Single-stage rubber membrane sealed gas holder reconstructed from regular polygonal thin oil sealed gas holder

A regular polygon and polygon technology, applied in the field of single-stage rubber membrane sealed gas cabinets, can solve the problems of insufficient installation accuracy, stuck piston guide wheel, high precision requirements, etc., achieve fast running speed, flexible pressure adjustment function, and huge economy value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

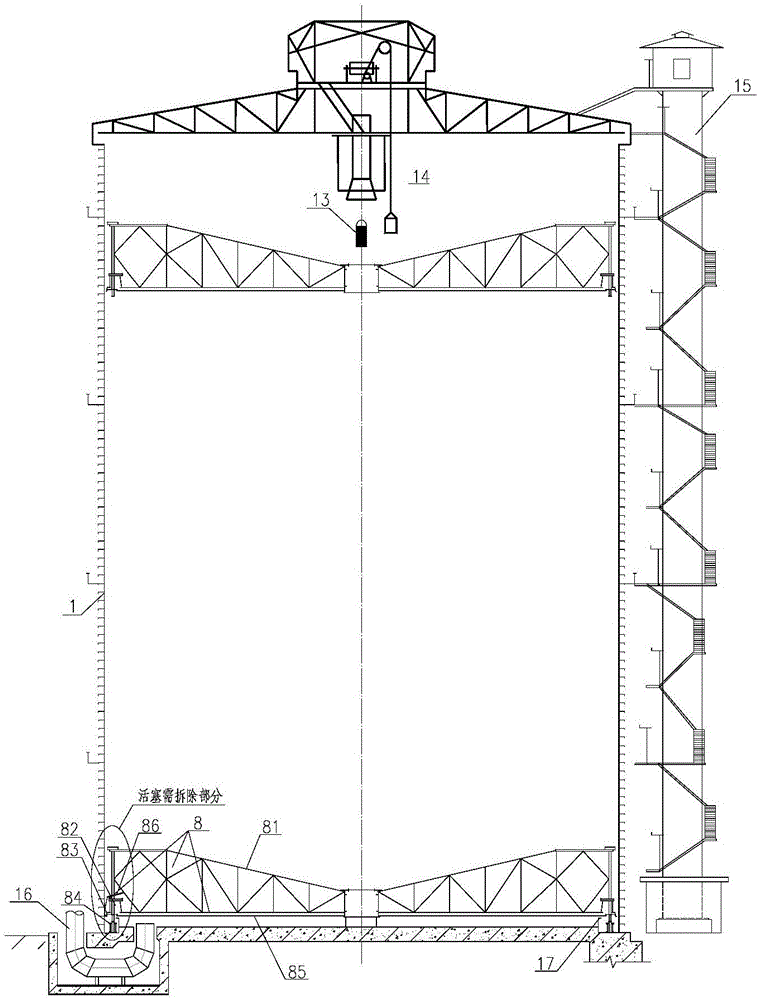

[0027] like figure 1 As shown, the existing regular polygonal thin oil-sealed gas tank includes a cabinet body 1, a hanging cage 13, a temporary rescue device 14, an external elevator 15, an inlet and outlet pipe 16, a bottom oil groove 17 and a piston 8; the piston 8 includes the Piston truss 81, oil groove support 82, piston oil groove 83, piston support bracket 84, piston bottom plate 85, thin oil-sealed gas cabinet sealing mechanism 86, etc. The polygonal thin oil-sealed gas cabinet is sealed by thin oil, which has high requirements on the working temperature. At the same time, if the side plate of the cabinet body is greatly deformed, the sealing performance will be reduced for a long time, and the oil leakage will be serious. As for the polygonal thin oil-sealed gas holders that have been scrapped or are about to be scrapped, if the gas holders are rebuilt after dismantling, a lot of money and time need to be invested.

