Patents

Literature

48results about How to "Small transmission power" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

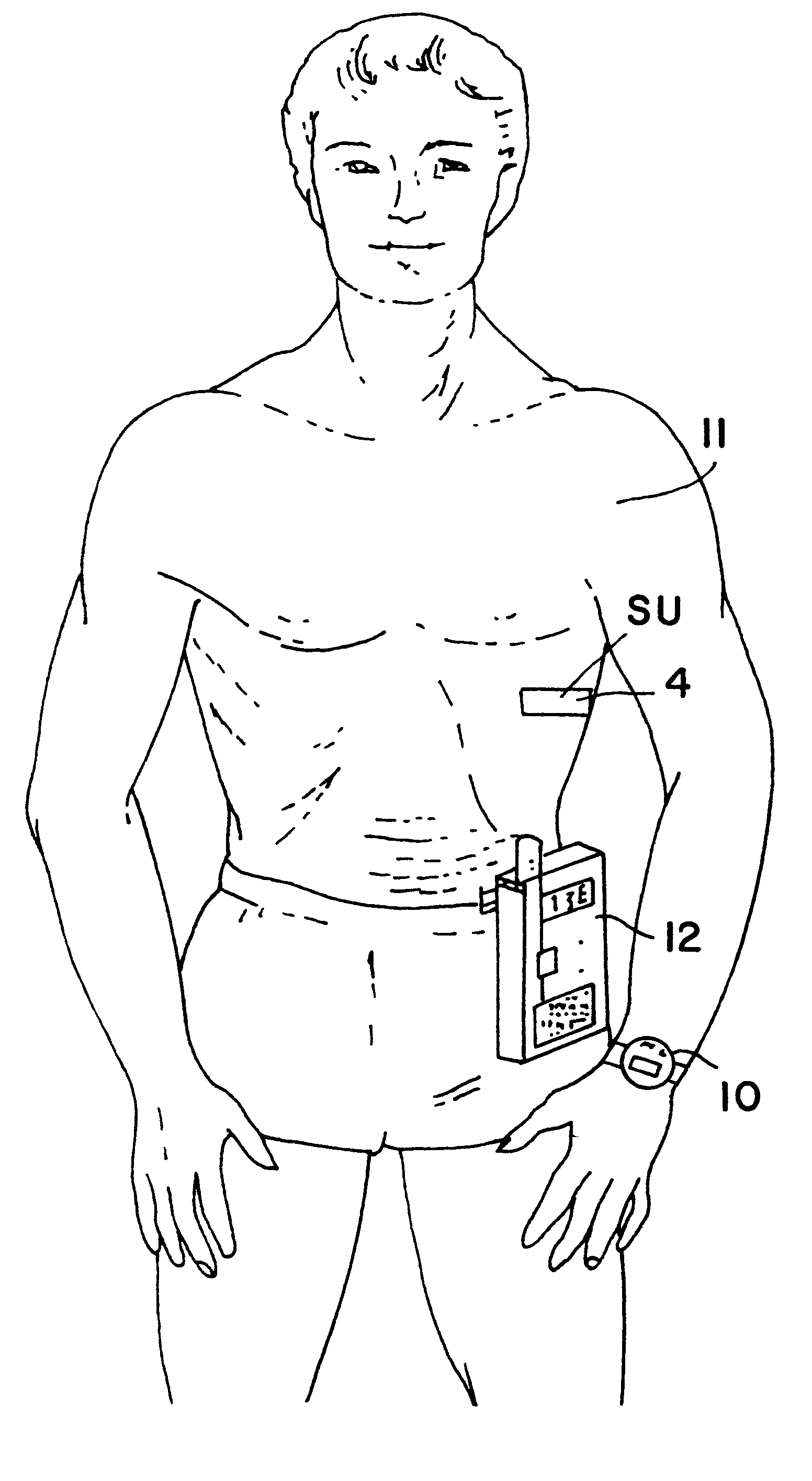

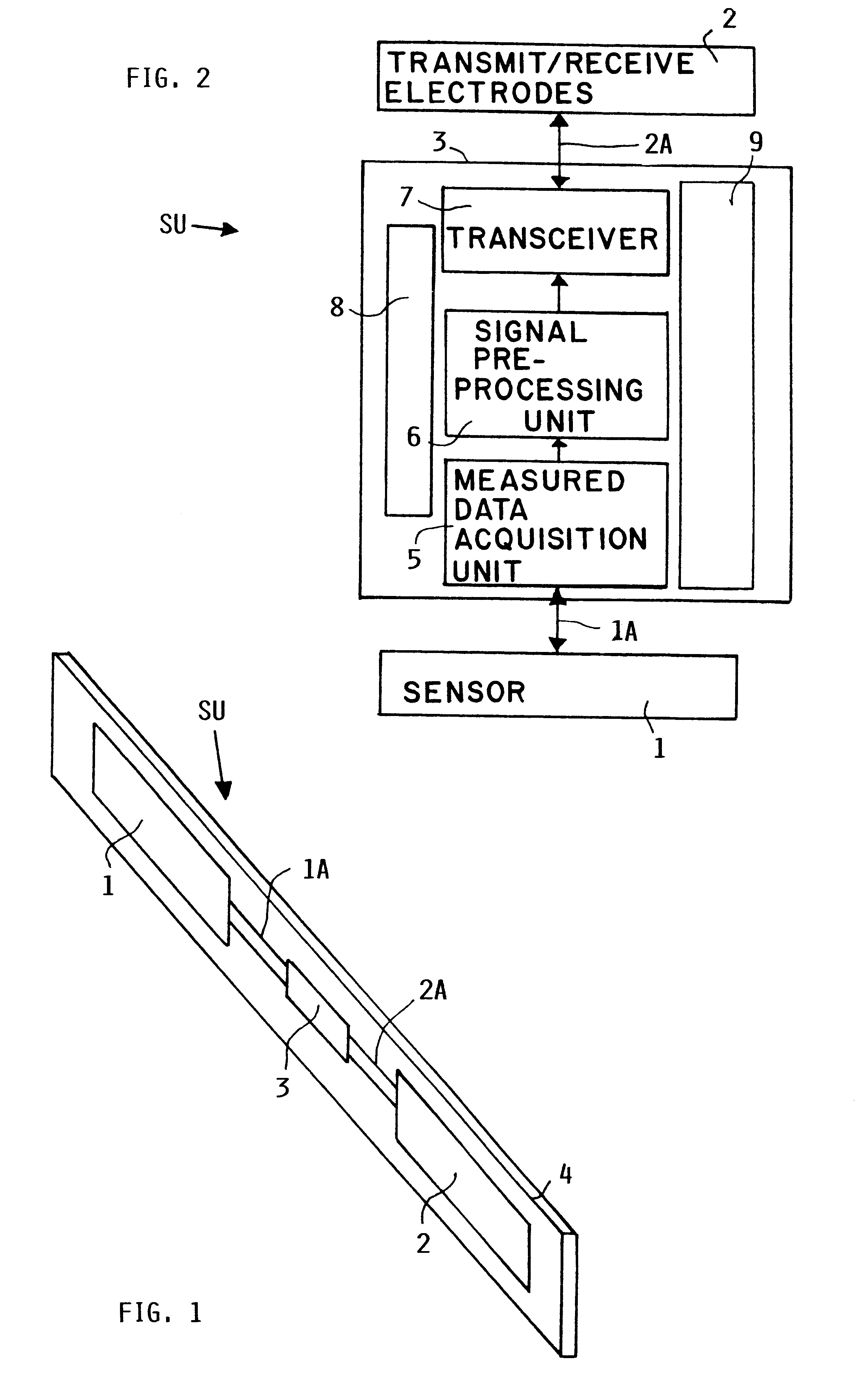

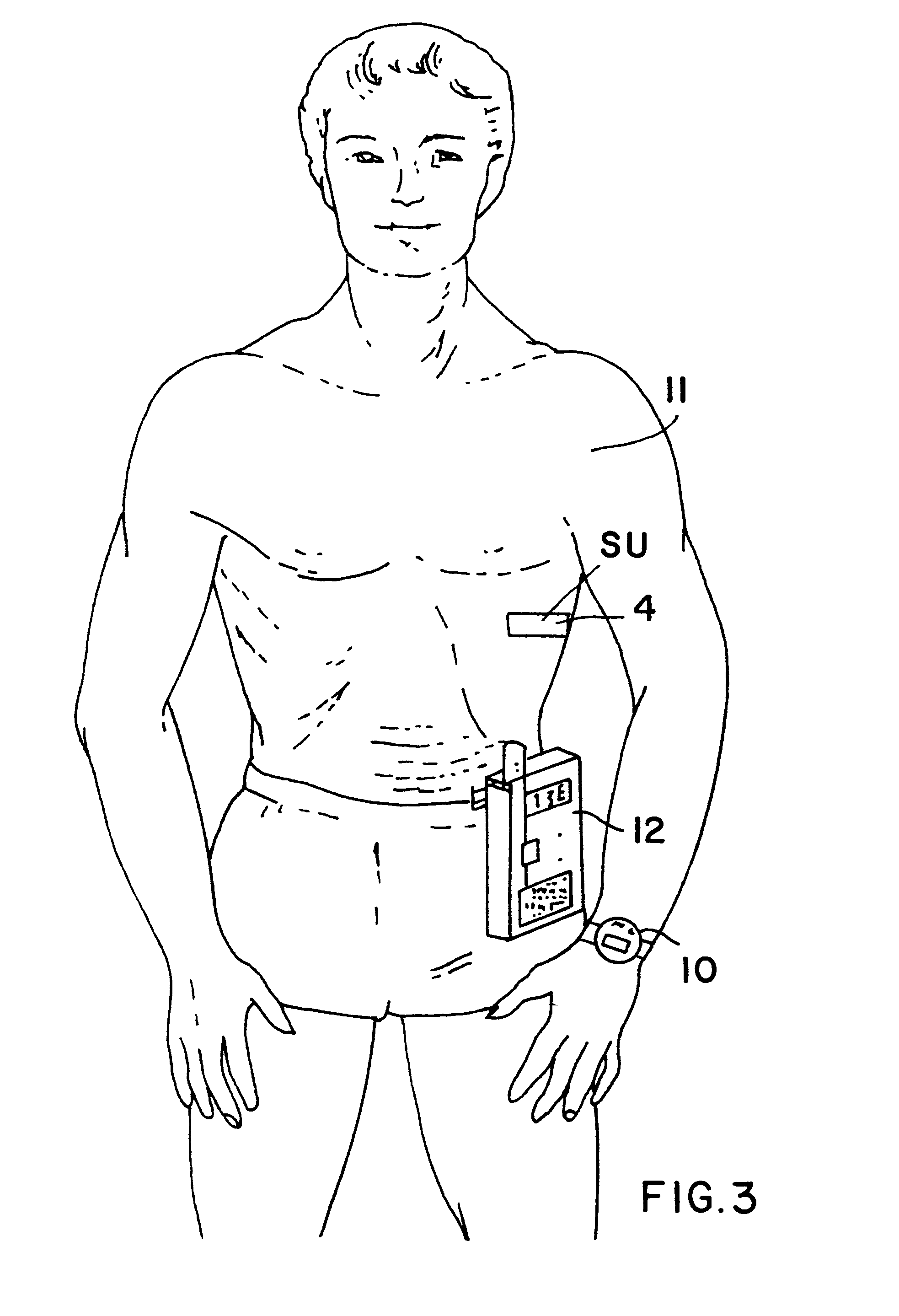

System for long-term remote medical monitoring

InactiveUS6315719B1Avoid it happening againPrevent unintended interceptionElectrotherapyLocal control/monitoringTransceiverAir temperature

A system for long-term remote medical monitoring is especially suitable for the medical supervision of astronauts onboard a space station. The system includes at least one autonomous sensor unit (SU) with a sensor (1) and transmit / receive electrodes (2) connected to a microchip (3) and mounted on a carrier (4) in the form of an adhesive bandage that can easily be applied to the skin of the subject astronaut (11). The system further includes a body transceiver (10) that is worn on the body of the subject and acts as a centralized transmitting and receiving unit, and a portable data logger (12). Medical data such as the pulse rate and the like, as well as environmental data such as the ambient surrounding air temperature, are sensed by respective allocated sensor units (SU) and transmitted from the sensor units as electrical signals via the skin and other body tissues of the subject (11) to the body transceiver (10). From the body transceiver (10), the data signals are further transmitted, for example by a radio or infrared transmission, to the data logger (12), where the data can be recorded, displayed, processed, or further transmitted via a satellite (14) to a base station (13) or a ground-based facility such as a hospital (15). Polling signals are also transmitted from the body transceiver (10) to the sensor units (SU) in a wireless manner through the skin and other body tissues of the subject.

Owner:ZUERICH MEDTECH

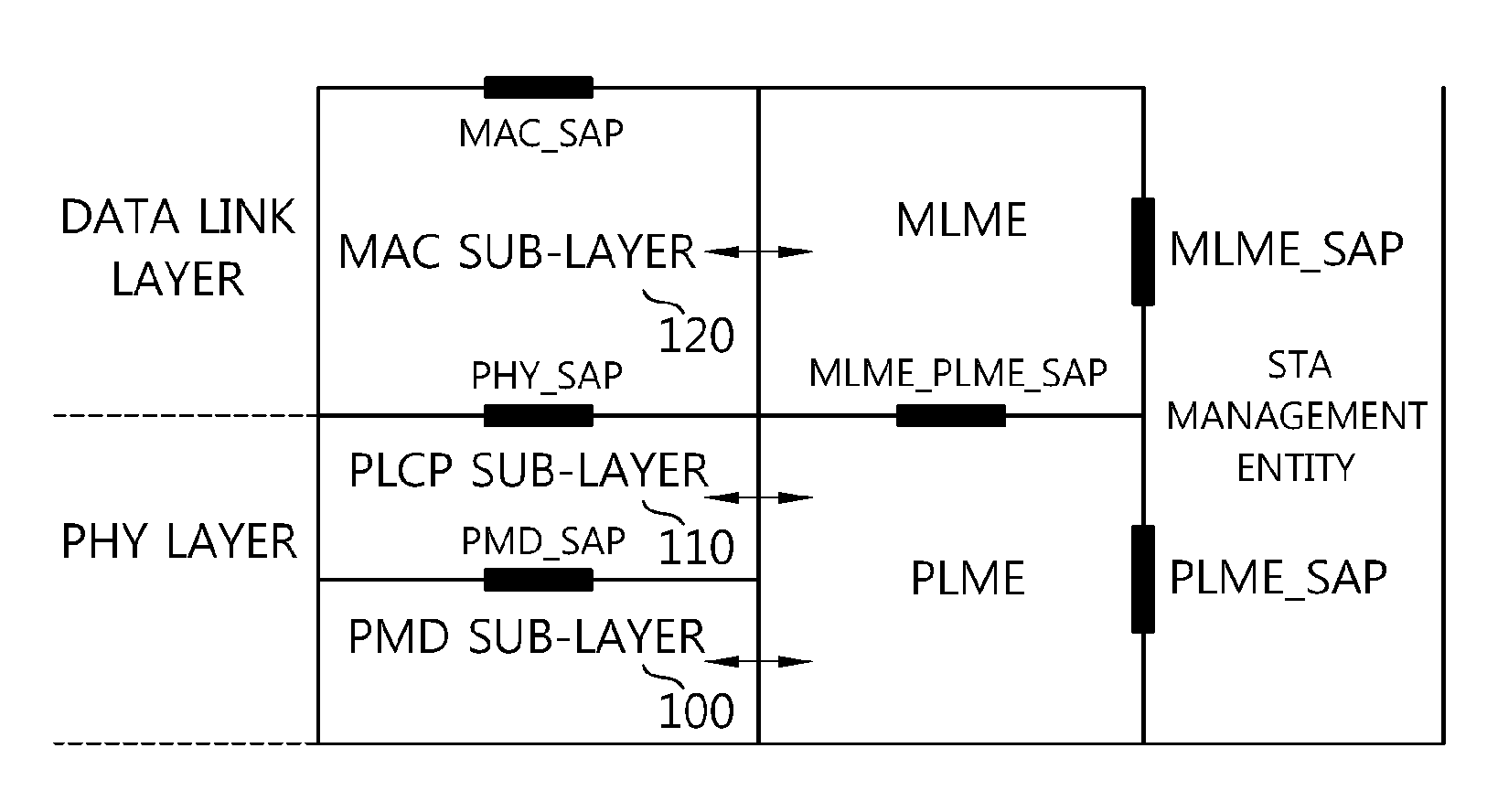

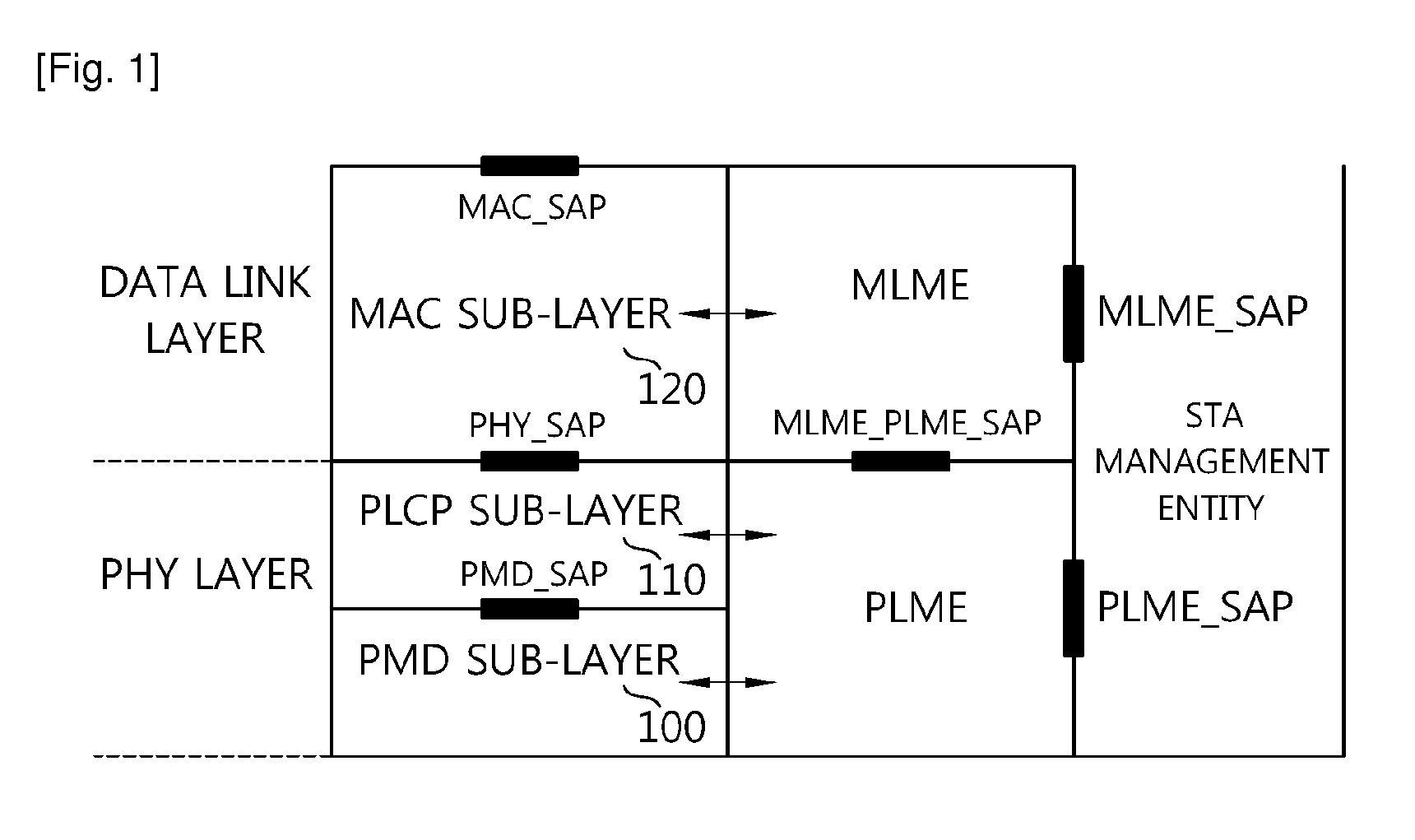

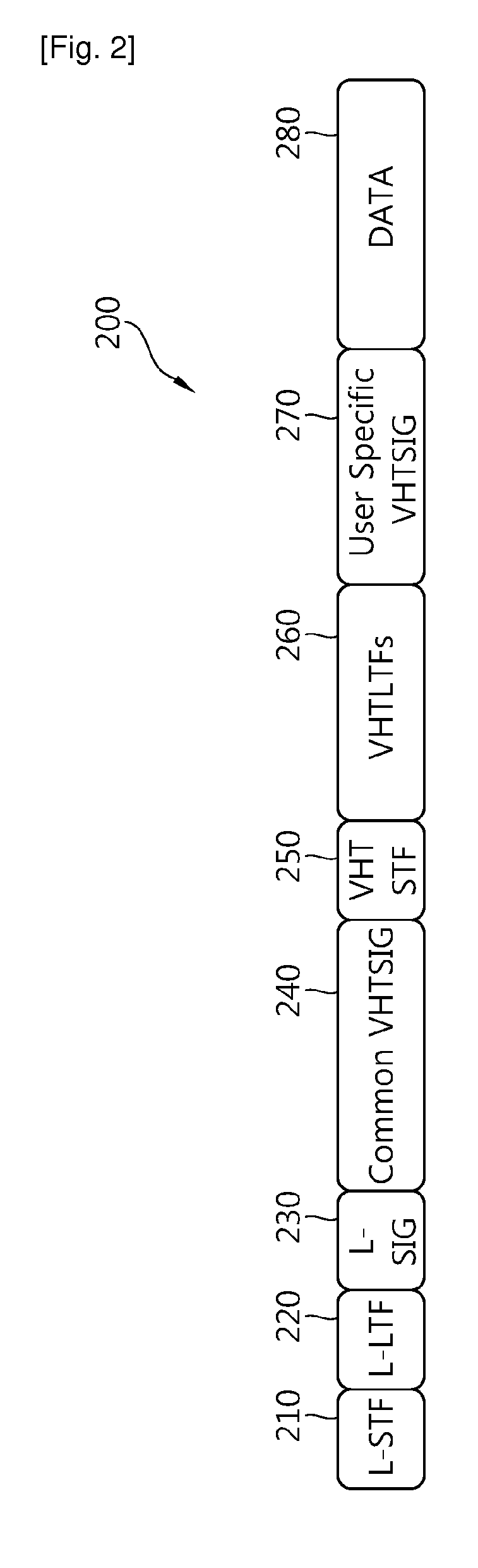

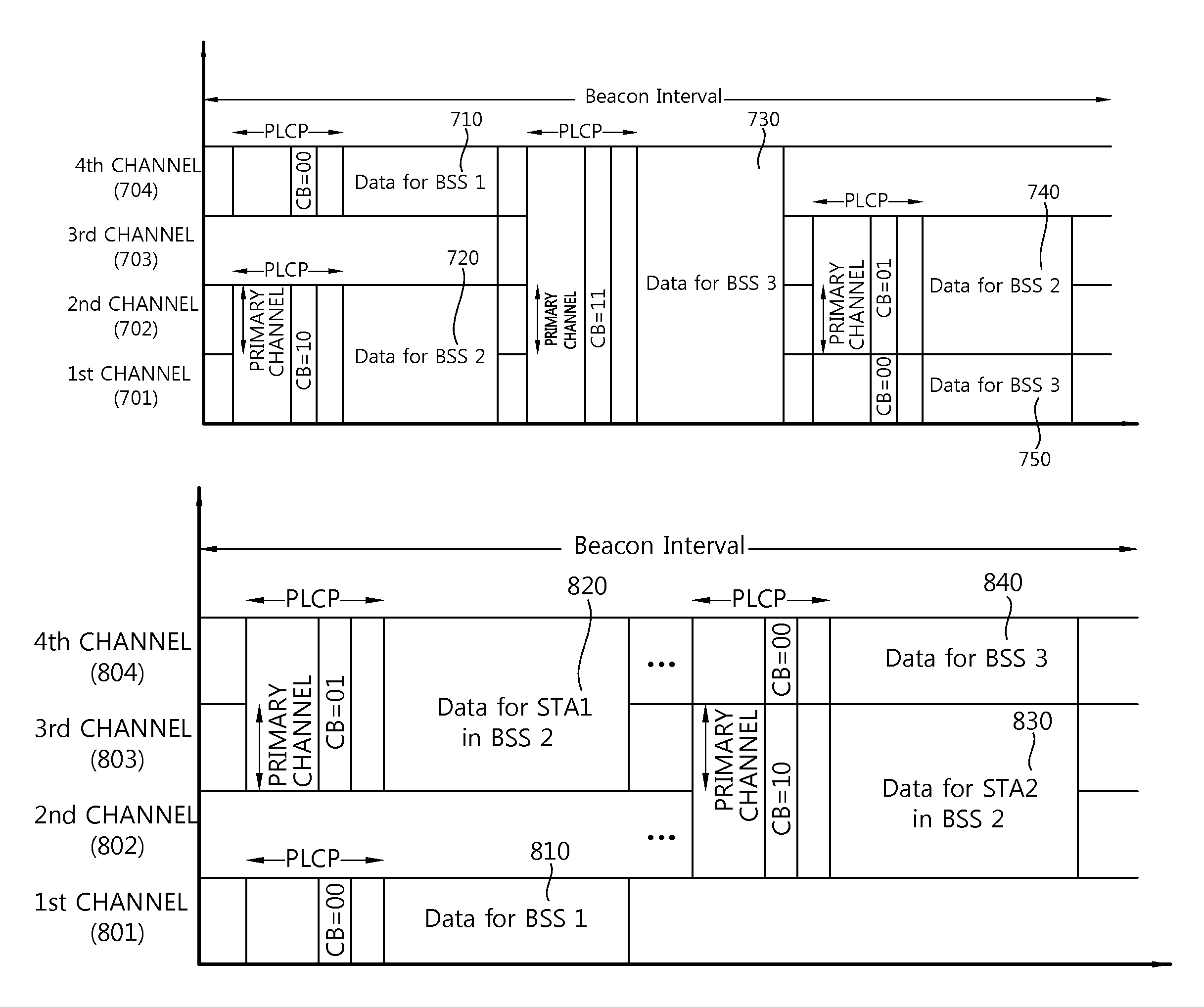

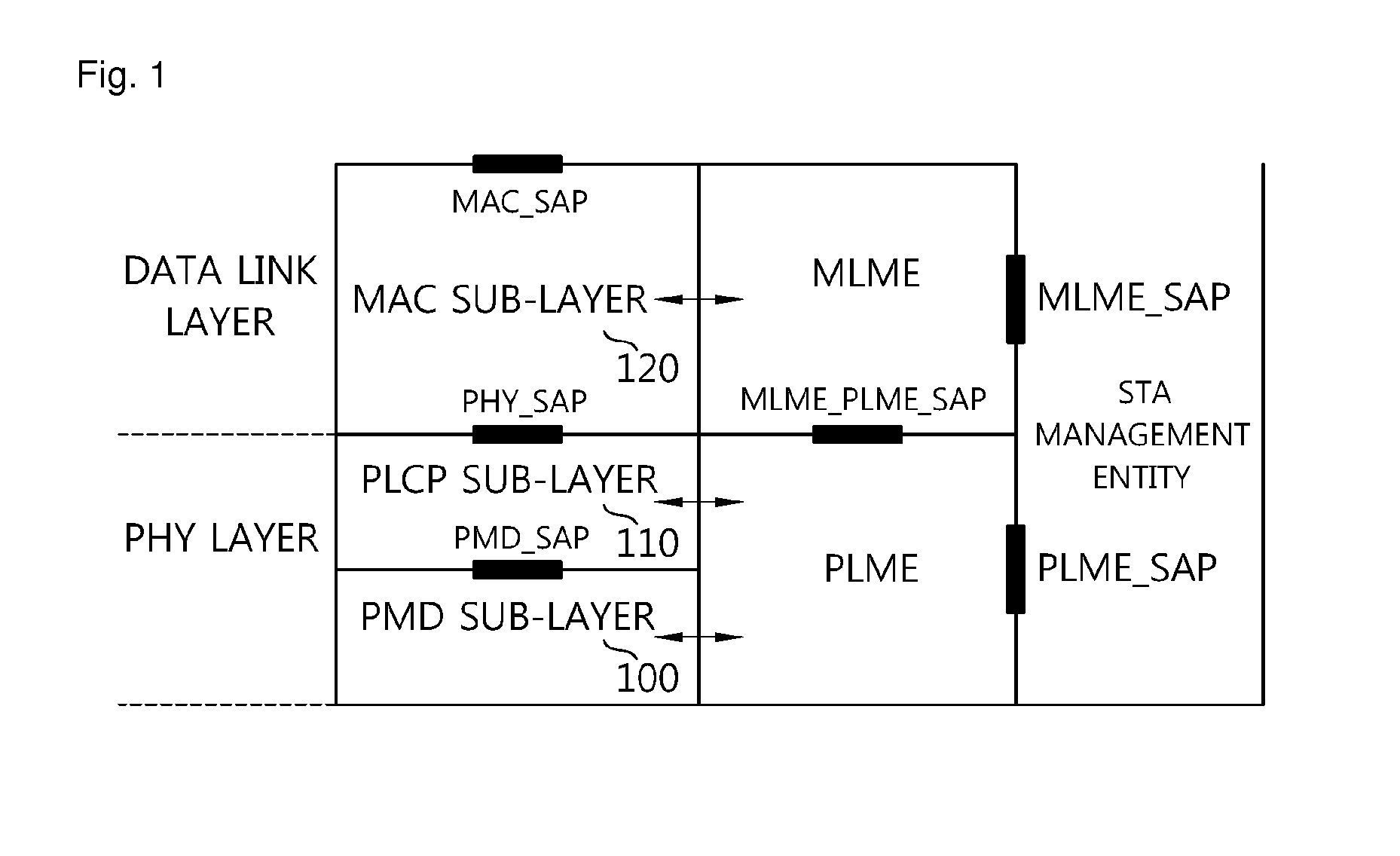

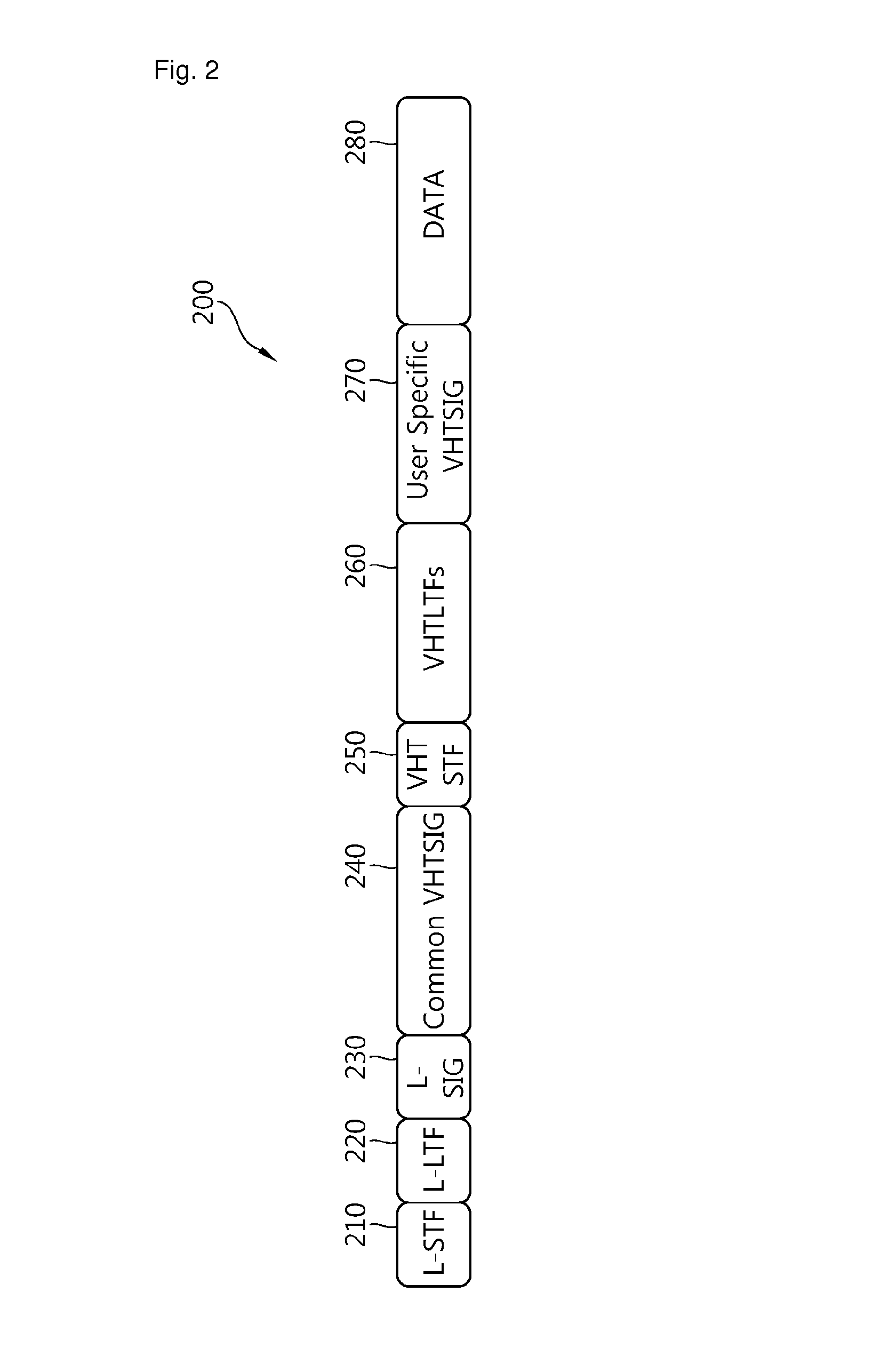

Method and apparatus for allocating transmission channel in wireless local area network system

ActiveUS20120314673A1Small transmission powerImprove system throughputNetwork traffic/resource managementTransmission path divisionTelecommunicationsTransmission channel

A method of allocating a channel in a wireless local area network (WLAN) system is provided. The method includes generating a MAC protocol data unit (MPDU) to be transmitted to a target station (STA), generating a PLCP protocol data unit (PPDU) by attaching a physical layer convergence procedure (PLCP) header to the MPDU, and transmitting the PPDU to the STA, wherein the PLCP header includes channel allocation information for transmission of the PPDU.

