Stepped twin-screw extrusion device and bulking machine

A twin-screw extrusion and stepped technology, which is applied in the field of stepped twin-screw extrusion devices and extruders, can solve the problems of high pressure on the extruder template, uneven quality of extruded materials, and poor material maturity. Achieve good kneading effect, good product stability, and small current fluctuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

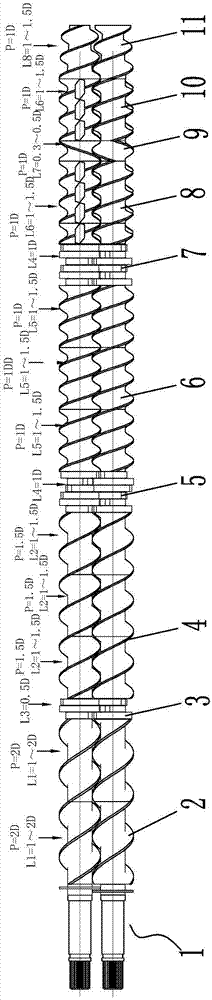

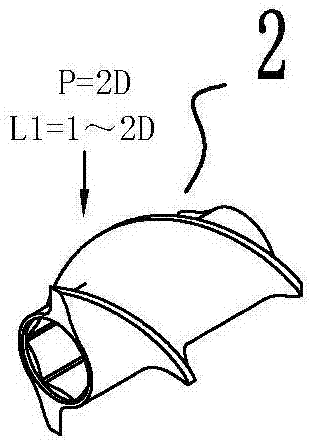

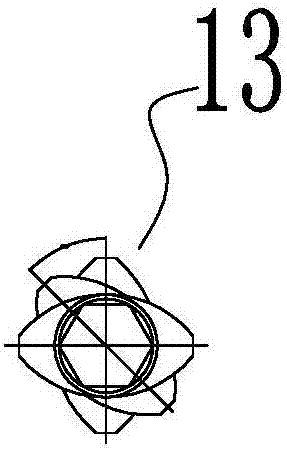

[0039] exist figure 1 In the shown embodiment, a stepped twin-screw extrusion device includes twin-screws 1 arranged in parallel. The helical configuration of the twin-screws 1 adopts a stepped variable-pitch double-headed helical structure, and the twin-screws 1 include feeding from the front end of the screw. The mouth is connected to the discharge port in sequence with double-headed helical structure with 2 times the helix diameter and large pitch 2, three positive kneading blocks 3, 1.5 times double helix structure 4, one-level three positive and three reverse kneading blocks 5, 1 times double helix Structure 6, two-stage three-positive three-reverse kneading block 7, one-stage 1-time slotted double helix structure 8, double-headed anti-helix structure 9, two-stage 1-times slotted double helix structure 10, and discharge cone helix structure 11.

[0040] 2 times the helix diameter and large pitch double-ended helix structure 2, the helix pitch is equal to 2 times the helix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com