High-efficiency and energy-saving leaf threshing and air separation process

A high-efficiency and energy-saving technology for leaf blowing and air separation. It is used in solid separation, air flow to separate solids from solids, and tobacco. It can solve problems such as increased power consumption, blocked air ducts, and increased dust removal equipment. The effect of reducing energy consumption and noise, small transmission power, and improving availability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

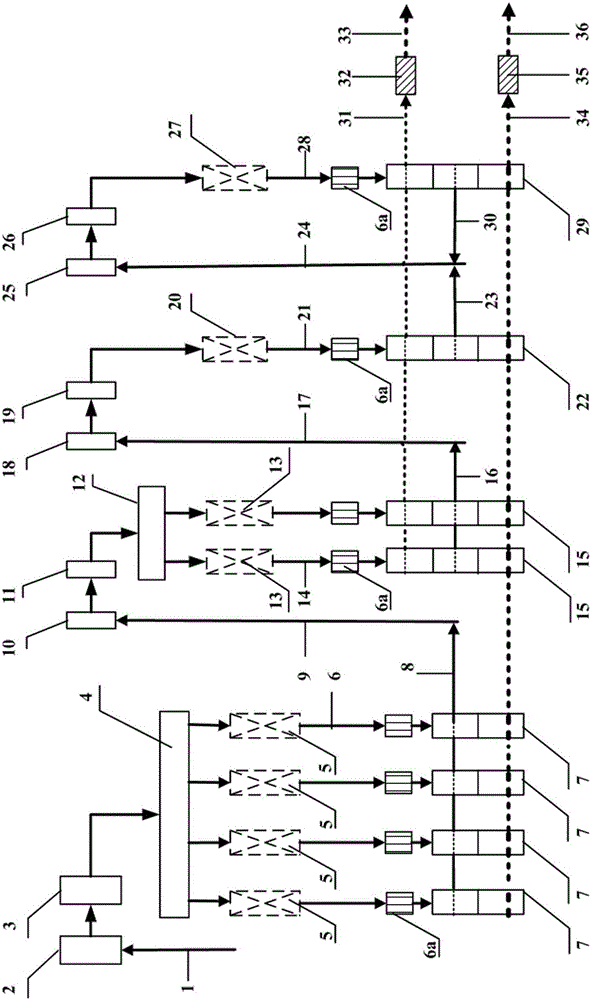

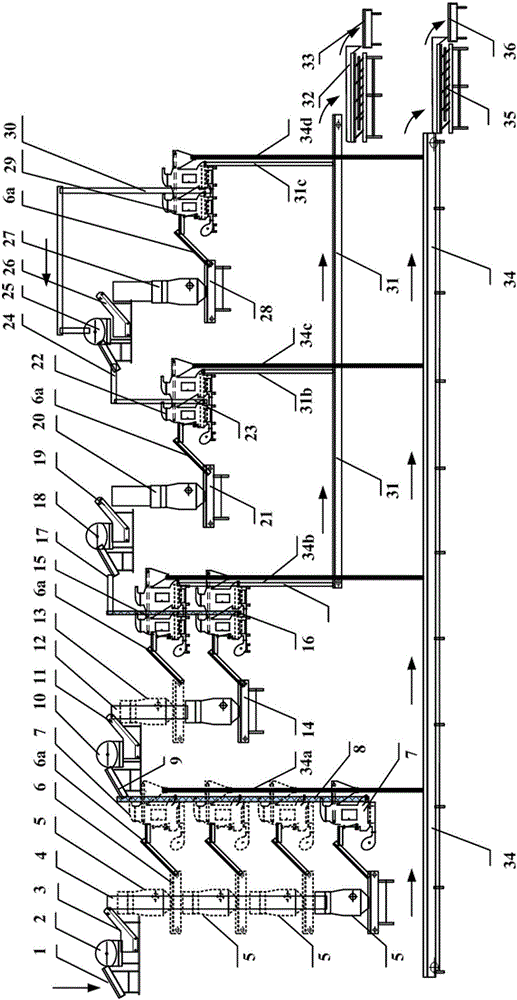

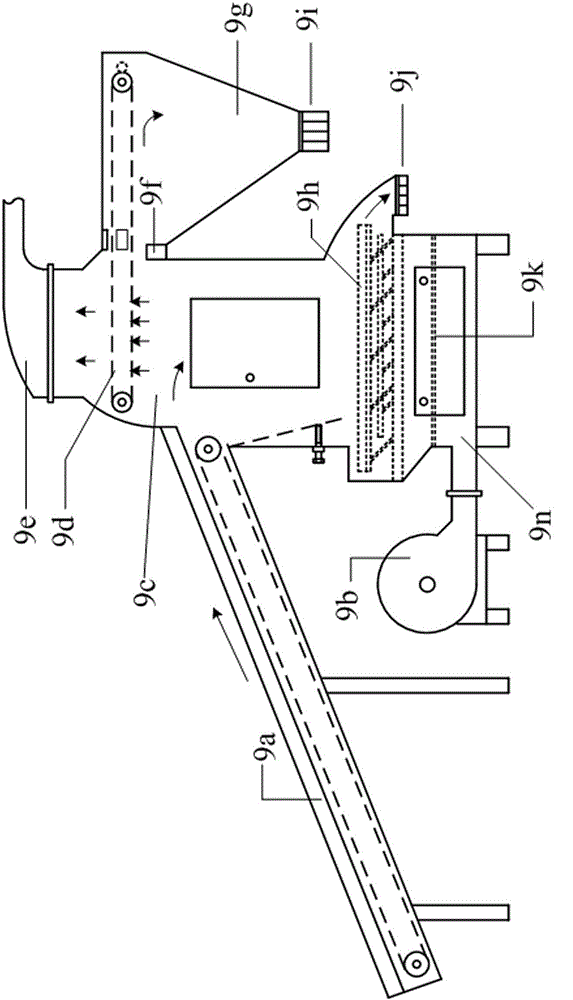

[0043] Example: Such as figure 1 Shown: the technological process of the present invention is made up of 4-stage leaf thresher unit and 4-stage air subunit, wherein the first-stage leaf thresher 5 is made up of four leaf threshers, the second-stage leaf thresher 13 is two leaf threshers Composition, the third-stage leaf-thresher 20 and the fourth-stage leaf-thresher 27 are respectively made up of a leaf-thresher, and the outlet end of each leaf-thresher 5 is equipped with an accelerated conveyor belt 6a, and the first-stage leaf-thresher The air sub-machine 7 configured is a double-chamber air sub-machine, and the second-stage, third-stage, and fourth-stage leaf toppers are equipped with two air sub-machines 15, three-chamber type air sub-machines 22, and three-chamber type air sub-machines. There are 29 warehouse-type wind extension machines.

[0044] The first-stage leaf-threshing air sub-unit consists of a feed conveyor belt 1, a scraper feeder 2, a bin feeder 3, a propo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com