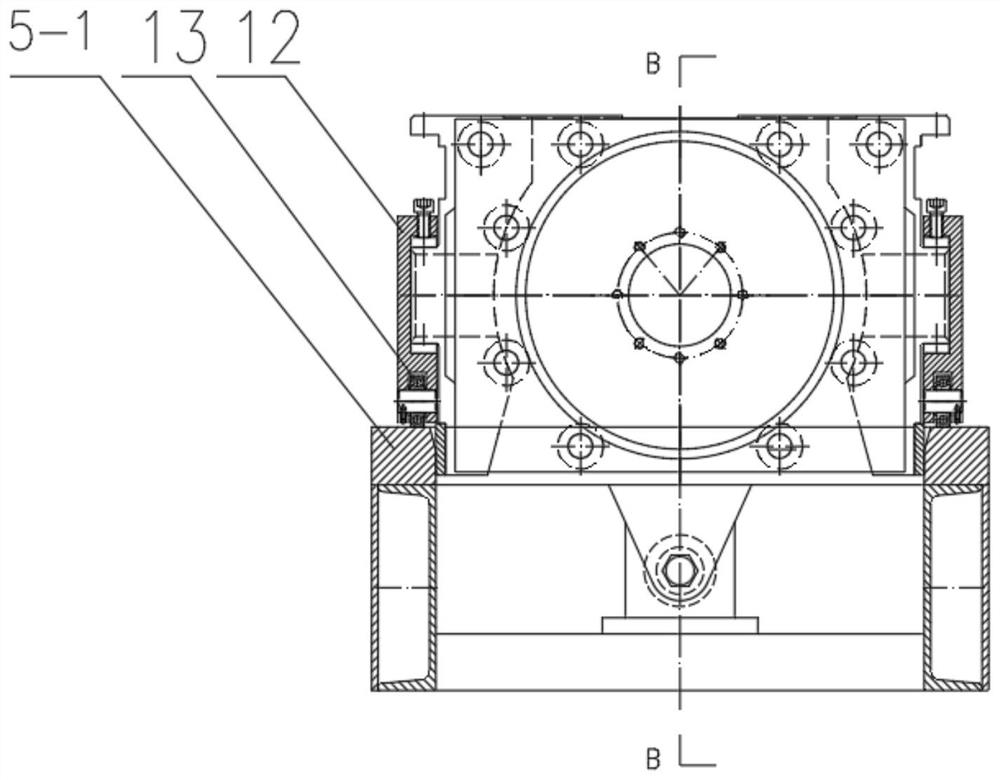

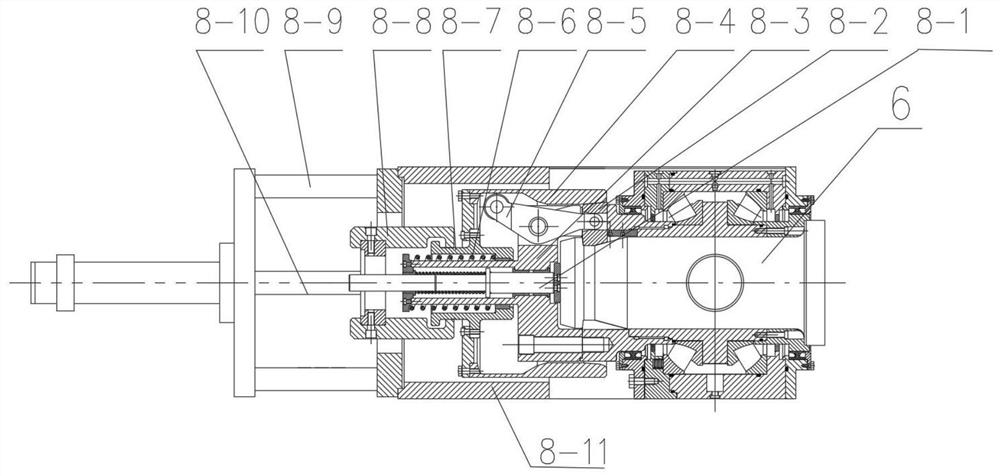

[0015] like figure 1 and figure 2 The shown off-line detection platform for intermediate roll shifting of a rolling mill includes a stand 5, a motor 1 installed on the stand 5, an imitation intermediate roll 6, a traverse cylinder 9, an intermediate roll coupling device 8, and a coupling cylinder 11. The motor shaft of the motor 1 is connected to one end of the imitation intermediate roller 6 through a shaft coupling 2, and at least one bearing is configured on the imitation intermediate roller 6, and the bearing is fixed on the machine base 5 through a bearing seat; the other end of the imitation intermediate shaft is connected to the The output end of the intermediate roller coupling device 8 is connected, and the input end of the intermediate roller coupling device 8 is connected with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com