Degradable plastic film recycling method

A plastic film recycling technology, applied in the field of plastic film, can solve problems such as difficult to handle, large area of plastic film, and easy re-adhesion of impurities, so as to improve the cleaning rate, enhance the cleaning effect, and achieve better results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034]In order to make the techniques of the present invention, the creation characteristics, the purpose and efficacy are readily understood, and the present invention is further illustrated in connection with the specific illustration. It should be noted that the features of the present application and the features in the embodiments in the present application can be combined with each other in the case of an unable conflict.

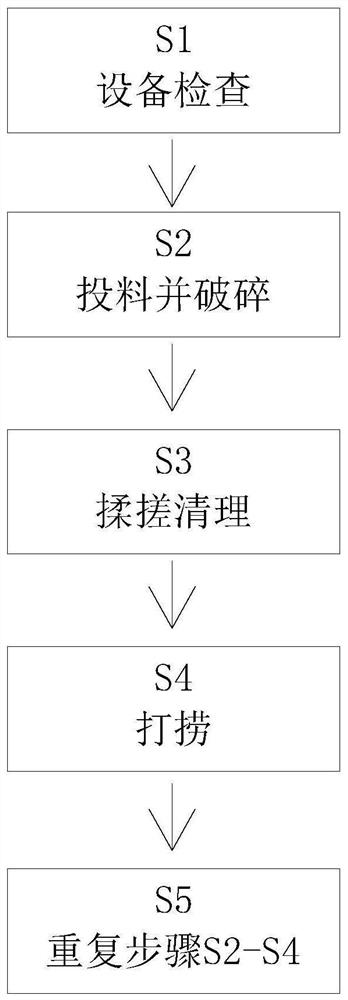

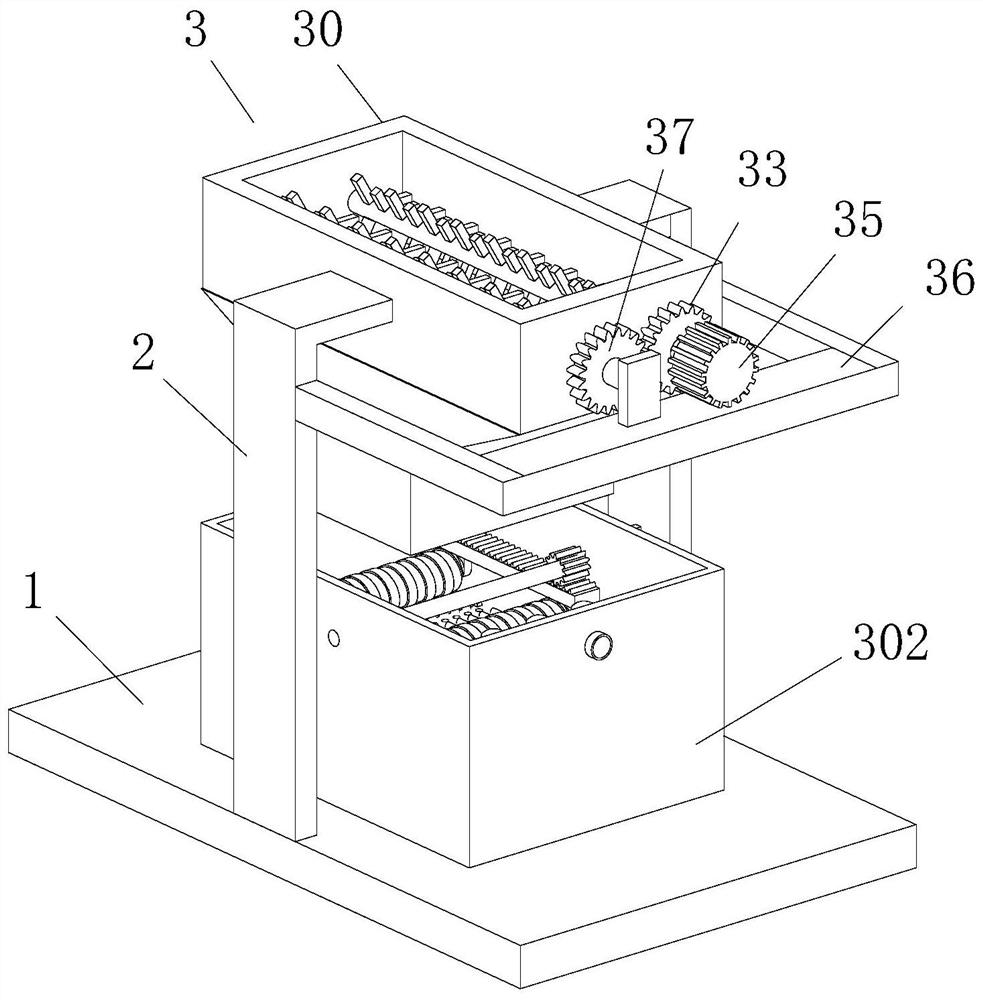

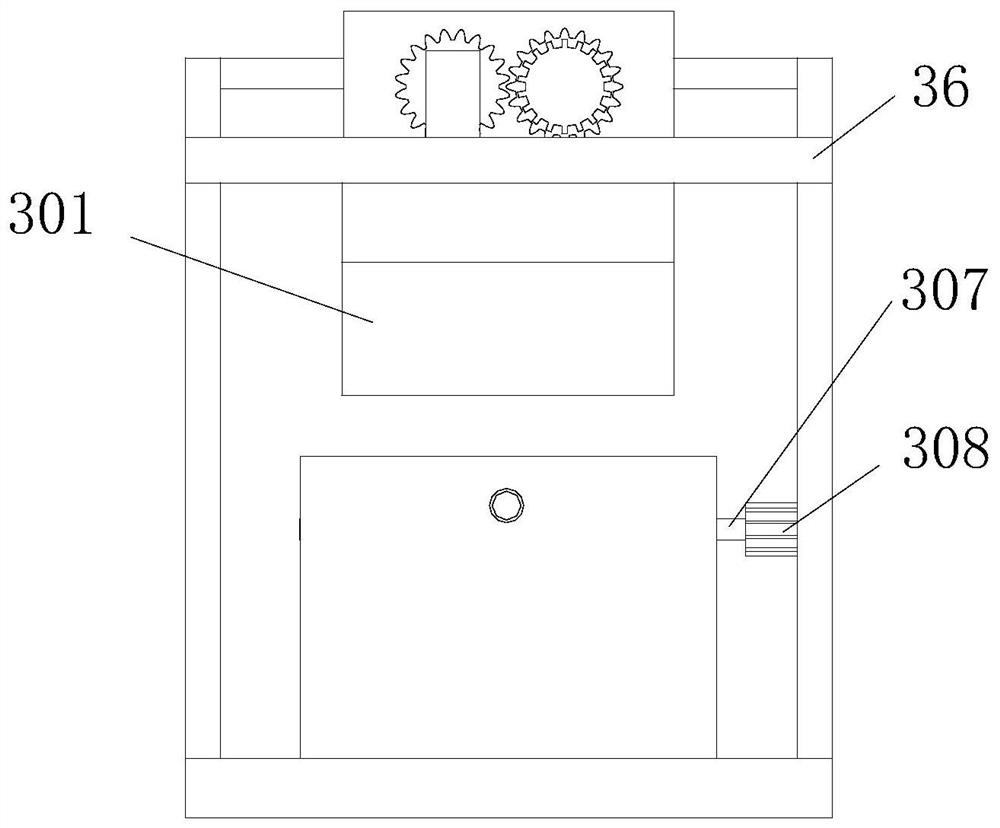

[0035]Such asFigure 1 to 8As shown, a degradable plastic film recovery method, the degradable plastic film recovery reuse method is recovered by the following equipment, the apparatus including the base 1, the L-frame 2 and the crushing device 3, the base 1 The lower end is connected to the existing ground, and the upper end of the base 1 is configured with the L-frame 2, and the crushing device 3 is mounted between the upper and rear, the upper and rear opposite L-type frame 2.

[0036]The crushing device 3 includes a crushing tank 30, a mounting shaft 31, a bro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com