Patents

Literature

87results about How to "Clean up completely" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

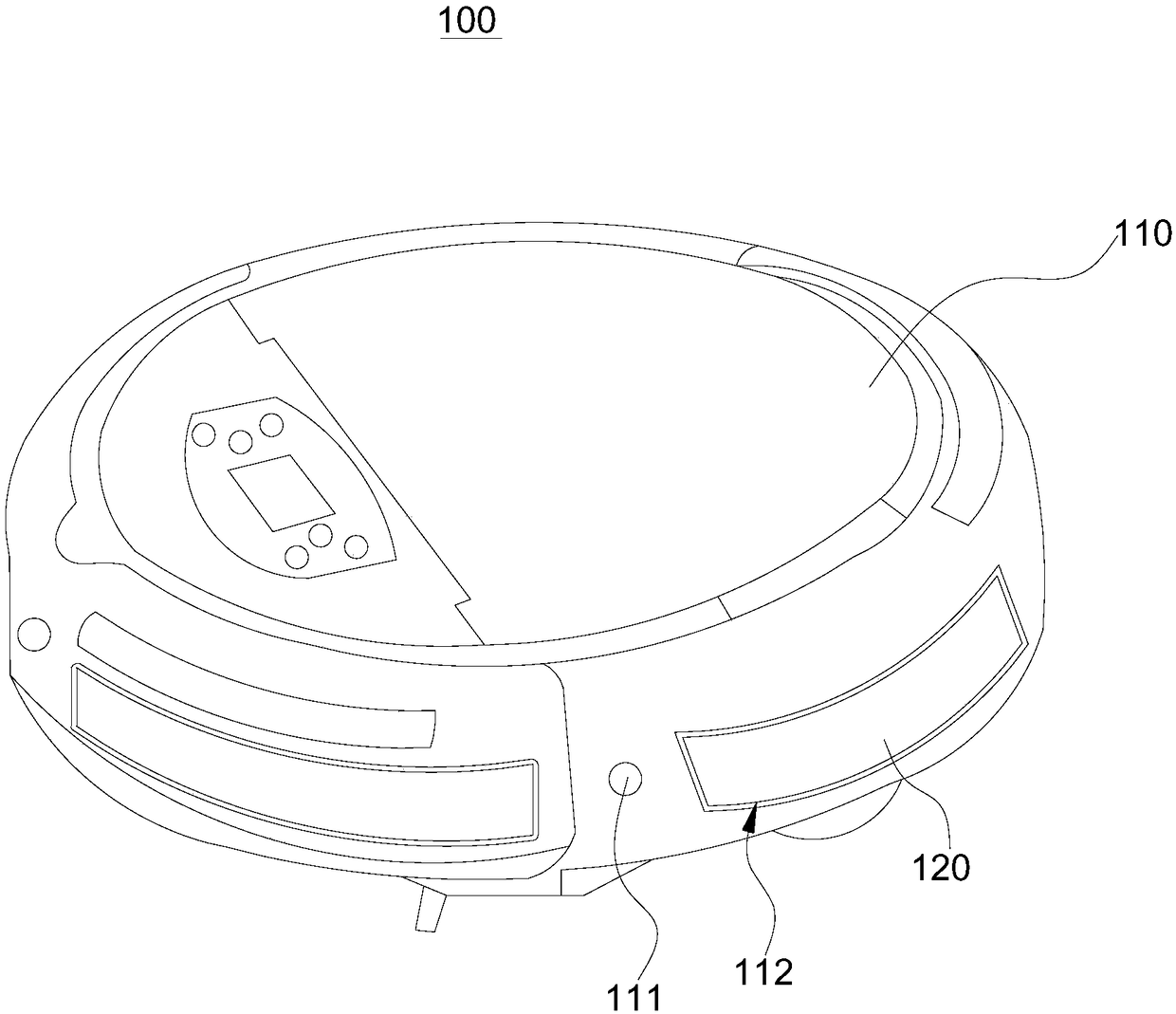

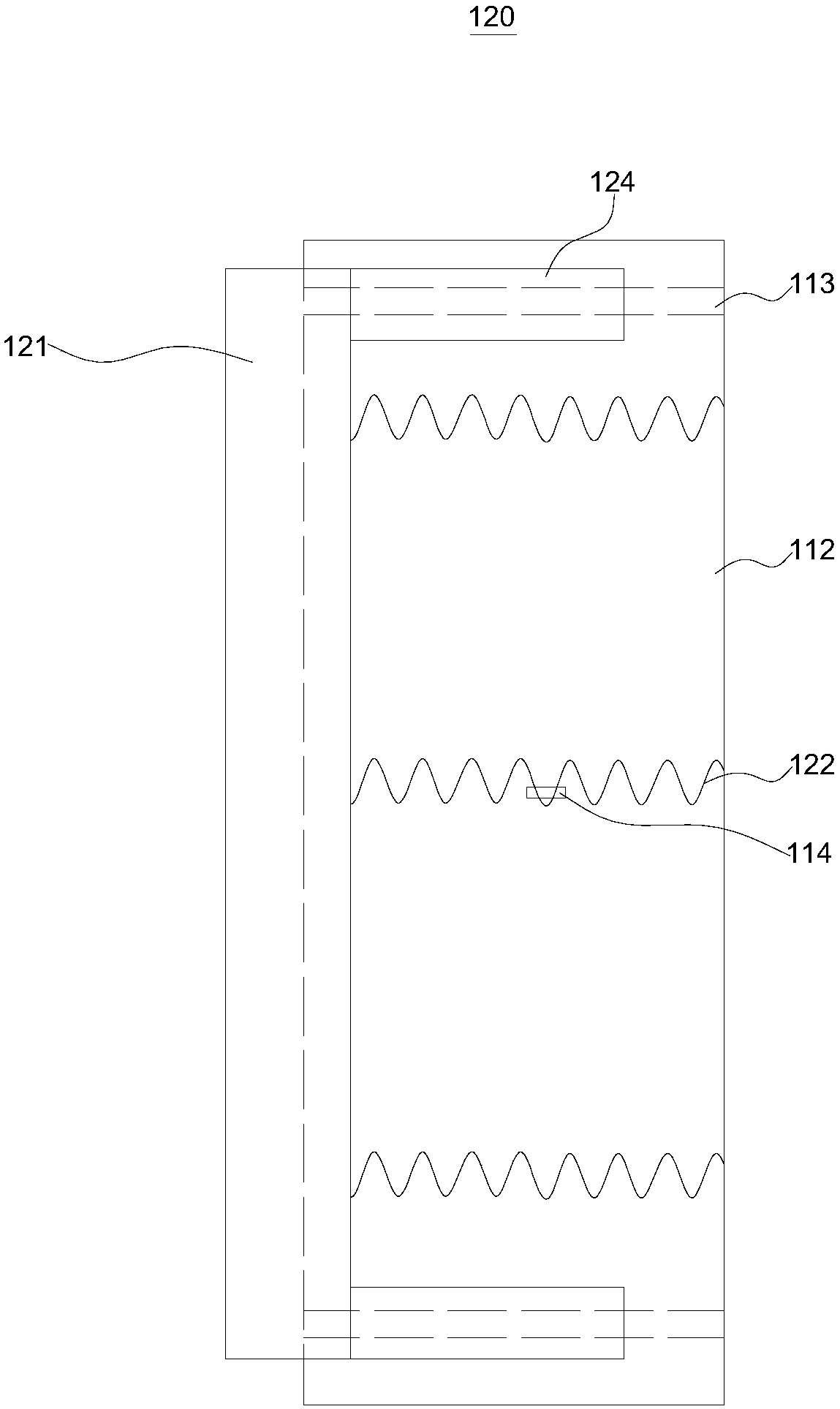

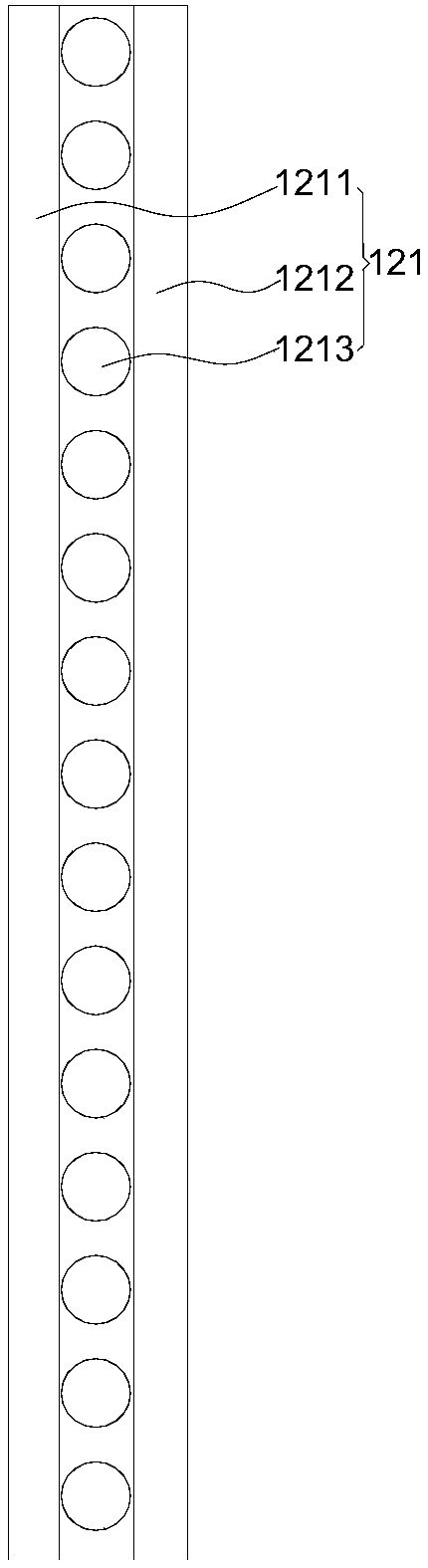

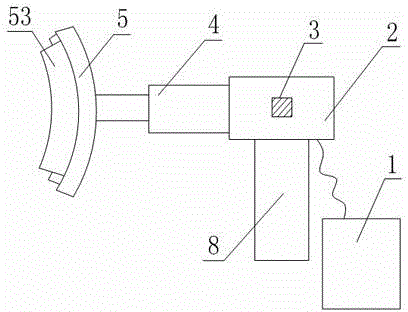

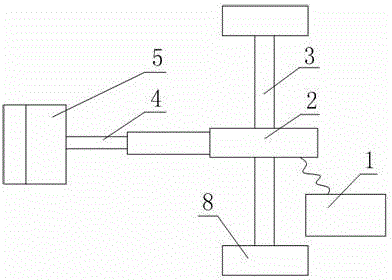

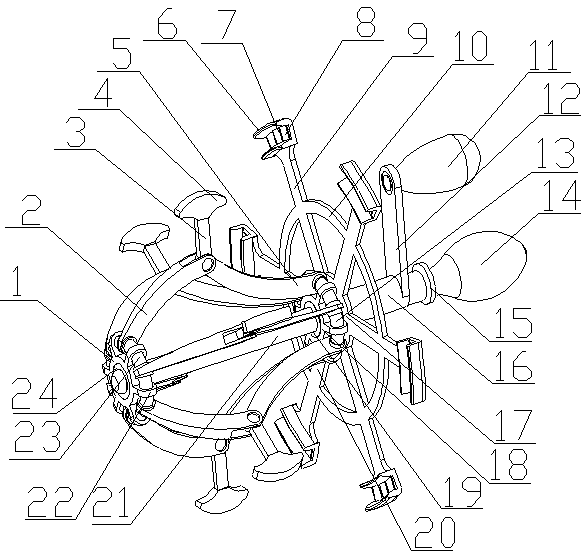

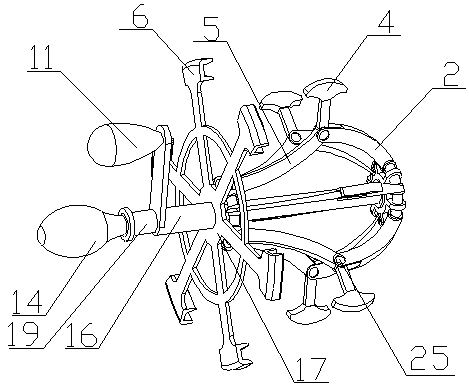

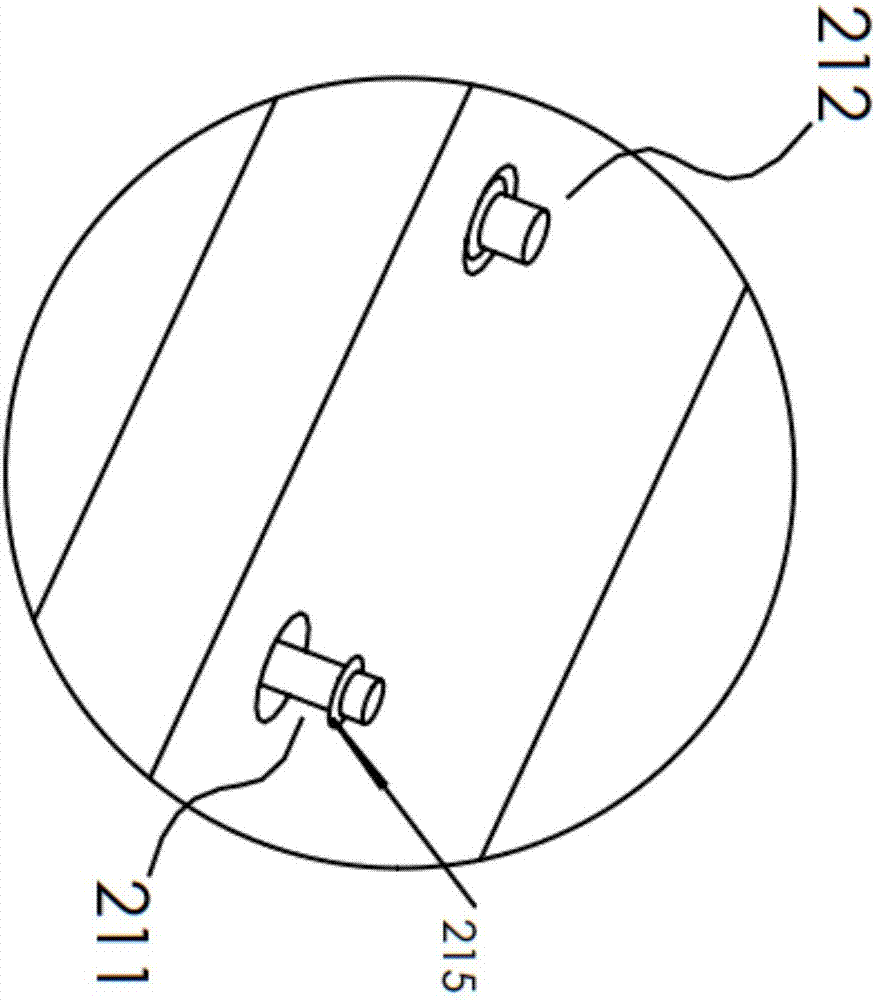

Anti-collision mechanism of floor sweeping robot and intelligent floor sweeping robot

