Device for continuous carbon felt impregnation

A technology of carbon felt and glue dipping, which is applied in the processing of textile materials, textiles and papermaking, liquid/gas/steam textile material processing, etc. It can solve the problems of large gaps in operation effects, affecting product quality, and waste of glue, etc., to achieve Improve production efficiency and product quality, realize mechanization and automation, and simplify equipment operation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

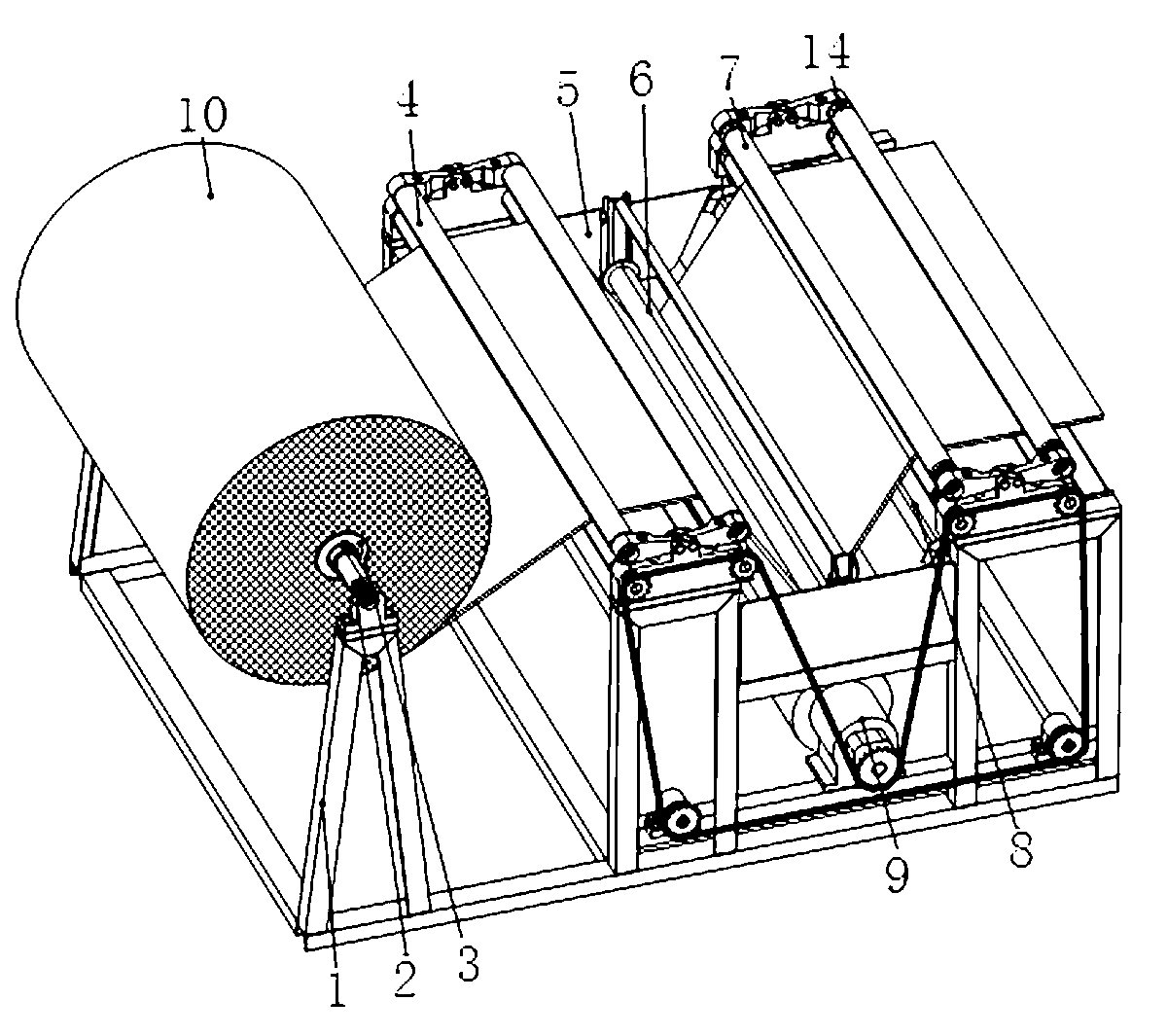

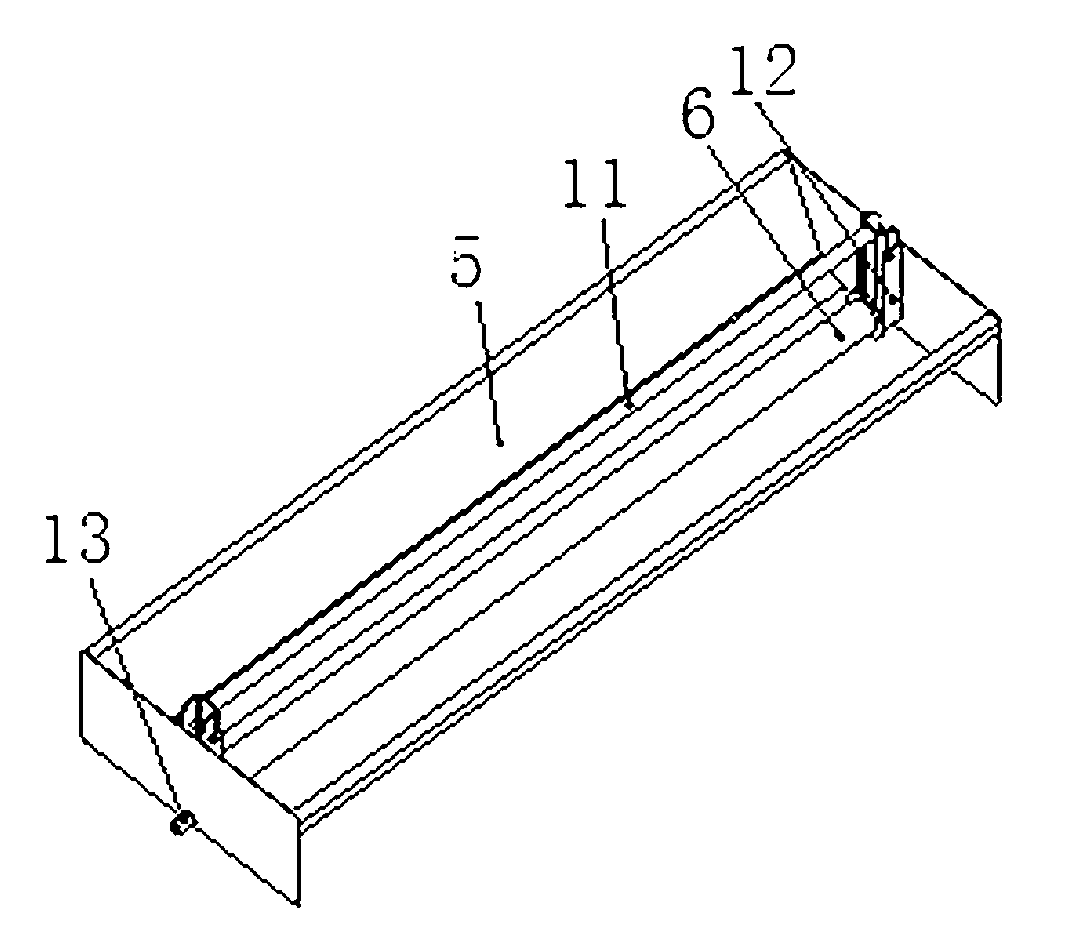

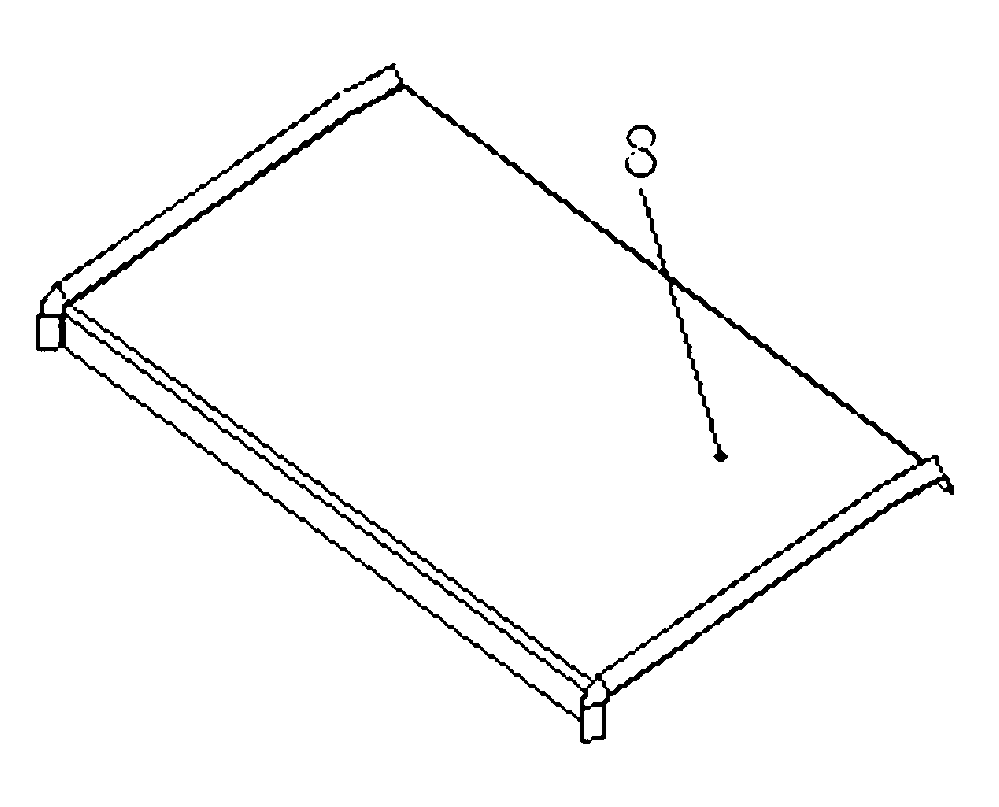

[0021] refer to figure 1 with figure 2 , the present embodiment includes a frame 1, and the frame 1 is provided with a loading shaft 2, a feeding roller shaft 4, a dipping tank 5, and a discharge roller shaft 7 in turn from left to right, and the feeding roller shaft 4 and the discharge roller shaft 7 are provided with a stepless speed regulation drive motor 9, the stepless speed regulation drive motor 9 is connected to the feed roller shaft 4 and the discharge roller shaft 7 through a transmission device, and the dipping tank 5 The inner sides of both ends of the rubber dipping roller shaft bracket 12 are respectively provided, the rubber dipping tank 5 is provided with a glue discharge port 13, and the rubber dipping roller shaft bracket 12 is provided with a rubber dipping roller shaft 6 and a rubber dipping tank handle 11. An inclined deflector 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com