Detecting assembly for whole body of transporting and fuelling vehicle at test center

A test center and detection tooling technology, which is applied in the direction of measuring devices, vehicle testing, mechanical parts testing, etc., can solve the problems of slow detection speed, high labor intensity of testing personnel, and the large number of refueling vehicles that are not suitable for transportation, and achieve reduction Waste, improve labor productivity, and save manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

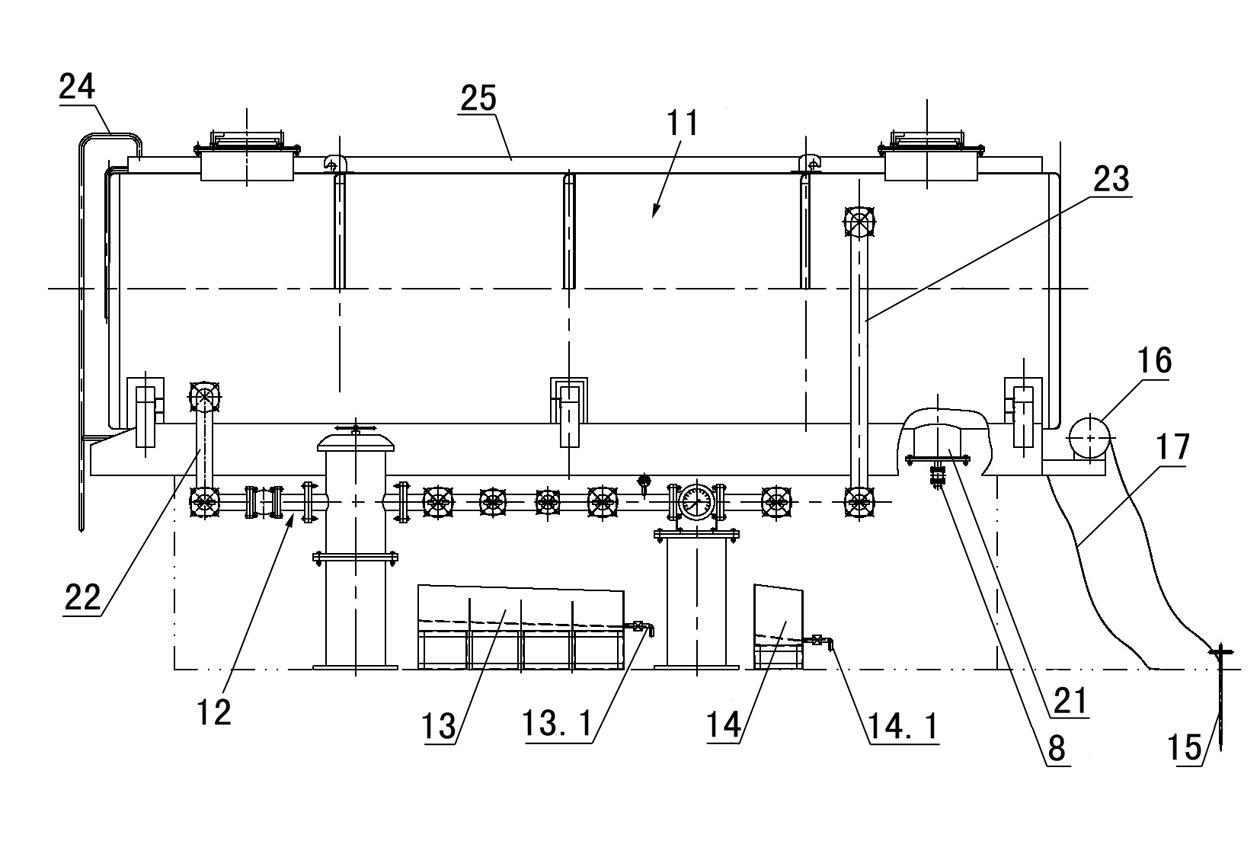

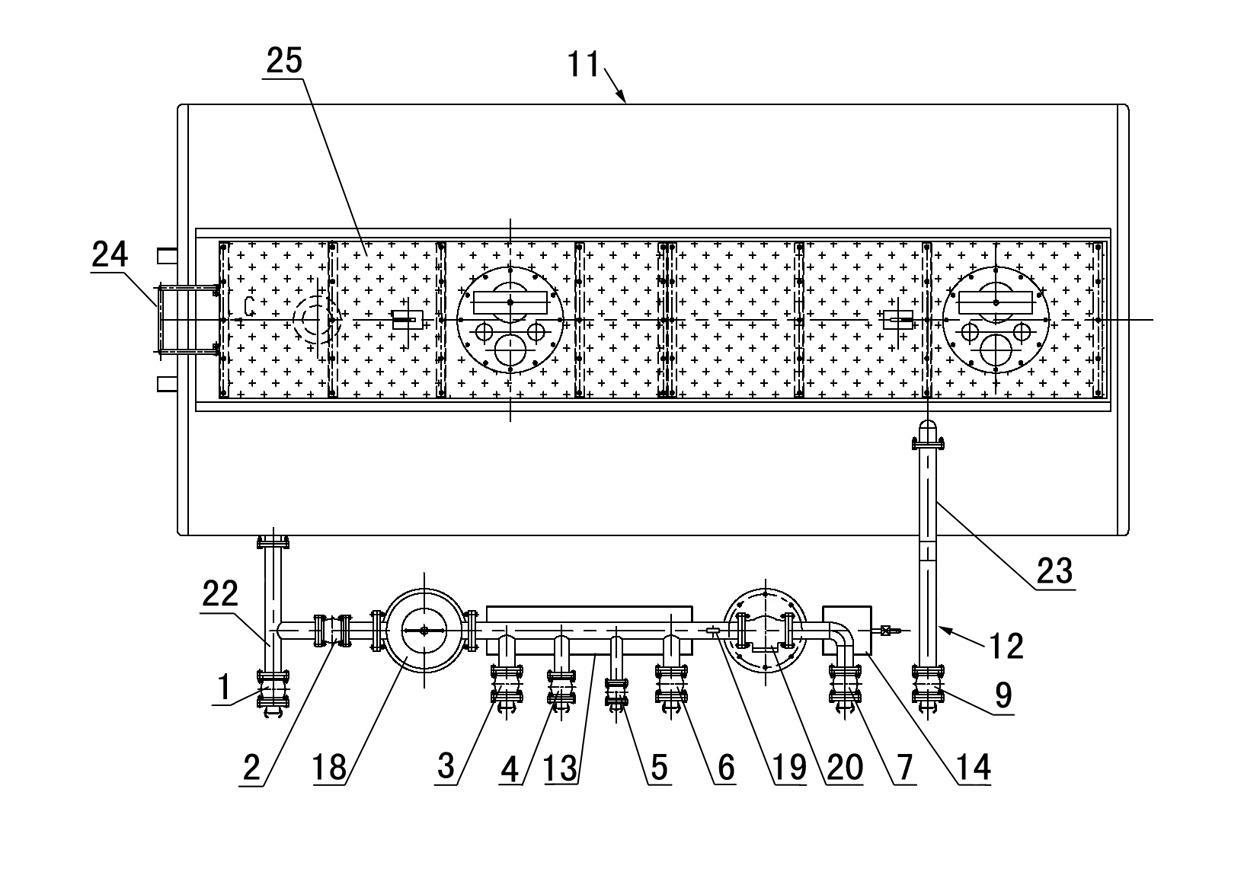

[0027] Examples see Figure 1-4 As shown in the figure, this kind of testing equipment for refueling vehicles transported by the test center includes a test oil tank assembly 11, an oil circuit assembly 12 connected with the test oil tank assembly, an anti-static system connected with the test oil tank assembly, and The oil collection tank assembly placed under the oil circuit assembly.