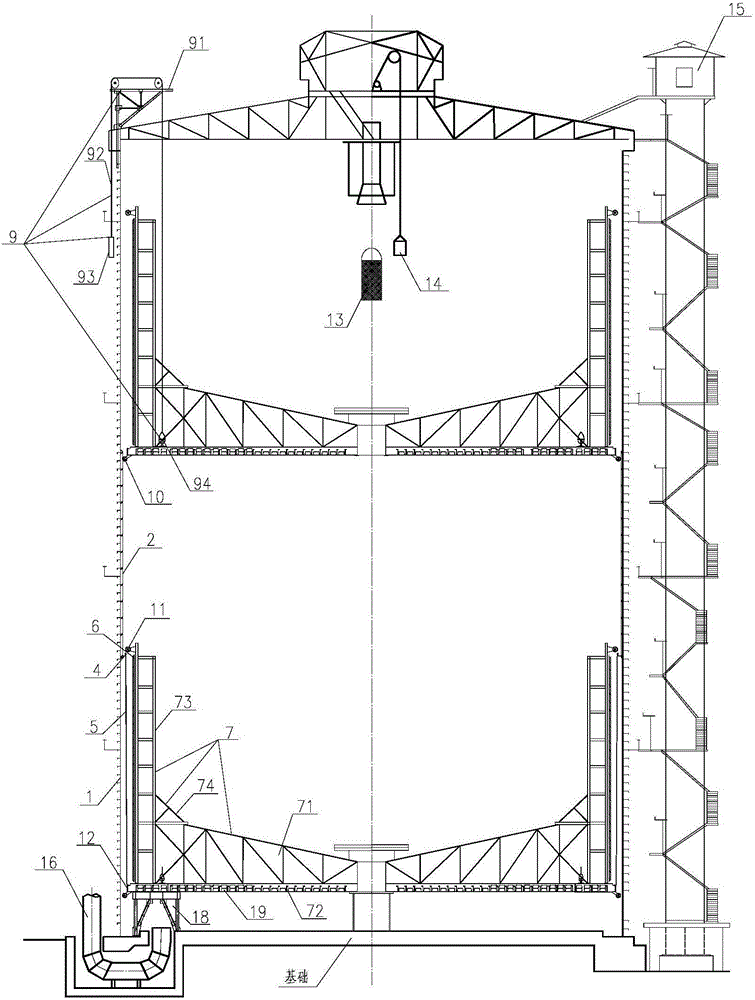

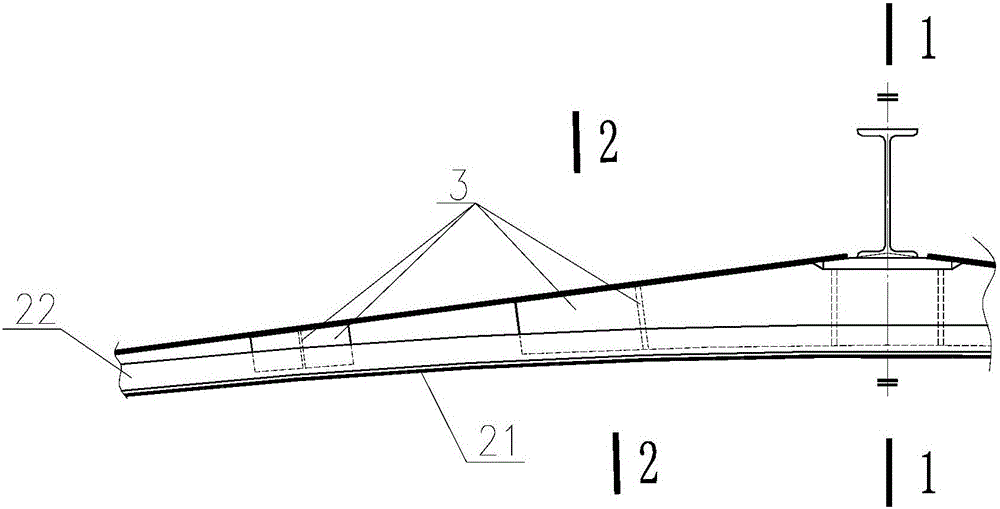

[0028] like Figure 2-5 As shown, the single-sta...

Embodiment 2

[0034] On the basis of the above-mentioned embodiments, several piston guide wheels 11 are arranged respectively along the circumferential direction of the piston at the upper end and the lower end of the piston fence 72, and the piston guide wheels 11 include a guide wheel support connected with the piston fence 72 And connect the spring roller with the piston guide wheel support.

[0035] The guide wheel support and the piston guide wheel 11 of this embodiment can make the piston flexibly contact with the inner cylinder when it drifts, instead of rigid collision, and avoid damage to the rubber membrane 5 due to the rigid collision between the piston and the inner cylinder.

Embodiment 3

[0037] On the basis of the foregoing embodiments, a piston support 18 is provided on the bottom plate of the polygonal cabinet, and the piston support 18 includes four legs and a piston support crossbeam arranged on the four legs, and the piston support 18 The outer column stands in the bottom oil ditch of the regular polygonal thin oil-sealed gas tank, and the inner column stands on the bottom plate steel plate; the legs include four columns, connecting rods connecting the four columns, and the two ends are respectively connected to the columns and The diagonal brace connected by the rod, the two ends of the beam of the piston bracket are respectively connected with the upper ends of the two supporting legs, and the piston brackets are arranged along the circumferential direction of the piston.

[0038] In this embodiment, a piston support 18 is arranged at the bottom of the polygonal cabinet, so that the piston also keeps a certain distance from the bottom plate of the polygo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com