Lifting device

A lifting device and lifting platform technology, which is applied in textiles and papermaking, etc., can solve the problems of low success rate of picking up full tubes and empty tubes, difficulty in completely consistent height of hanging spindles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation, structure, features and effects provided by the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

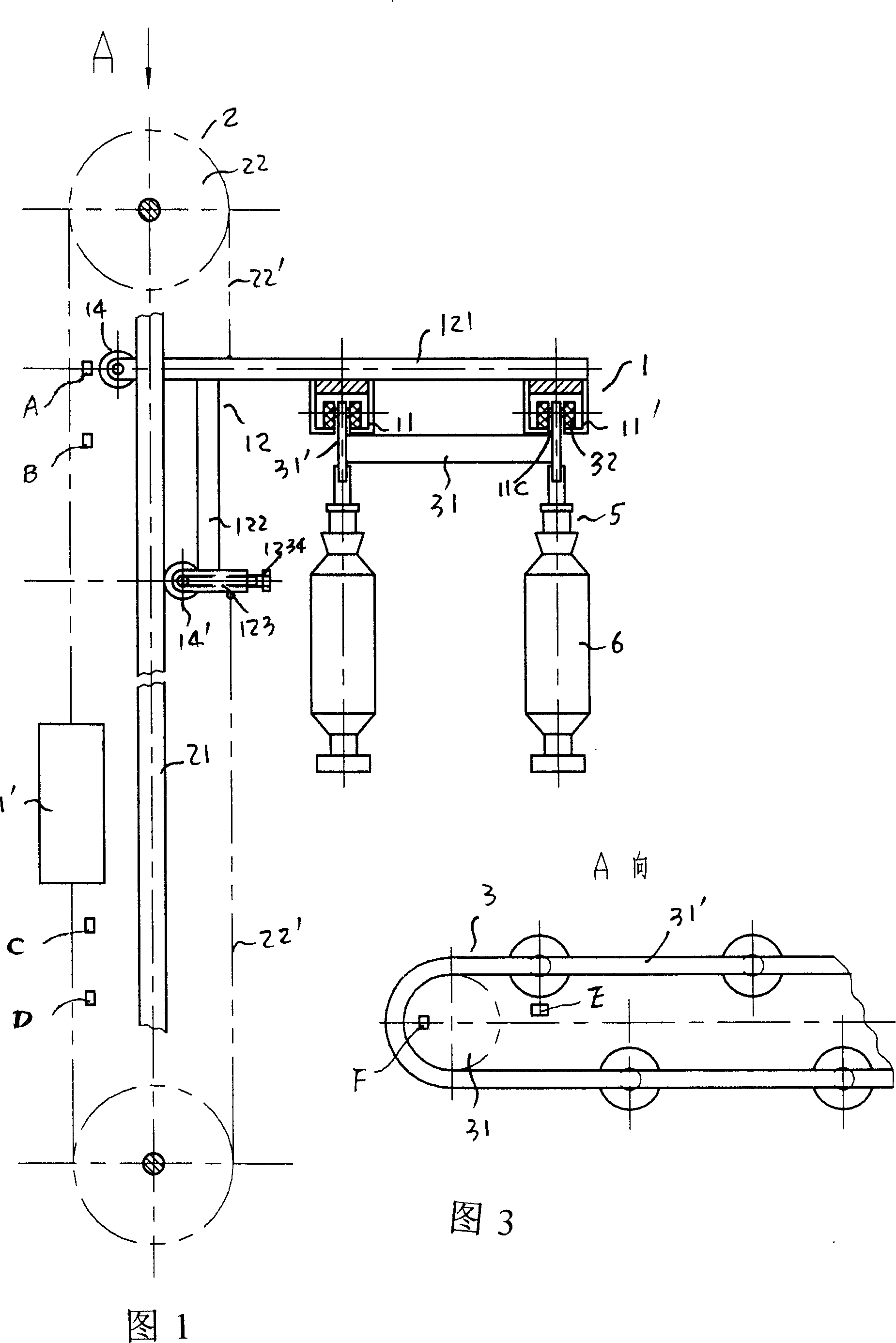

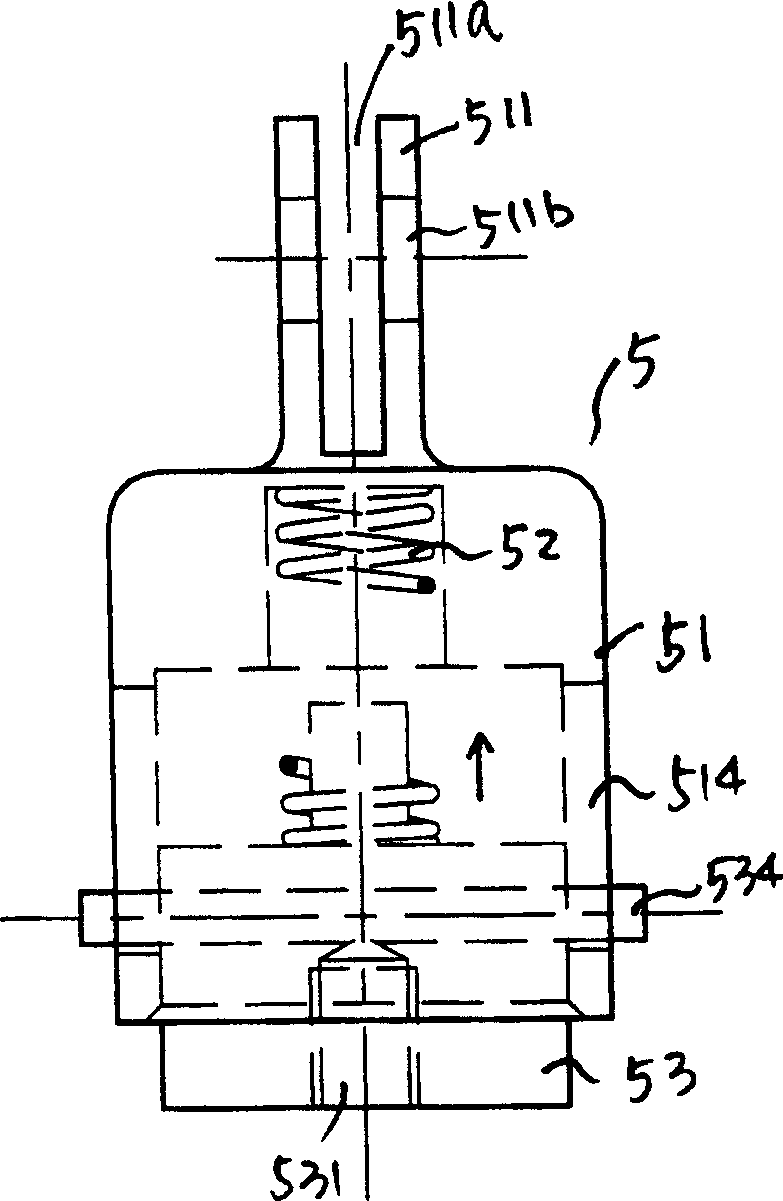

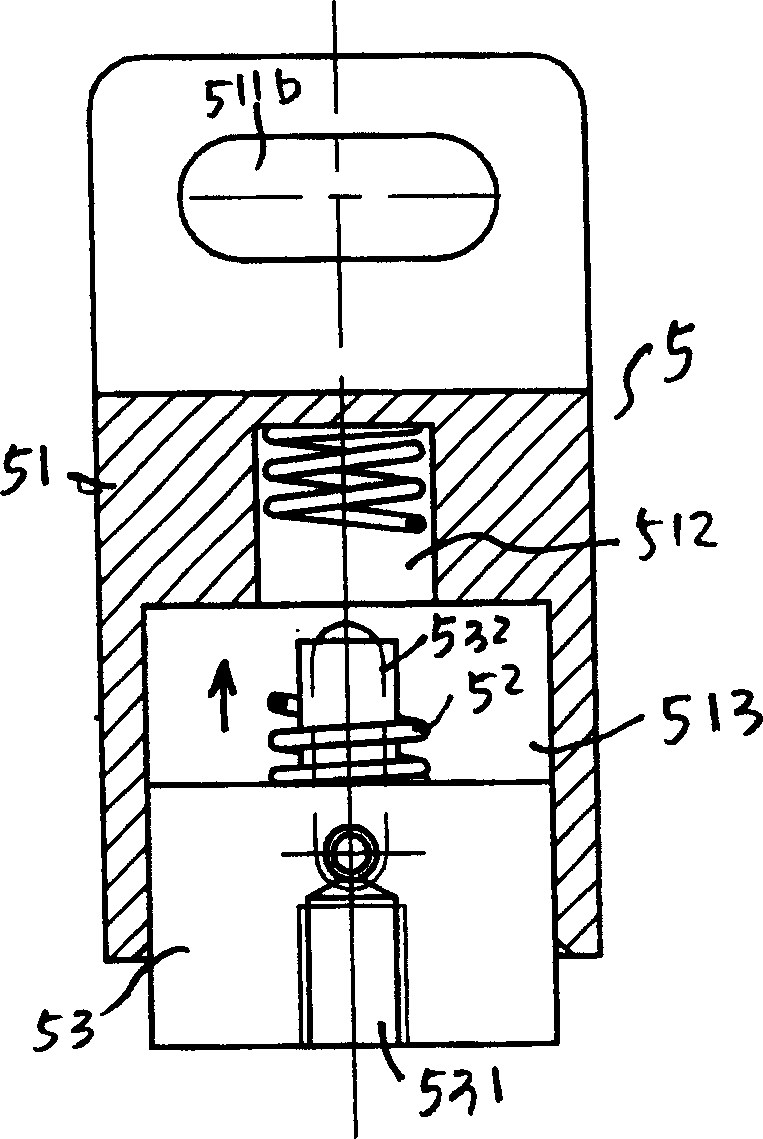

[0019] As shown in Figure 1-3, a lifting device consists of a lifting platform 1, a lifting platform transmission device 2 symmetrically arranged in groups, a toothed belt transmission device 3 arranged on the lifting platform 1, and hoisting empty pipes and full pipes 6 The hanging spindle 5 is composed of the lifting platform transmission device and the toothed belt transmission device respectively driven by a motor; the group number of the symmetrically arranged lifting platform transmission device 2 matches the number of spindles of the roving frame;

[0020] The lifting platform 1 is composed of a lifting arm 12 running along a column track 21, and a set of transverse rails 11, 11' installed by the lifting arm. The lifting arm is composed of a first roller The hori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com