Owner:LG ELECTRONICS INC

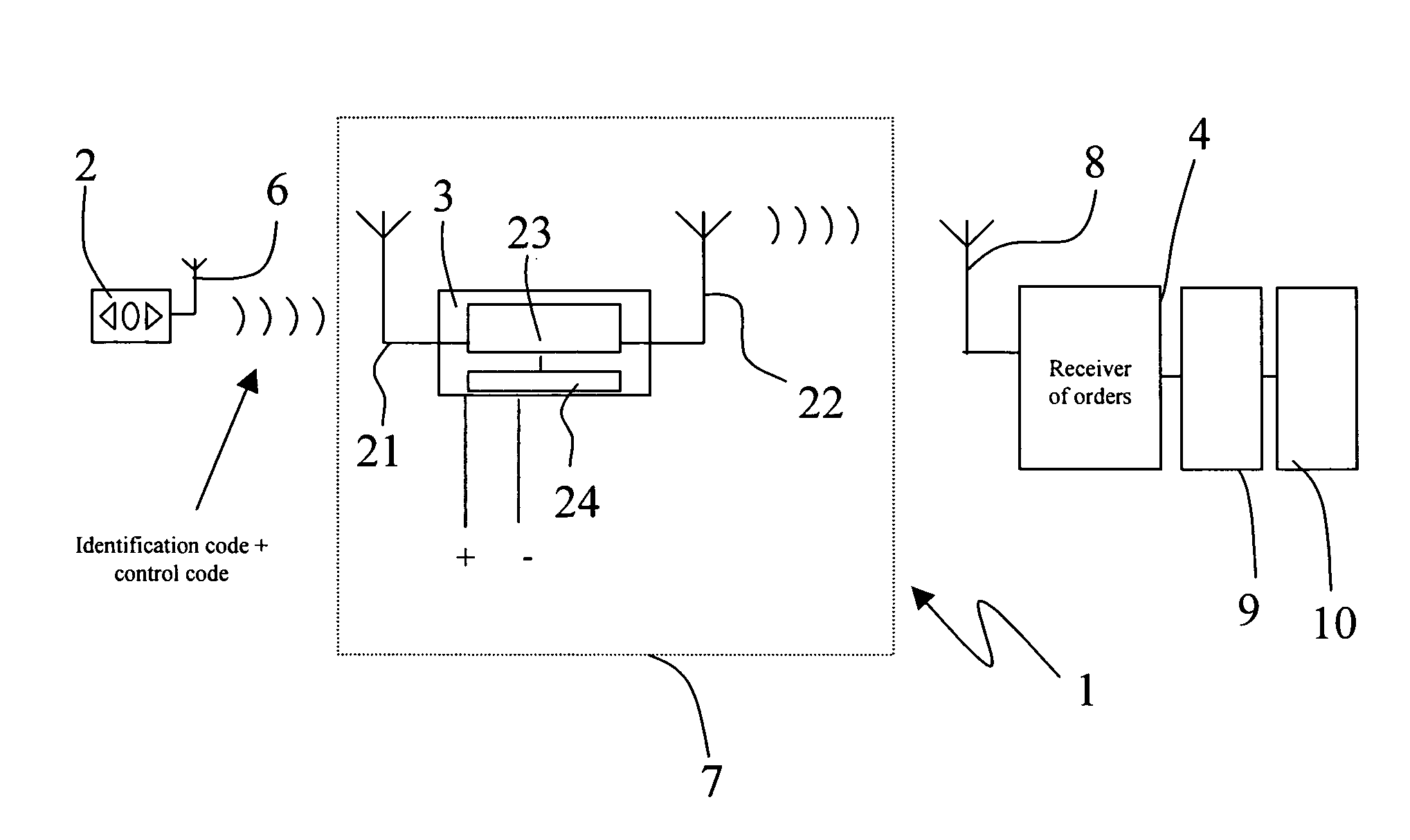

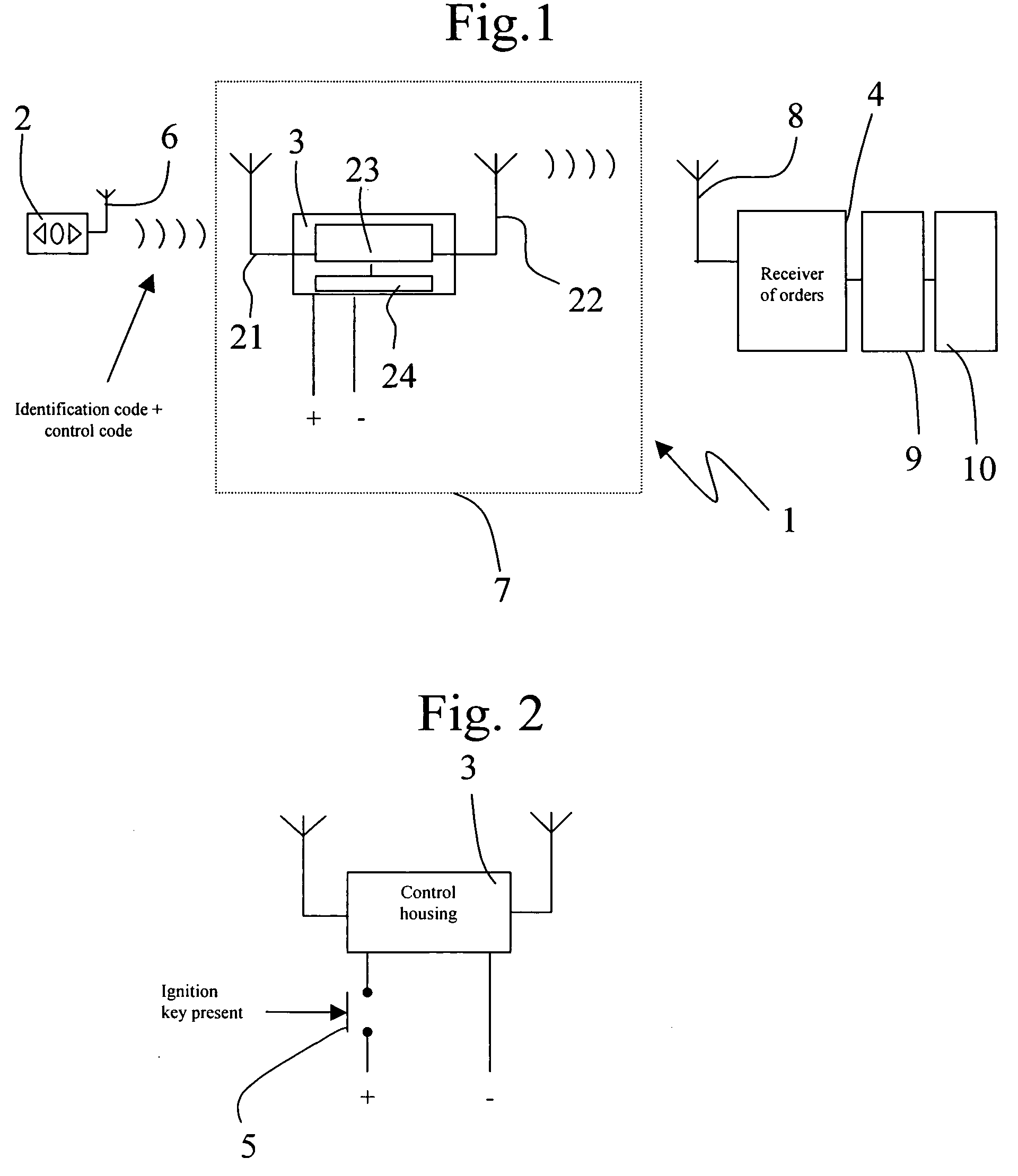

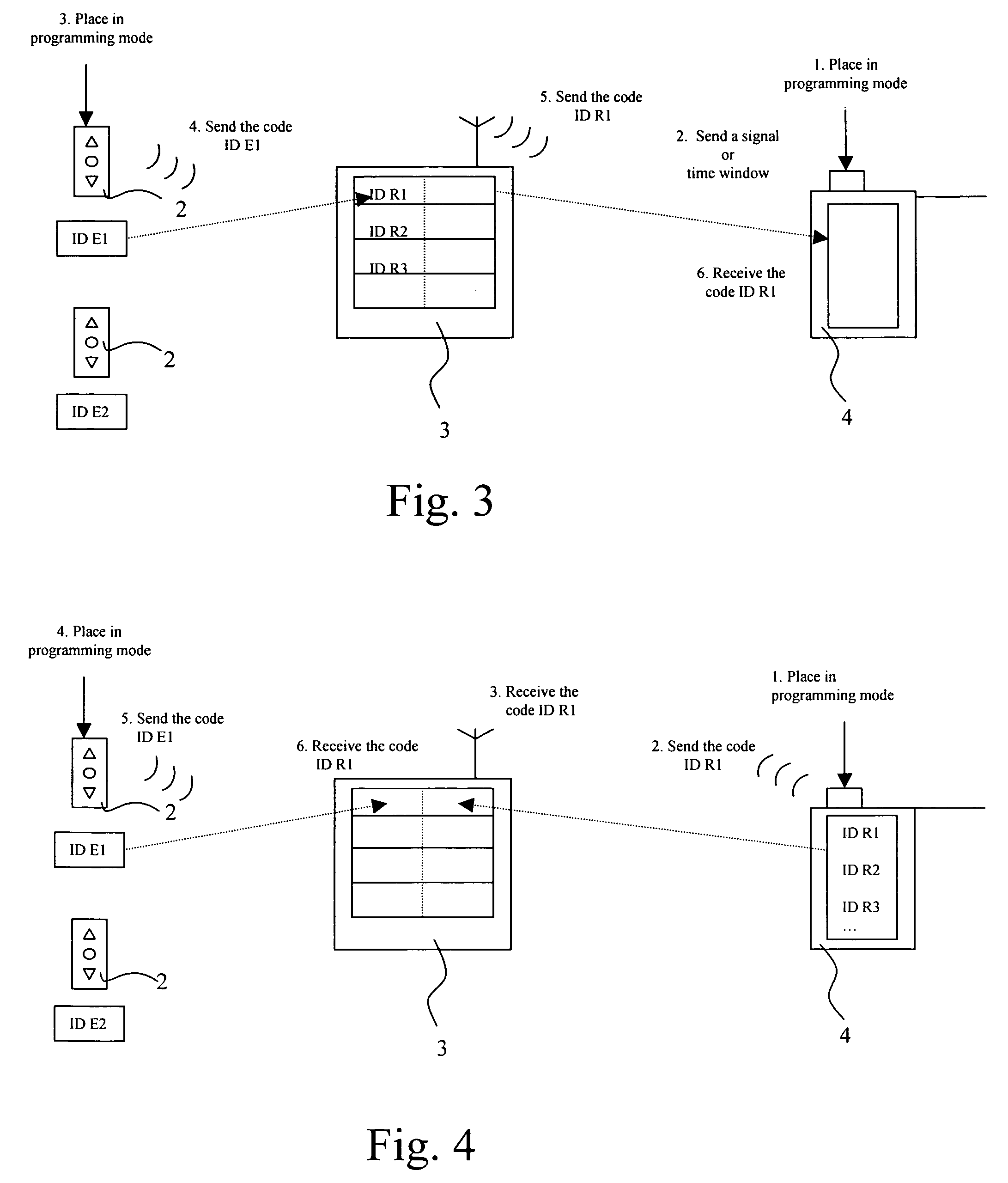

Process for remote communication between a command transmitter and a command receiver

InactiveUS7142849B2Improve anti-theft security performanceSmall rangeElectric signal transmission systemsDigital data processing detailsEngineeringRemote communication

A system for activating an object actuating system coupled to a movable object such as a gate or garage door includes a user command transmitter that is manipulable by a person to generate a signal representing an identification and a command. A repeater receives the signals from the command transmitter and in turn, in the presence of a valid ID, sends a command signal to the object actuating system, which in turn moves the object only if the ID from the repeater (which can be different from the ID from the command transmitter) is valid.

Owner:SOMFY SAS

Method and apparatus for allocating transmission channel in wireless local area network system

ActiveUS8625562B2Improve system throughputReliable dataNetwork traffic/resource managementTransmission path divisionTelecommunicationsTransmission channel

A method of allocating a channel in a wireless local area network (WLAN) system is provided. The method includes generating a MAC protocol data unit (MPDU) to be transmitted to a target station (STA), generating a PLCP protocol data unit (PPDU) by attaching a physical layer convergence procedure (PLCP) header to the MPDU, and transmitting the PPDU to the STA, wherein the PLCP header includes channel allocation information for transmission of the PPDU.

Owner:LG ELECTRONICS INC

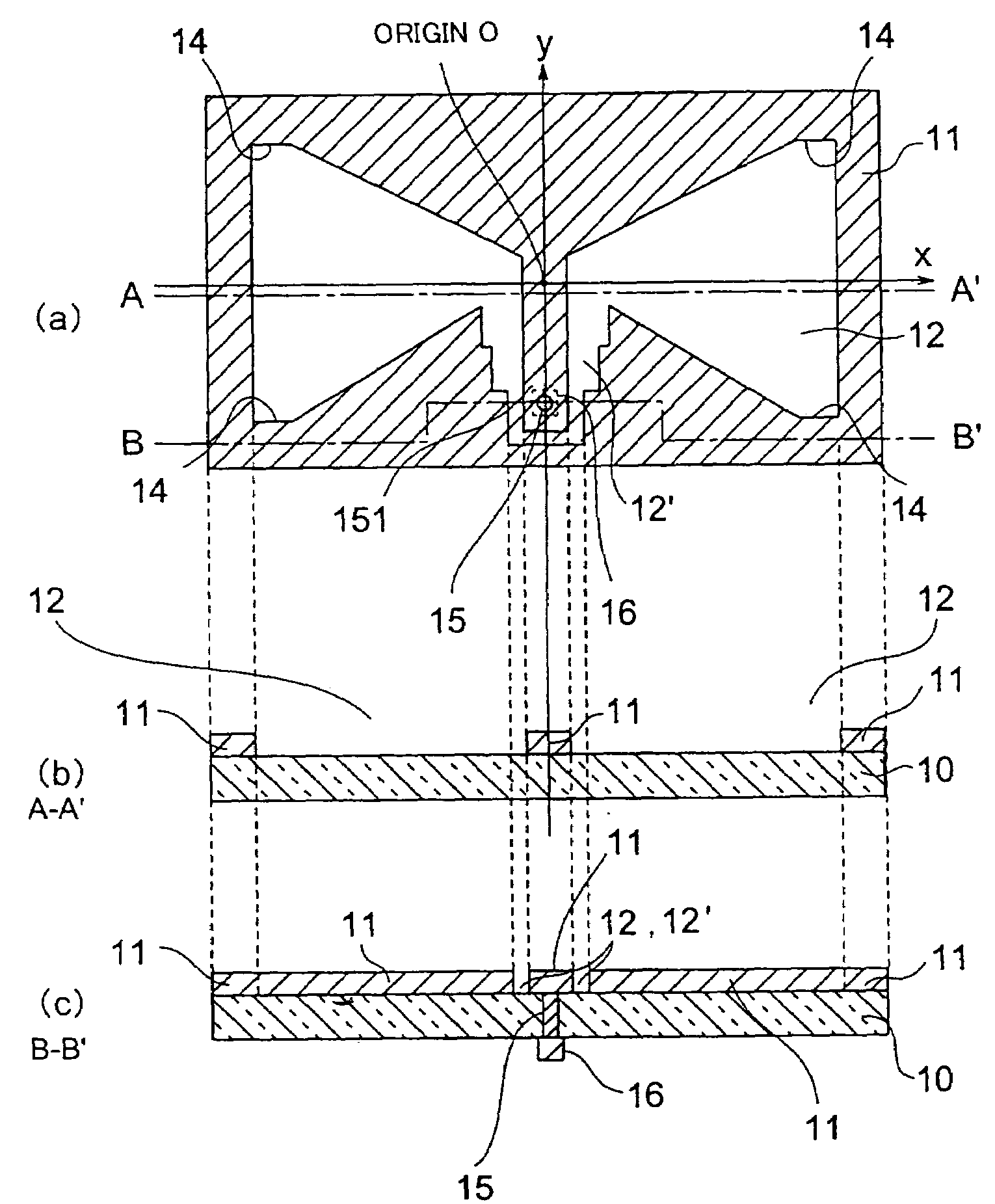

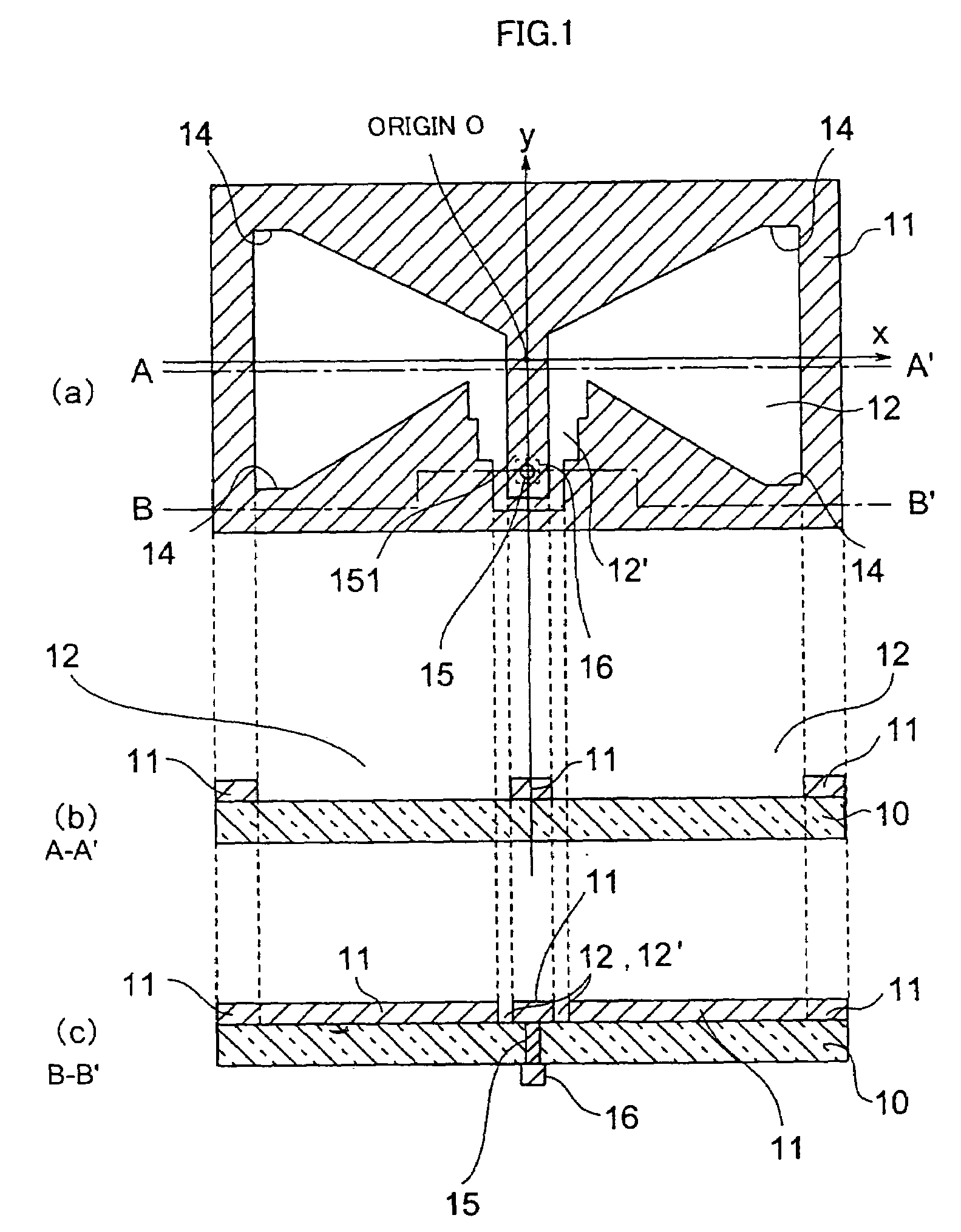

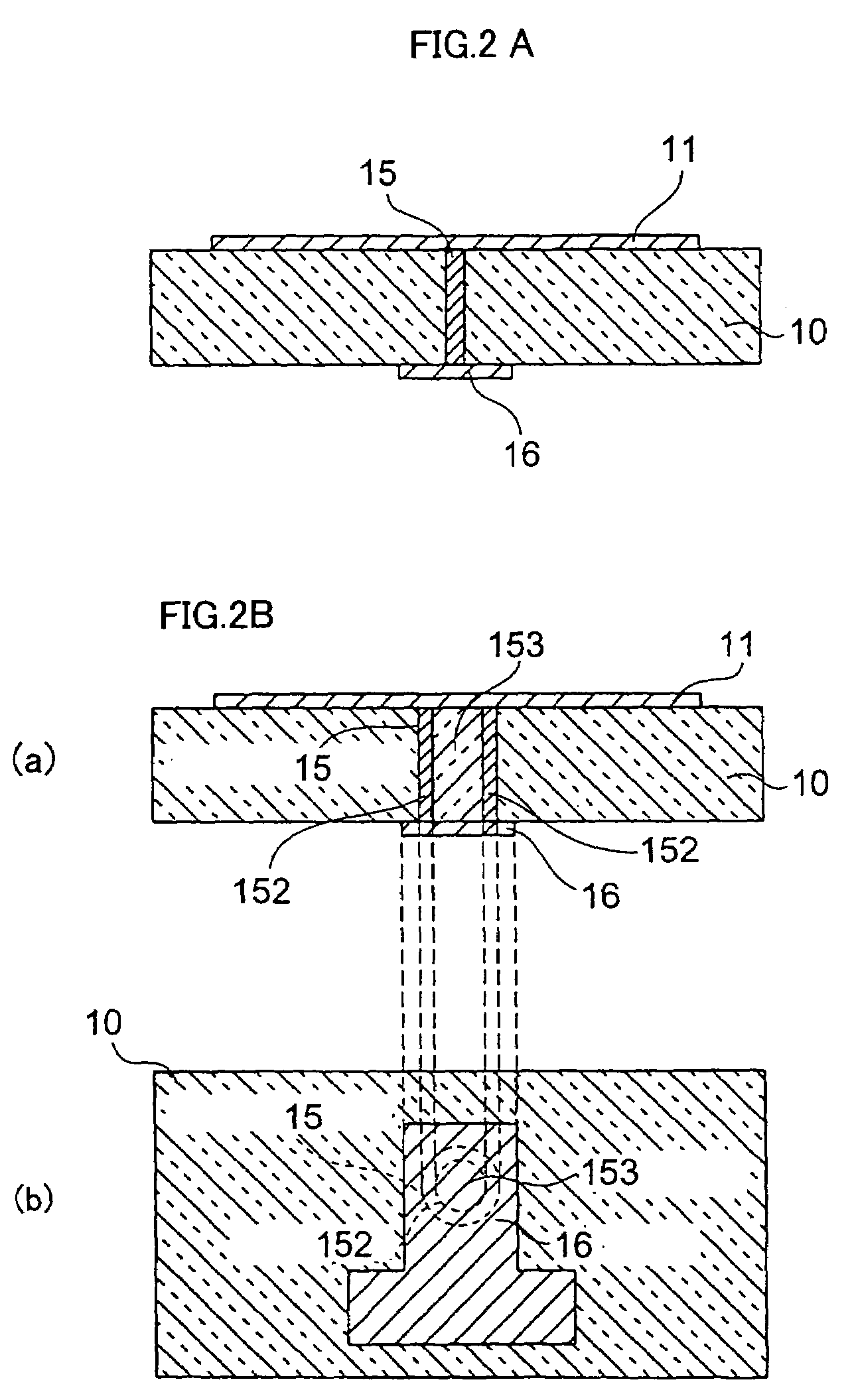

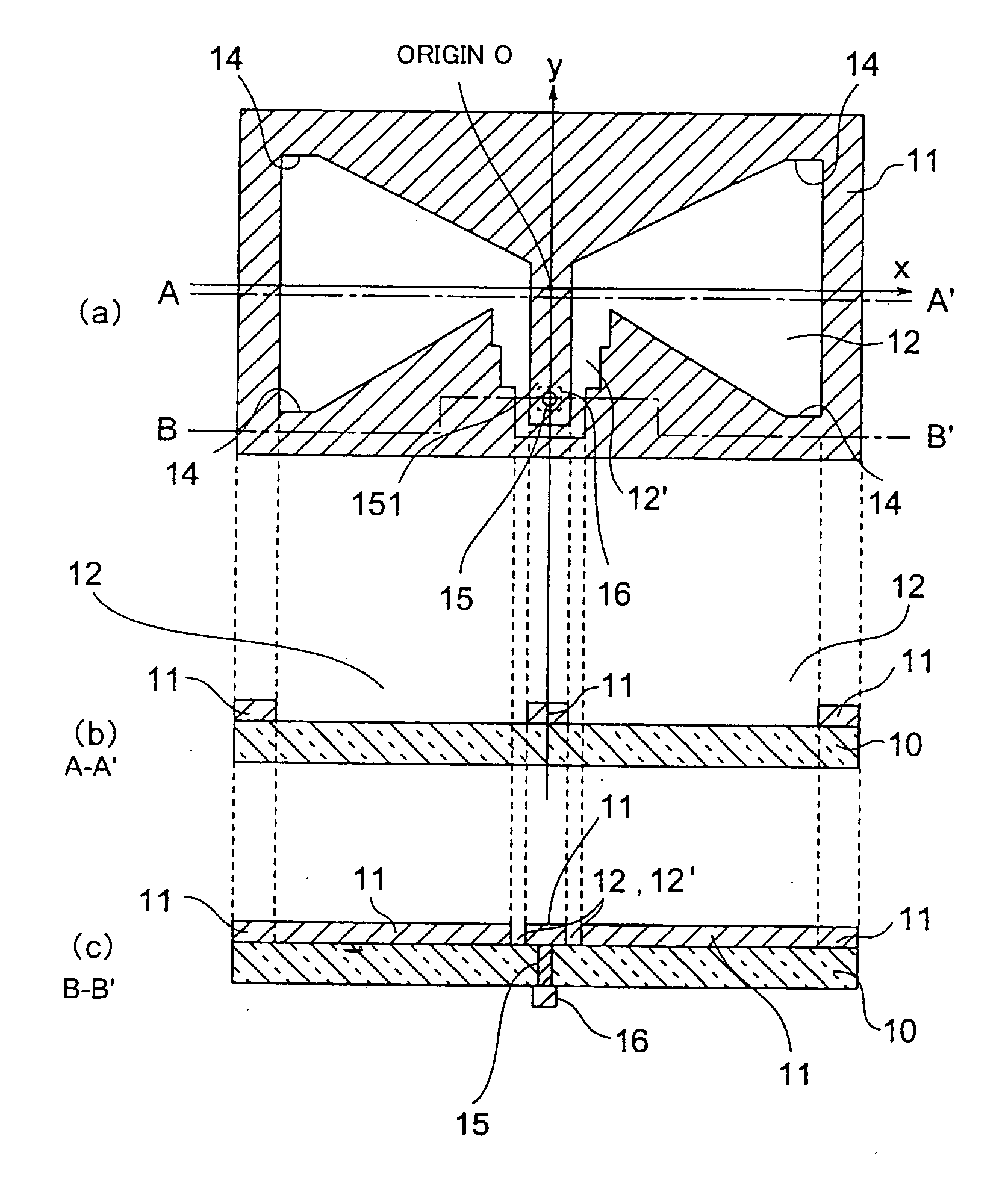

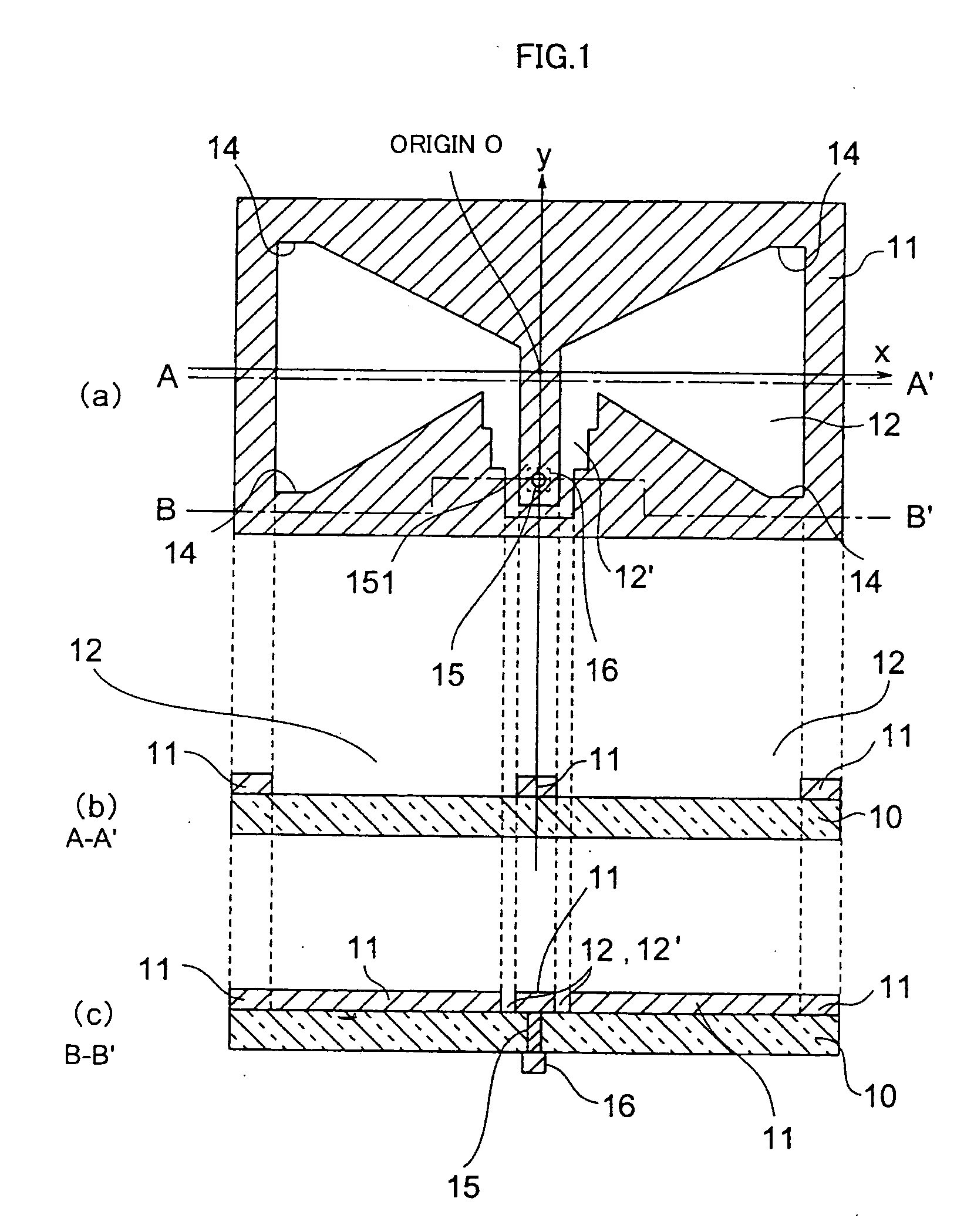

Ultra wideband bow-tie slot antenna

InactiveUS7193576B2Small shapeLight weightAntenna arraysSimultaneous aerial operationsUltra-widebandWide band

A slot antenna includes an insulation substrate, a metal layer provided on the insulation substrate, a slot formed in the metal layer, and a feeding part connected to the metal layer. The slot is symmetric with respect to a centerline. When an x-y coordinate system is defined on the metal layer so that the y-axis is the symmetric line, the origin is the center of the slot antenna, and the x-axis through the origin is perpendicular to the y-axis, the width of the slot in the direction of the y-axis increasing in proportion to the absolute value of the x-axis.

