Energy-saving and environment-friendly high-energy screw press

A screw press, energy saving and environmental protection technology, applied in the direction of presses, punching machines, manufacturing tools, etc., can solve the problems of only transmission efficiency, large acceleration mass, large energy consumption, etc., achieving low transmission power, large total inertia, saving energy The effect of power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

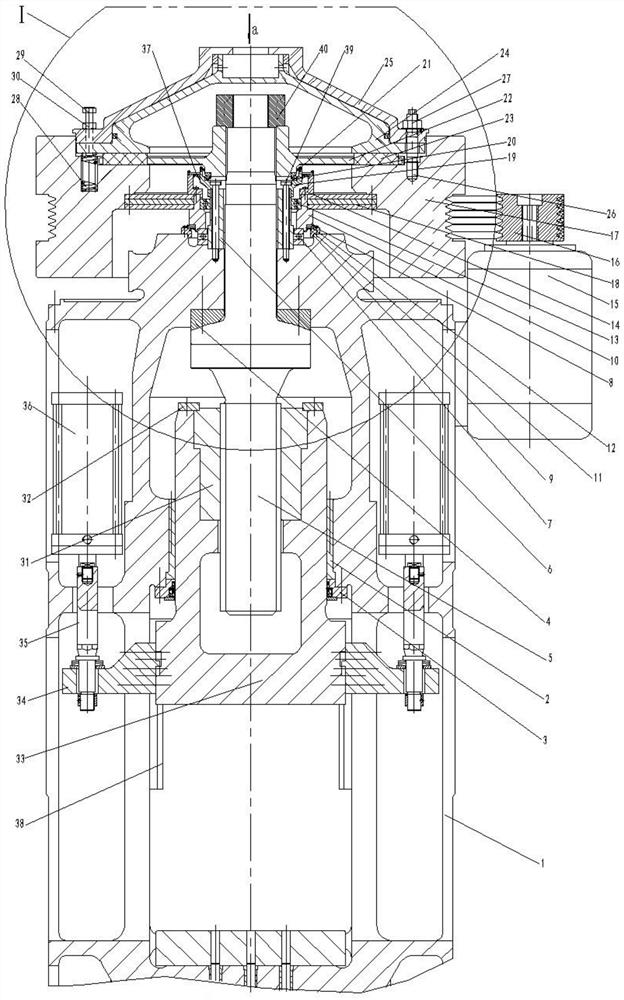

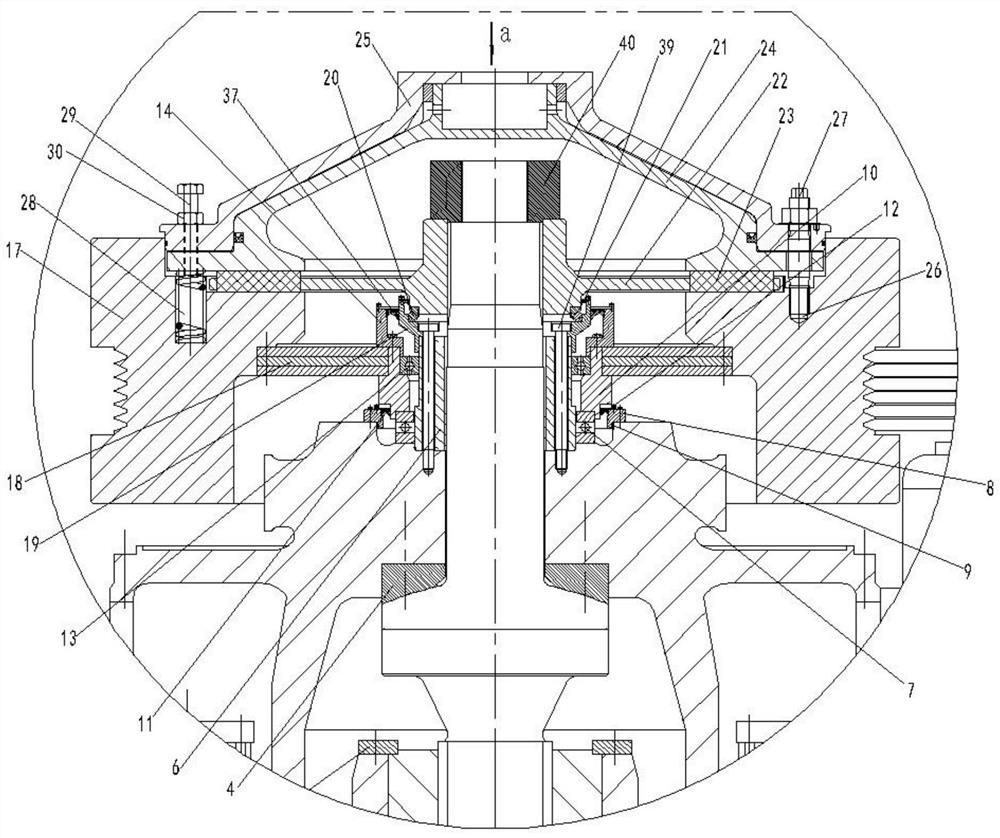

[0022] exist figure 1 , figure 2Among them, the energy-saving and environment-friendly high-energy screw press of the present invention includes a fuselage 1 provided with an X-shaped guide rail 38, and a circular guide rail 2 fixedly installed on the inner hole of the fuselage through interference fit for blocking the circular guide rail and installing The circular guide rail cover 3 on the fuselage, the spherical bearing seat 4 installed on the fuselage beam, the screw rod 5 passing through the fuselage beam hole, having a spherical surface and matching contact with the spherical bearing seat, passing through the screw rod and passing through Fastening bolts 39 are installed on the stepped ring bearing on the top surface of the fuselage beam to fix the inner body 6, pass through the stepped ring bearing to fix the inner body and install the thrust ball bearing 7 on the top surface of the fuselage beam, and are located in the thrust ball bearing The convex block cover 8 ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com