Aluminum alloy template cleaning equipment

A technology for aluminum alloy template and cleaning equipment, applied in the field of aluminum alloy template, can solve the problems of the service life of the aluminum film plate, reduce the service life, increase the cleaning cost, etc., and achieve the effect of low cleaning cost, fast speed, and reduced labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

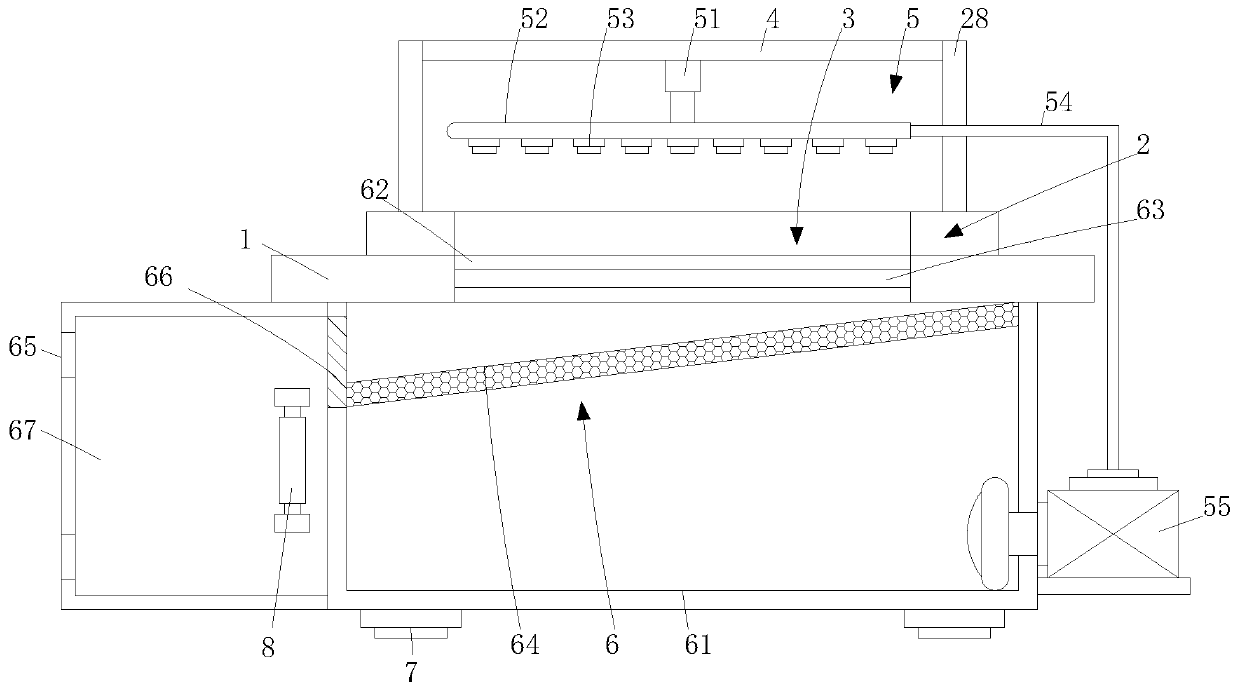

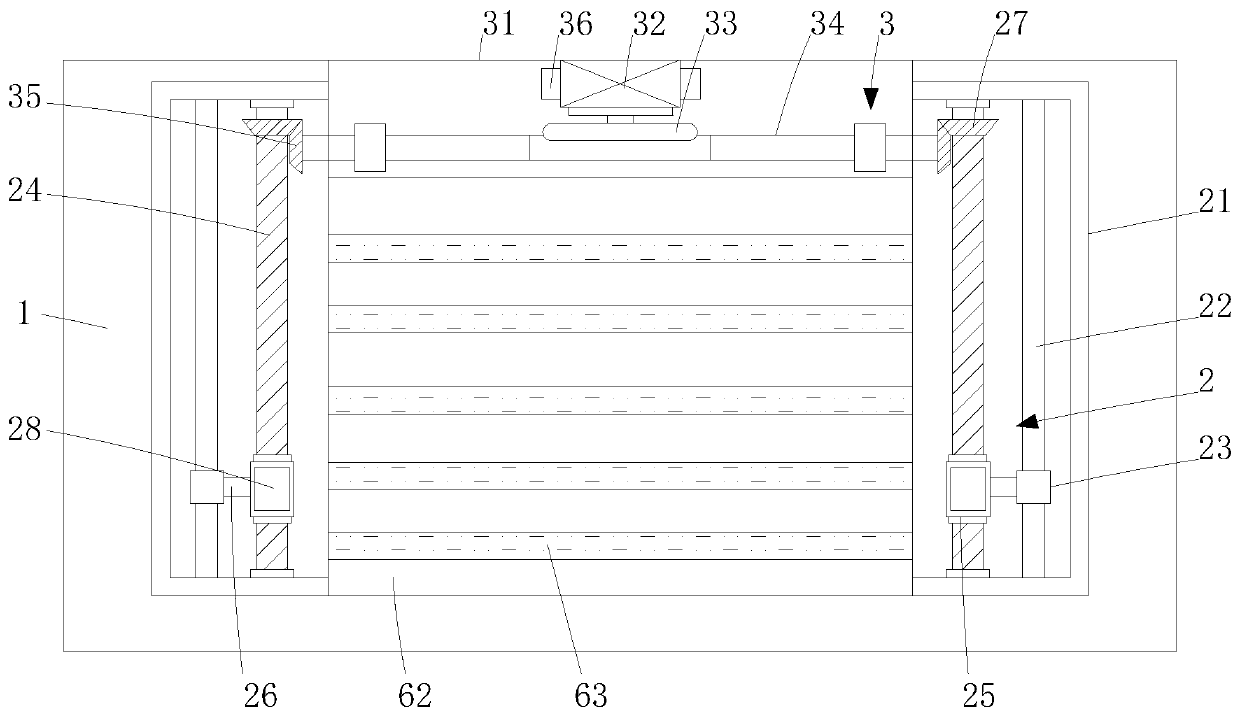

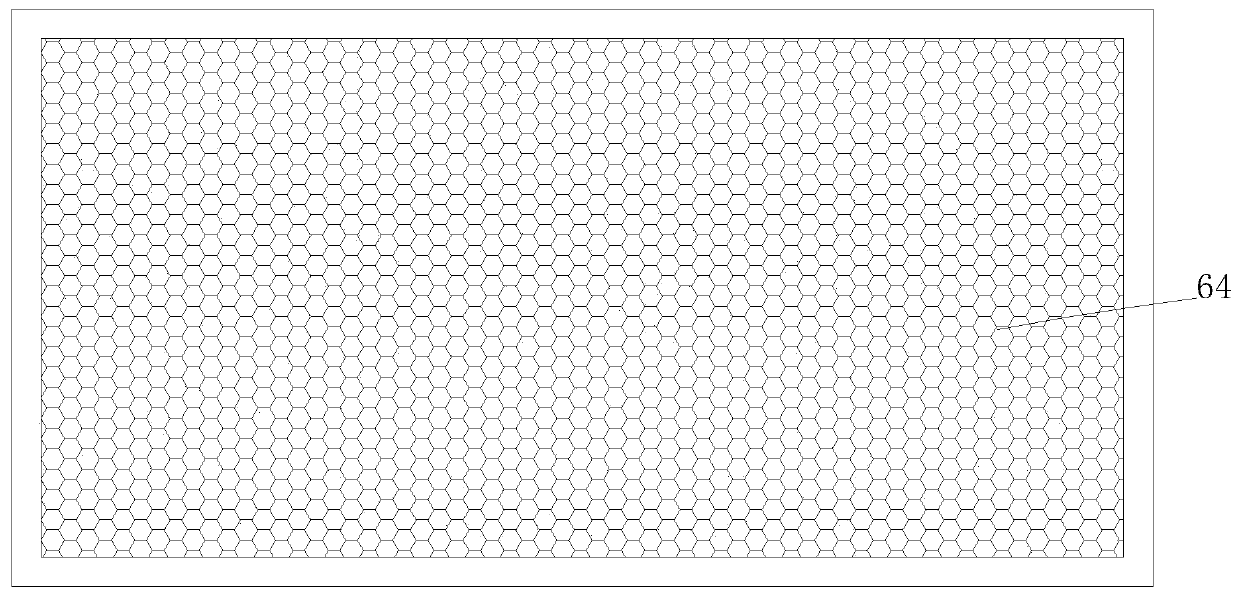

[0026] like Figure 1-3 As shown, the present invention provides a technical solution: an aluminum alloy template cleaning equipment, including an operation table 1, a traveling mechanism 2, a transmission mechanism 3, a beam plate 4, a cleaning mechanism 5, a recovery mechanism 6, a base 7 and a handle 8 , the two sides of the top of the console 1 are respectively fixedly connected to the bottoms of the two traveling mechanisms 2, the two traveling mechanisms 2 are connected through transmission mechanism 3, and the bottom of the transmission mechanism 3 is fixedly connected to the back of the top of the console 1, The beam plate 4 is located above the top of the console 1, the cleaning mechanism 5 is positioned at the bottom of the beam plate 4, the recovery mechanism 6 is positioned at the bottom of the console 1, and the surroundings of the bottom of the settling tank 61 are respectively fixedly connected to the tops of the four bases 7, and The bottom of the base 7 is fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com