Owner:NAT INST OF INFORMATION & COMM TECH

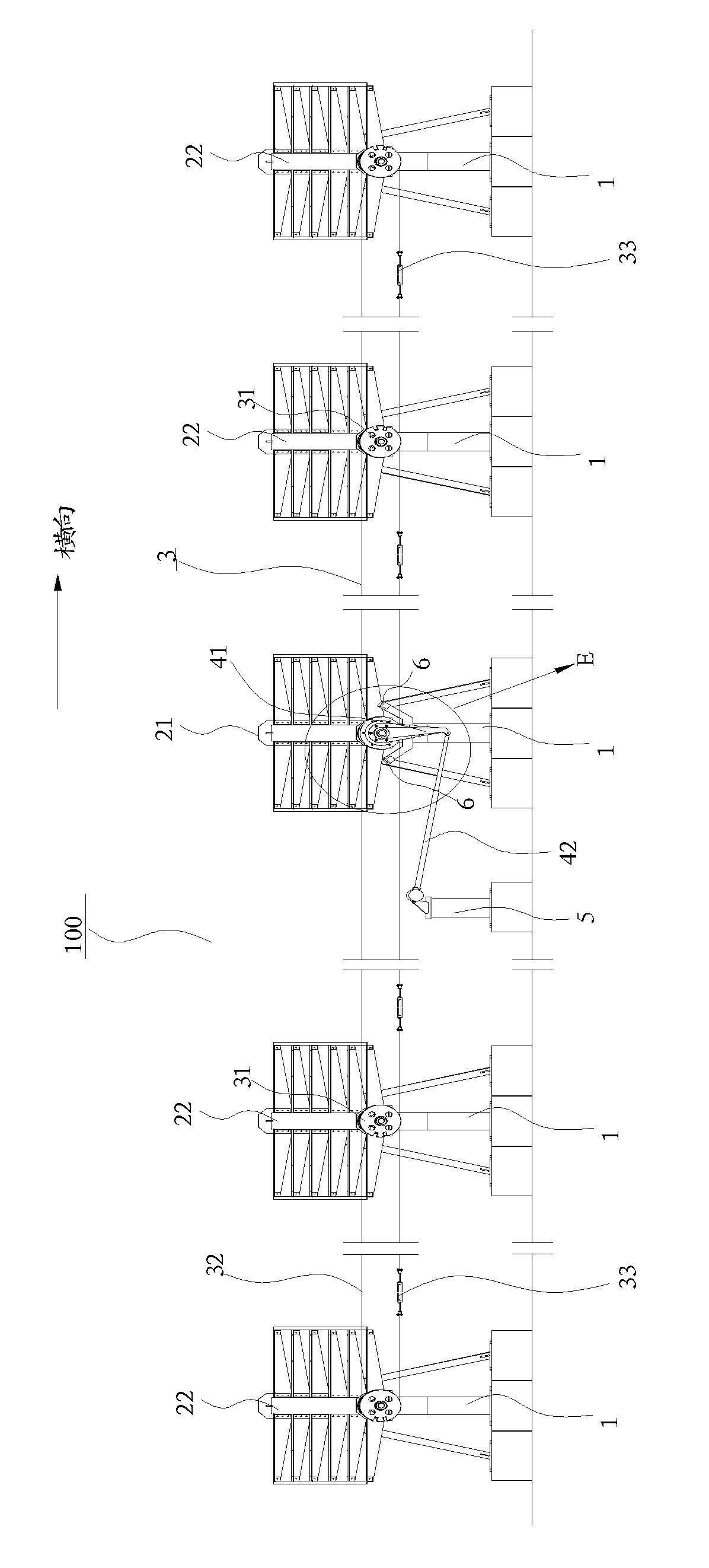

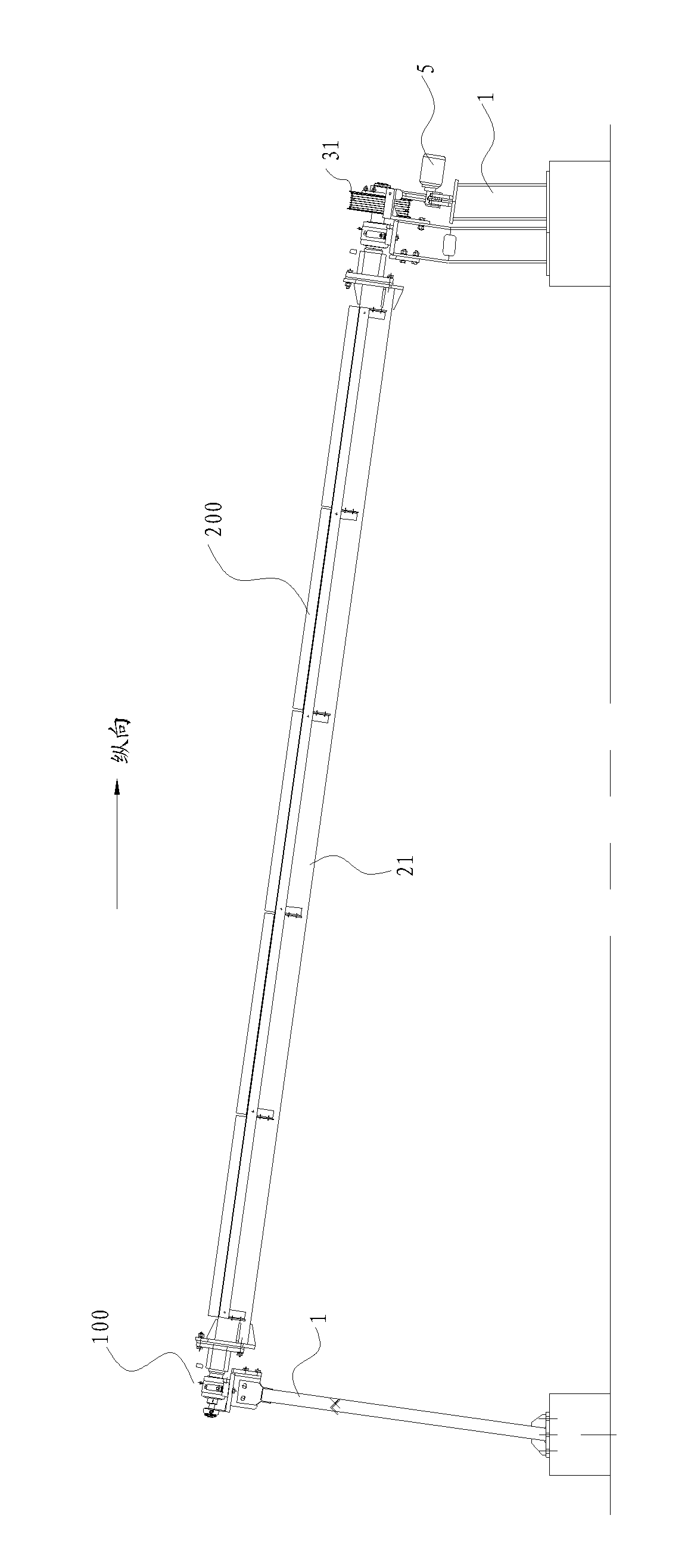

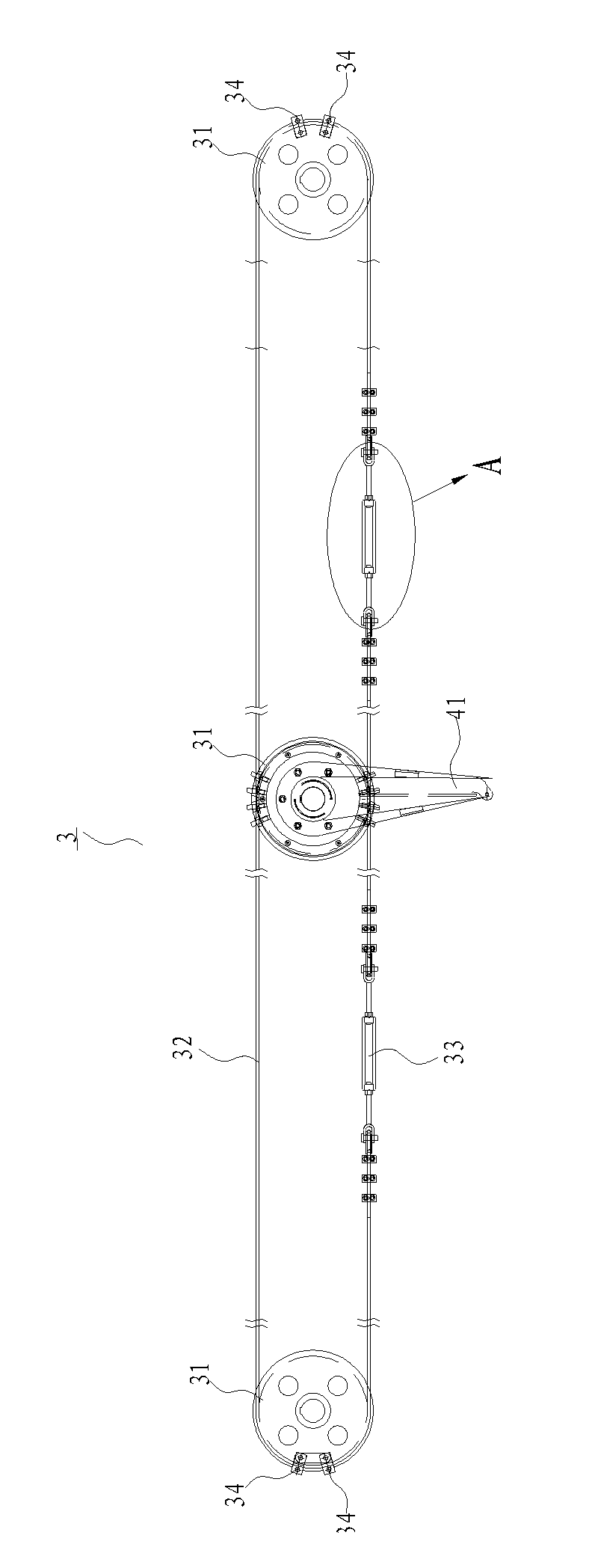

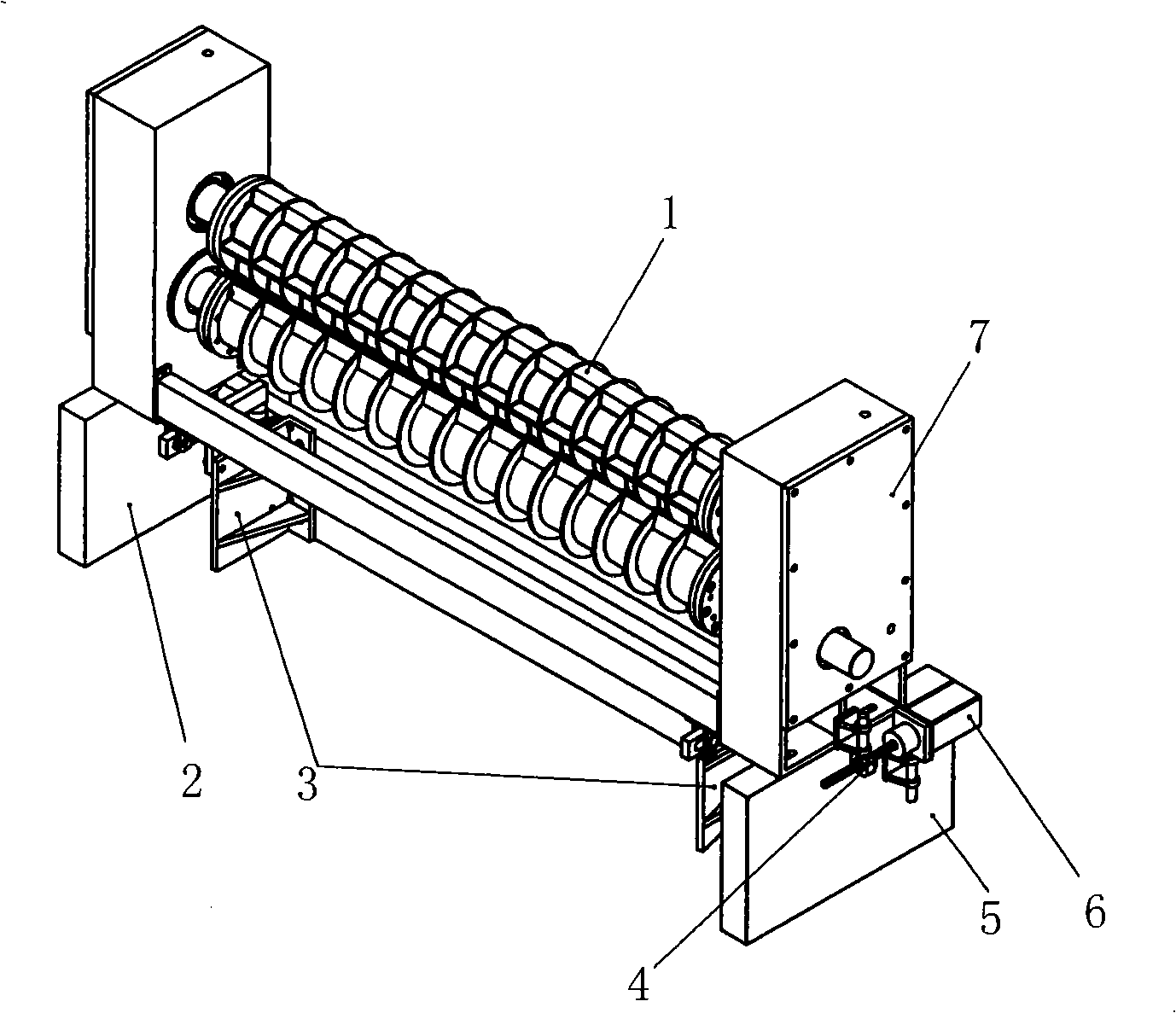

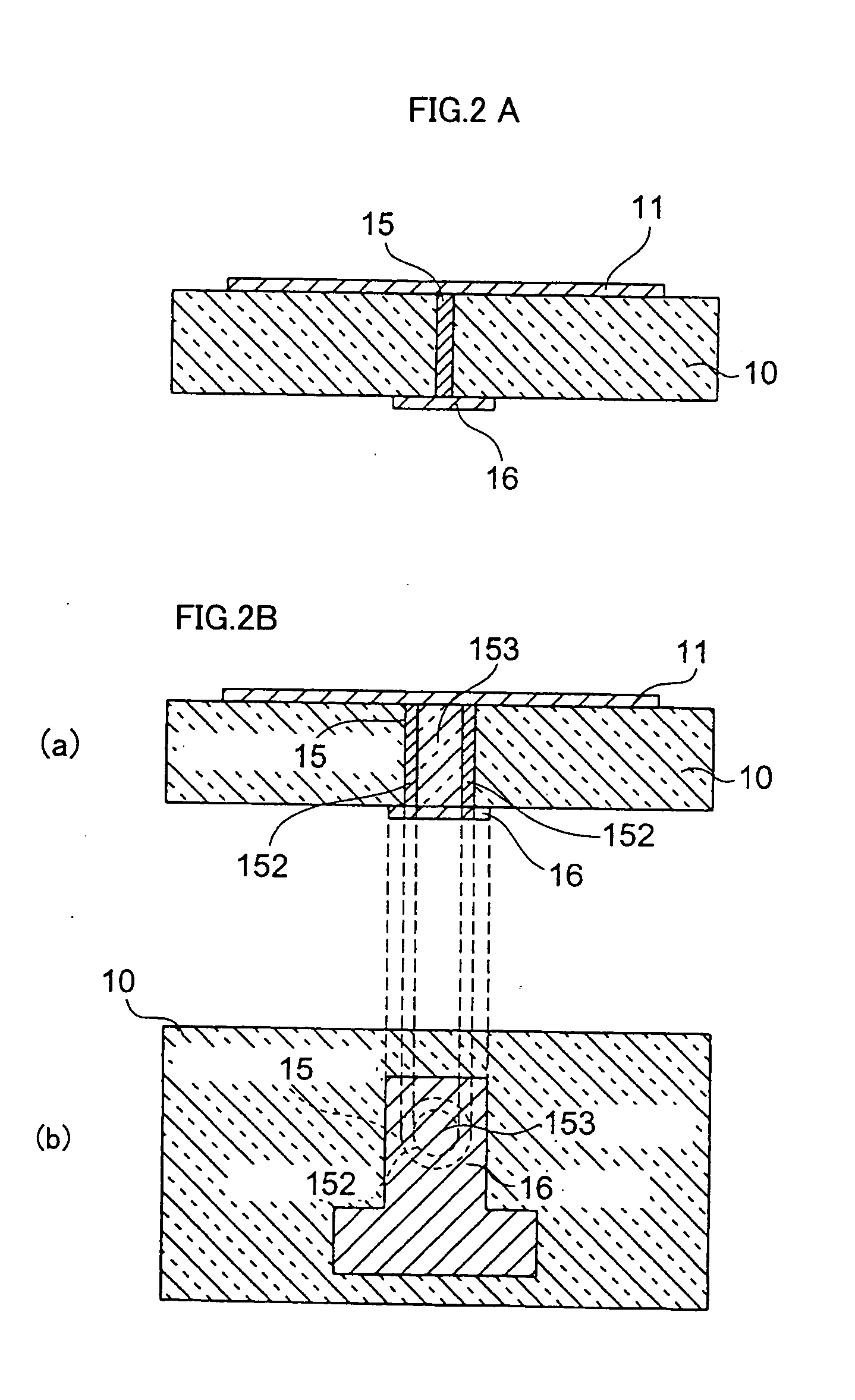

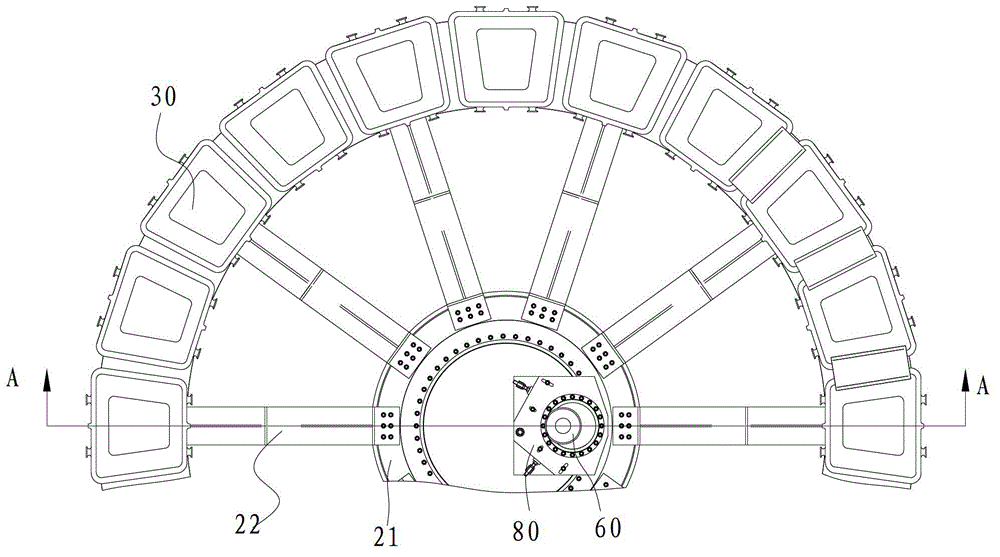

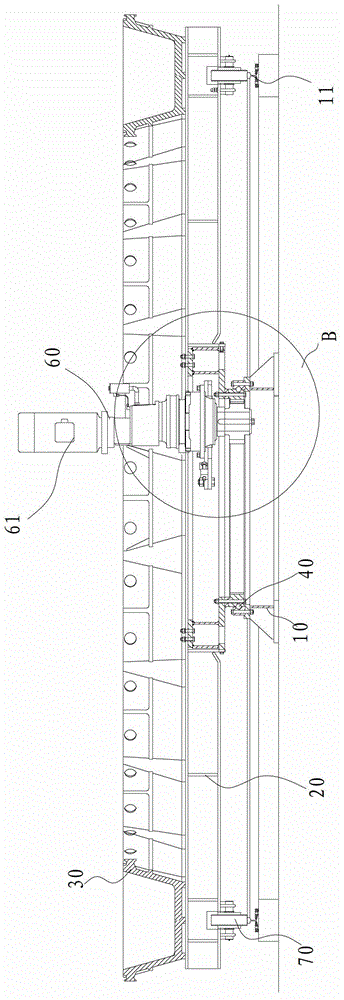

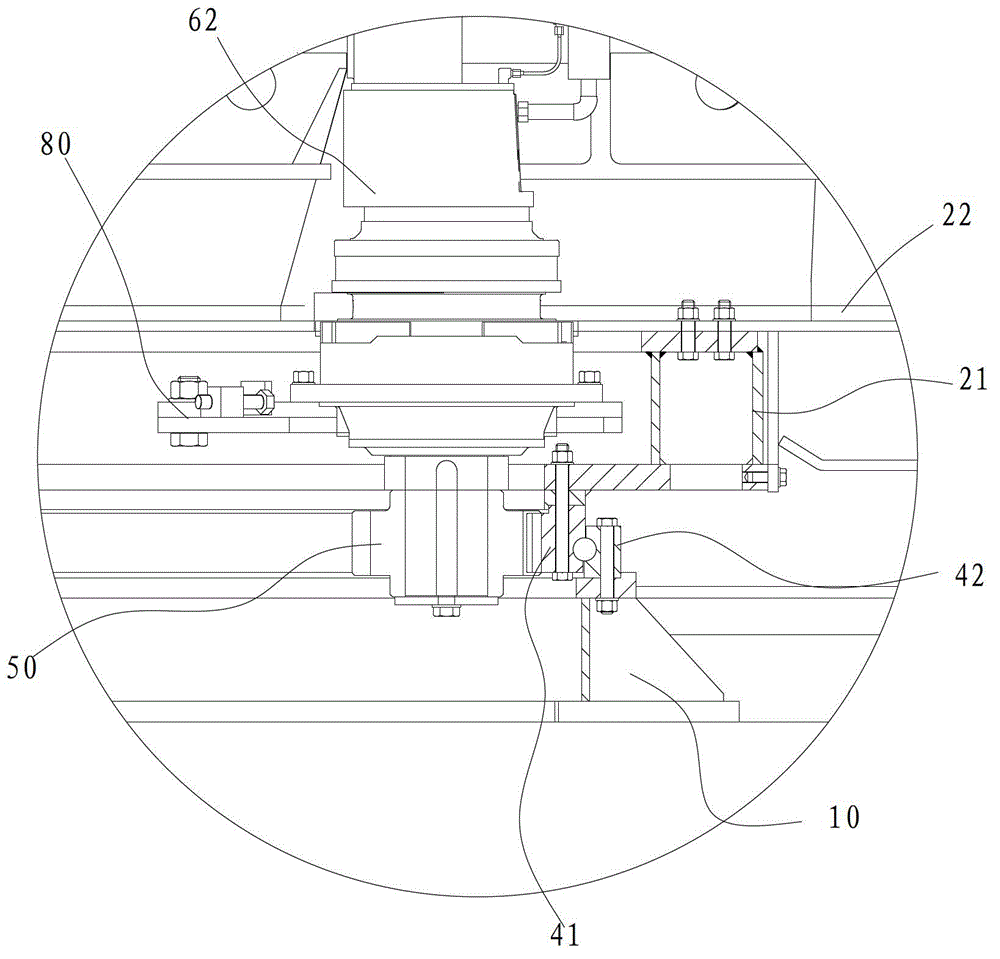

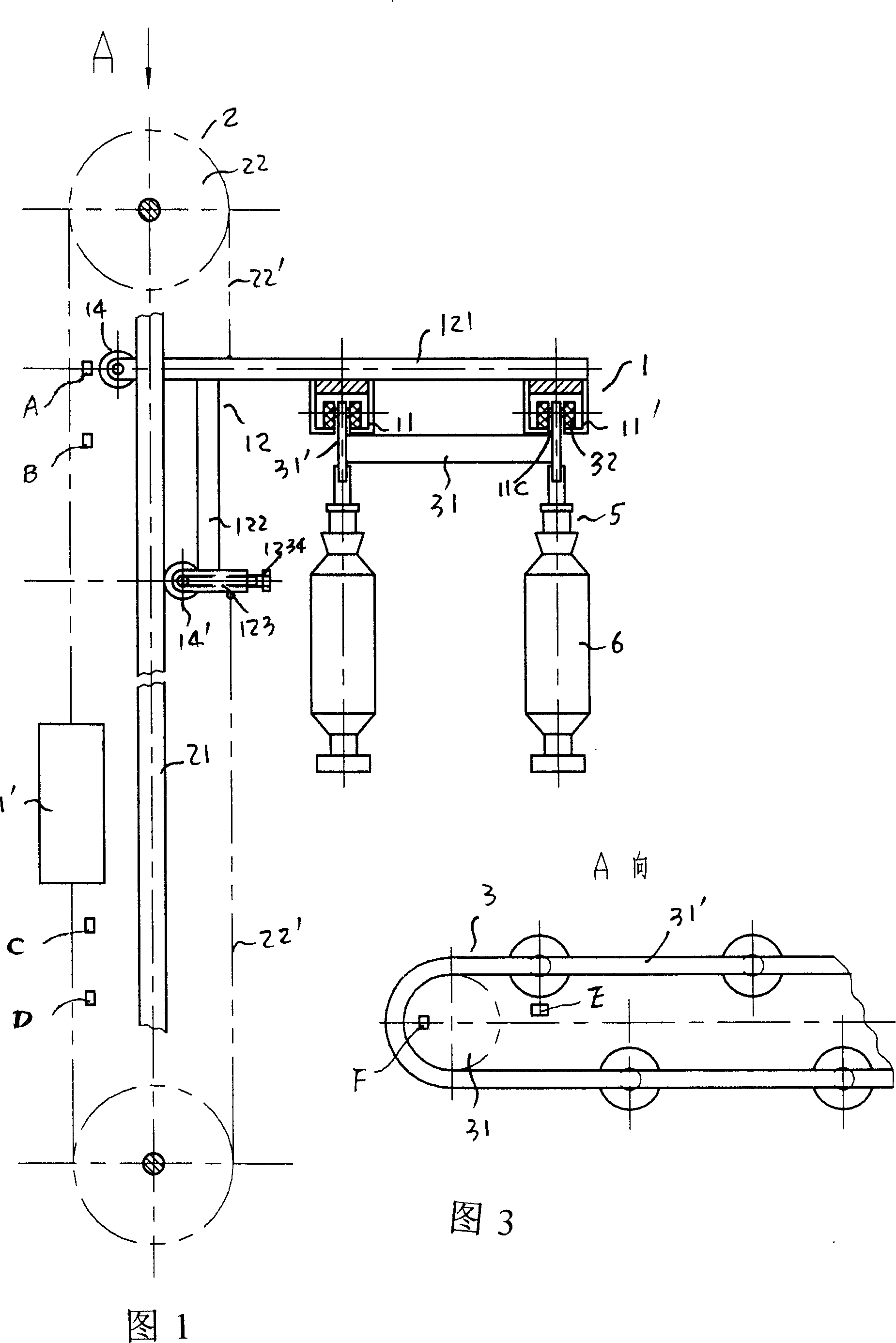

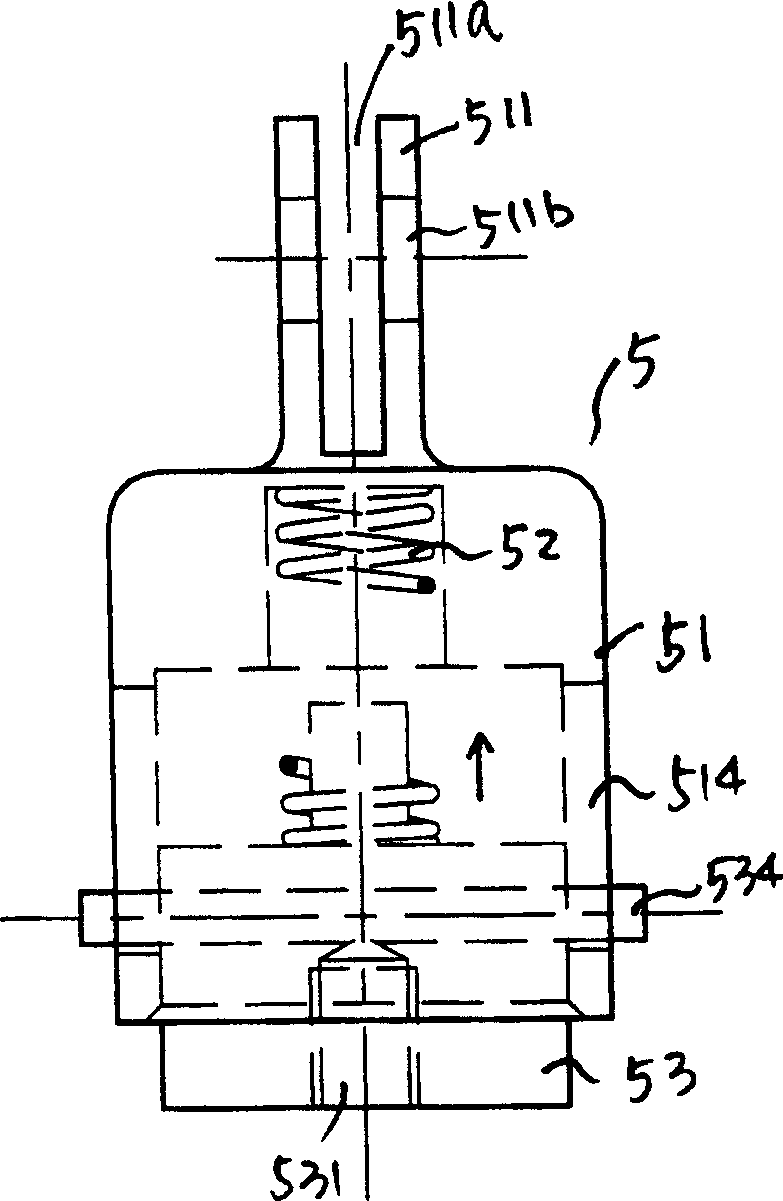

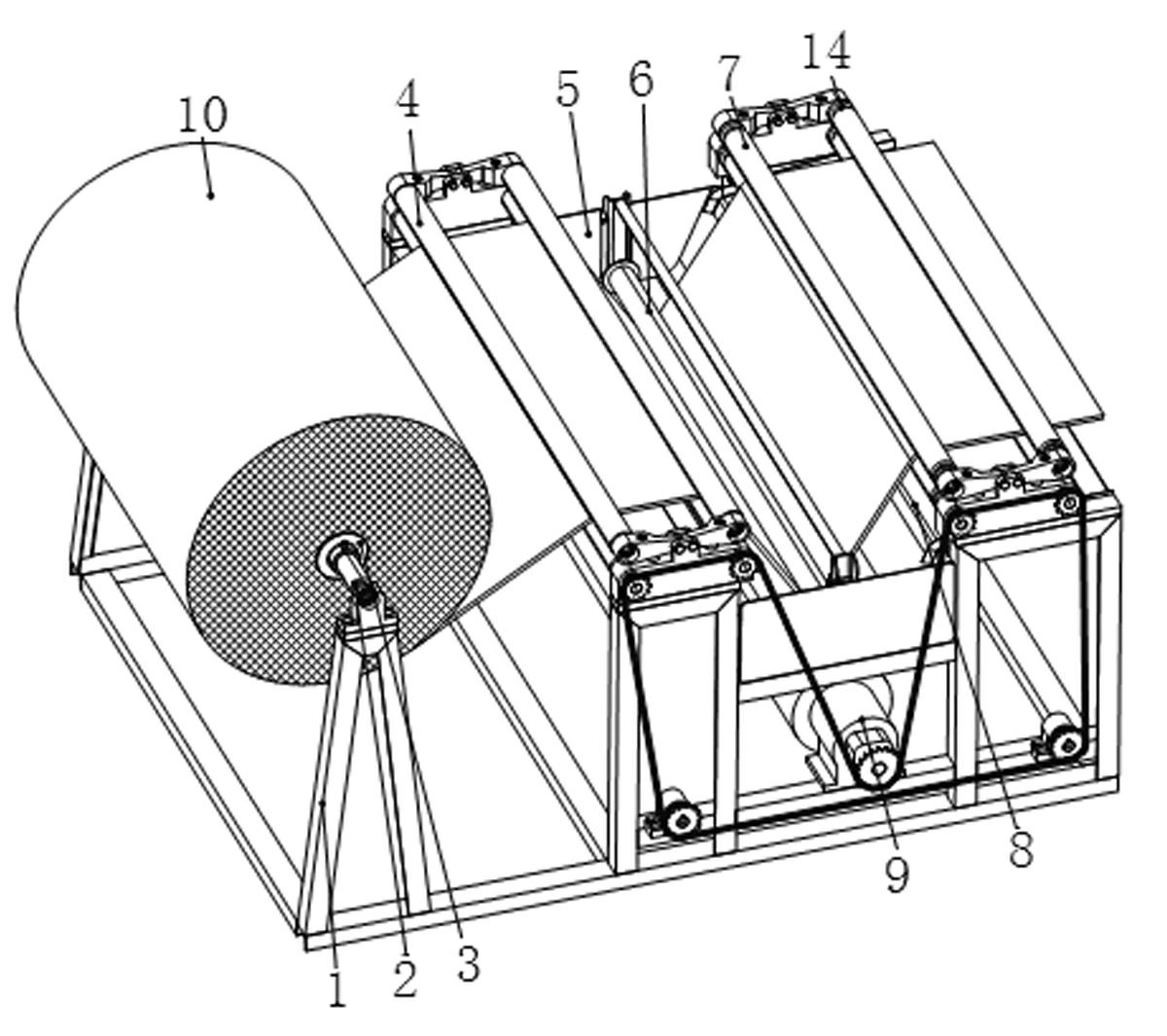

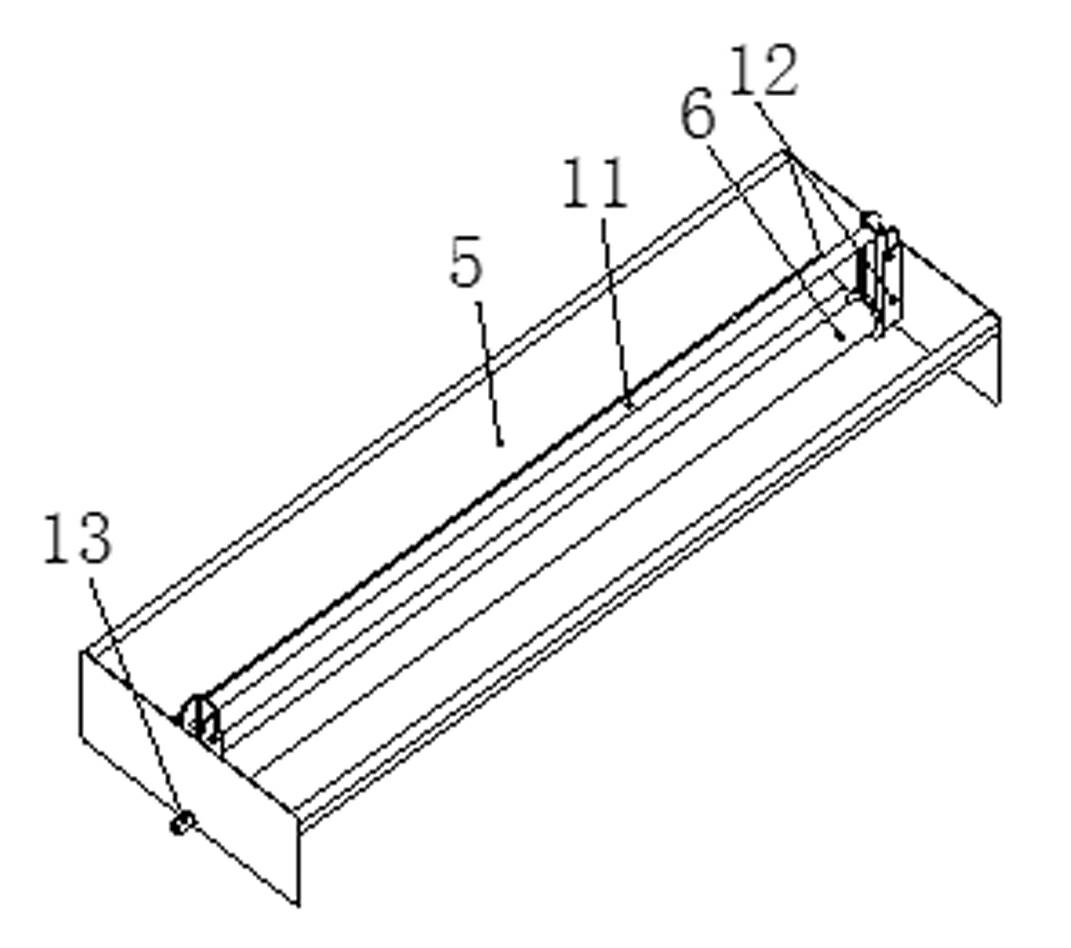

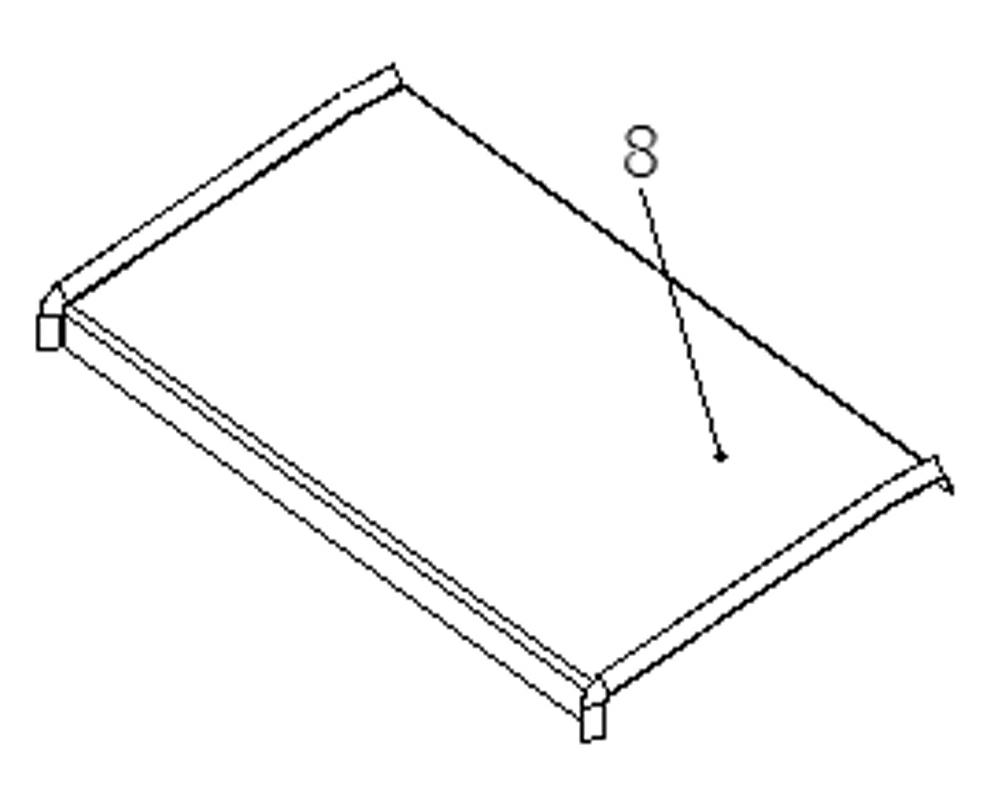

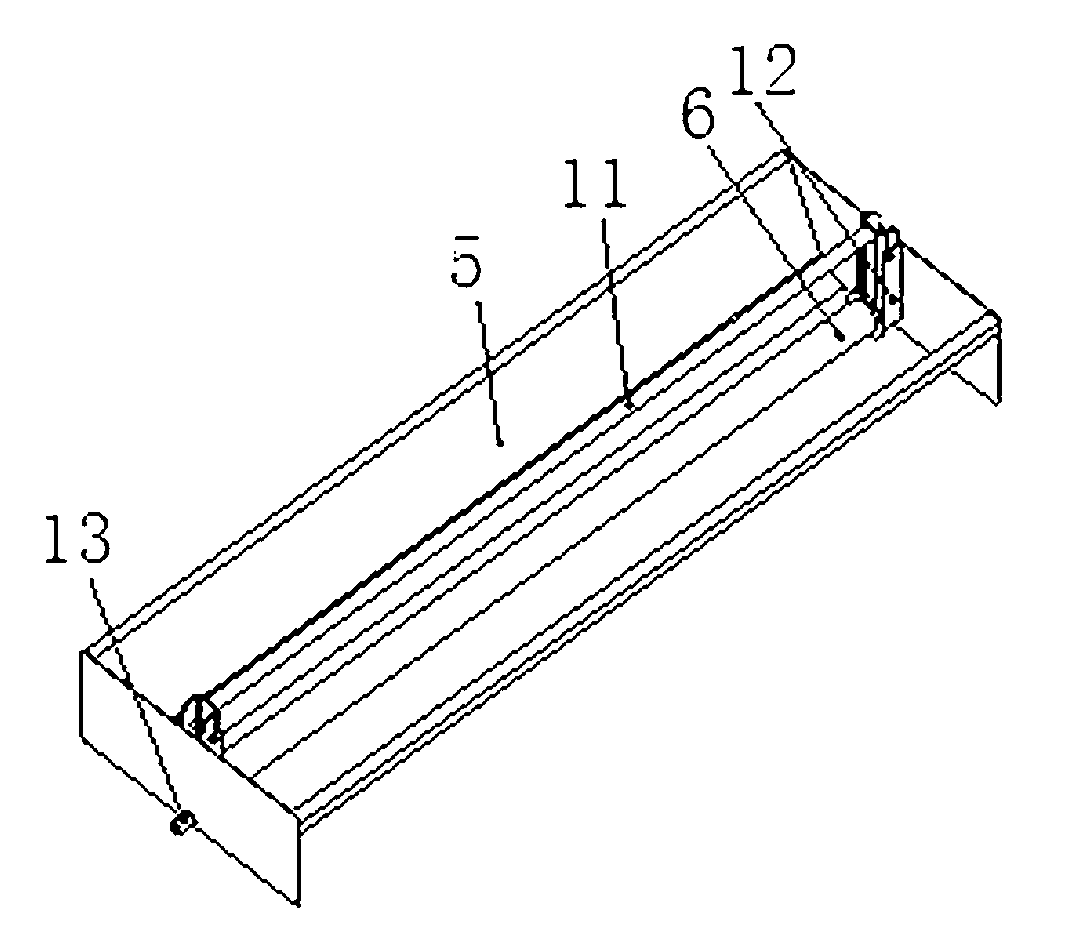

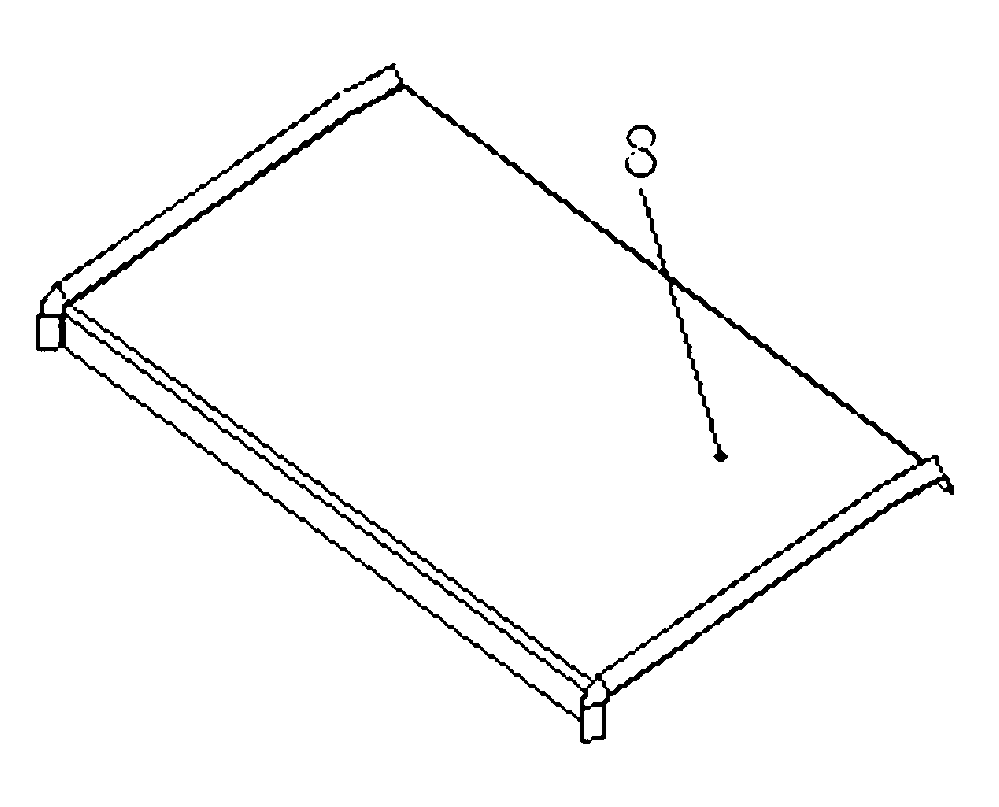

Solar cell assembly and bearing device therefor

ActiveCN102142474AEfficient conversionSmall transmission powerPhotovoltaic supportsControl using feedbackEngineeringSolar cell

The invention discloses a bearing device for a solar cell assembly. The bearing device comprises a plurality of supports, a plurality of rotating brackets and a driving mechanism, wherein the plurality of supports are arranged at intervals; the plurality of rotating brackets for supporting a solar cell panel are rotationally supported on the plurality of supports respectively and comprise drivingrotating brackets and driven rotating brackets, and the two adjacent rotating brackets are connected through a flexible linkage mechanism so that the plurality of rotating brackets rotate synchronously; and the driving mechanism is connected with the driving rotating brackets to drive the driving rotating brackets to rotate. According to the embodiment, the flexible linkage mechanisms are linked with the plurality of rotating brackets to rotate synchronously, so that the bearing device for the solar cell assembly has low transmission power, light weight, low cost and low installation precision requirement. The invention also discloses the solar cell assembly adopting the bearing device.

