Not isodiametric rollers in use for molding welded steel pipes

A technology of welding steel pipes and rolls, which is applied in the field of radial rolls, can solve the problems of accelerated roll wear, many parts of sliding friction, and affecting the surface quality of steel pipes, etc., and achieve the effects of reducing sliding friction, reducing running resistance, and overcoming scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

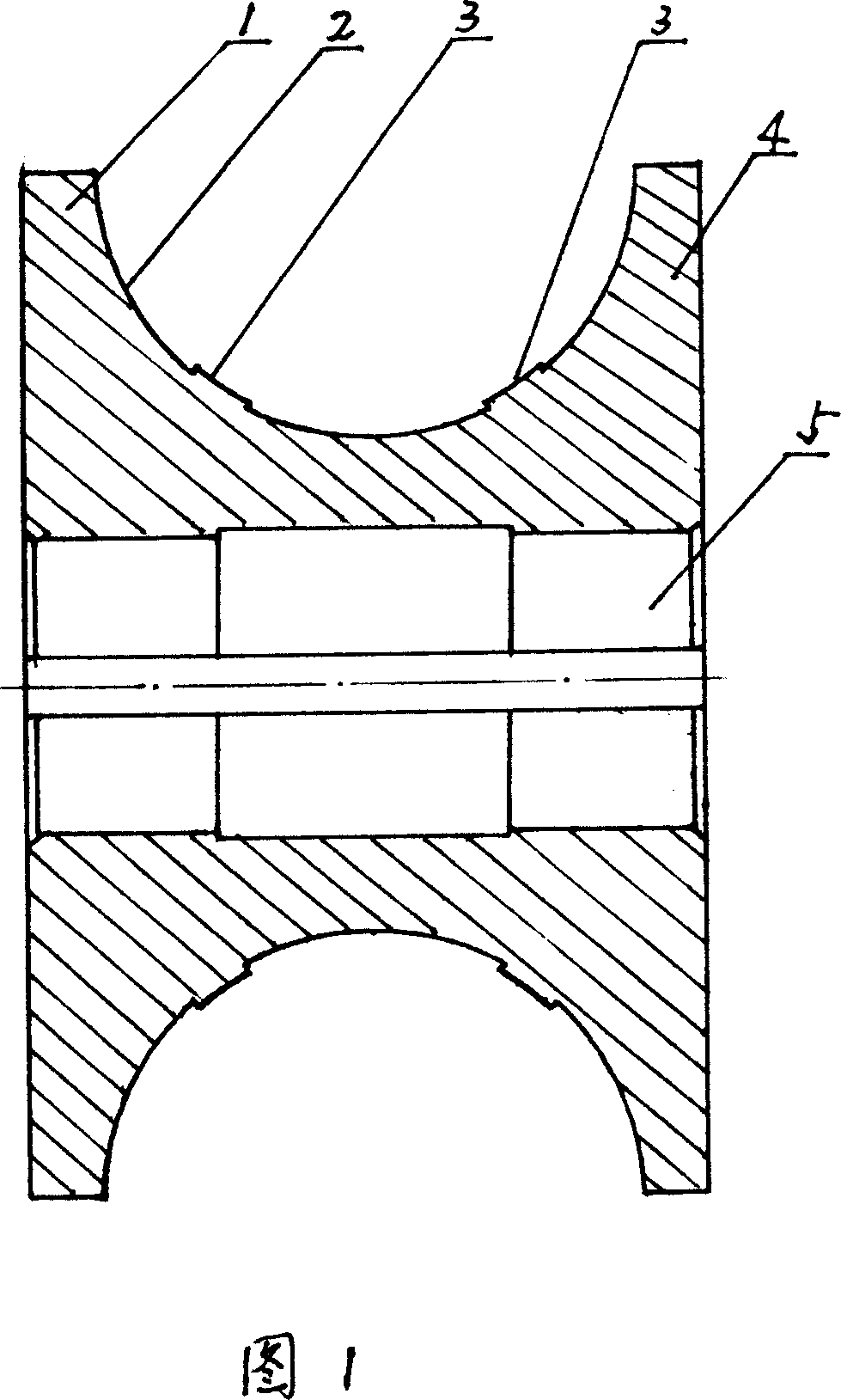

[0007] In the accompanying drawings, the unequal-diameter rolls for forming welded steel pipes of the present invention are composed of corresponding upper rolls and lower rolls. The shape and structure of the upper and lower rolls are the same, and only the drawings of the lower rolls are shown. The roll 1 is composed of a roll body 4, a roll hole 5 that can be fixedly connected with the roll shaft, and a working concave surface 2; the working concave surface 2 has a convex band 3 that is slightly raised relative to the concave surface, so that welded steel pipes can be formed. diameter rolls. The above-mentioned convex strip 3 slightly protruding relative to the concave surface is only different in tolerance relative to the concave surface in actual processing. When the forming rollers finish forming and sizing the round tube blank, the working surface of the tube blank and the roll only has real contact between the raised part and the tube blank without relative movement, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com