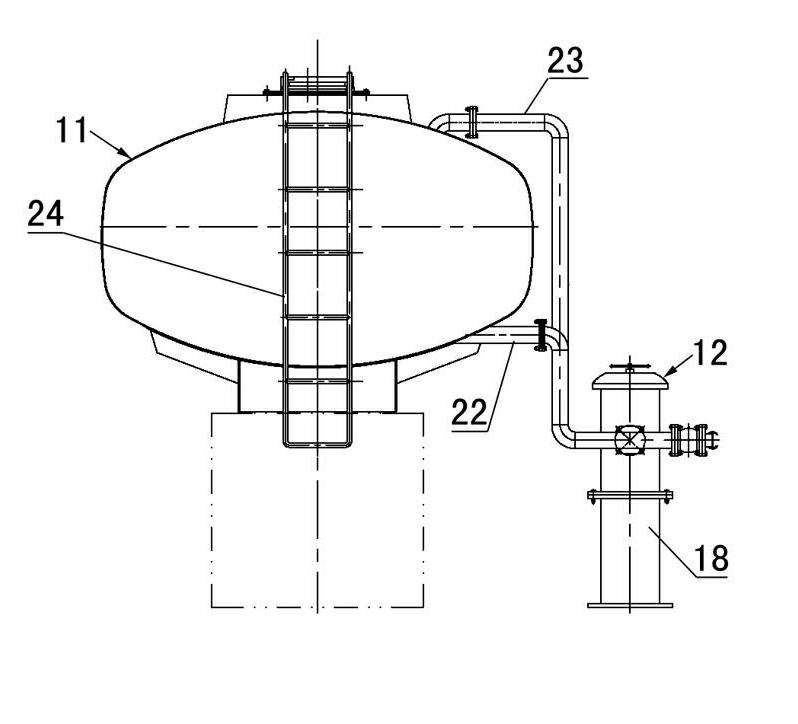

[0028] The bottom of the test oil tank assembly 11 is provided with a settling tank 21, and the bottom of the settling tank 21 is provided with a sinking valve 8. The sinking valve 8 is DN25 (nominal diameter: 25 mm). , there is a lot of oil and impurities in the oil tank, the oil and impurities will be discharged out of the tank through the sink valve, otherwise the oil and impurities will block the filter and damage the filter screen in the filter, frequent replacement of the filter screen , which increases maintenance costs. The test oil tank assembly 11 is provided with a ladder 24 and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Nominal diameter | aaaaa | aaaaa |

| Nominal diameter | aaaaa | aaaaa |

| Nominal diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com