Owner:CHINA ENFI ENGINEERING CORPORATION

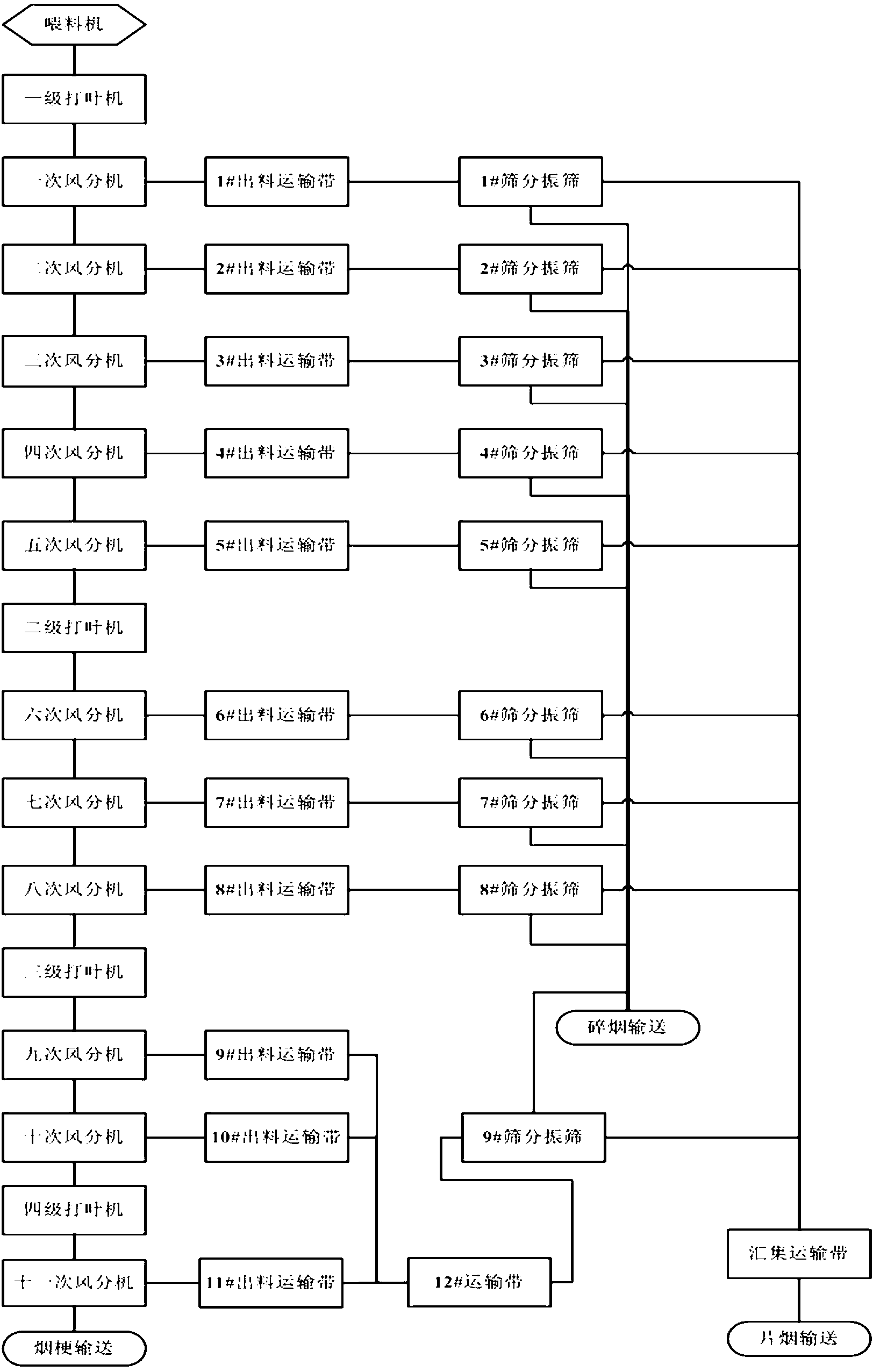

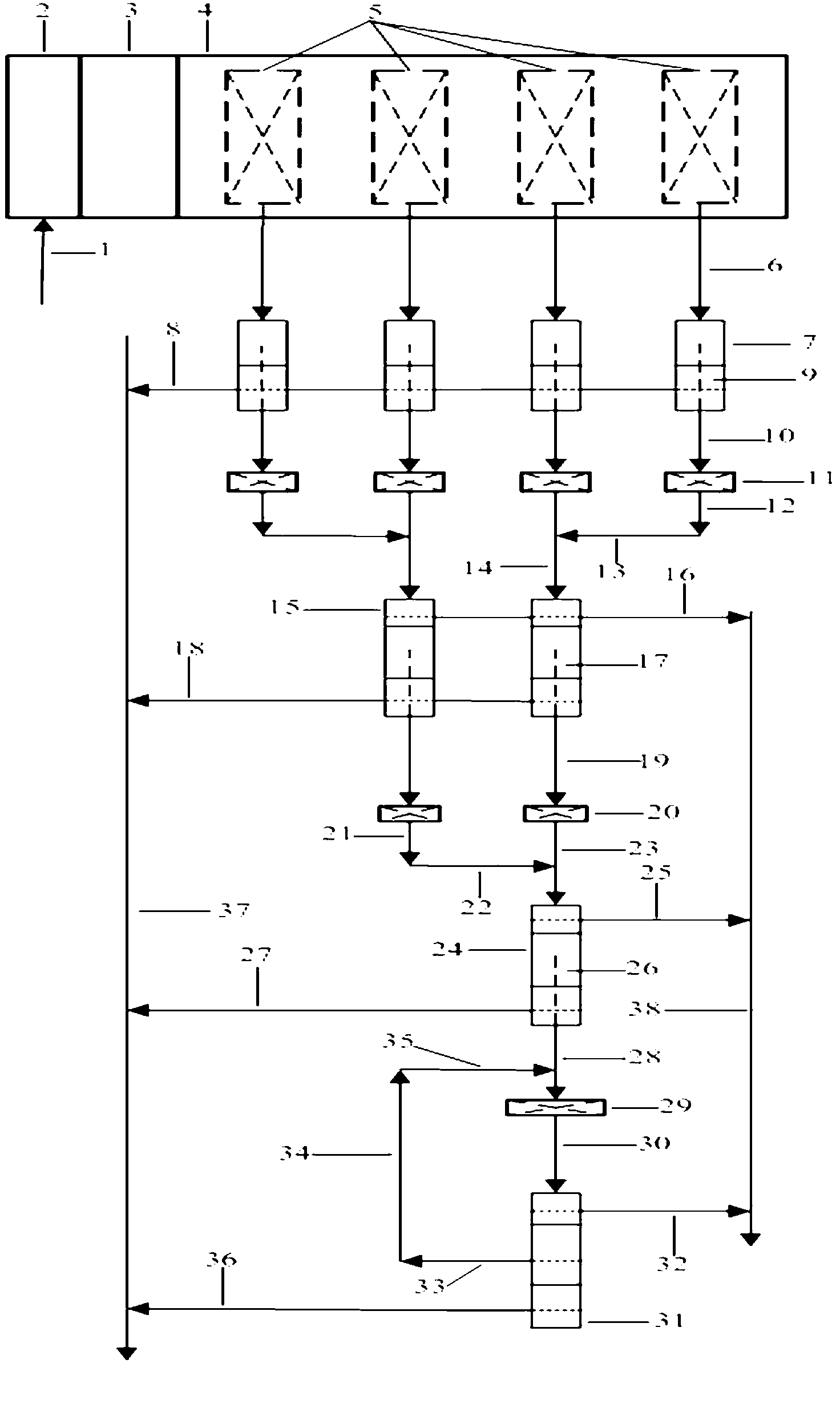

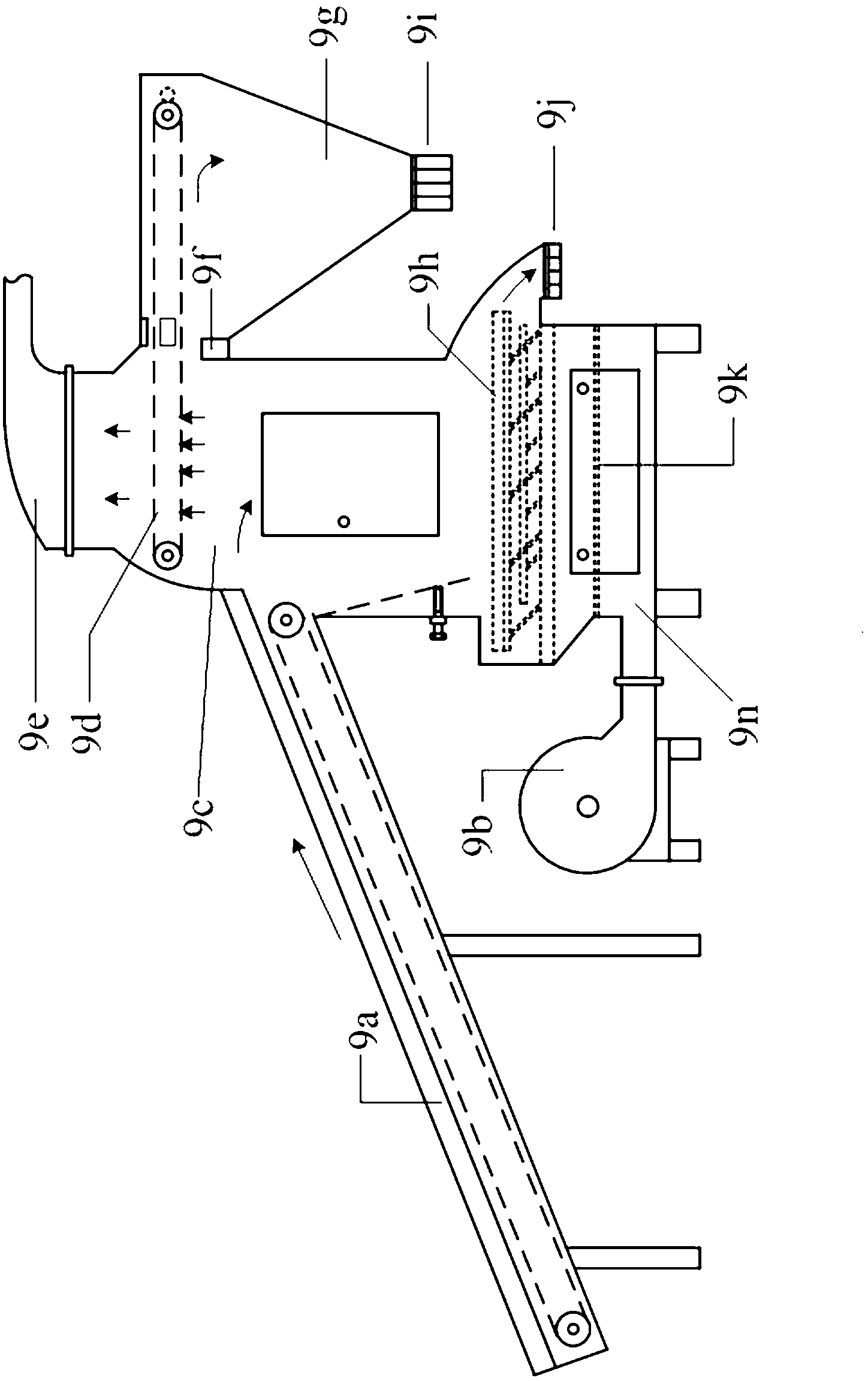

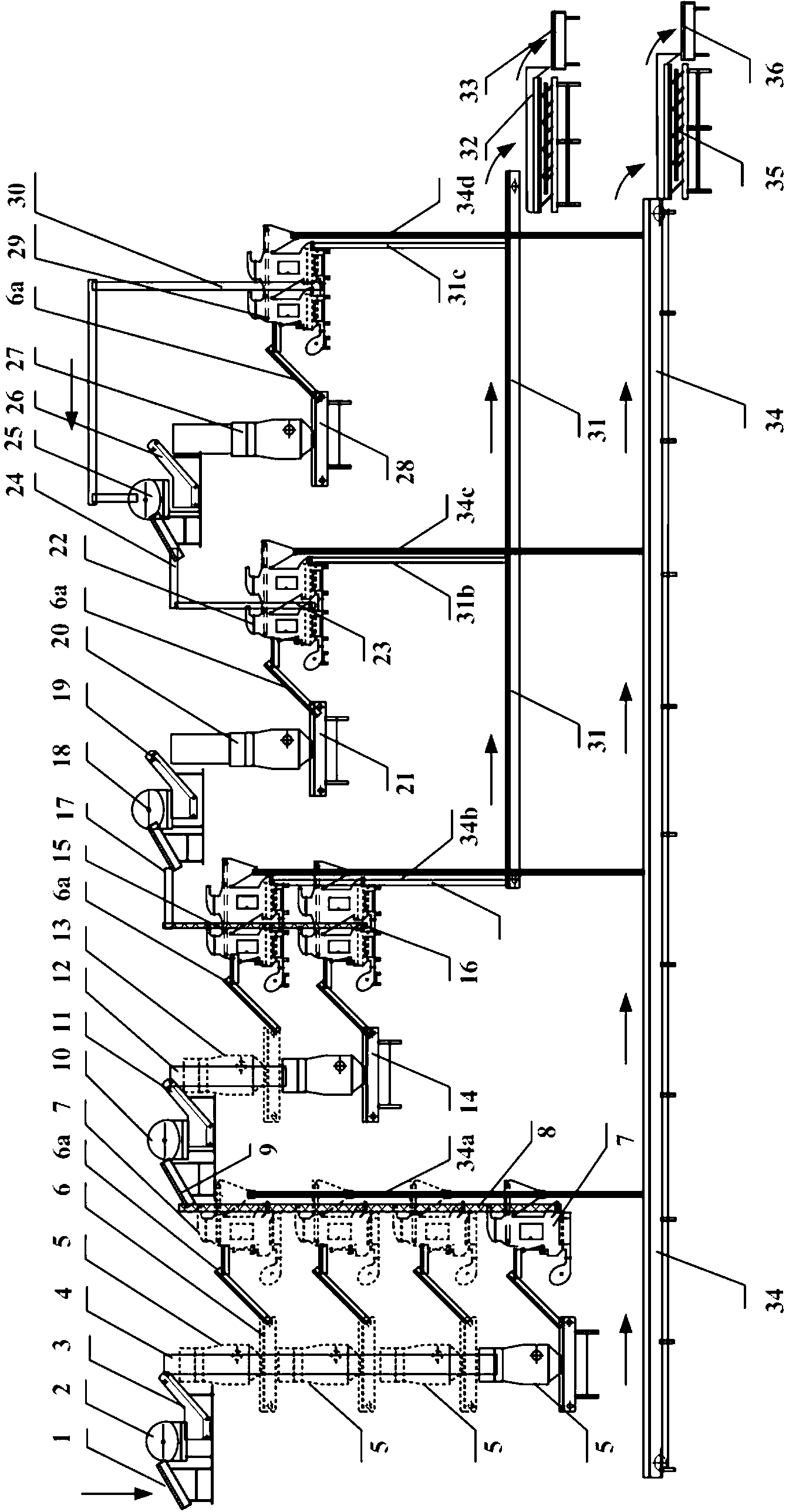

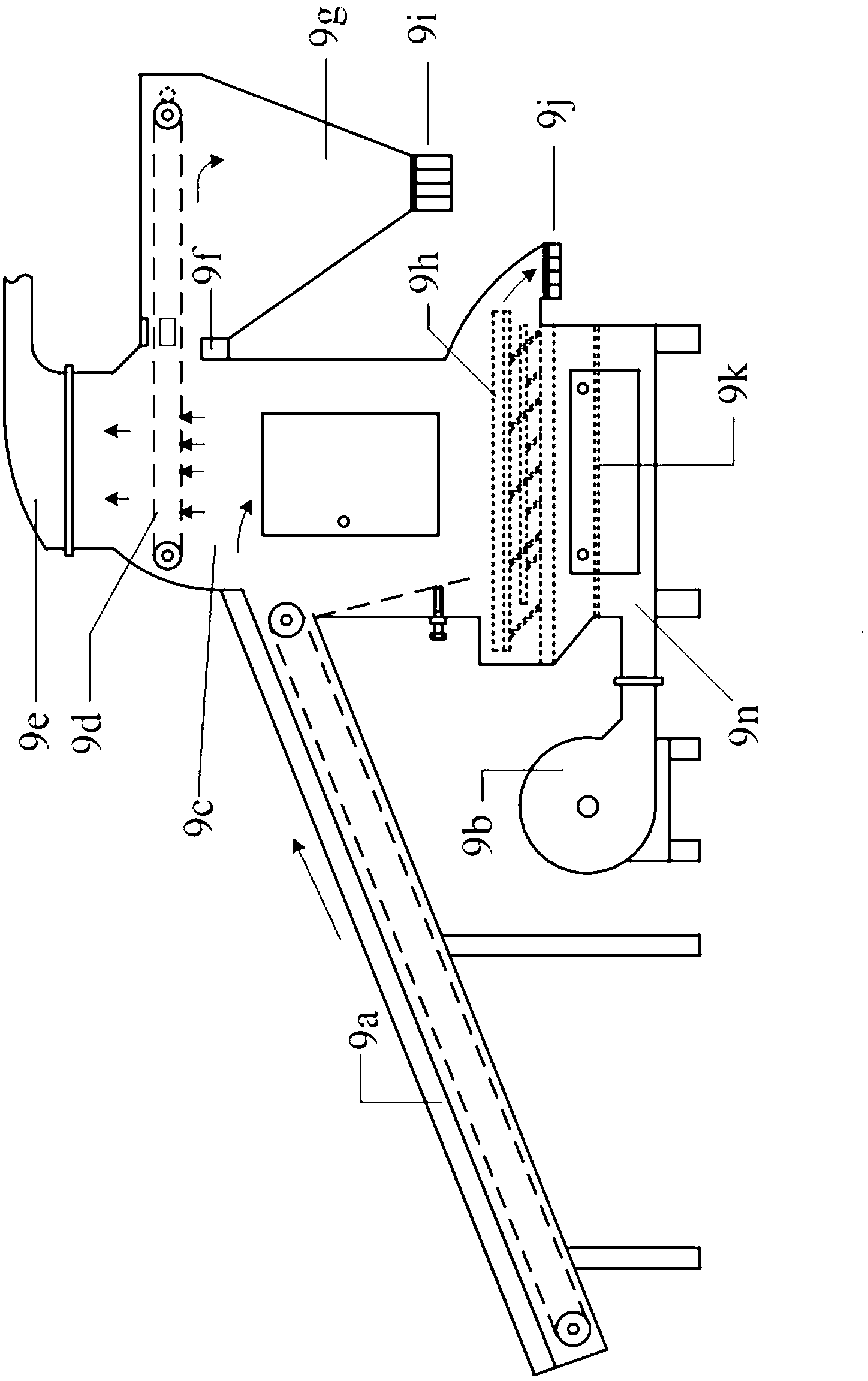

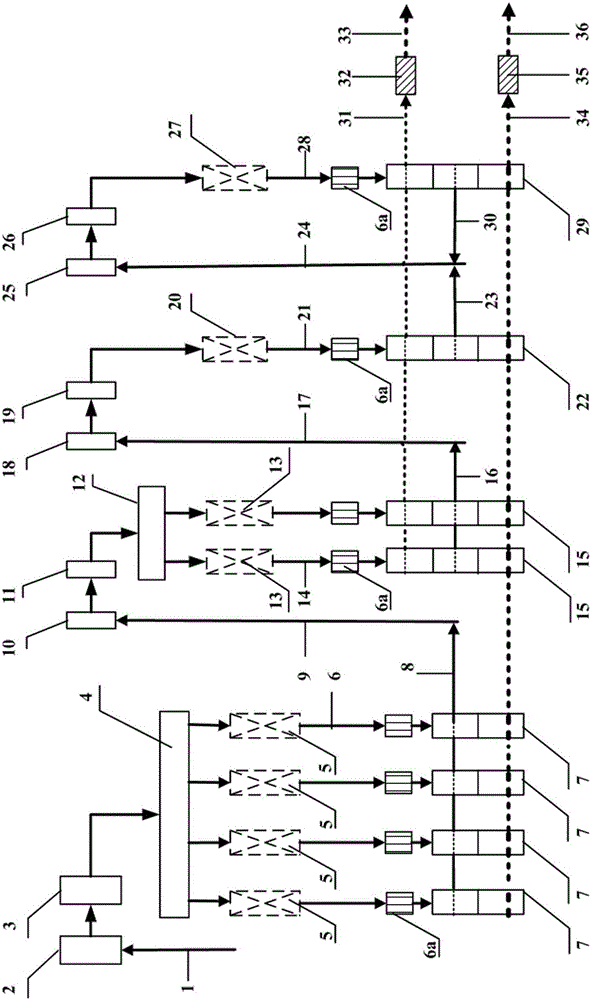

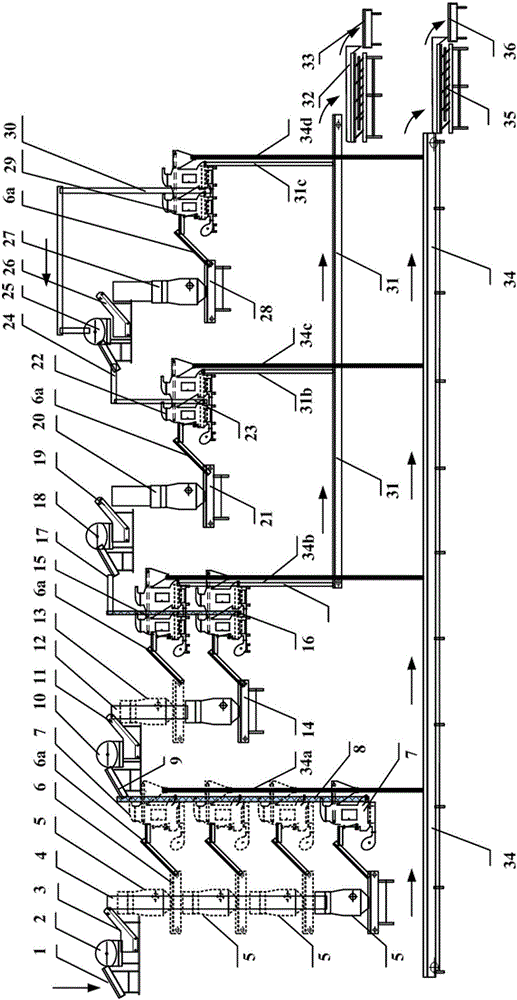

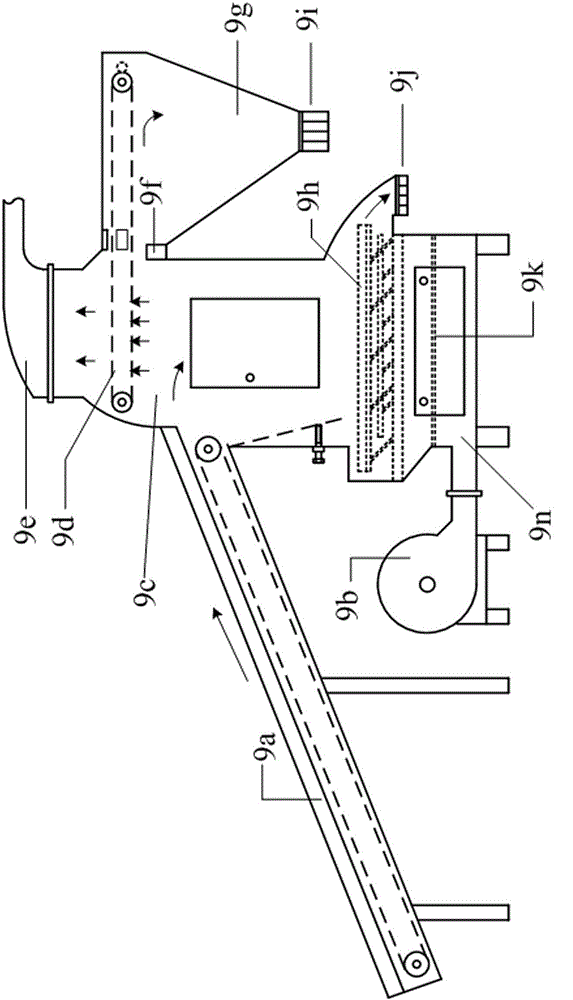

High-efficiency energy-saving threshing air separation new process and equipment

ActiveCN103263075AReduce the temperatureReduce drynessTobacco treatmentGas current separationAir separationMechanical engineering

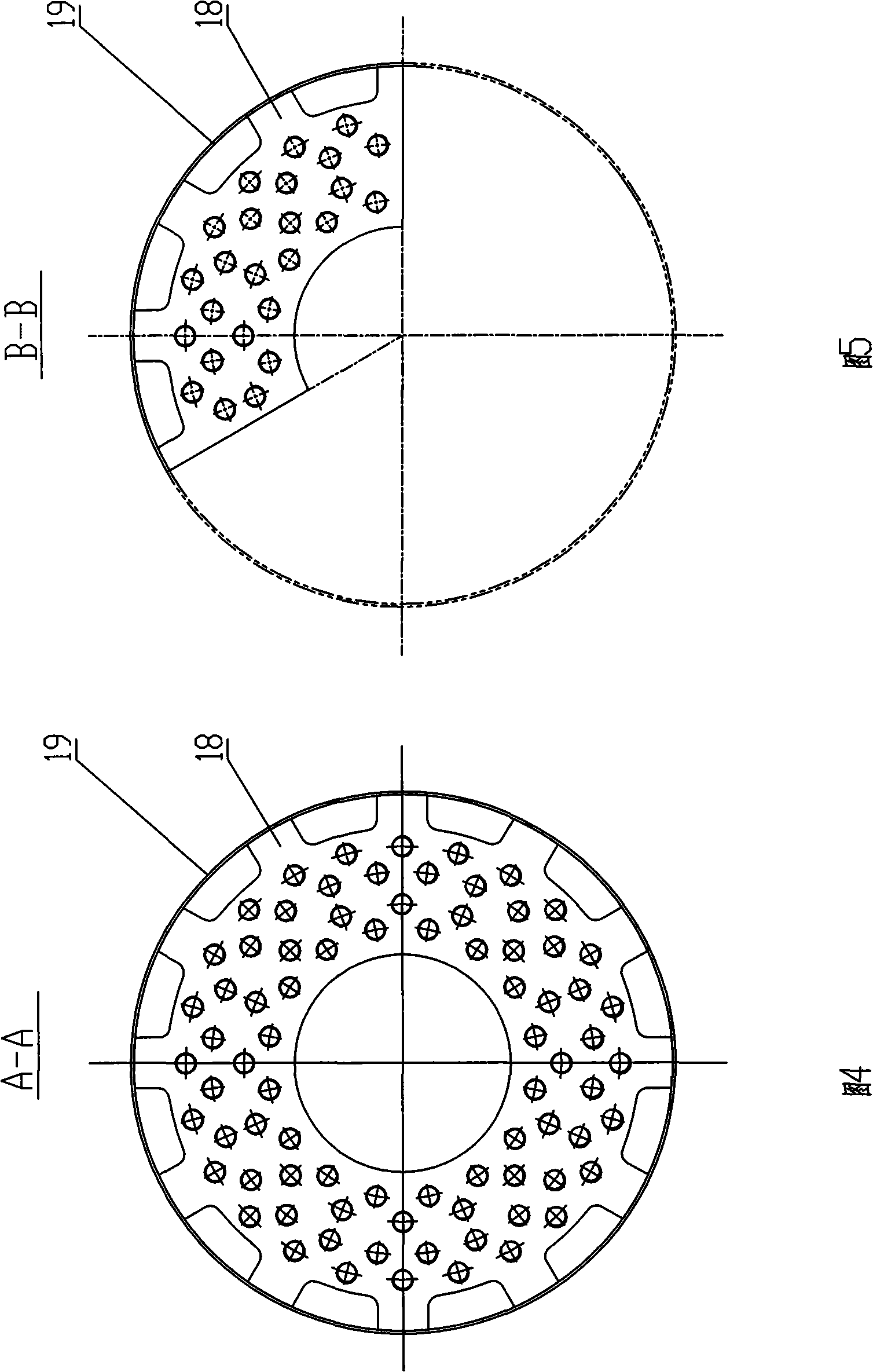

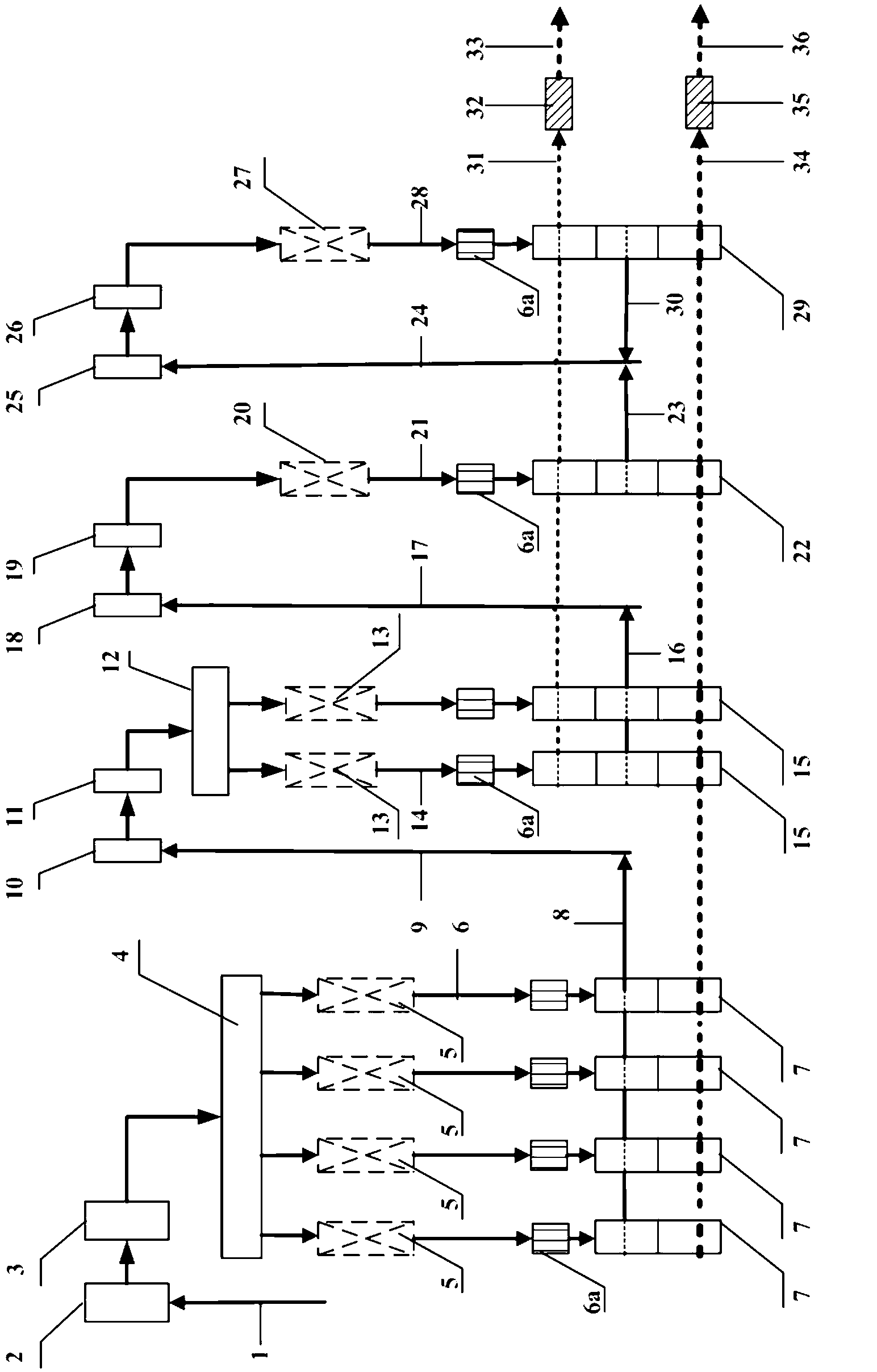

The invention relates to a high-efficiency energy-saving threshing air separation new process and equipment, and particularly relates to a threshing redrying process which carries out air separation on tobacco flakes and tobacco stalks and belongs to a tobacco processing industry and the technical field of equipment. The threshing redrying process sequentially comprises the following steps of: a scraping plate feeding machine, a bin type feeding machine, a proportional distributor, a first-level threshing machine set, a conveying belt, a first-level air separation machine set (double-bin air separator), a stalky leaf conveying belt, a second-level threshing machine set, the conveying belt, a second-level air separation machine set (three-bin air separator), the stalky leaf conveying belt, a third-level threshing machine set, the conveying belt, a third-level air separation machine set (three-bin air separator), the stalky leaf conveying belt, a fourth-level threshing machine set, the conveying belt and a fourth-level air separation machine set (three-bin air separator), wherein the first-level air separation machine set is provided with an air pressure type double-bin air separator which only separates qualified tobacco flakes; and the second-level air separation machine set, the third-level air separation machine set and the fourth-level air separation machine set are provided with air pressure type three-bin air separators which can separate qualified tobacco flakes and tobacco stalks.

