Method and device for controlling hydraulic system

A control method and technology of hydraulic system, applied in the direction of fluid pressure actuating device, servo motor, servo meter circuit, etc., can solve the problems such as the inability to meet the constant running speed and the change of the running speed of the actuator.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

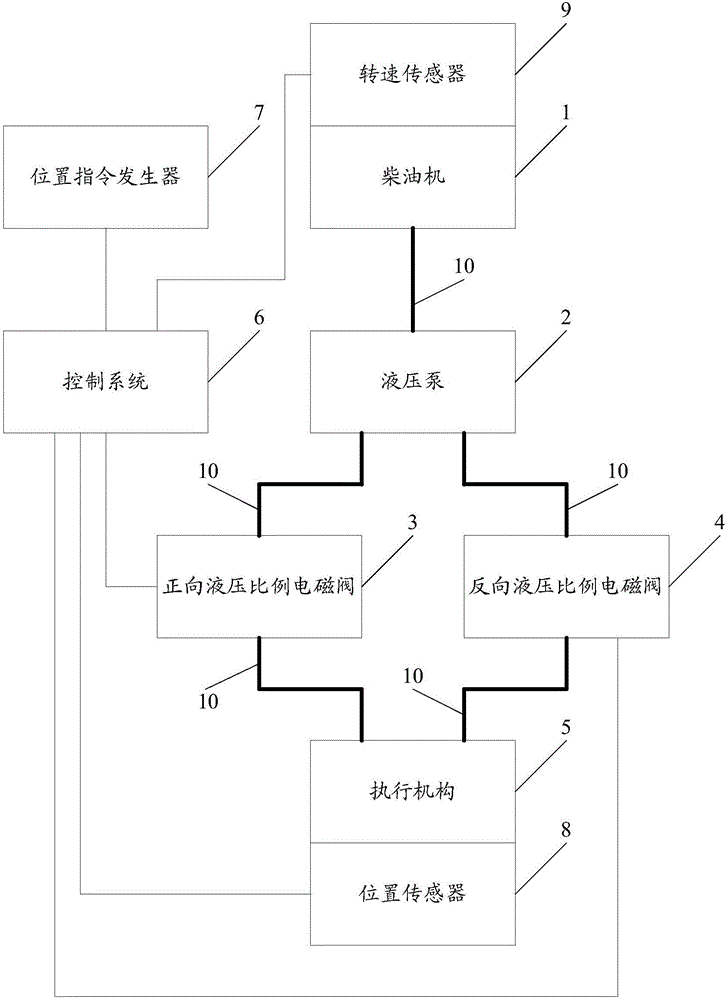

Image

Examples

Embodiment 1

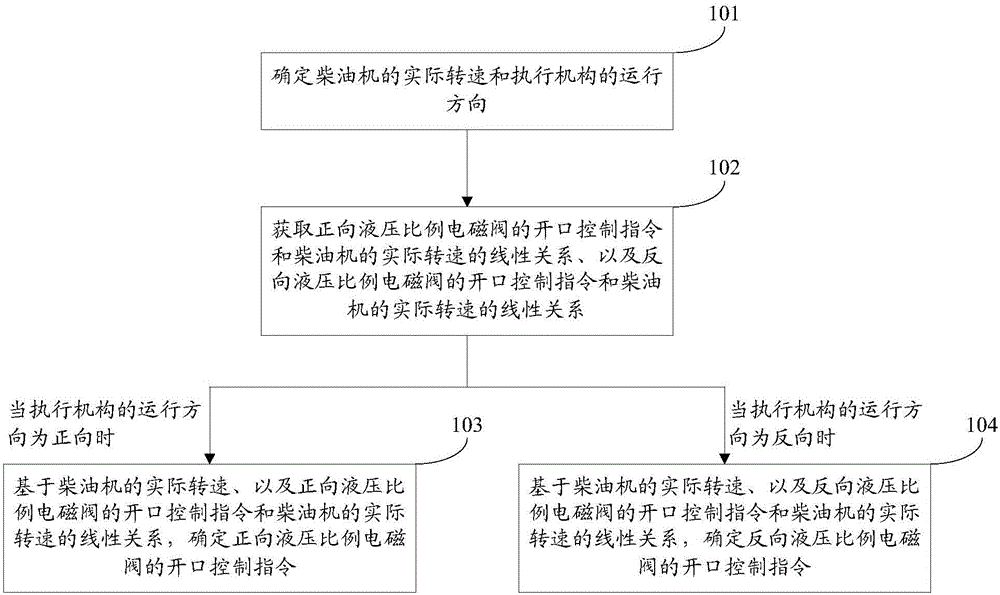

[0078] An embodiment of the present invention provides a hydraulic system control method, see figure 2 , the control method includes:

[0079] Step 101: Determine the actual rotational speed of the diesel engine and the running direction of the actuator. The running direction of the actuator includes forward and reverse.

[0080] In practical applications, when the actuator is a hydraulic cylinder, the forward direction refers to the direction in which the hydraulic oil is used to push the piston, and the reverse direction refers to the direction in which the piston moves relying on gravity or spring force; when the actuator is a hydraulic motor, the positive direction Direction refers to the direction in which the hydraulic motor rotates clockwise, and reverse refers to the direction in which the motor rotates counterclockwise.

[0081] Optionally, this step 101 may include:

[0082] Use the speed sensor to detect the actual speed of the diesel engine;

[0083] The positi...

Embodiment 2

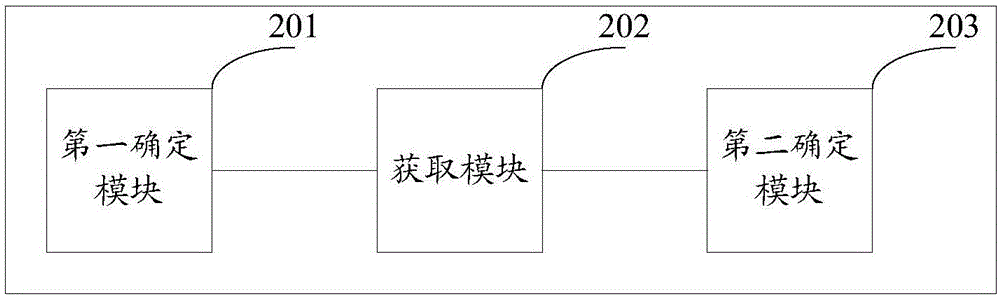

[0138] An embodiment of the present invention provides a control device for a hydraulic system, which is suitable for realizing the control method for a hydraulic system provided in Embodiment 1, see image 3 , the control unit consists of:

[0139] The first determination module 201 is used to determine the actual rotational speed of the diesel engine and the running direction of the actuator, and the running direction of the actuator includes forward and reverse;

[0140] The obtaining module 202 is used to obtain the linear relationship between the opening control command of the forward hydraulic proportional solenoid valve and the actual speed of the diesel engine, and the linear relationship between the opening control command of the reverse hydraulic proportional solenoid valve and the actual speed of the diesel engine;

[0141] The second determination module 203 is used to determine the forward hydraulic ratio based on the actual rotational speed of the diesel engine and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com