High-efficiency energy-saving threshing air separation new process and equipment

A high-efficiency and energy-saving technology for leaf threshing and air separation, which is applied in the direction of solid separation, separation of solids from solids by air flow, tobacco, etc., can solve the problems of increased crushing rate, poor transportation stability, large water loss, etc., and achieves reduction Effects of energy consumption and noise, low transmission power, and improved availability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

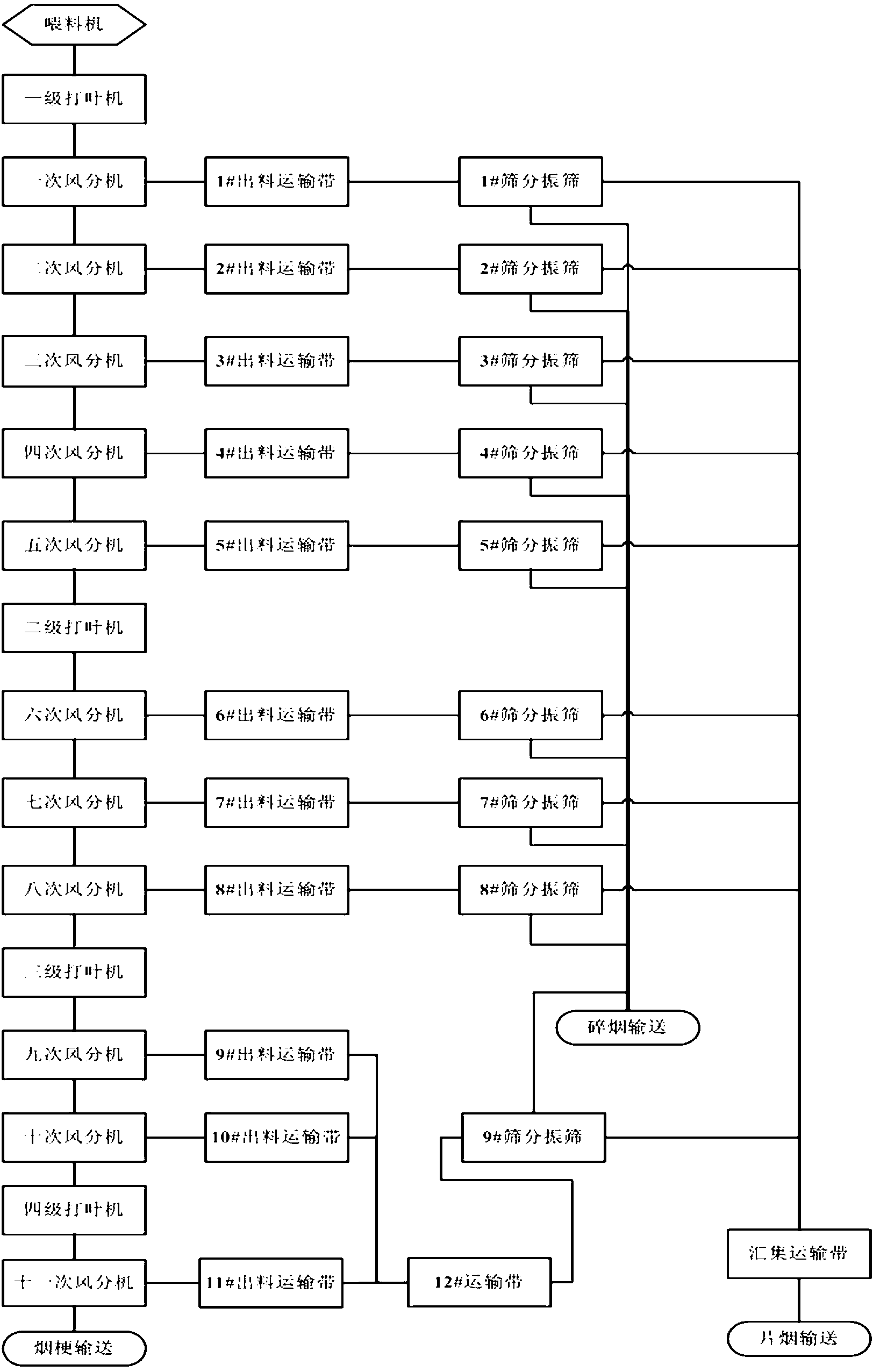

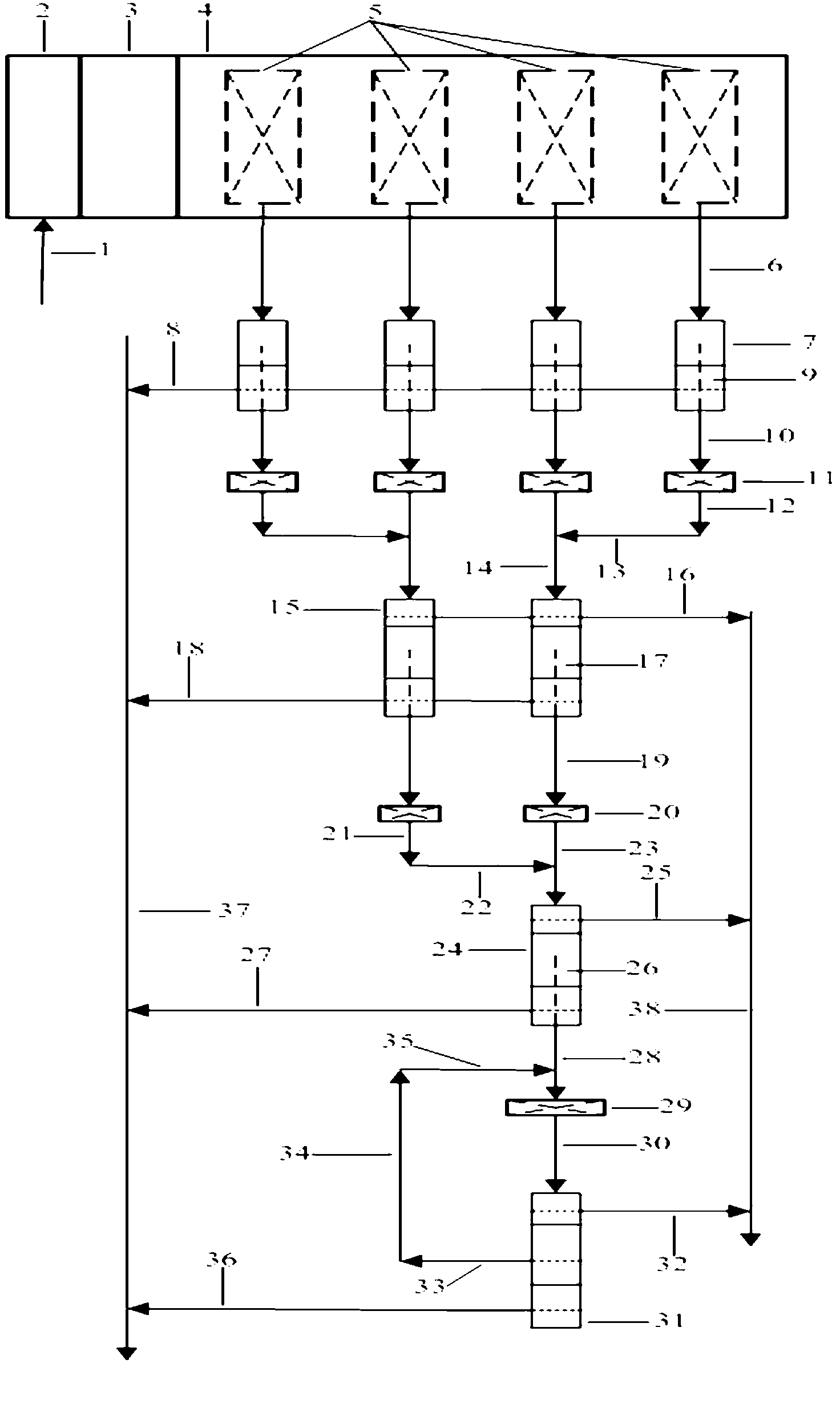

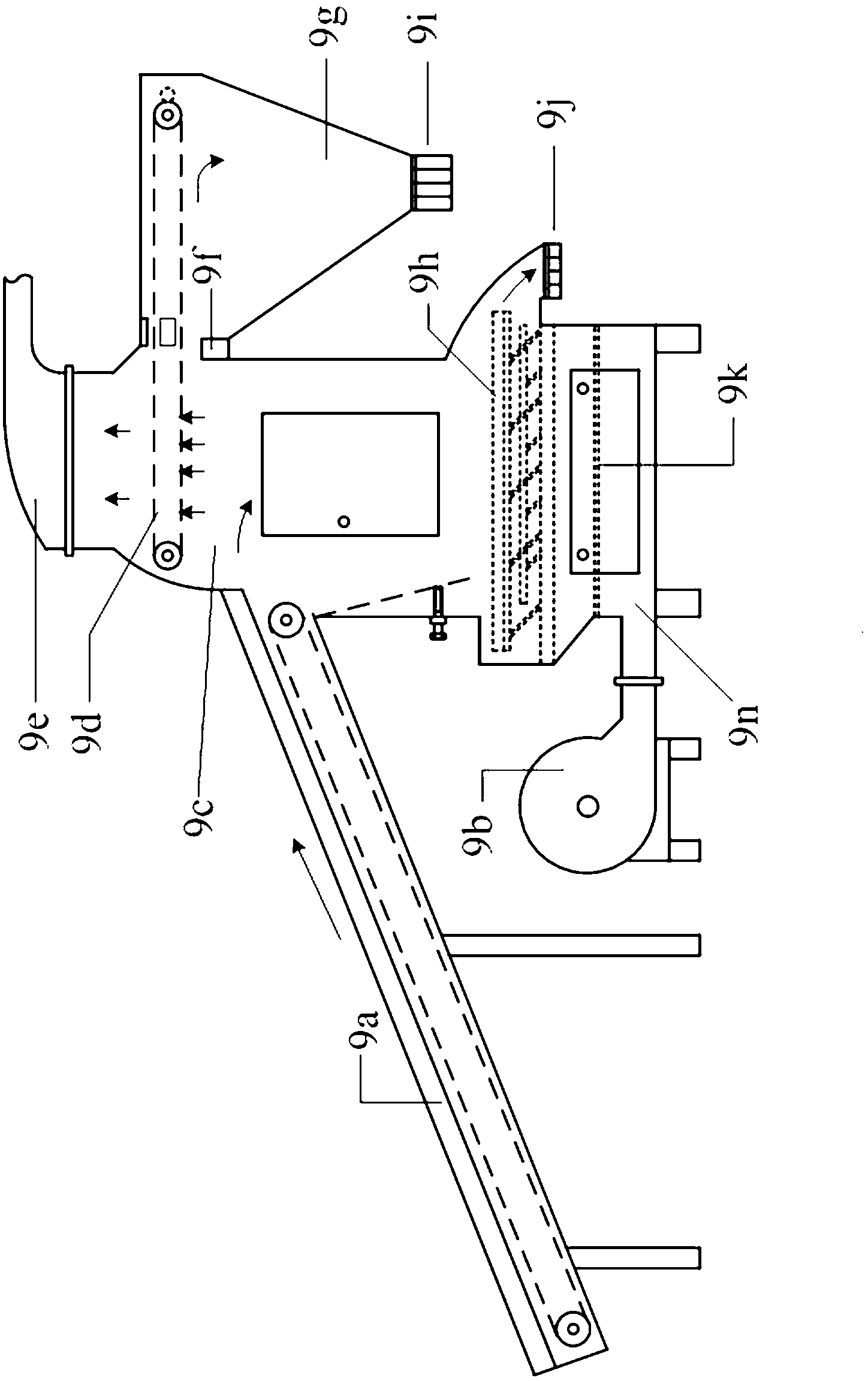

[0052] Work process such as figure 2 As shown, the heated and humidified tobacco leaves in the moistening process are put into the bin feeder 3 through the feeding conveyor belt 1 and the scraper feeder 2 to balance the feed flow, and the proportional distributor 4 evenly distributes the tobacco leaves to a Each leaf-threshing machine of the first-stage leaf-threshing unit 5 is to tear off the tobacco sheet and tobacco stem, and the tobacco sheet and tobacco stem mixture from each leaf-threshing machine are sent to each air sub-machine branch of the first-stage air sub-unit 7 by the conveyor belt 6 , the smoke sheets selected by the double warehouse air sub-machine 9 fall on the smoke sheet conveyor belt 8 and are taken out to the smoke sheet collection conveyor belt 37 for transportation, and the rest of the mixture falls on the stem blade conveyor belt 10 and is again conveyed to Secondary leaf thresher unit 11; the mixture of tobacco flakes and tobacco stems from every two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com