Owner:HONGTA TOBACCO GRP

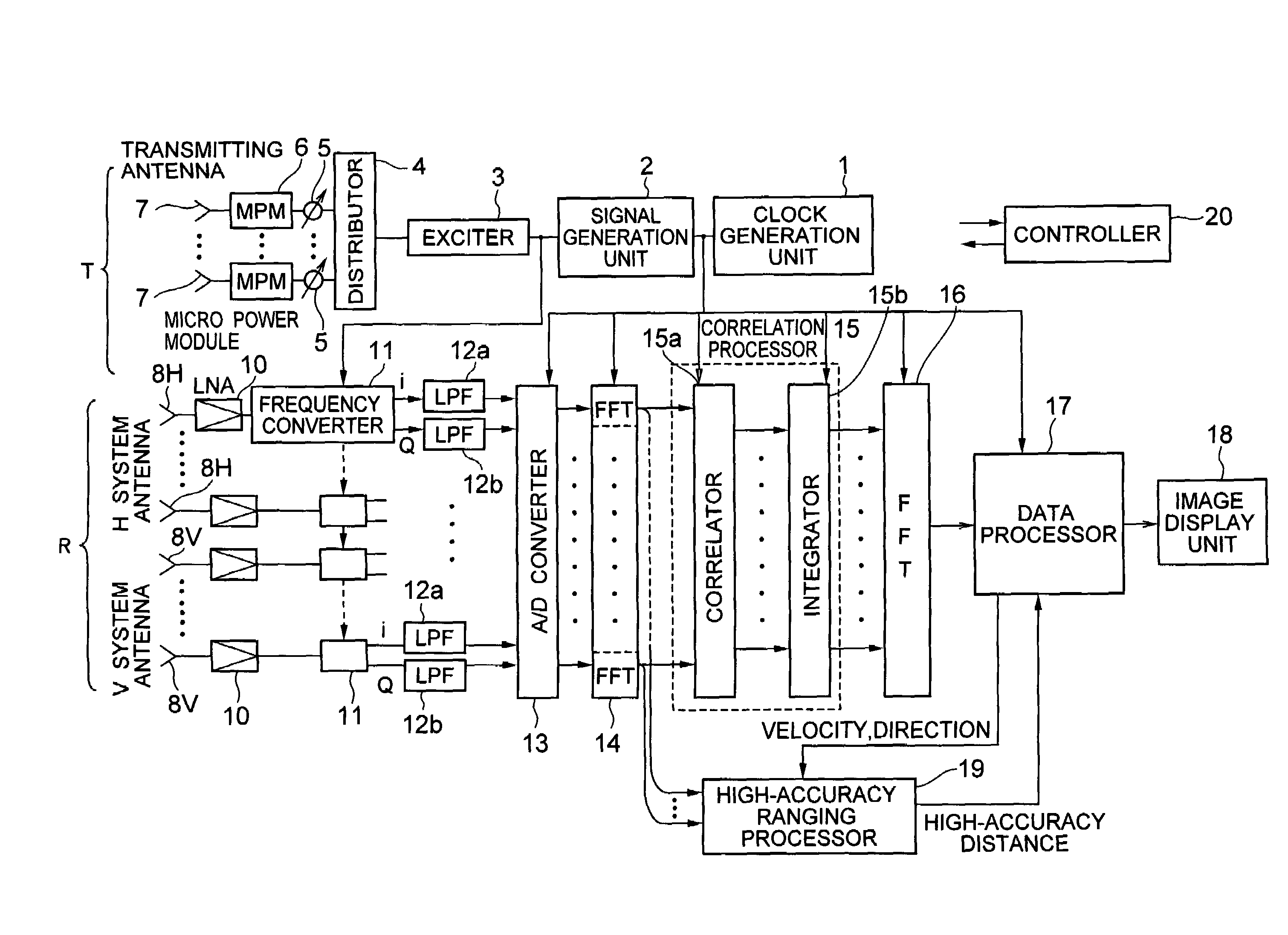

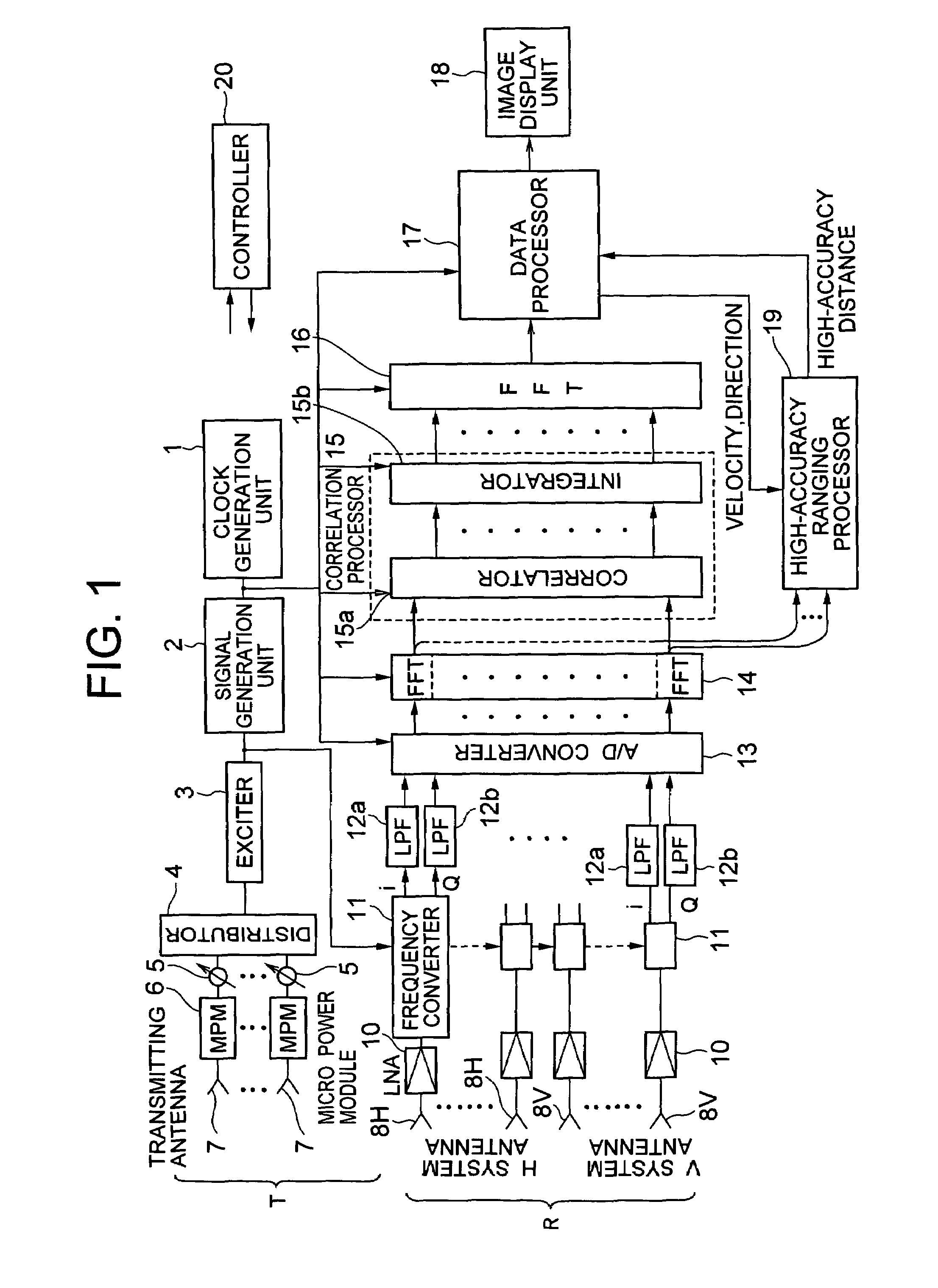

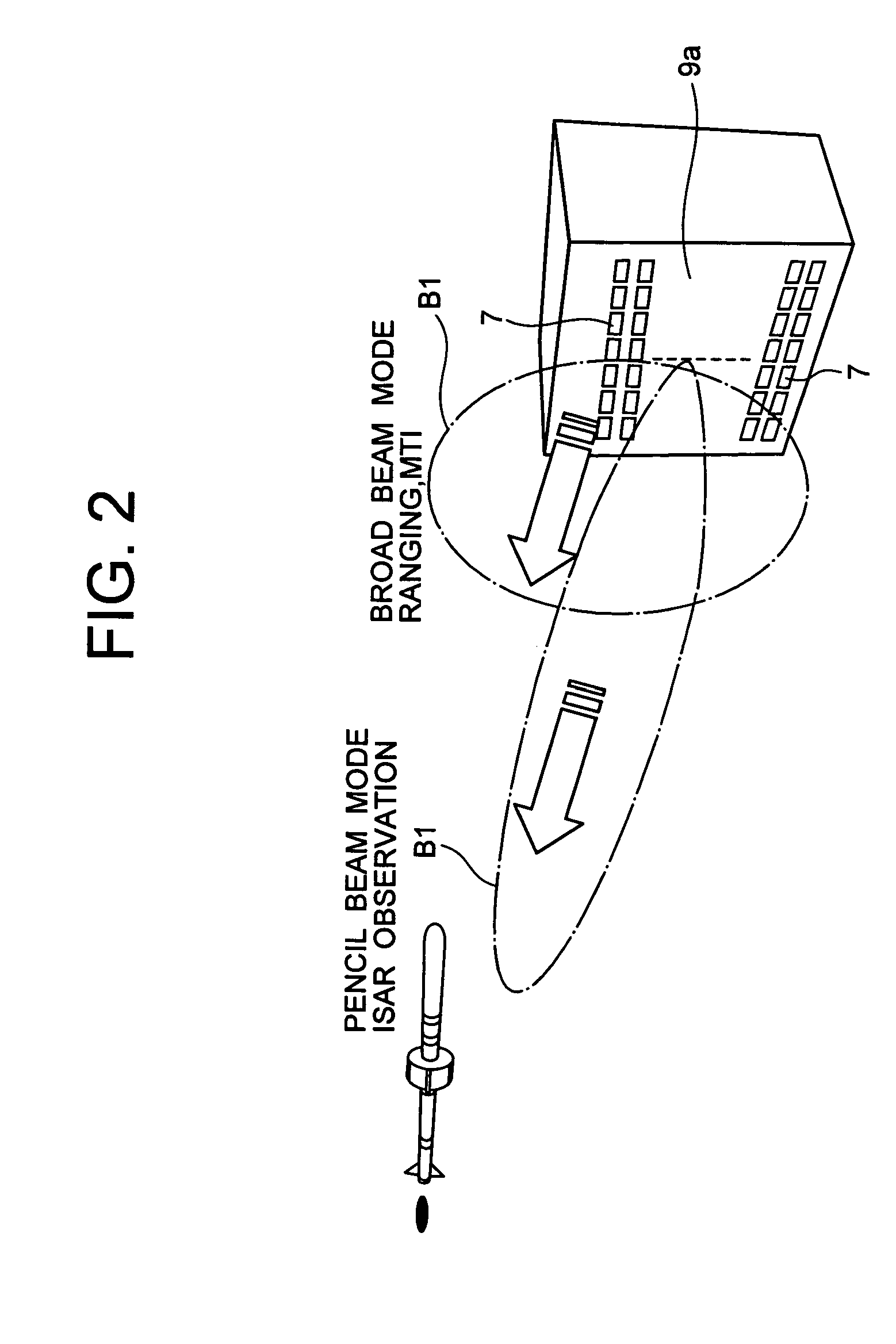

Interferometer-type radar

InactiveUS7394422B2Easily realizedImprove reliabilityRadio wave reradiation/reflectionRadarPhase difference

A transmitter for transmitting signals to targets and a receiver for receiving signals reflected from targets are included. The transmitter outputs CW signals for detecting direction and velocity of the target. The receiver performs: a function of receiving signals reflected from targets with a plurality of receiving antennas at the same time as transmitting from the transmitter, and performing spectral analysis with respect to receiving signals to thereby classify them by velocity component; a function of correlating signals of the receiving antenna systems; a function of integrating the signals correlation-processed; and a function of obtaining phase fronts of signals made incident on an antenna face from the phase differences of signals between receiving antennas, and performing two-dimensional FFT to the outputs to thereby measure the direction and velocity of the target.

Owner:NEC CORP

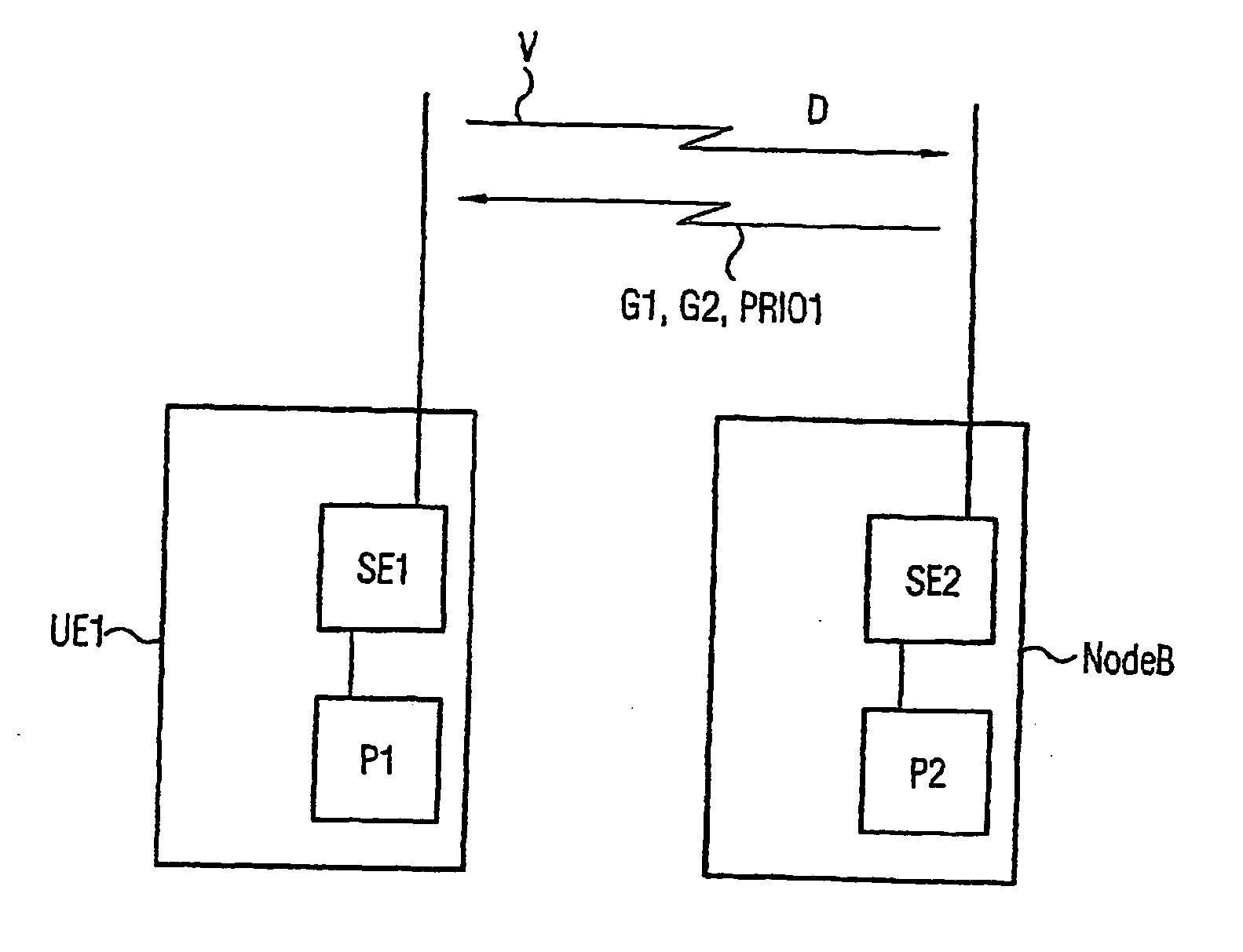

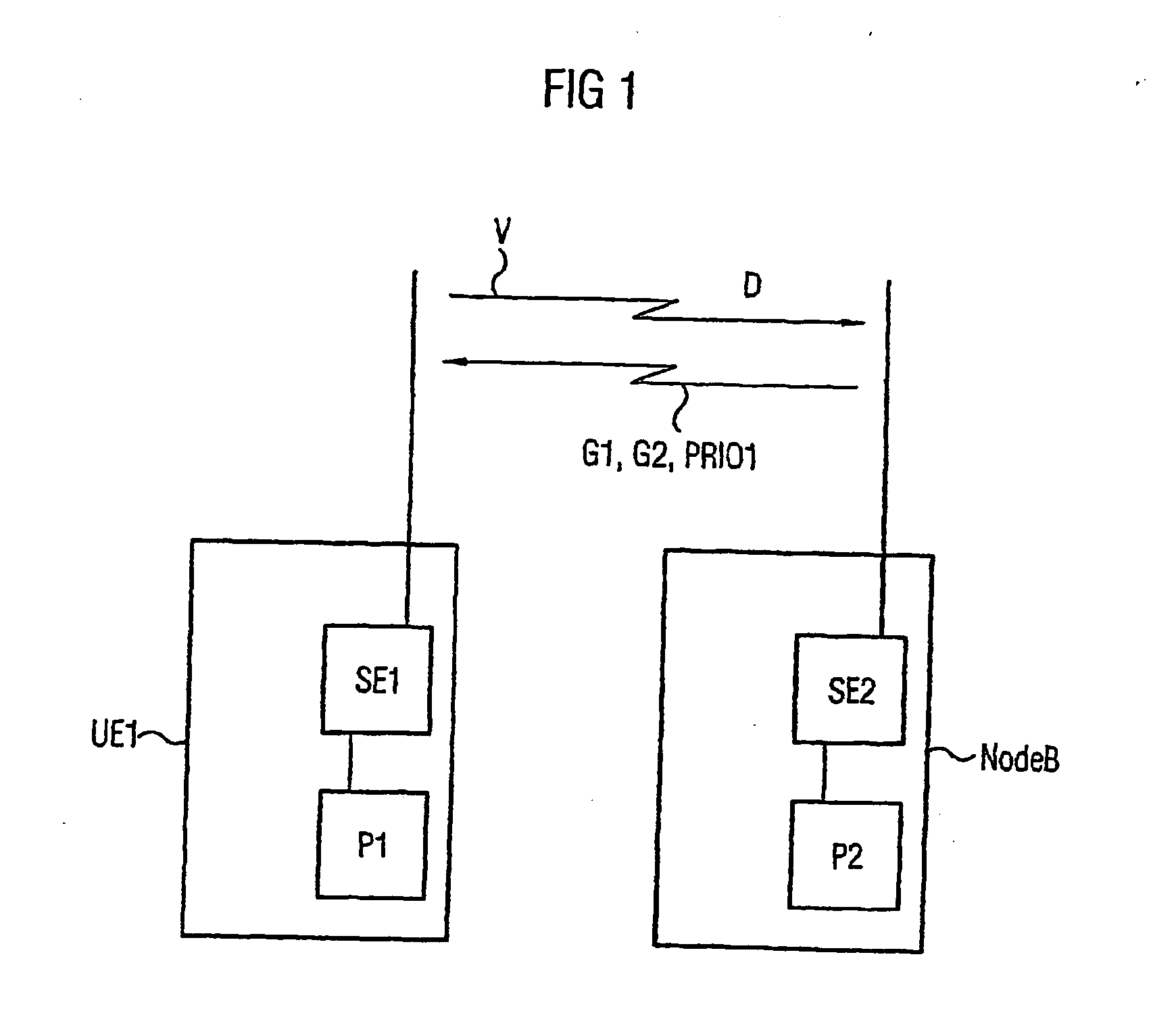

Method for transmitting data from a transmitting station to a receiving station via a radio link, and corresponding receiving station and transmitting station

InactiveUS20070004440A1Reduce noise levelHigh interference level at the receiving station is reducedRadio transmissionTransmission noise suppressionTelecommunicationsTime duration

Owner:CELLULAR COMM EQUIP LLC

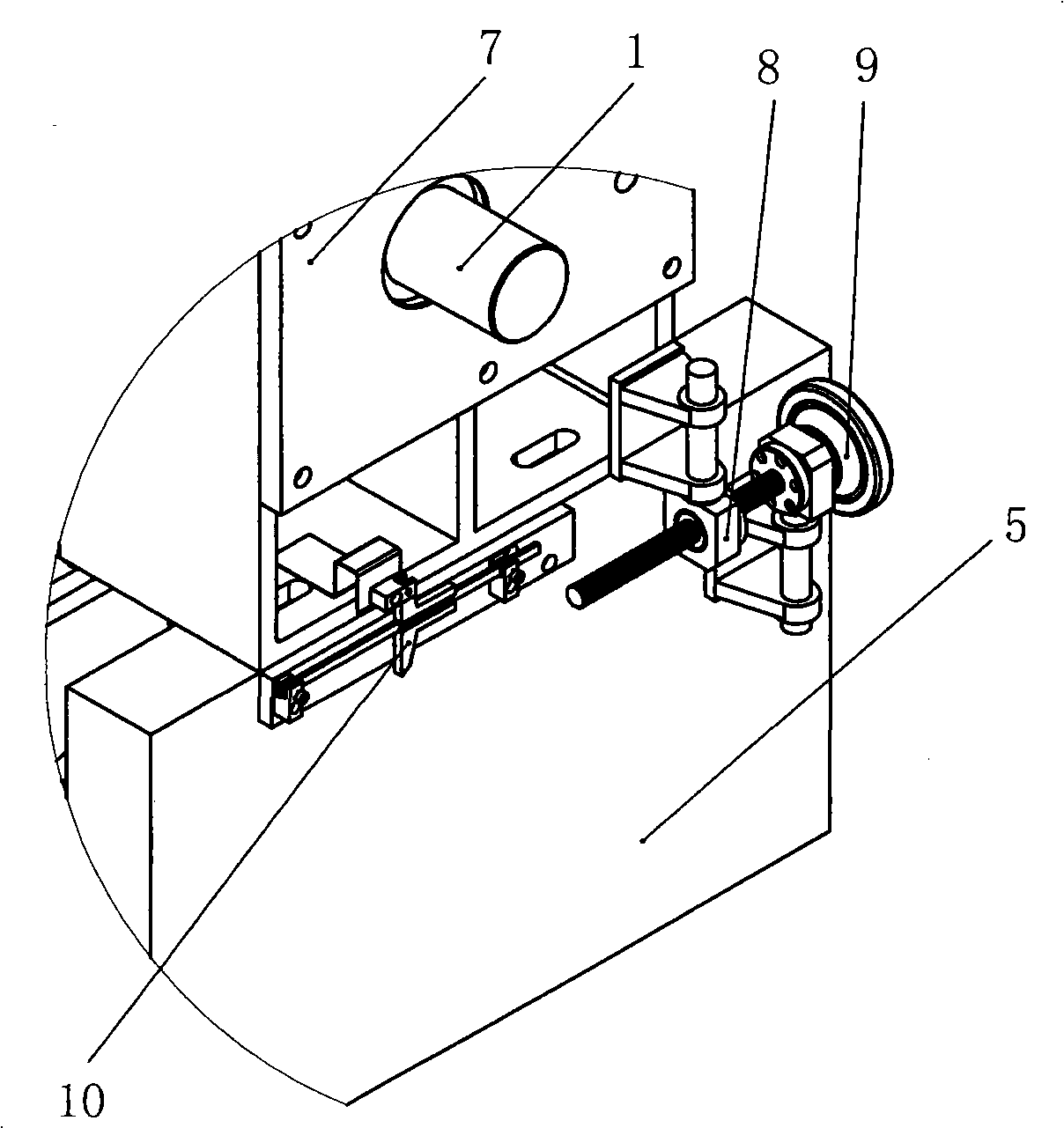

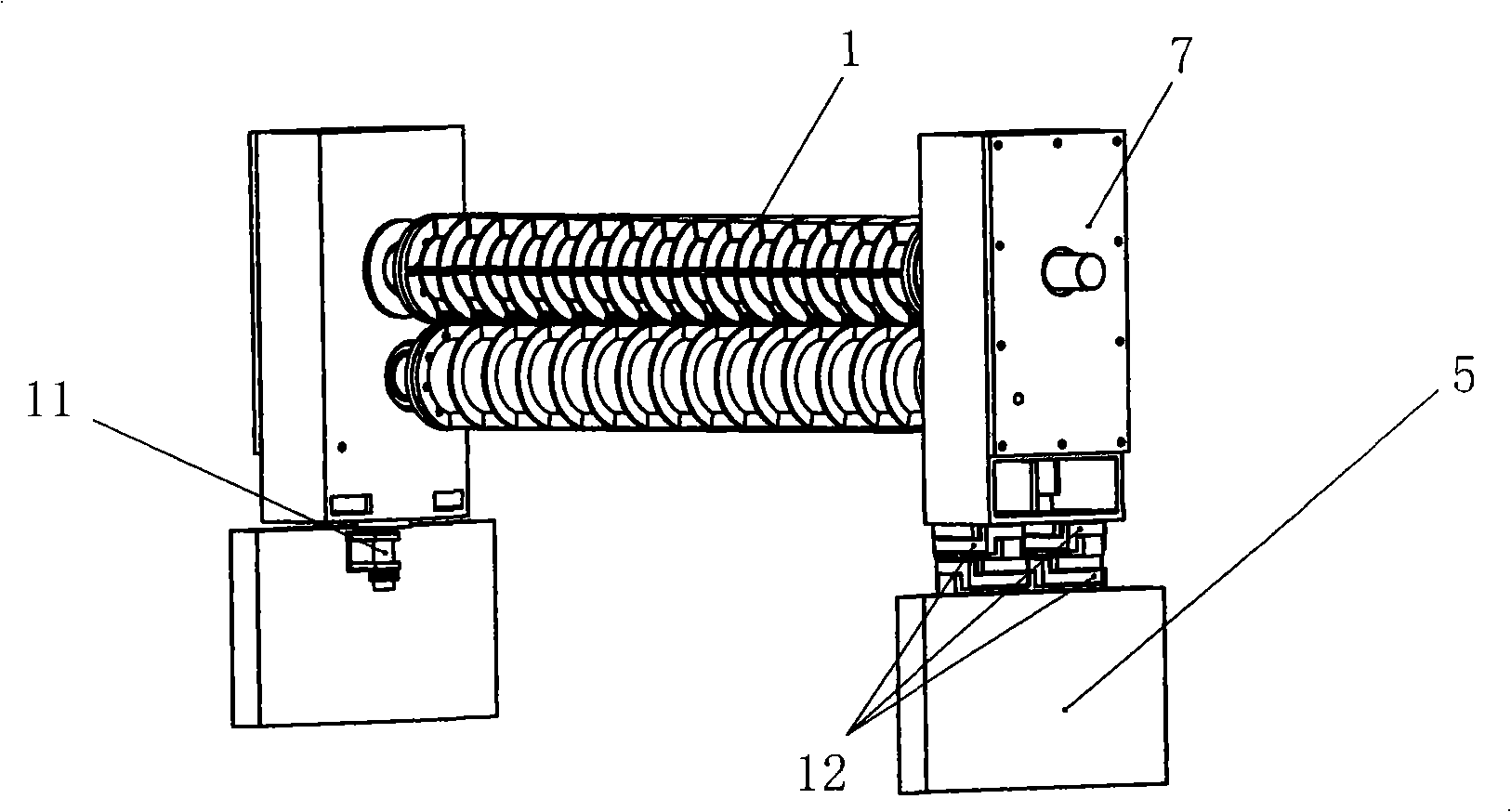

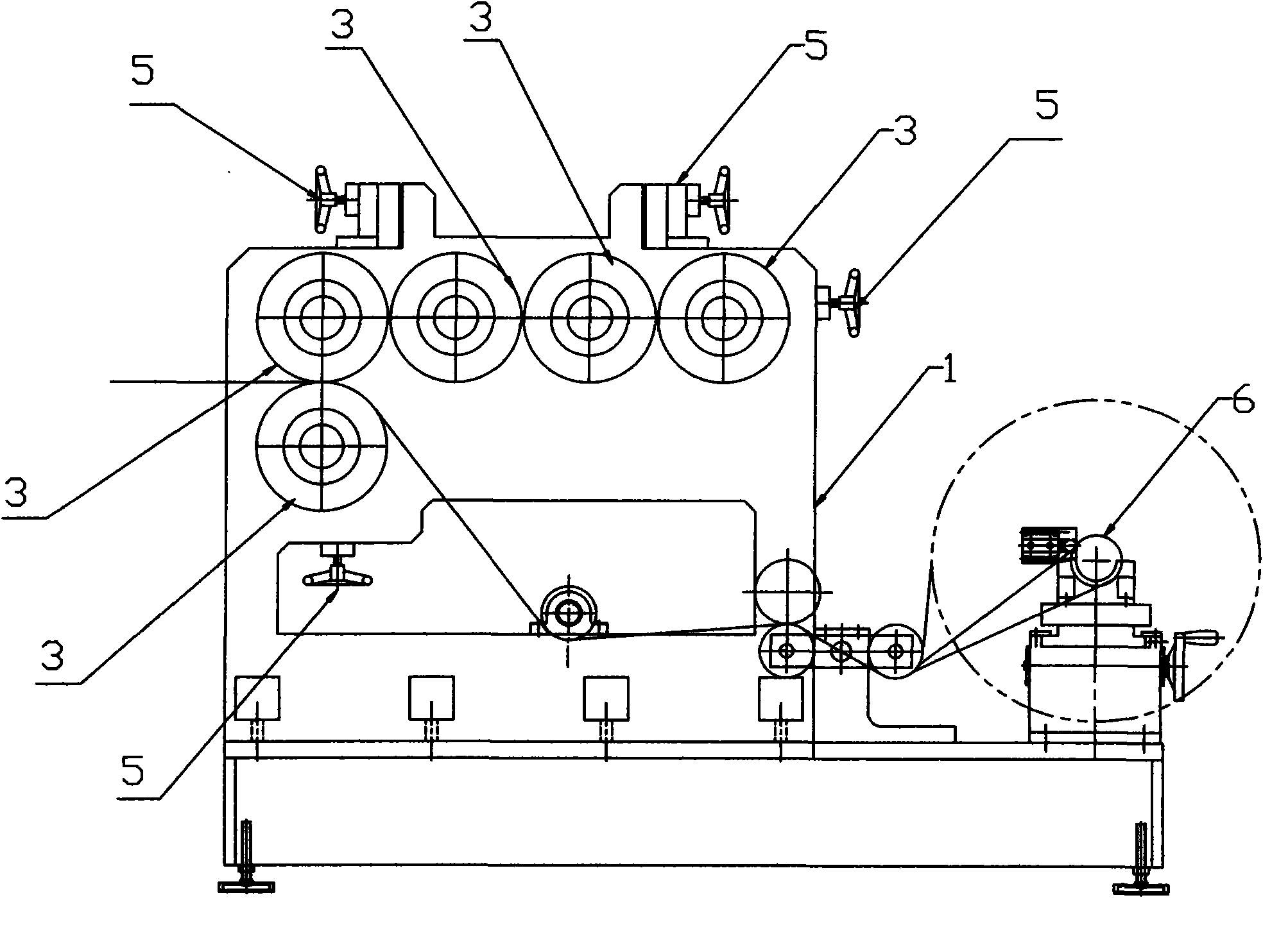

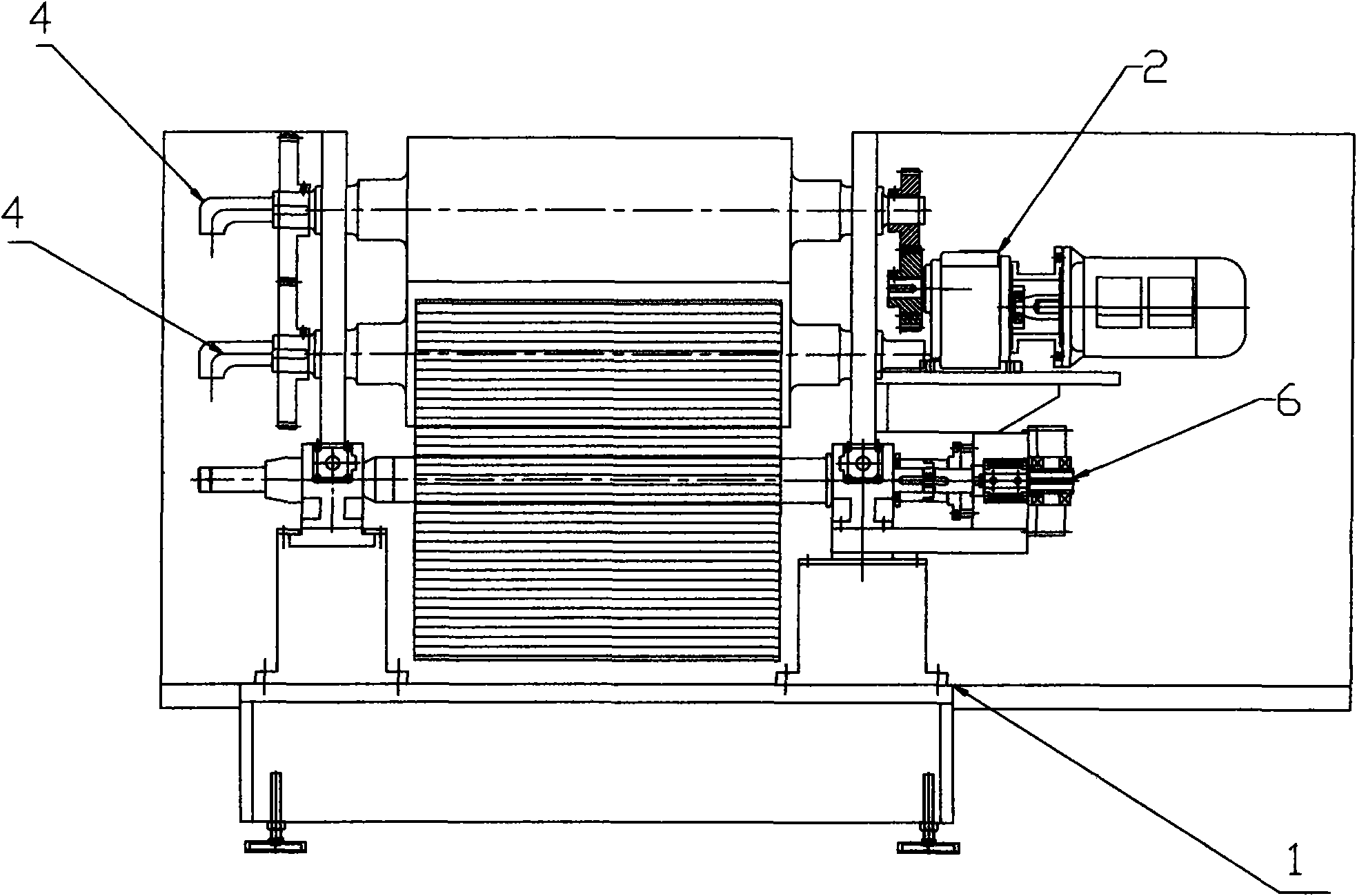

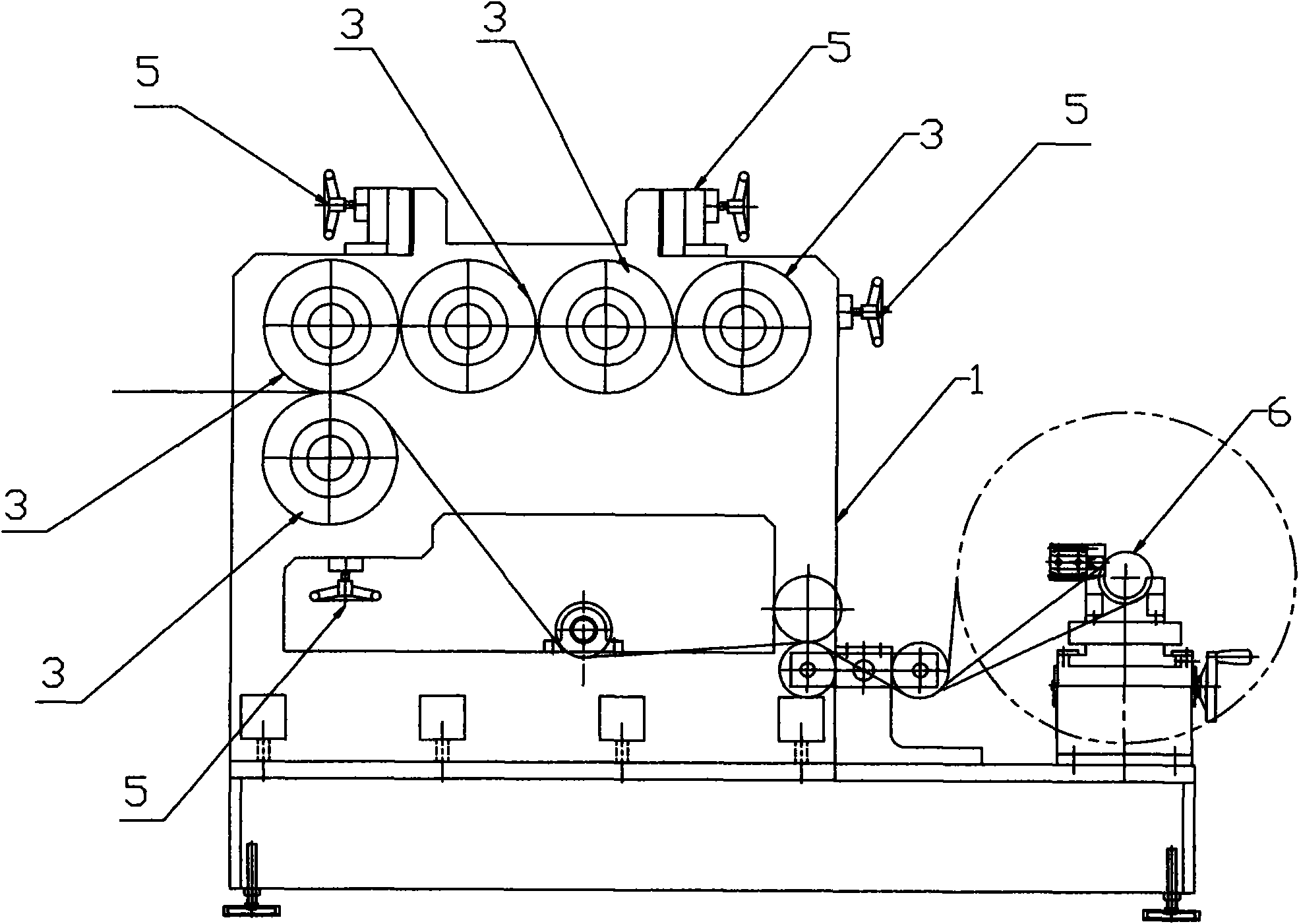

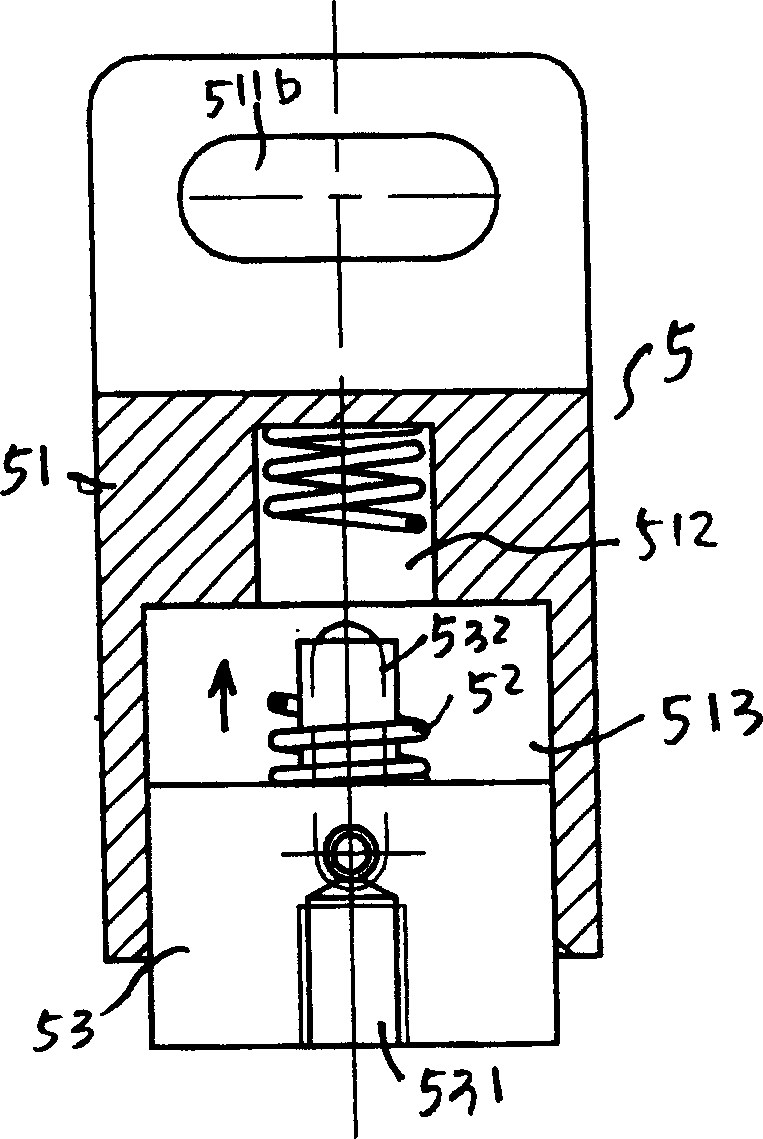

Transversely cutting device of paper cutter with double flying knives and method for adjusting length and squareness of cut paper

InactiveCN101537645AGuaranteed squarenessSmall transmission powerMetal working apparatusPulp and paper industryElectric motor

The invention provides a transversely cutting device of a paper cutter with double flying knives and a method for adjusting the length and the squareness of cut paper. The transversely cutting device comprises stands and a double-rotary knife roll, wherein both ends of the double-rotary knife roll are arranged on the stands by bearing supports, one bearing support is articulated with the stand at one side by a rotating axle, a knife roll adjusting mechanism is arranged on the stand at the other side, and a revolving knife hold-down mechanism is arranged on a connecting plate between the stand at one side and the stand at the other side, and articulated with the bearing supports by adjustable post rods and connecting pieces. The positions of the adjustable post rods are adjusted, which enables the bearing supports at both ends of the knife roll, the stand at both sides to be compressed or loosened. The speed ratio of the peripheral speed of the knife roll to the running line speed of paper is adjusted for adjusting the length of the cut paper. When cutting the paper, the knife roll rotates at a uniform speed all the time. A method that the angle between an axial line of the knife roll and the running direction of the paper is adjusted is adopted to ensure the cutting squareness. The invention can greatly decrease the installed capacity of an electric motor of the transversely cutting device and lower the complexity and the cost of manufacture.

Owner:李秉江

Ultra wideband bow-tie slot antenna

InactiveUS20050184919A1Small shapeLight weightAntenna arraysSimultaneous aerial operationsUltra-widebandWideband

A slot antenna includes an insulation substrate, a metal layer provided on the insulation substrate, a slot formed in the metal layer, and a feeding part connected to the metal layer. The slot is symmetric with respect to a centerline. When an x-y coordinate system is defined on the metal layer so that the y-axis is the symmetric line, the origin is the center of the slot antenna, and the x-axis through the origin is perpendicular to the y-axis, the width of the slot in the direction of the y-axis increasing in proportion to the absolute value of the x-axis.

Owner:NAT INST OF INFORMATION & COMM TECH

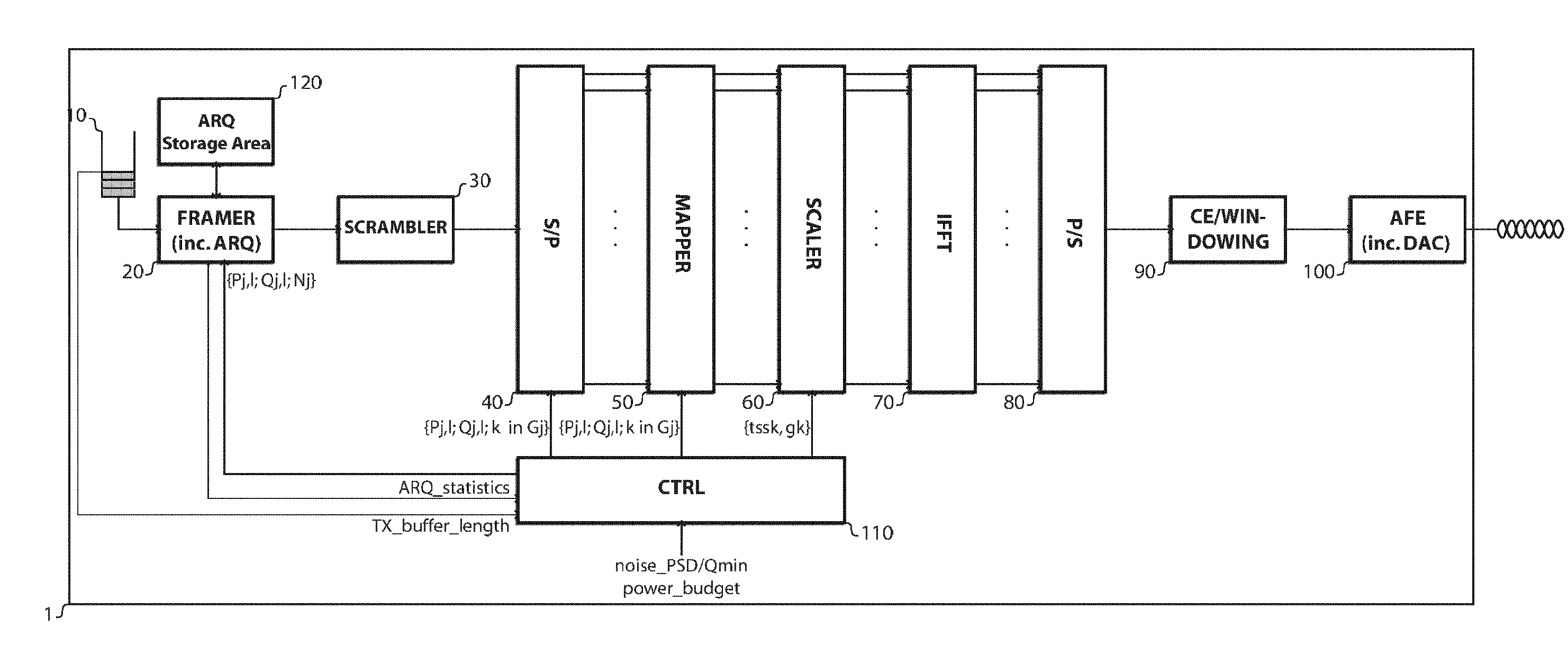

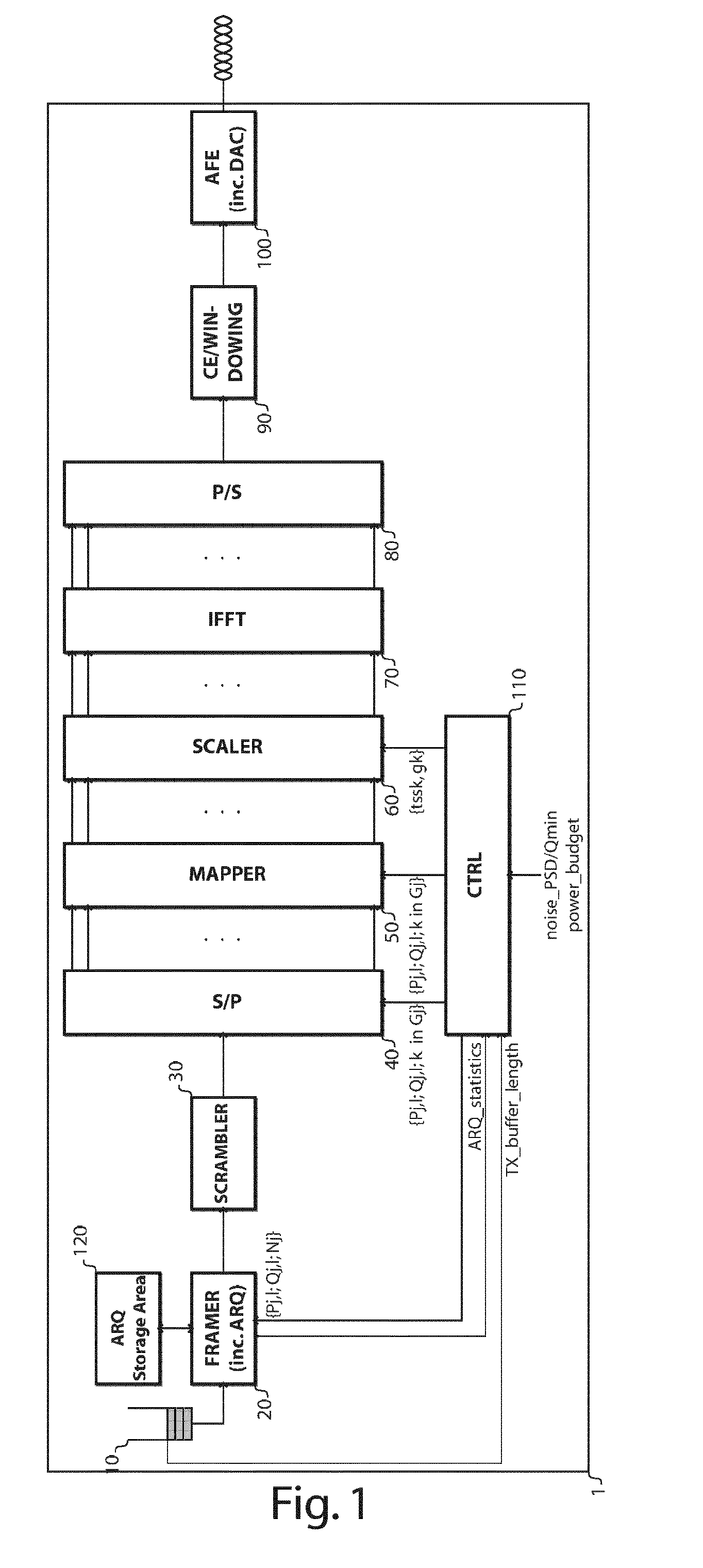

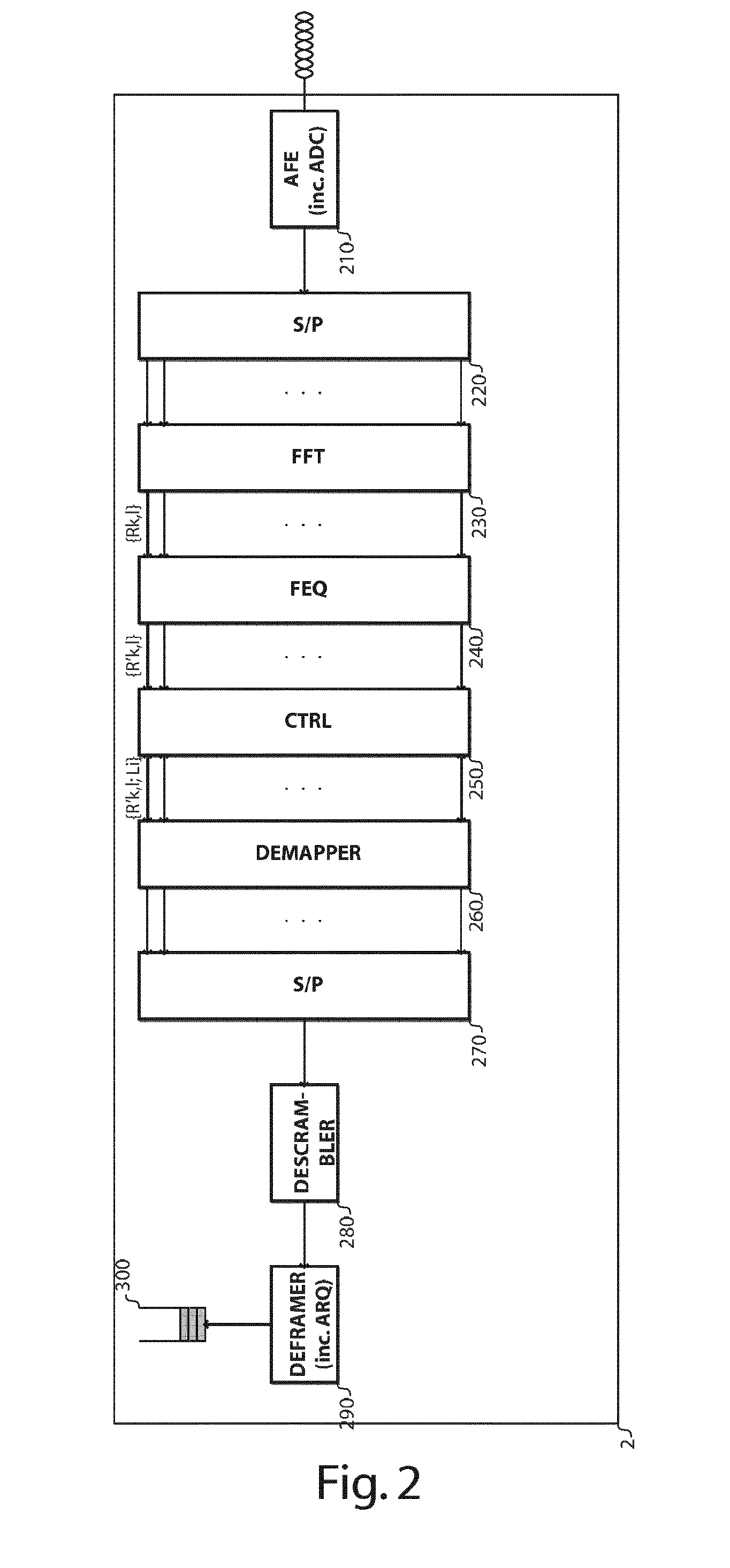

Hierarchical and adaptive multi-carrier digital modulation and demodulation

ActiveUS20140241378A1Accurate estimateStatistical characterization is improvedTime-division multiplexMultiple carrier systemsCarrier signalEngineering

In an embodiment the method includes, at a transmit side, grouping carriers into carrier groups, and selecting a group constellation diagram for modulation of the carriers of a given carrier group. The selected group constellation diagram is built as a hierarchical sum of I super-imposed constellations vectors having predefined decreasing powers with the P strongest and the Q weakest constellation vectors being omitted. The carriers of the carrier group are modulated by means of the selected group constellation diagram, and P and / or Q parameters per carrier group and per multi-carrier data symbol are adjusted.

Owner:RPX CORP

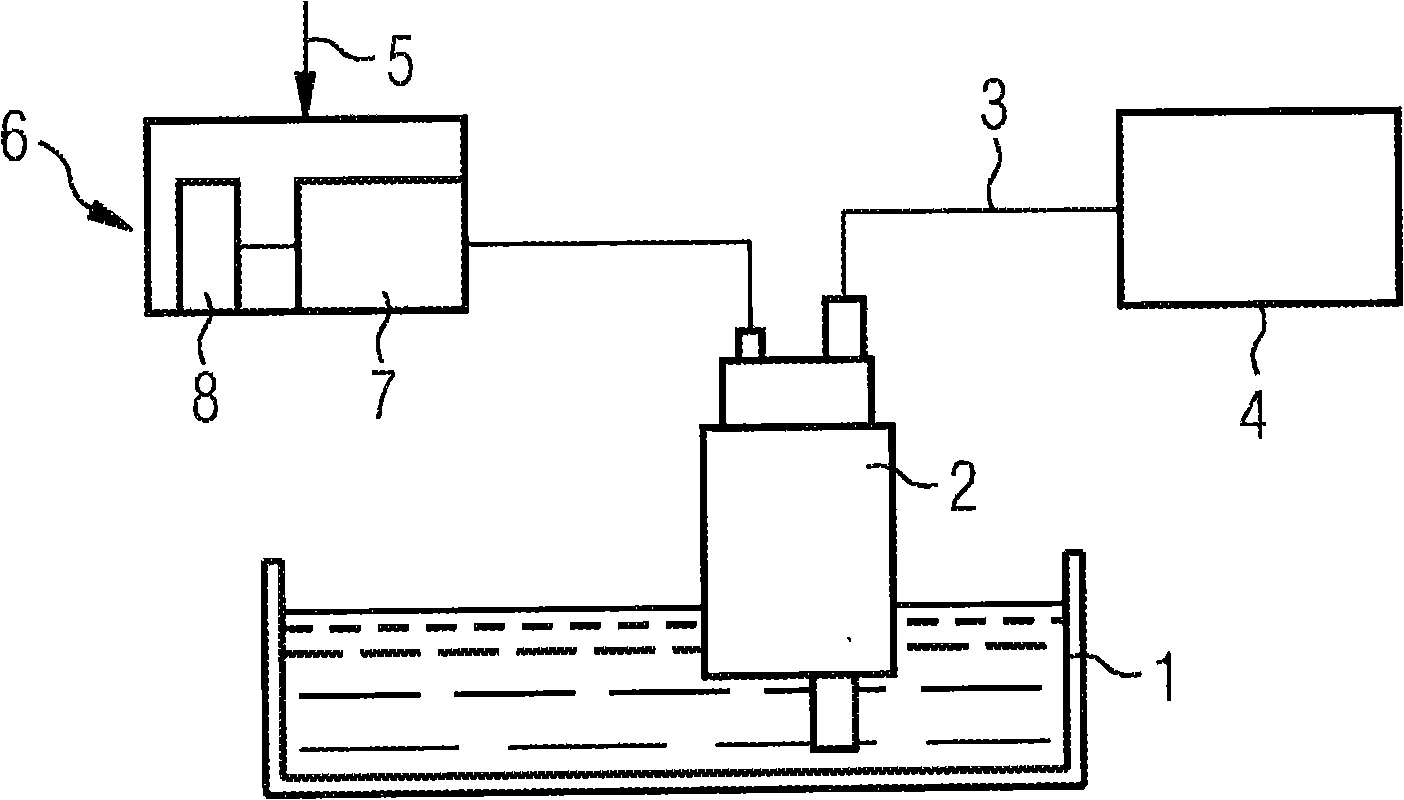

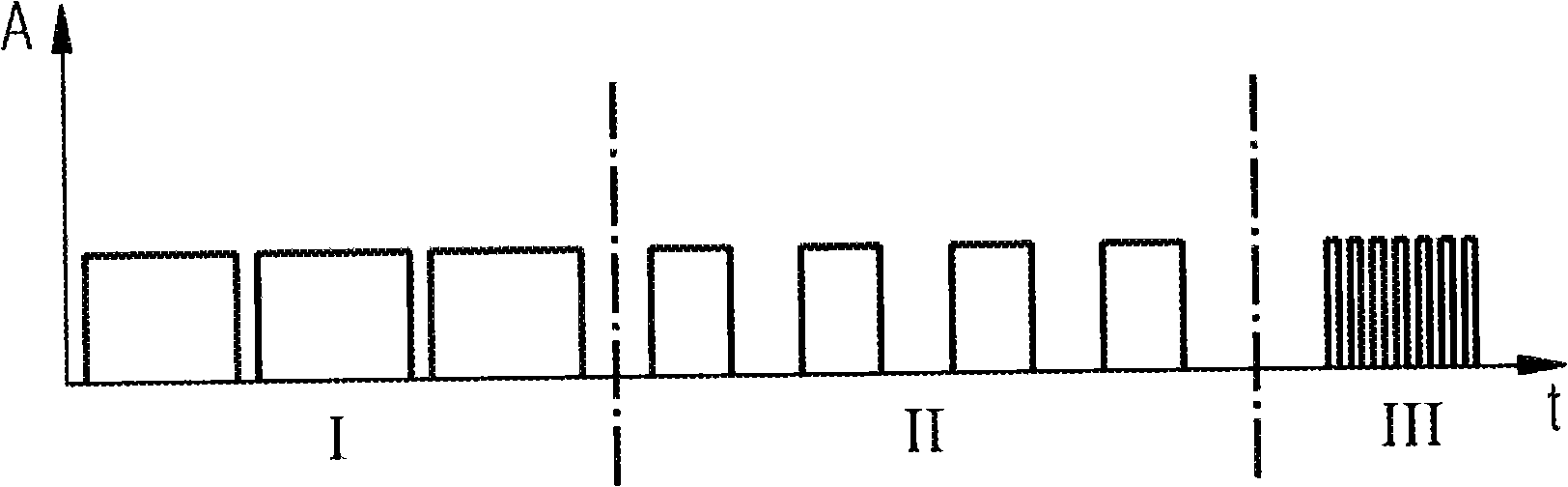

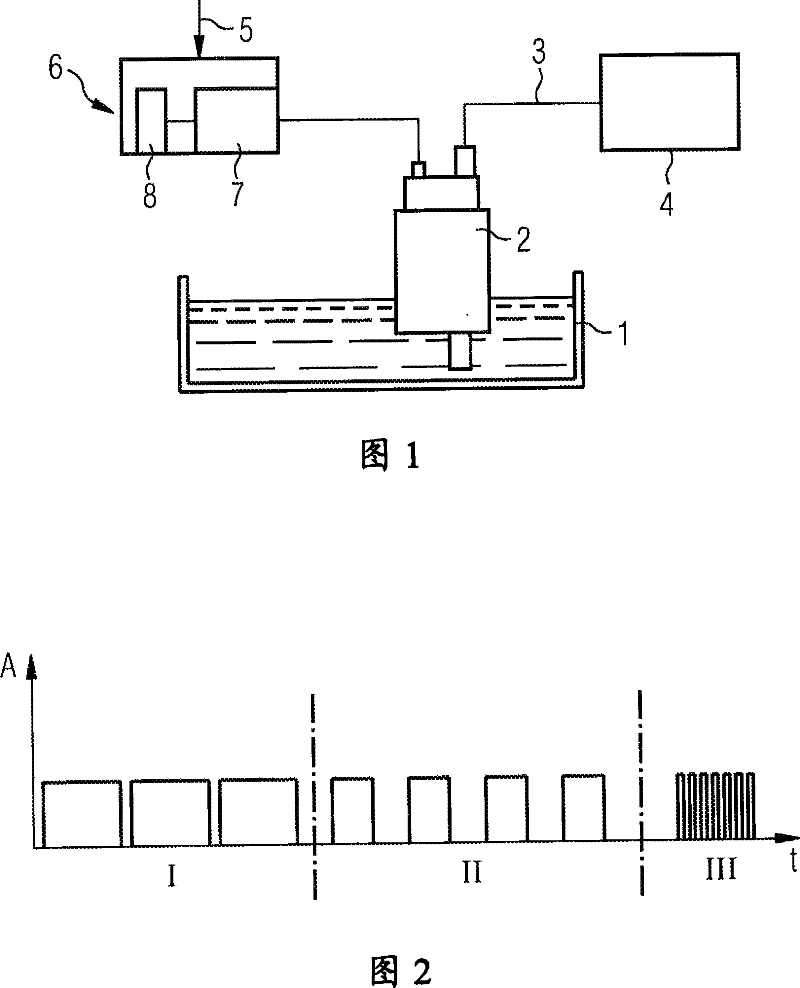

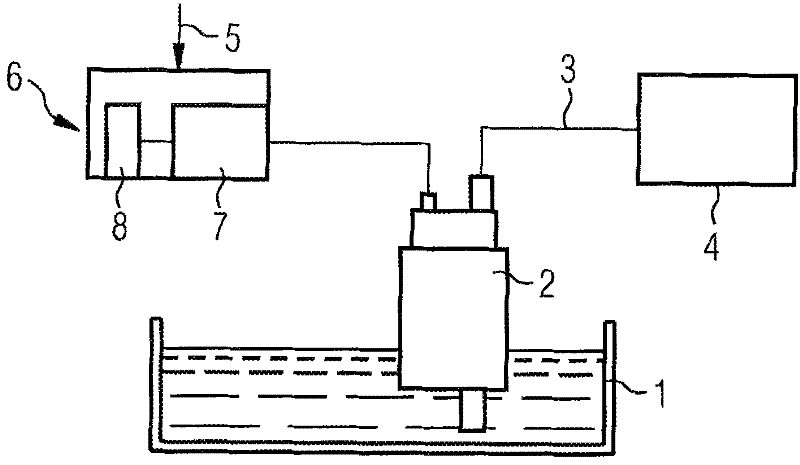

Method for operating a fuel pump

ActiveCN101278115AAvoid solid soundWon't noticeElectrical controlMachines/enginesInternal combustion engineElectric energy

The invention relates to a method for operating a fuel pump in order to guide fuel from the fuel container of an internal combustion engine, wherein the electric energy, which is in the form of pulses, is periodically guided to the fuel pump and the duration of the pulses is controlled according to the fuel required by the internal combustion engine. The frequency of the pulses is controlled in such a manner that, in the event of low pump capacity of the fuel pump, the frequency is controlled to a higher level than in the even of a high pump capacity.

Owner:VTESCO TECH GMBH

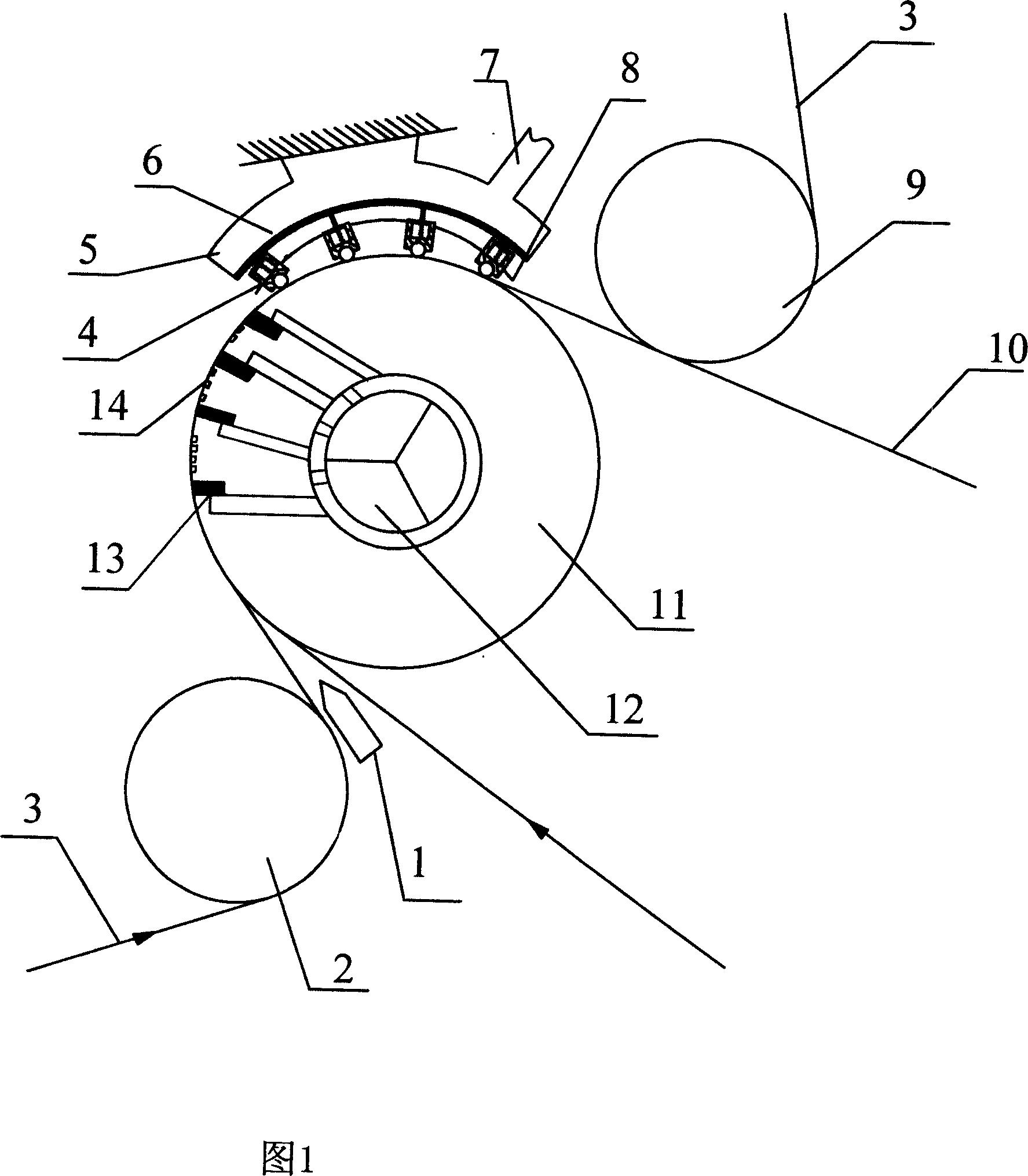

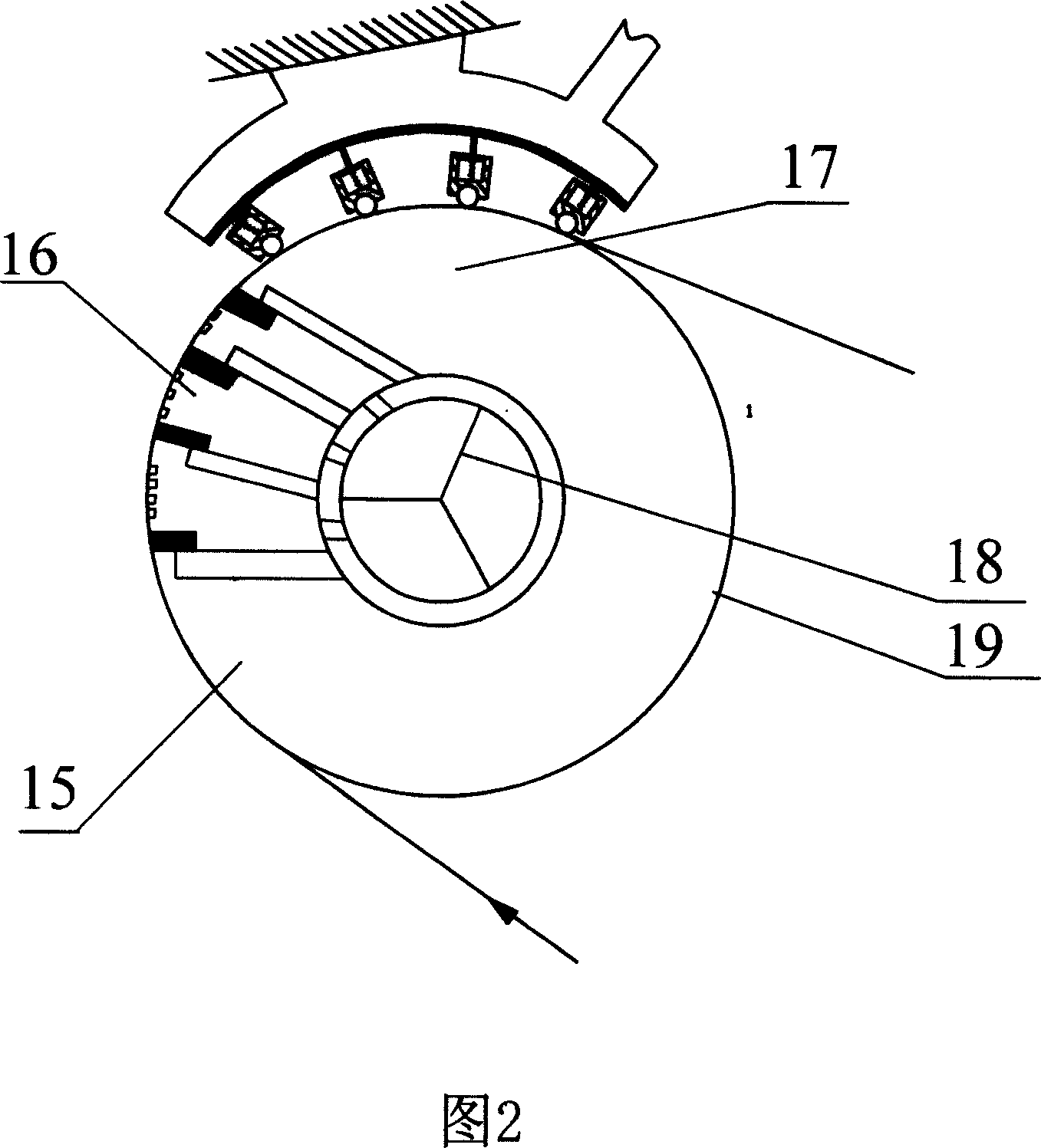

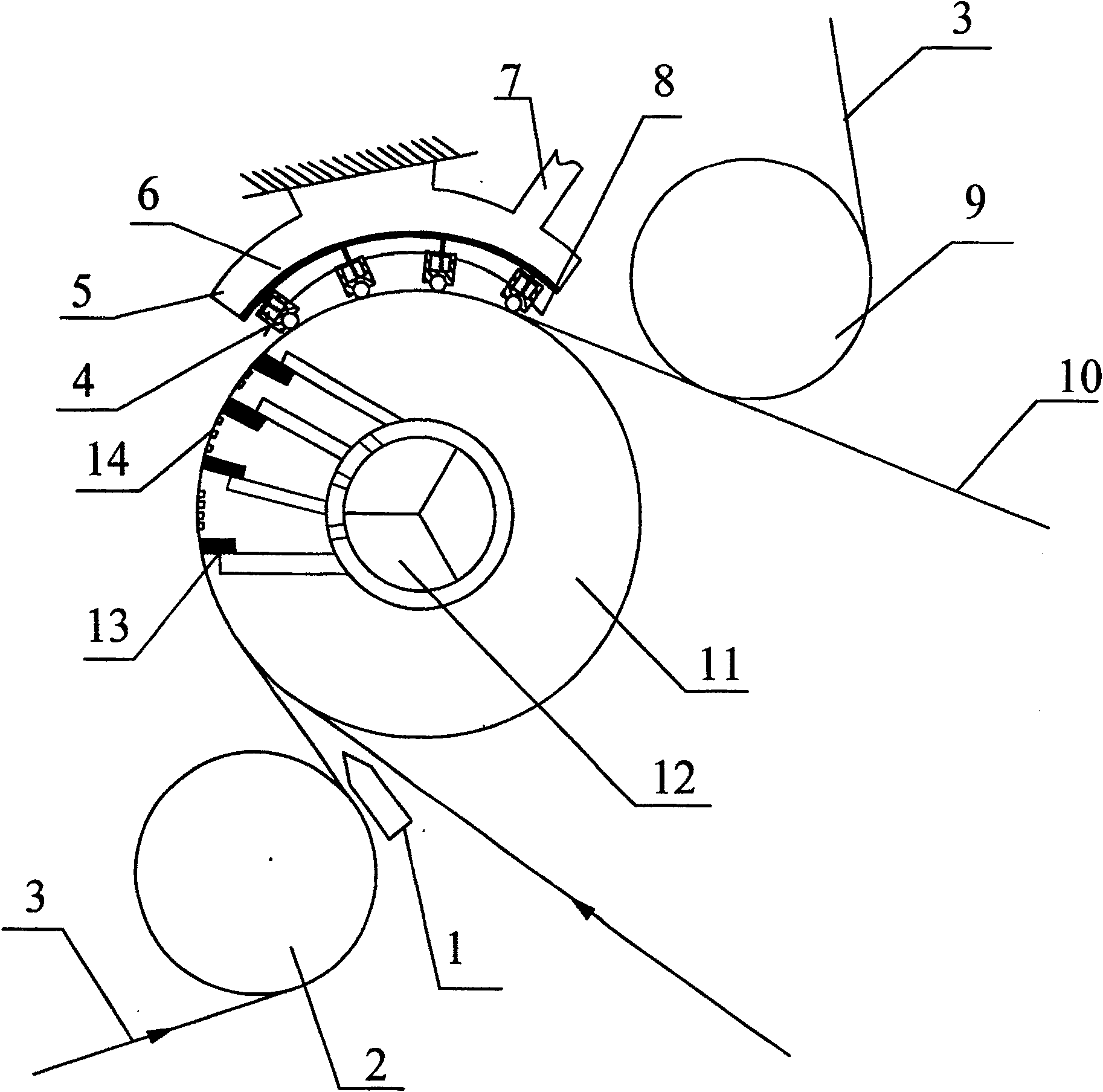

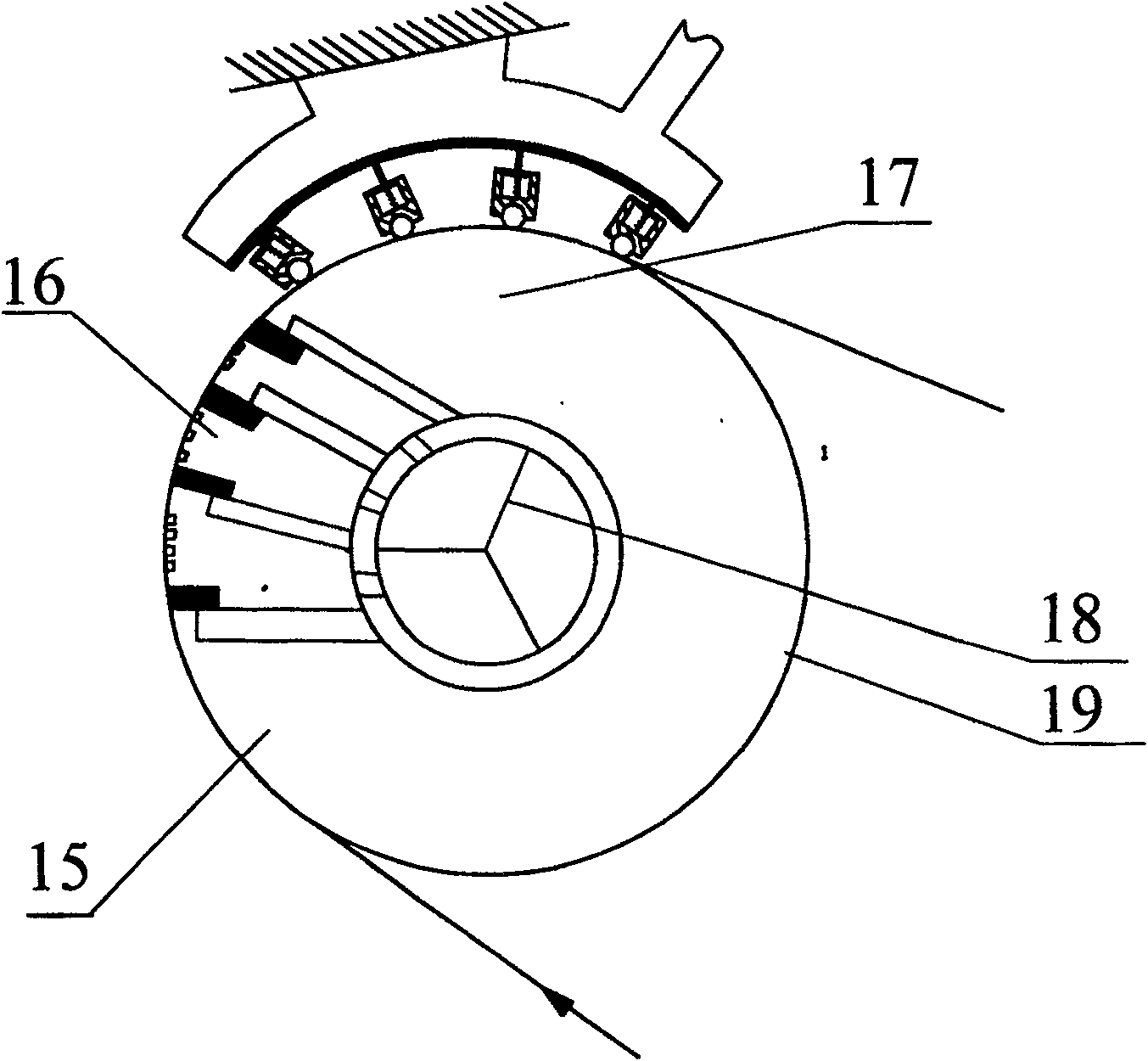

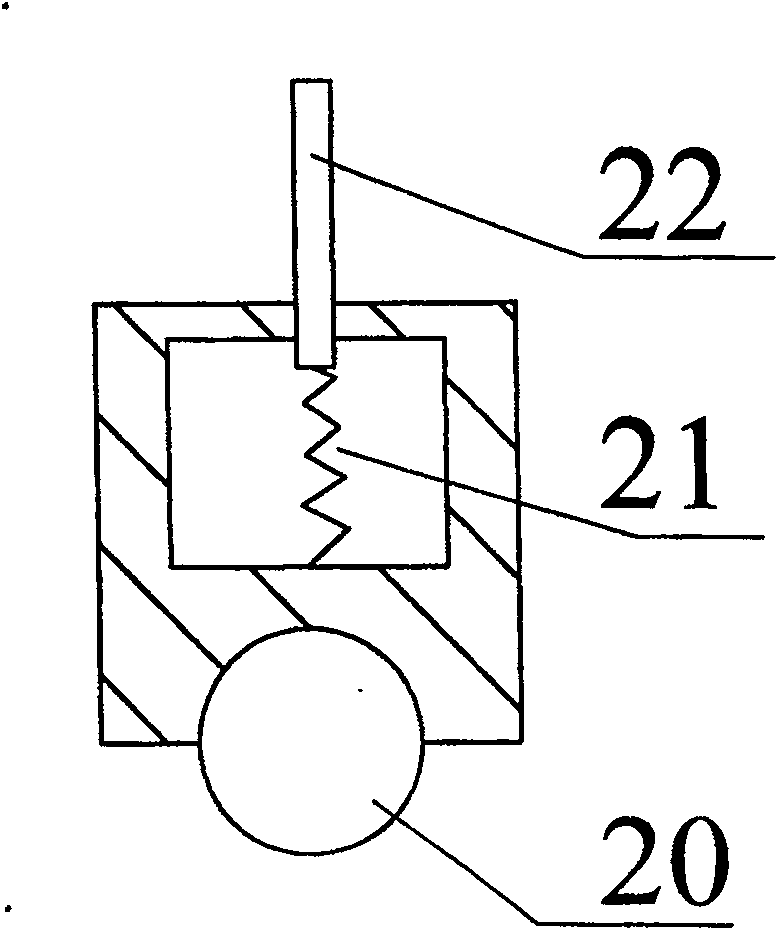

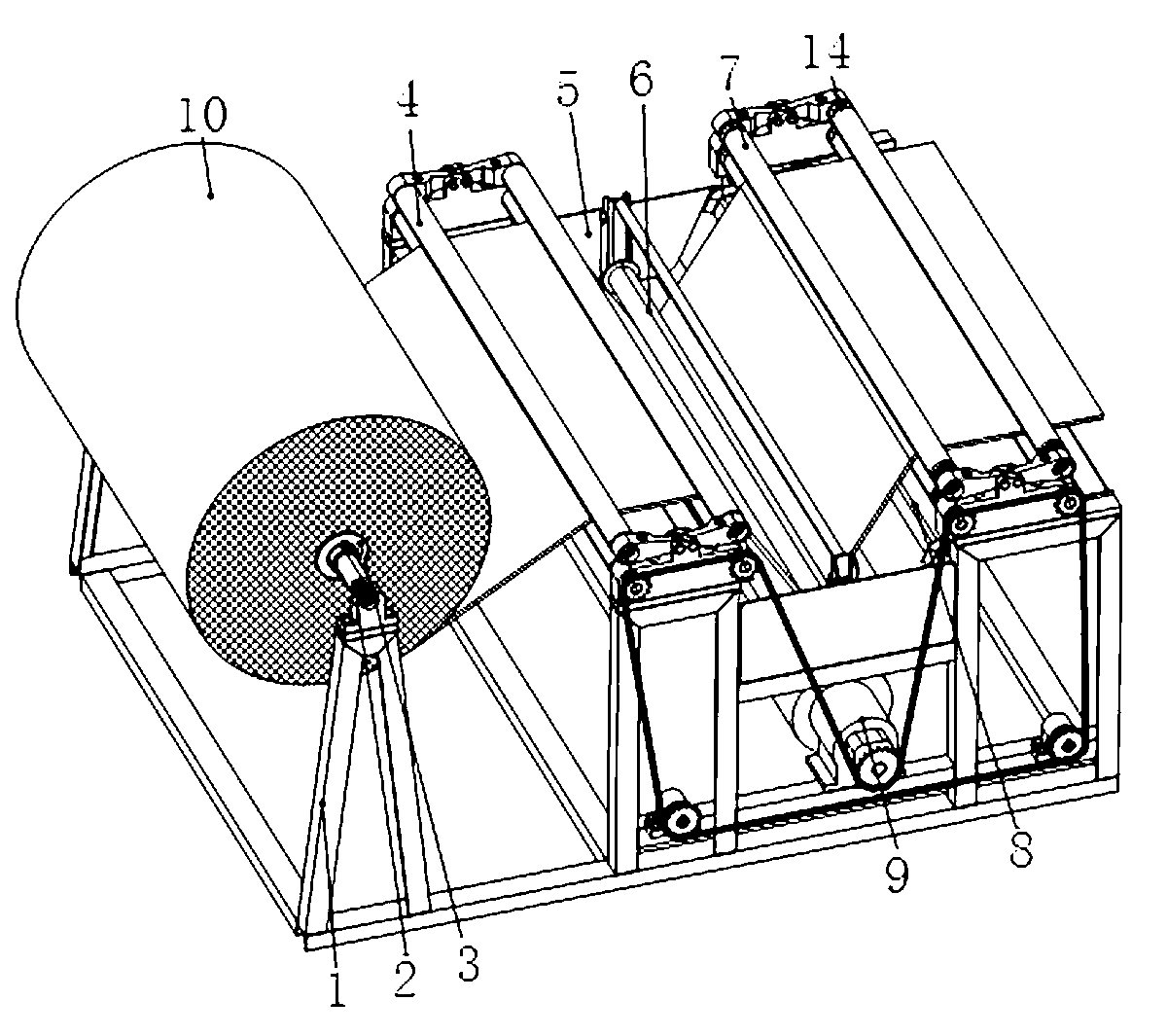

Internet vacuum drum shaping apparatus used for high speed thin sheet toilet paper machine

The invention discloses a kind of folder meshwork vacuum roller former for high speed tissue paper machine. The former realizes two-sided dehydration depending on mental efforts and vacuum suction procreated by high speed circumvolving of vacuum roller. Thanks to fixing pressure pulse extruding device on meshwork of formation arc zone, brace procreated by the meshwork can also make slurry dewater vastly. The former is characterized in that the dewatering zone is divided into three areas including centrifugal, vacuum and centrifugal pressure dehydration, which realizes step dewatering and efficient forming. The former including guide roll, vacuum forming roll, outer-mesh, inner-mesh, flexible pressure pulse extruding device on meshwork, air compartment etc. It makes slurry to dewater and form efficiently without agitating. Because of the balanced property of two-sided dewatering nature, sheet uniformity and two-side compatibility are good. With simple structure, low drive power and good reliability, the former is applicable on tissue paper machine with high speed and low range.

Owner:SOUTH CHINA UNIV OF TECH

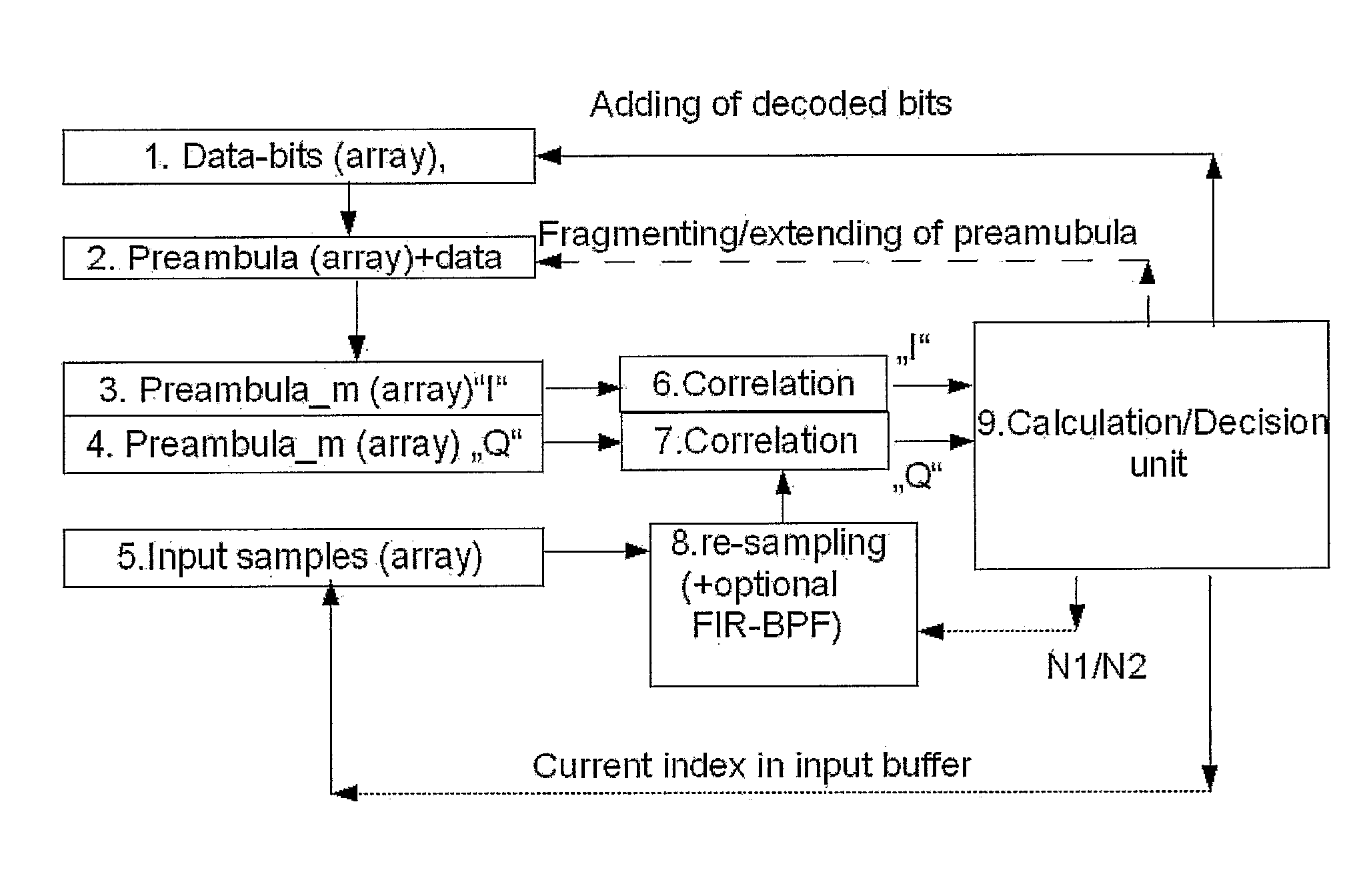

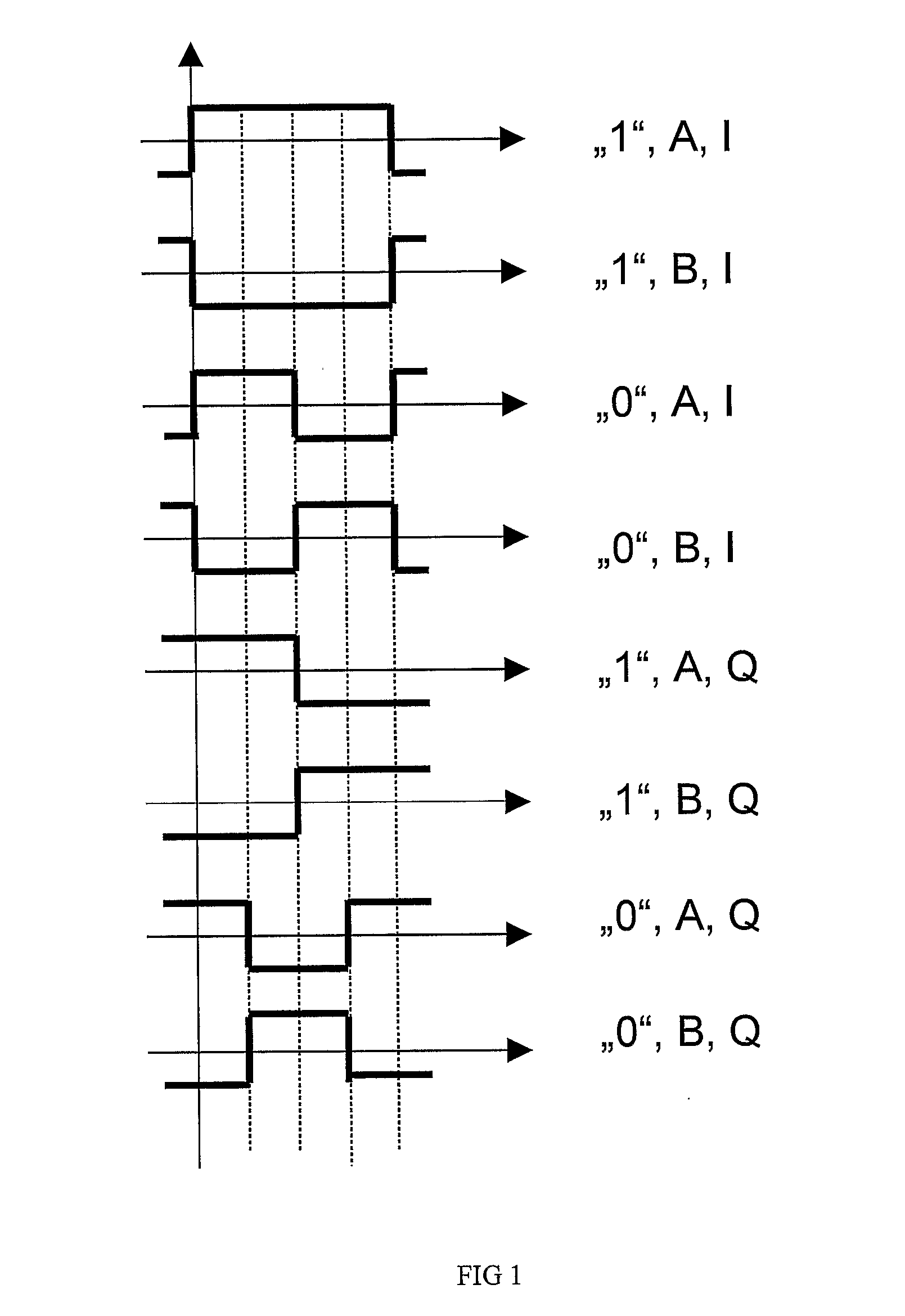

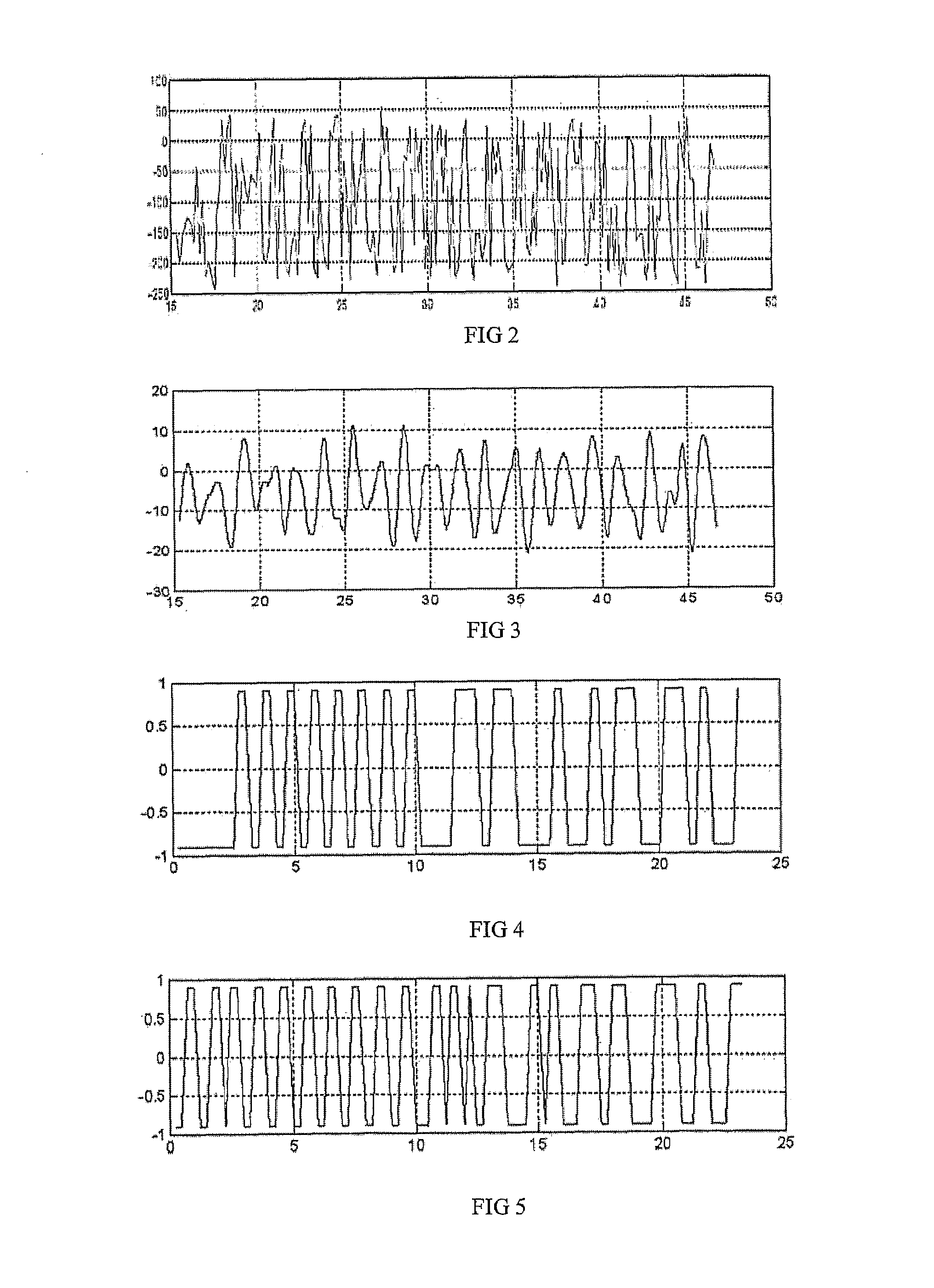

Method and device for synchronization of a decoder of a RFID receiver

InactiveUS20100026496A1Low signal to noise ratioSmall transmit powerBurglar alarm by hand-portable articles removalSynchronising arrangementZero correlationComputer science

A method for synchronizing a RFID receiver, comprising receiving an input signal from a RFID tag, said input signal comprising a preamble section, creating a first reference waveform, comprising at least a fraction of said preamble section, calculating a first correlation value by correlating said input signal and said first reference waveform, creating a second reference signal so that there is virtually zero correlation between said first reference waveform and said second reference waveform, and using said first correlation value and said second correlation value for adjusting synchronization timebase, wherein the sign and the size of said second correlation value indicates the size and the sign of phase inaccuracy of the synchronization timebase.

Owner:TALLINN UNIVERSITY OF TECHNOLOGY +1

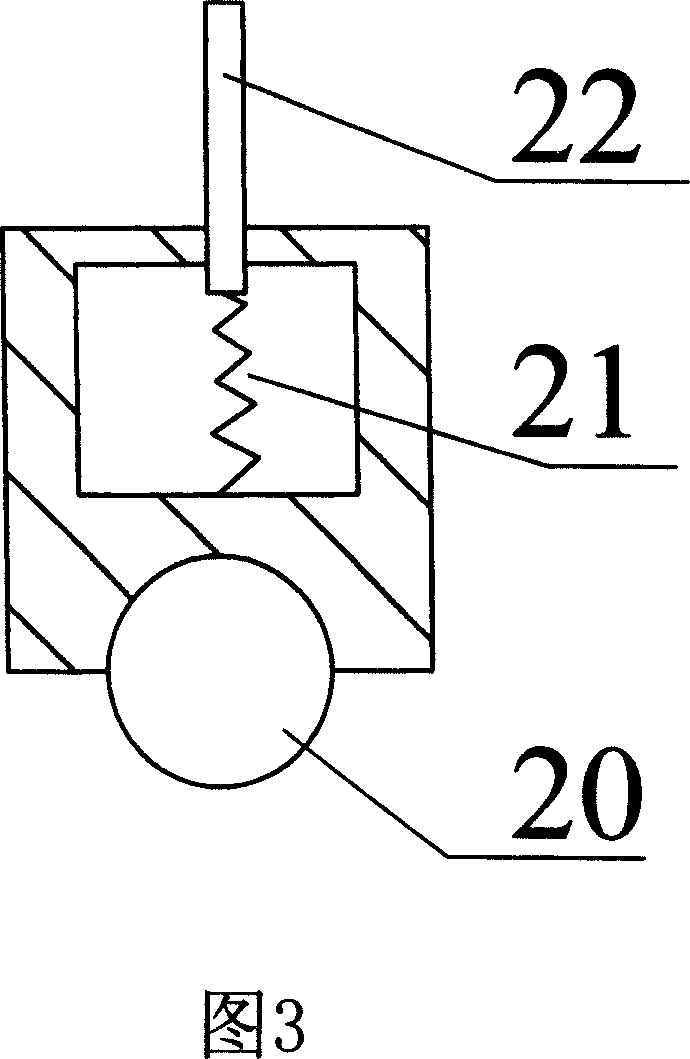

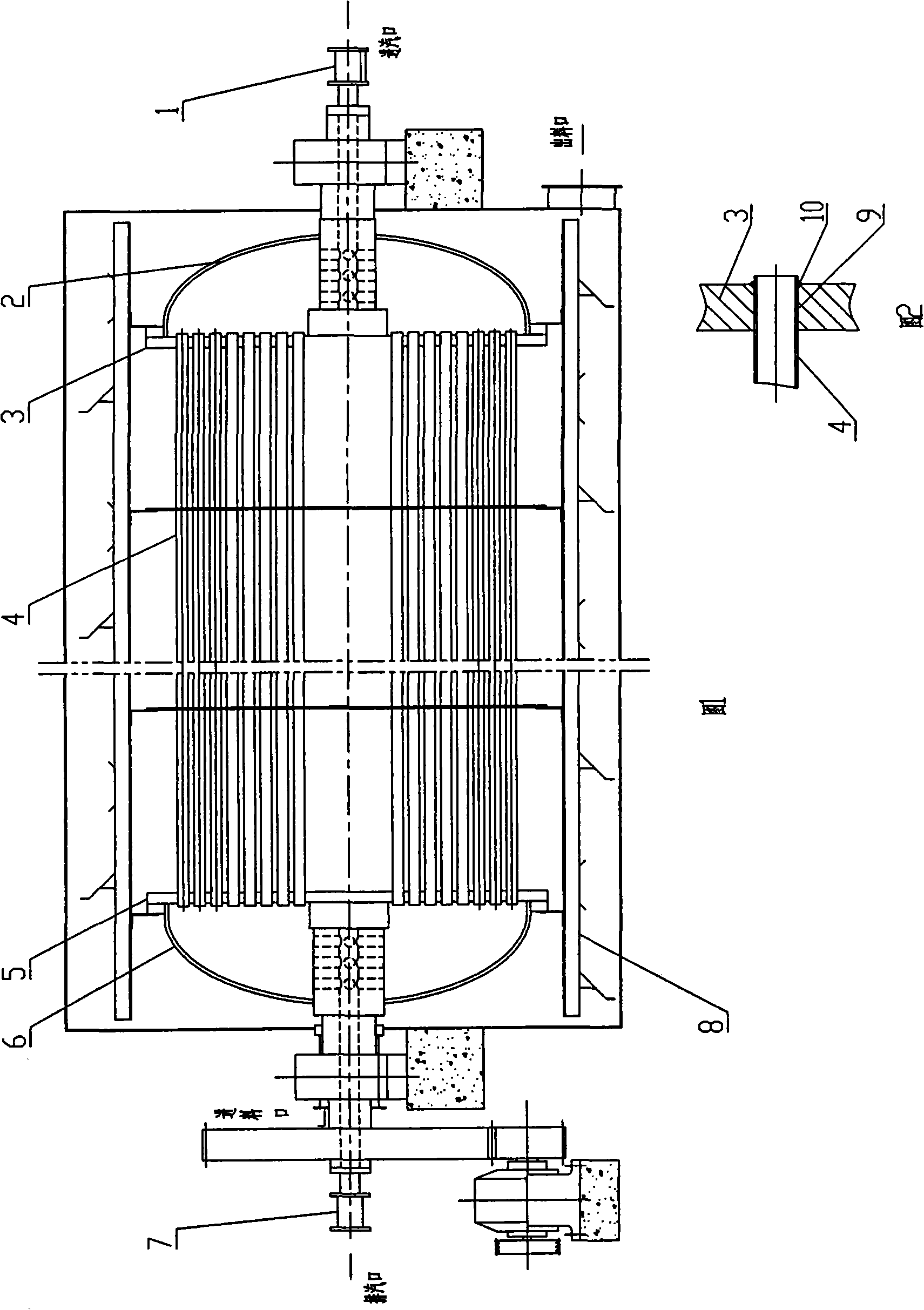

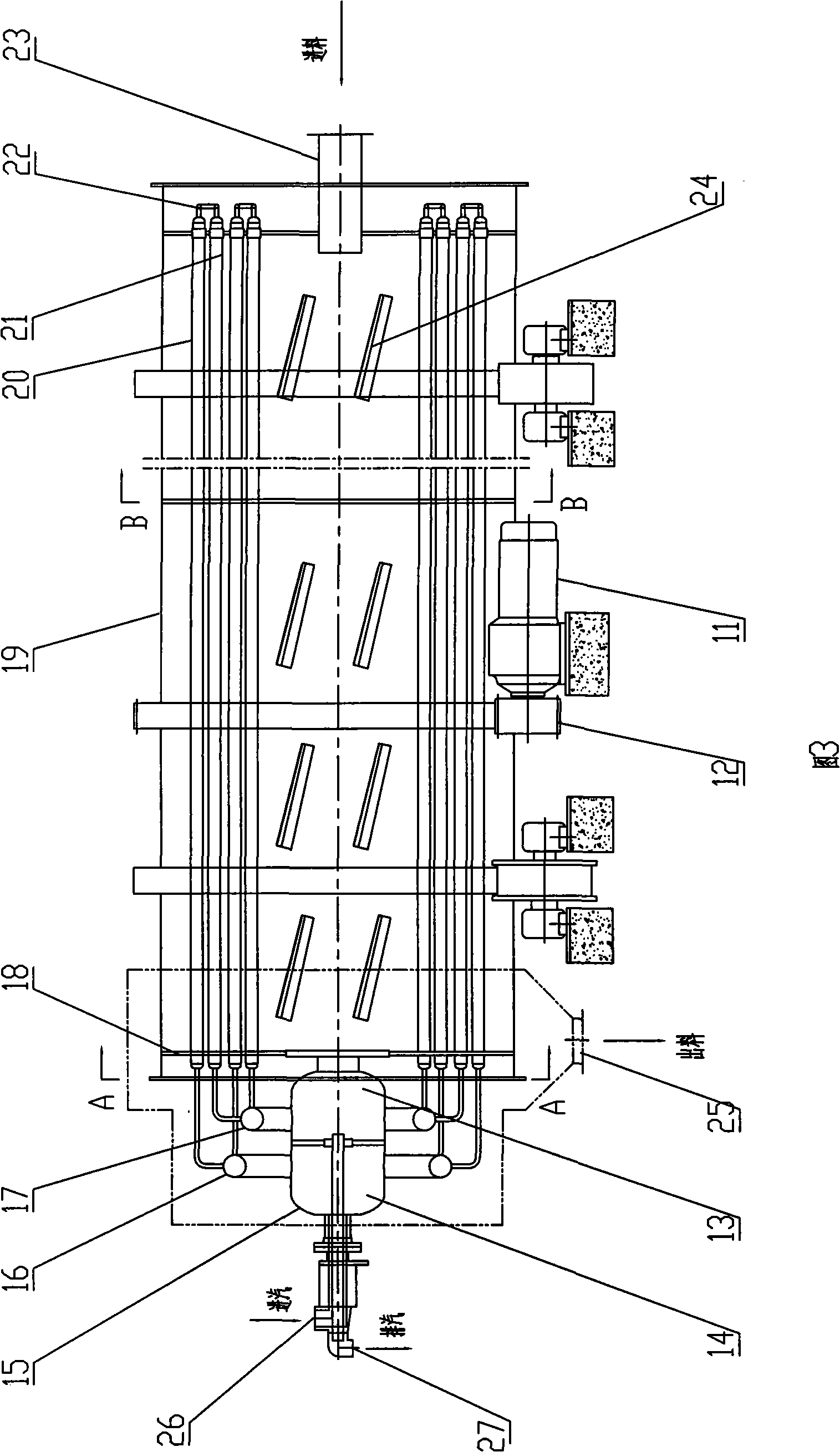

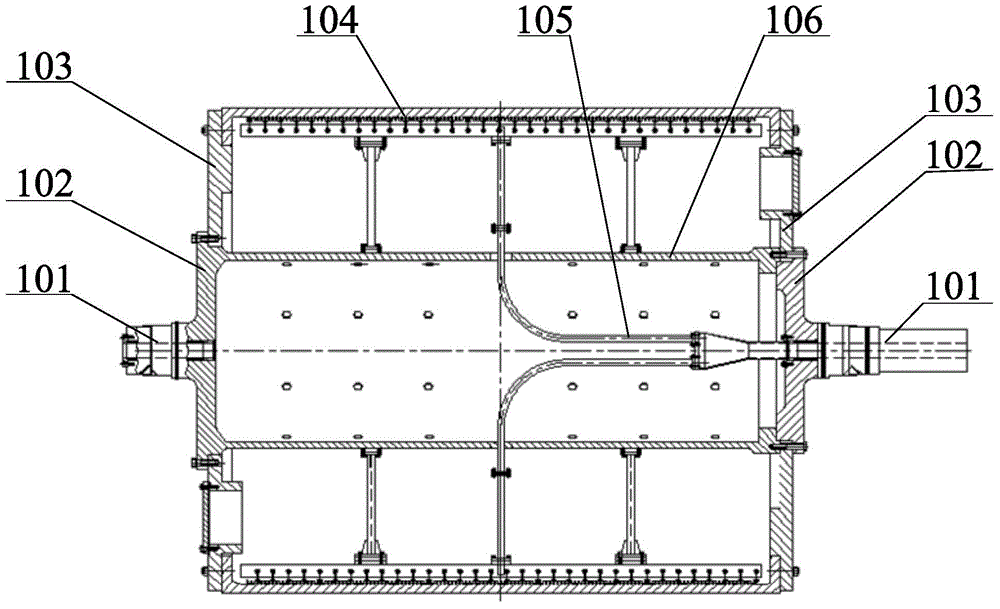

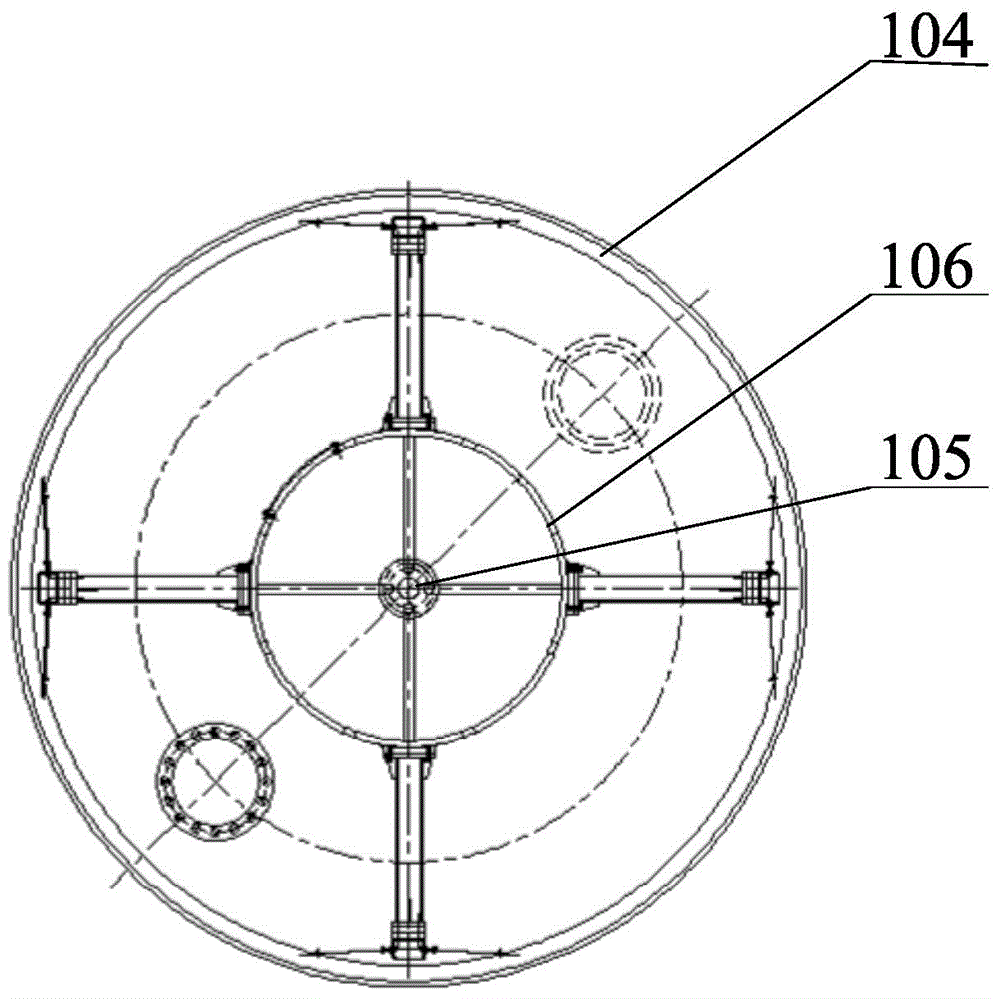

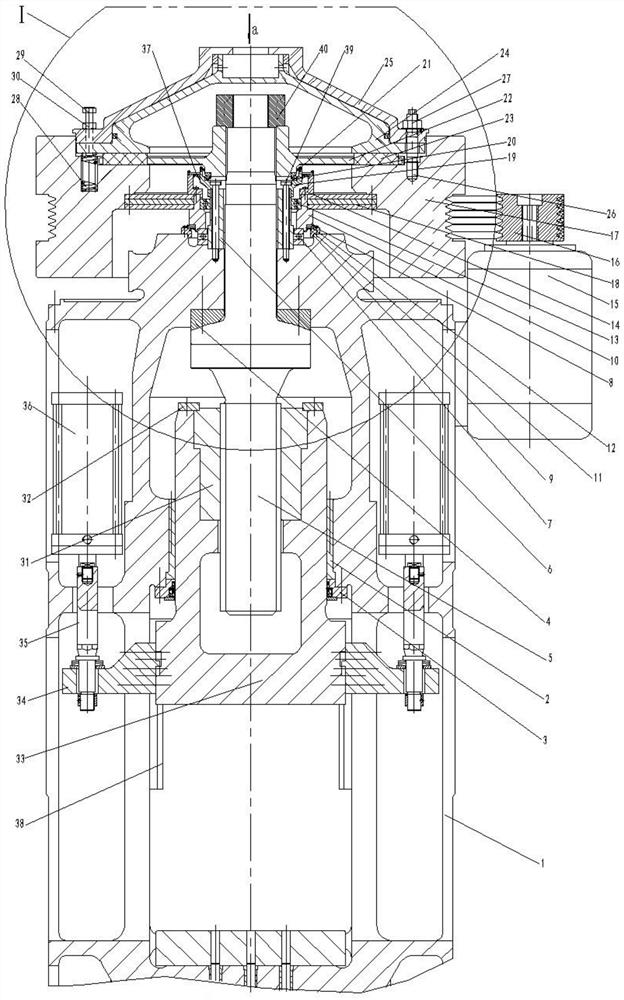

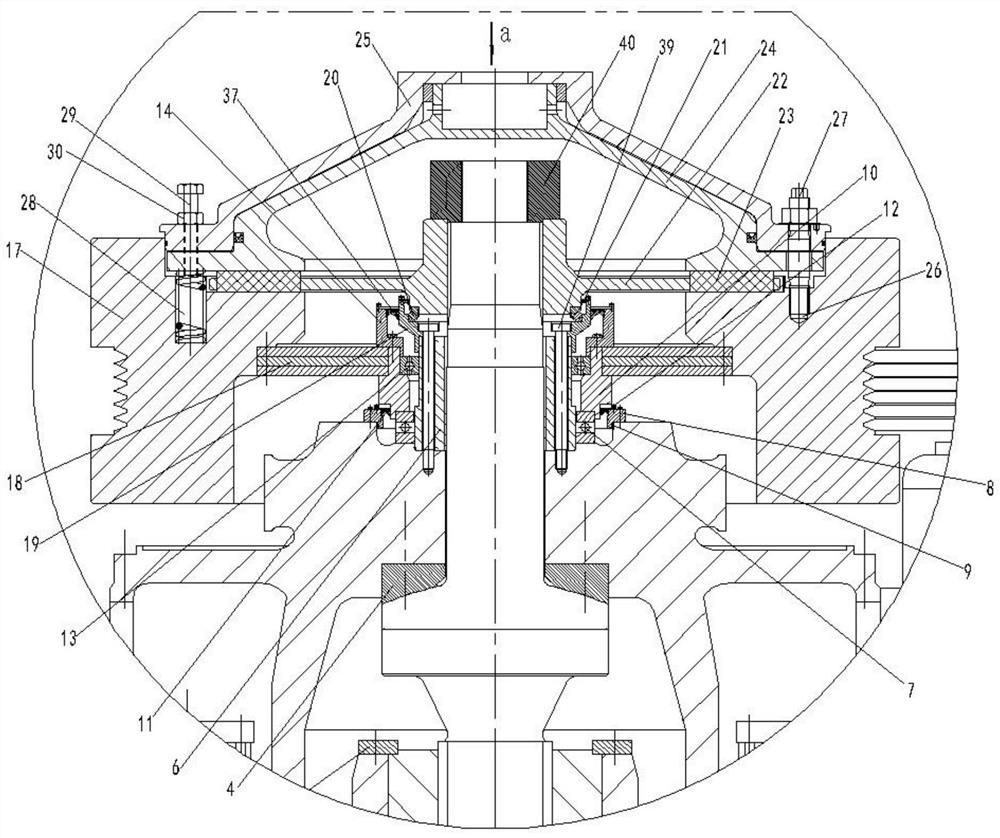

Revolving drum type tube bundle drying machine

InactiveCN101294766AReduce manufacturing costReduce processing difficultyDrying solid materials with heatDrying machines with non-progressive movementsEngineering

A rotary-drum type tube bundle drier comprises a rotary drum (19) and a plurality of heat exchange tubes arranged in a hollow cavity of the rotary drum (19) in an axial arrangement manner. The drier is characterized in that the heat exchange tubes are arranged in the inner cavity of the rotary drum (19) through at least two supporting tube sheets (18) which are arranged transversely and fixedly connected with the inner wall of the rotary drum (19); the heat exchange tubes are composed of steam feeding heat exchange tubes (20) and steam exhausting heat exchange tubes (21) arranged at intervals, and one end of the steam feeding heat exchange tube (20) communicates with one end of the steam exhausting heat exchange tube (21) through connecting tubes to form a loop, wherein the steam feeding heat exchange tube (20) and the steam exhausting heat exchange tube (21) are adjacent, and the other ends of the two heat exchange tubes are respectively connected with a steam feeding collecting ring (16) and a steam exhausting collecting ring (17); the steam feeding collecting ring (16) and the steam exhausting collecting ring (17) respectively communicate with a steam feeding cavity (14) and a steam exhausting cavity (13) in a steam collector (15). The rotary-drum tube bundle drier not only reduces production cost and processing difficulty, but also effectively solves the problems of uneven stress when the heat exchange tubes rotate and leakage between the heat exchange tubes and the tube sheets.

Owner:ZHENGZHOU WANGU MACHINERY

Energy-efficient threshing and pneumatic separating process and device

ActiveCN103271431AReduce the temperatureReduce drynessTobacco treatmentGas current separationProcess engineeringMechanical engineering

The invention relates to an energy-efficient threshing and pneumatic separating process and device. The energy-efficient threshing and pneumatic separating process is characterized in that a two-bin pneumatic separator is adopted for a first stage pneumatic separating unit; three-bin pneumatic separators are adopted for a second stage pneumatic separating unit, a third stage pneumatic separating unit and a fourth stage pneumatic separating unit; and the strips yield of the first stage pneumatic separating unit, the second stage pneumatic separating unit, the third stage pneumatic separating unit and the fourth stage pneumatic separating unit is respectively 45-64%, 15-30%, 10-15% and 5-15%. The strips yield is decreased gradually so that the device dimensions and capacities of the second stage pneumatic separating unit, the third stage pneumatic separating unit and the fourth stage pneumatic separating unit are decreased gradually, and the physical dimension of the fourth stage pneumatic separating unit is 1 / 2 that of the first stage pneumatic separating unit. The purpose of separating qualified tobacco flakes and tobacco stalks is achieved through the technological process, adjustment of the pressure balancing surface position in separation bins of the two-bin pneumatic separator and each three-bin pneumatic separator of the first to fourth stage pneumatic separating units and speed adjustment of a conveying mesh belt.

Owner:HONGTA TOBACCO GRP

Paper machine and drying cylinder thereof

InactiveCN105200839ASmall transmission powerImprove heat transfer efficiencyDryer sectionHeat resistanceAlloy

The invention discloses a drying cylinder. The drying cylinder comprises a cylinder body and flanges located at the two axial sides of the cylinder body and used for installing spindle noses, the cylinder body is a steel cylinder body, an interlayer is arranged at the circumferential inner side of the cylinder body and used for storing conduction oil with the heat-resistance temperature equal to or higher than 300 DEG C, and heaters used for heating the conduction oil are placed on the interlayer. As the steel cylinder body is adopted, the wall thickness and dead weight of the steel cylinder body are reduced compared with a cast iron cylinder body in the prior art, the transmission power of the drying cylinder is reduced, the heat transfer efficiency is improved, and energy is saved; the surface of the steel cylinder body is sprayed with chromium-based alloy and nitrided to prolong the service life. In addition, as the interlayer is additionally arranged on the drying cylinder and filled with the conduction oil with the heat-resistance temperature equal to or higher than 300 DEG C, and the heaters are used for heating the conduction oil, the temperature of the drying cylinder can be kept constant within the range of 240 DEG C-260 DEG C, wet paper is dried more easily, and the production efficiency is effectively improved. The invention further discloses a paper machine comprising the drying cylinder.

Owner:白城福佳科技有限公司

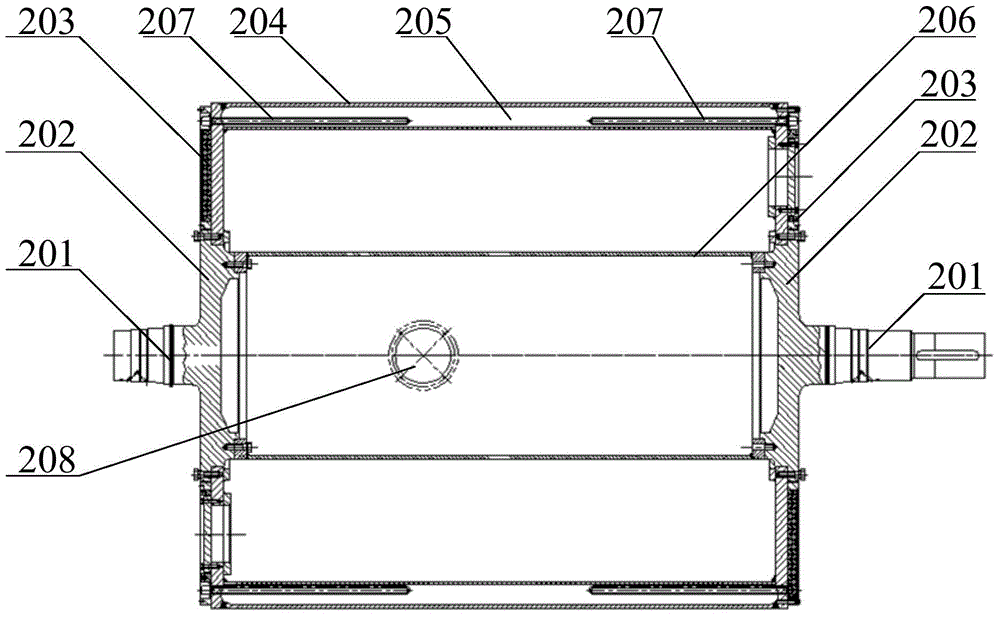

Pouring device

The invention discloses a pouring device. The pouring device comprises a base, a bracket, a plurality of pouring dies, a rotating bearing, a pinion and a driving device, wherein the bracket is rotatably arranged on the base; a pouring cavity of which the upper part is provided with an opening is formed on each of a plurality of pouring dies; a plurality of pouring dies are uniformly arranged on the peripheral edge of the bracket; the rotating bearing comprises an inner gear ring and an outer ring; the inner gear ring is connected with the bracket to drive the bracket to rotate; the outer ring is connected with the base; the pinion is meshed with the inner gear ring; and the driving device is arranged on the base and connected with the pinion to drive the pinion to rotate. According to the pouring device in the embodiment of the invention, the operation stability and reliability of the pouring device are improved; and the working efficiency of the pouring device is improved, transmission power is low, and the pouring device is energy-saving and environment-friendly, has a simple structure and is convenient to produce and install.

Owner:CHINA ENFI ENGINEERING CORPORATION

Internet vacuum drum shaping apparatus used for high speed thin sheet toilet paper machine

InactiveCN100558980CReduce disturbanceGood effectMachine wet endPress sectionPulp and paper industrySlurry

The invention discloses a sandwich vacuum roller former for a high-speed tissue paper machine. The former relies on the centrifugal force and vacuum suction force generated by the high-speed rotation of the vacuum roller to dehydrate both sides. The wire part of the forming area is equipped with a pressure pulse extrusion device, so the tension generated by the wire part can also dehydrate the pulp in large quantities. The feature of the former is that the dehydration area is divided into three areas: centrifugal dehydration, vacuum dehydration, and centrifugal extrusion dehydration, dehydration in sections, and efficient forming. The former includes guide rollers, large-diameter vacuum forming rollers, outer nets, inner nets, flexible pressure pulse extrusion devices in the net part, air chambers and other devices, which can not only make the pulp flow efficient dehydration and forming without disturbance, but also Due to the balanced dehydration performance on both sides of the pulp, the formed paper web has better uniformity and consistency on both sides. The former has simple structure, low transmission power and good reliability, and is more suitable for use on high-speed and low-weight tissue tissue machines.

Owner:SOUTH CHINA UNIV OF TECH

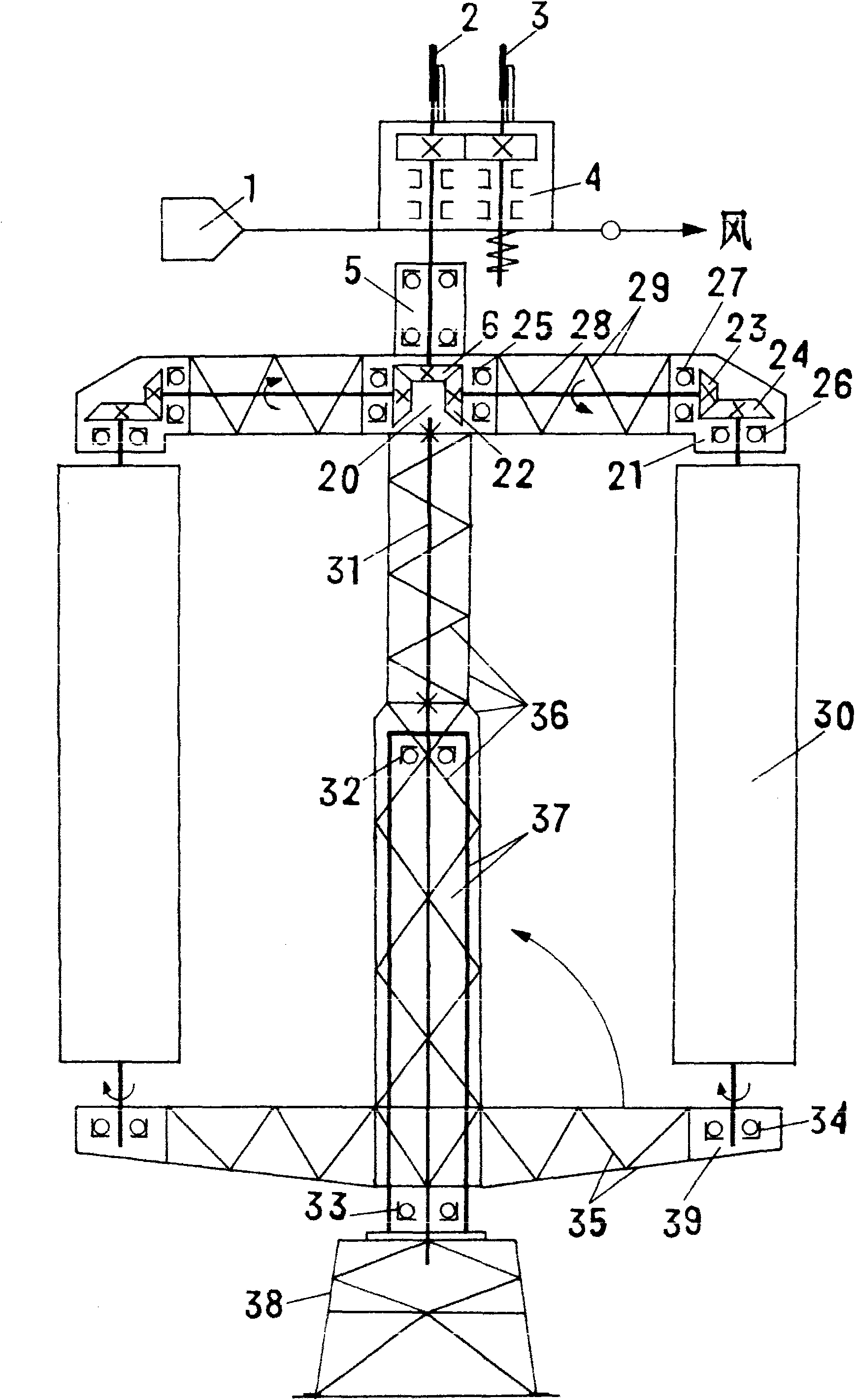

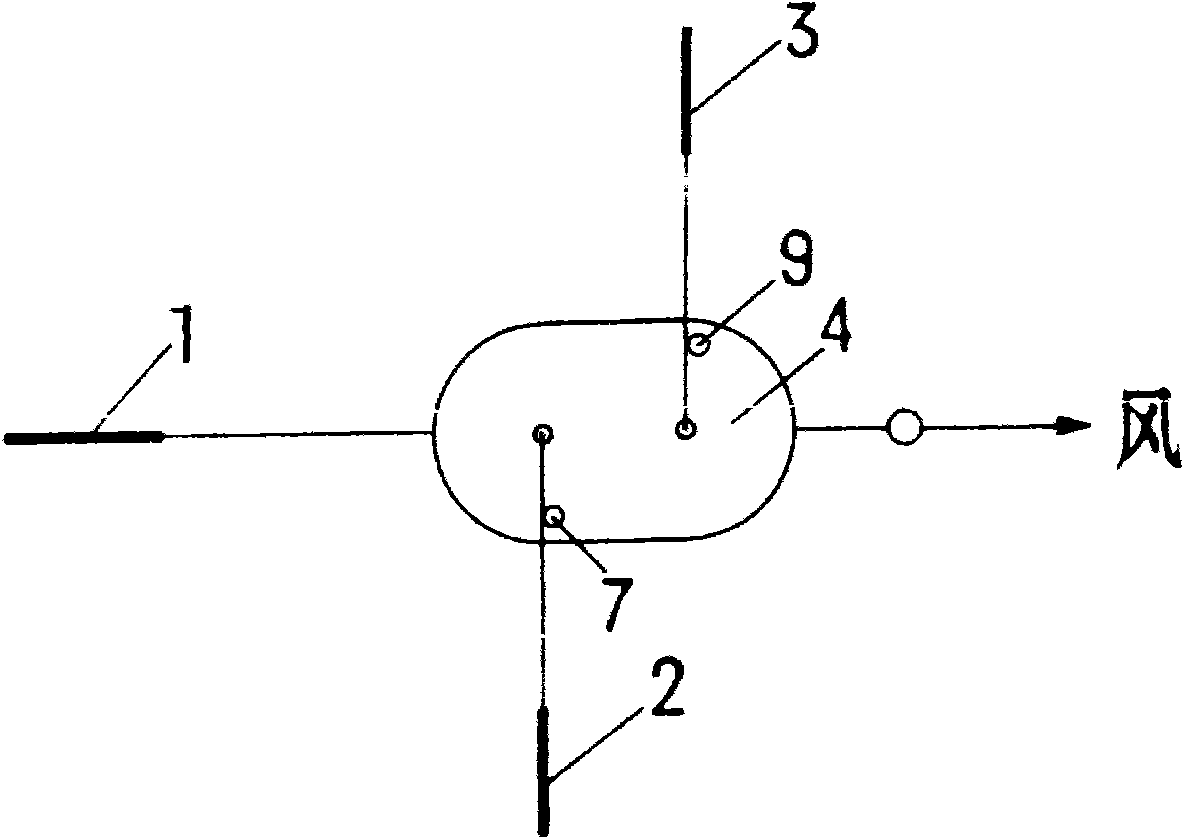

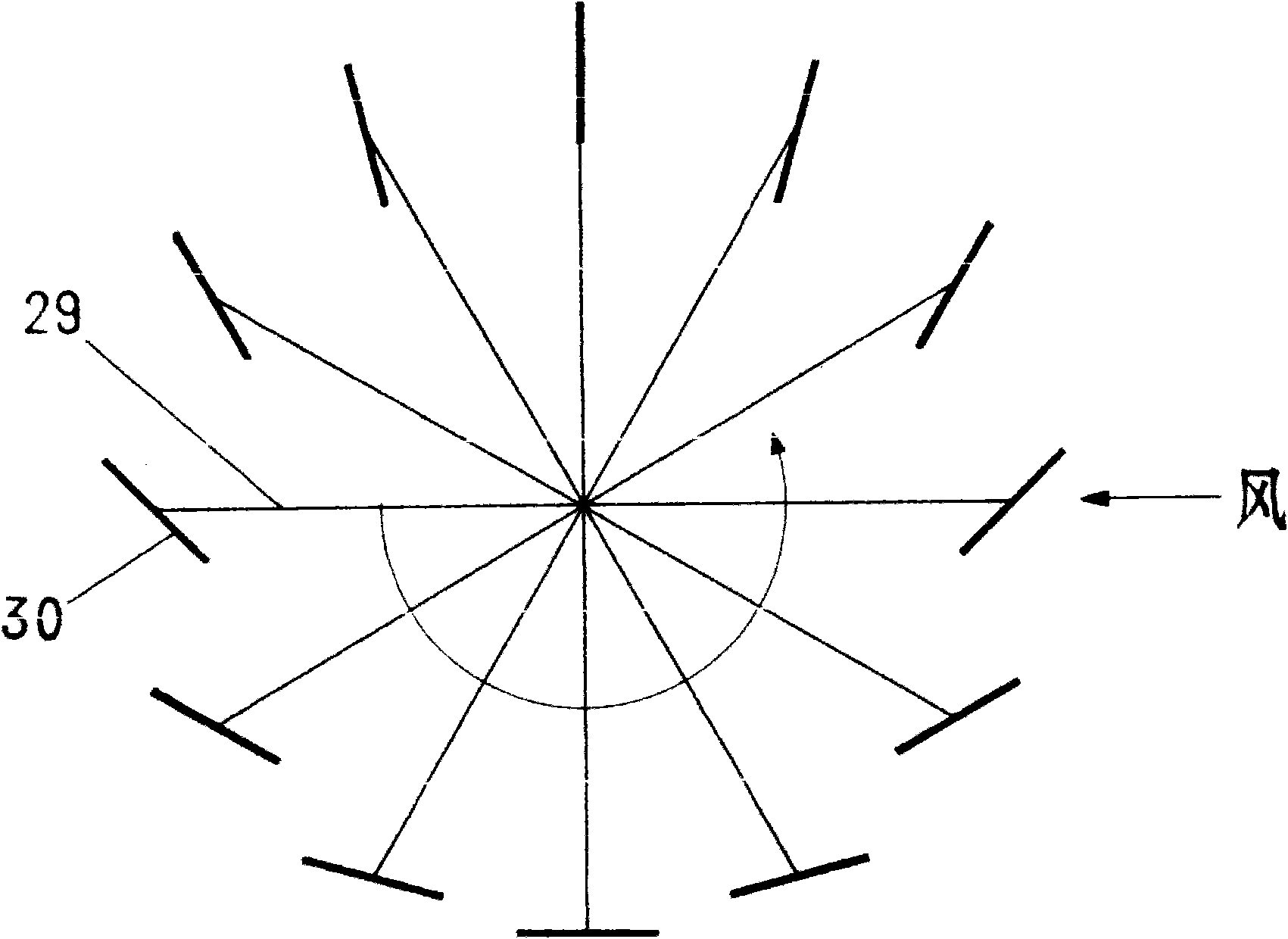

Vertical axis wind turbine with blade angle varying along with wind direction and wind velocity

InactiveCN101956653AReduce manufacturing costReduce power generation costsWind motor controlRenewable energy generationDrive shaftControl system

The invention relates to a vertical axis wind turbine with a blade angle varying along with wind direction and wind velocity, which comprises a control system, a planetary gearbox, a fixed axis gearbox, a transmission shaft, a main support, an upper cantilever beam, a lower cantilever beam, a bearing pedestal, a bearing, blades, a vertical axis, a tower and the like, wherein the vertical axis is connected with the tower through the bearing and the bearing pedestal; the main support is sleeved outside the vertical axis and the bearing pedestal, so that the middle part of the main support is connected with the middle part of the vertical axis, and the top end of the main support and the head of the vertical axis are connected with the bottom of the planetary gearbox; the control system is connected with the top of the planetary gearbox through the bearing pedestal; the root part and the end part of the upper cantilever beam are respectively connected with the side face of the planetary gearbox and the side face of the fixed axis gearbox, and the root part and the end part of the lower cantilever beam are respectively connected with the lower end of the main support and the bearing pedestal; both ends of the transmission shaft are respectively connected with the planetary gearbox and the fixed axis gearbox; and the blades are respectively connected with the fixed axis gearbox and the bearing pedestal so that output power maintains near the rated power value.

Owner:孙世杰

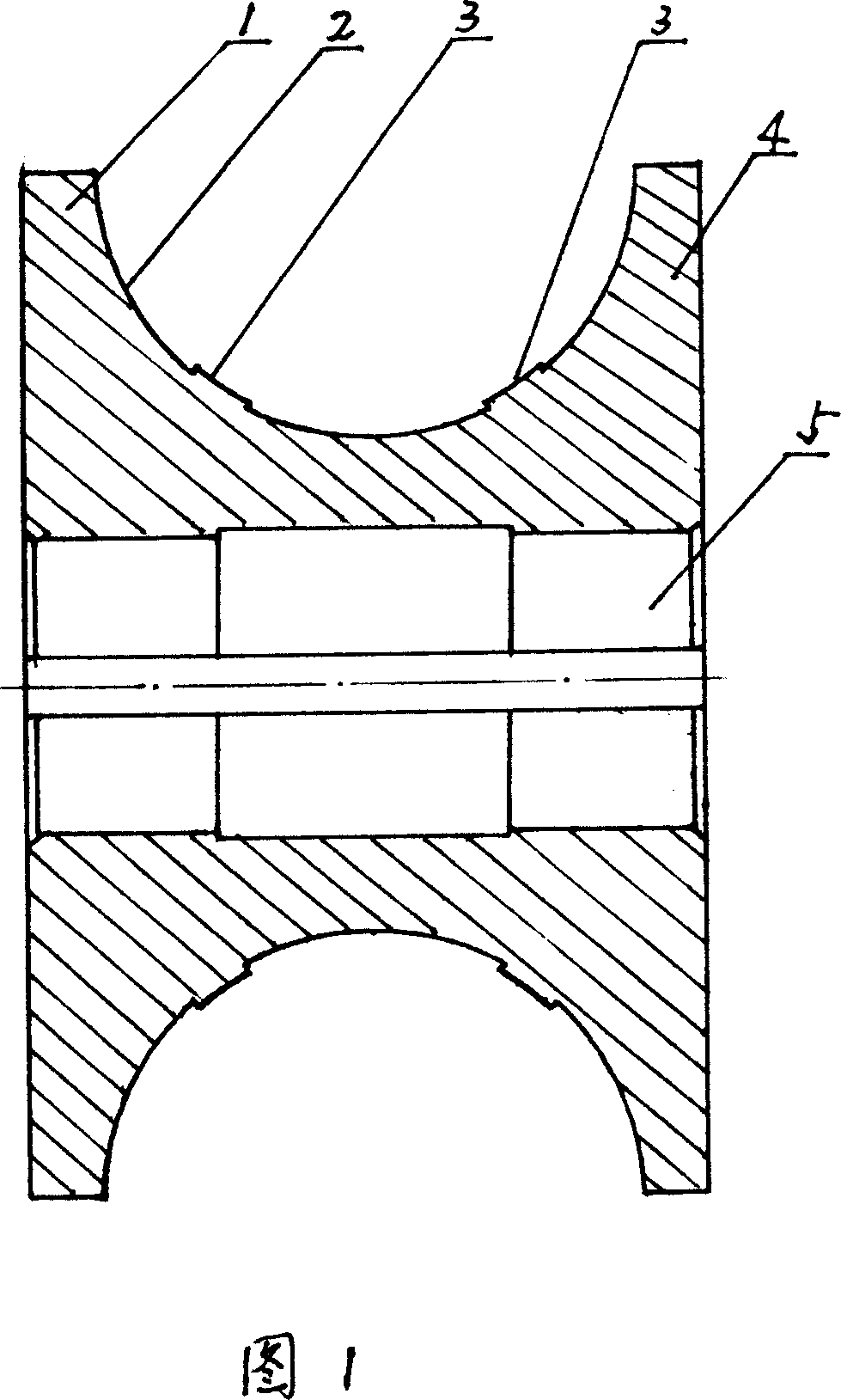

Not isodiametric rollers in use for molding welded steel pipes

InactiveCN101091959AAvoid scratchesImprove product qualityRollsMetal rolling arrangementsEngineeringElectric power

The invention discloses a welded steel pipe molding using diameter-inequality roller that is formed by upper roller and down roller which have the same shape and structure. The roller includes roller identity, roller hole and working concave. The invention could decrease the sliding friction of roller working surface and tube blank to avoid the scratches and improve the quality of the product. It also decreases running resistance of tube blank, and increases driving efficiency, saves electric power and prolongs useful life of roller.

Owner:葫芦岛市钢管工业有限公司

Silica gel calendering compounding machine

The invention discloses a silica gel calendering compounding machine, comprising a rack and five rollers, wherein, the rollers are connected with the rack through a bearing pedestal, and each roller is respectively connected with an independent variable frequency motor. According to the invention, a plurality of variable frequency motors are used to independently drive each roller to enable the speed ratio among rollers to be arbitrary ratio, cooperate the reasonable collocation of distance between rollers and generate certain buildup between rollers, so that the quality defect of bubbles carried in the products can be solved, and the advantages of low electricity consumption, small volume, high production efficiency, labor saving and the like of the silica gel calendering compounding machine are achieved.

Owner:SUZHOU DOFLY M & E TECH

Lifting device

InactiveCN1285785COptimize structural configurationAdjustable levelTextiles and paperState of artBobbin

A lifting device is composed of a lifting platform, a counterweight, a set of symmetrically arranged lifting platform transmission devices, a toothed belt transmission device arranged on the lifting platform, and a hanging spindle for hoisting empty and full pipes. The lifting platform transmission device and the toothed belt transmission device are respectively driven by motors; the lifting platform is composed of a lifting arm and a set of transverse rails installed by the lifting arm. Compared with the existing technology, the structure is simpler and the operation is more reliable; the problem of counterweight balance between the lifting platform and the full pipe is solved; the transmission power is reduced; the load and wear of the transmission parts are reduced; the level adjustment element is set to adjust the lifting platform The levelness; improve the operational reliability of the unit, and can also realize the lifting and the exchange of empty and full pipes according to the requirements of displacement and displacement speed.

Owner:TIANJIN HONGDA TEXTILE MACHINERY

Device for continuous carbon felt impregnation

InactiveCN102560928ARunning speed is stableStable and adjustable extrusion forceTextile treatment carriersLiquid/gas/vapor textile treatmentCarbon feltEngineering

A device for continuous carbon felt impregnation comprises a frame, a carrier shaft, a feed roll shaft, an impregnation tank and a discharge roll shaft, wherein the carrier shaft, the feed roll shaft, the impregnation tank and the discharge roll shaft are sequentially arranged on the frame. A drive motor is arranged between the feed roll shaft and the discharge roll shaft, the drive motor is respectively connected with the feed roll shaft and the discharge roll shaft through a transmission device, impregnation roll shaft brackets are disposed inside two ends of the impregnation tank respectively, an impregnation roll shaft is arranged on the impregnation roll shaft brackets, and a slanting guide board is disposed below the discharge roll shaft and connected with the impregnation tank. Thedevice can be used for continuous, mechanical and automatic impregnation for carbon felts, labor intensity can be reduced greatly, impregnation efficiency can be improved, and product quality stability can be improved.

Owner:HUNAN NANFANG BOYUN NOVEL MATERIAL

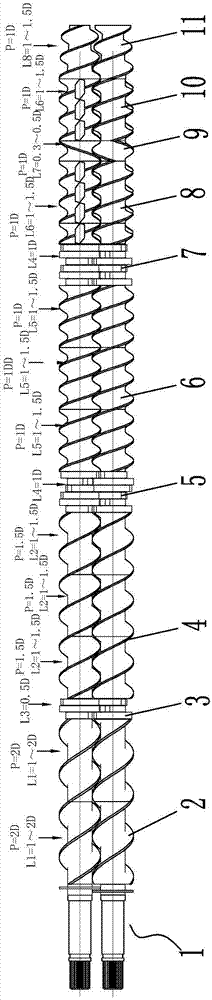

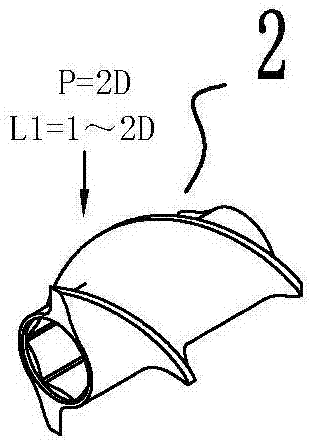

Stepped twin-screw extrusion device and bulking machine

The invention discloses a stepped twin-screw extrusion device and a bulking machine which comprises twin screws arranged in parallel, wherein screw configuration of the twin screws adopts a stepped variable pitch double-threaded screw structure; and the twin screws comprise a 2-time screw diameter coarse pitch double-threaded screw structure, a three-forward kneading block, a 1.5-time twin-screw structure, a primary three-forward three-backward kneading block, a one-time twin-screw structure, a secondary three-forward three-backward kneading block, a primary one-time slotted twin-screw structure, a double-threaded inverted screw structure, a secondary one-time slotted twin-screw structure and a discharging conical screw structure which are connected in sequence from a feeding hole in the front end of the screw to a discharging hole. According to the stepped twin-screw extrusion device and the bulking machine, retention time of materials in a chamber of the bulking machine is long, thekneading effect is excellent, the pressure in the chamber is uniform, the product stability is high, discharging uniformity is realized, the product is uniform in material form and excellent in kneading effect, the material curing degree is excellent, and the machine is suitable for producing high-oil low-starch (with starch content of 10% or less) high-grade floating and sinking feed.

Owner:嘉兴润阳机械有限公司

Device for continuous carbon felt impregnation

InactiveCN102560928BRunning speed is stableStable and adjustable extrusion forceTextile treatment carriersLiquid/gas/vapor textile treatmentCarbon feltEngineering

A device for continuous carbon felt impregnation comprises a frame, a carrier shaft, a feed roll shaft, an impregnation tank and a discharge roll shaft, wherein the carrier shaft, the feed roll shaft, the impregnation tank and the discharge roll shaft are sequentially arranged on the frame. A drive motor is arranged between the feed roll shaft and the discharge roll shaft, the drive motor is respectively connected with the feed roll shaft and the discharge roll shaft through a transmission device, impregnation roll shaft brackets are disposed inside two ends of the impregnation tank respectively, an impregnation roll shaft is arranged on the impregnation roll shaft brackets, and a slanting guide board is disposed below the discharge roll shaft and connected with the impregnation tank. Thedevice can be used for continuous, mechanical and automatic impregnation for carbon felts, labor intensity can be reduced greatly, impregnation efficiency can be improved, and product quality stability can be improved.

Owner:HUNAN NANFANG BOYUN NOVEL MATERIAL

Method for operating a fuel pump

ActiveCN101278115BReduce driving noiseReduce temperature loadElectrical controlMachines/enginesEngineeringInternal combustion engine

Owner:VTESCO TECH GMBH

Energy-saving and environment-friendly high-energy screw press

The invention discloses an energy-saving and environment-friendly high-energy screw press. The energy-saving and environment-friendly high-energy screw press comprises a machine body, a circular guiderail, a circular guide rail cover, a spherical bearing seat, a screw rod, a bearing fixed inner body, a thrust ball bearing, a convex cover, an O-shaped sealing ring, a bearing outer body, a lower sealing ring, a lower sealing ring cover, a deep groove ball bearing, a deep groove ball bearing cover, a main motor, a driving pulley, a driven pulley-type flywheel, a multi-layer positioning plate, aroller bearing seat, a pushing self-aligning roller bearing, an inner sealing ring, a friction clutch disc, a friction block, a pneumatic conical separation-reunion piston, a conical cylinder body, aguide screw rod, a cylinder body fastening nut, an up-down adjusting bolt, a back tightening nut, a copper nut, a top surface baffle plate, a sliding block, a lifting frame, a lifting rod, a return stroke lifting cylinder and an upper sealing ring. According to the energy-saving and environment-friendly high-energy screw press, the output energy is high, the transmission power is small, power is saved, energy saving is remarkable, the return stroke is quick, the production efficiency is high, the anti-bias load ability is high, multi-position die forging is achieved, environmental protection is achieved, the service life is long, and the safety of the whole machine is ensured; and the energy-saving and environment-friendly high-energy screw press can be widely used in the forging pressureforming process.

Owner:青岛浩源益友锻压机械有限公司

High-efficiency and energy-saving leaf threshing and air separation process

ActiveCN103271431BReduce the temperatureReduce drynessTobacco treatmentGas current separationProcess engineeringThreshing

The invention relates to an energy-efficient threshing and pneumatic separating process and device. The energy-efficient threshing and pneumatic separating process is characterized in that a two-bin pneumatic separator is adopted for a first stage pneumatic separating unit; three-bin pneumatic separators are adopted for a second stage pneumatic separating unit, a third stage pneumatic separating unit and a fourth stage pneumatic separating unit; and the strips yield of the first stage pneumatic separating unit, the second stage pneumatic separating unit, the third stage pneumatic separating unit and the fourth stage pneumatic separating unit is respectively 45-64%, 15-30%, 10-15% and 5-15%. The strips yield is decreased gradually so that the device dimensions and capacities of the second stage pneumatic separating unit, the third stage pneumatic separating unit and the fourth stage pneumatic separating unit are decreased gradually, and the physical dimension of the fourth stage pneumatic separating unit is 1 / 2 that of the first stage pneumatic separating unit. The purpose of separating qualified tobacco flakes and tobacco stalks is achieved through the technological process, adjustment of the pressure balancing surface position in separation bins of the two-bin pneumatic separator and each three-bin pneumatic separator of the first to fourth stage pneumatic separating units and speed adjustment of a conveying mesh belt.

Owner:HONGTA TOBACCO GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com