ActiveCN108201427AShorten speedReduce the impactCarpet cleanersFloor cleanersAgricultural engineeringDistance sensors

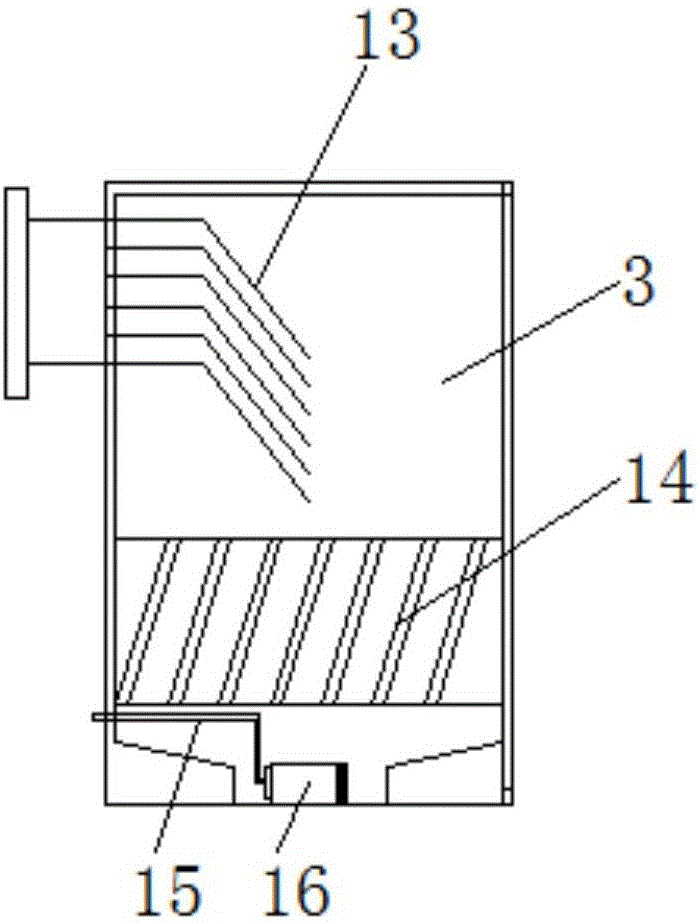

The invention relates to the field of floor sweeping robots, and provides an anti-collision mechanism of a floor sweeping robot and the intelligent floor sweeping robot. The anti-collision mechanism of the floor sweeping robot comprises a floor sweeper body, an anti-collision lantern ring, a first distance sensor, a speed regulation module and a steering module, wherein the first distance sensor is arranged on the floor sweeper body and is used for sensing the distance between the side face of the floor sweeper body and an obstacle, the first distance sensor is connected with the speed regulation module, and a mounting groove for containing the anti-collision lantern ring is formed in the floor sweeper body; the anti-collision lantern ring wraps the outer side of the floor sweeper body andcan slide in the mounting groove, and a steering switch is arranged in the mounting groove; the anti-collision lantern ring can be in contact with the steering switch and control the on-off state ofthe steering switch, and the steering switch is connected with the steering module. According to the anti-collision mechanism, the obstacle can be effectively detected, the working speed is reduced, the movement direction can be adjusted in time, and damage of collisions to the floor sweeping robot and furniture is reduced. The intelligent floor sweeping robot can effectively avoid the obstacle, and is complete in cleaning and long in service life.

Owner:YANCHENG INST OF IND TECH

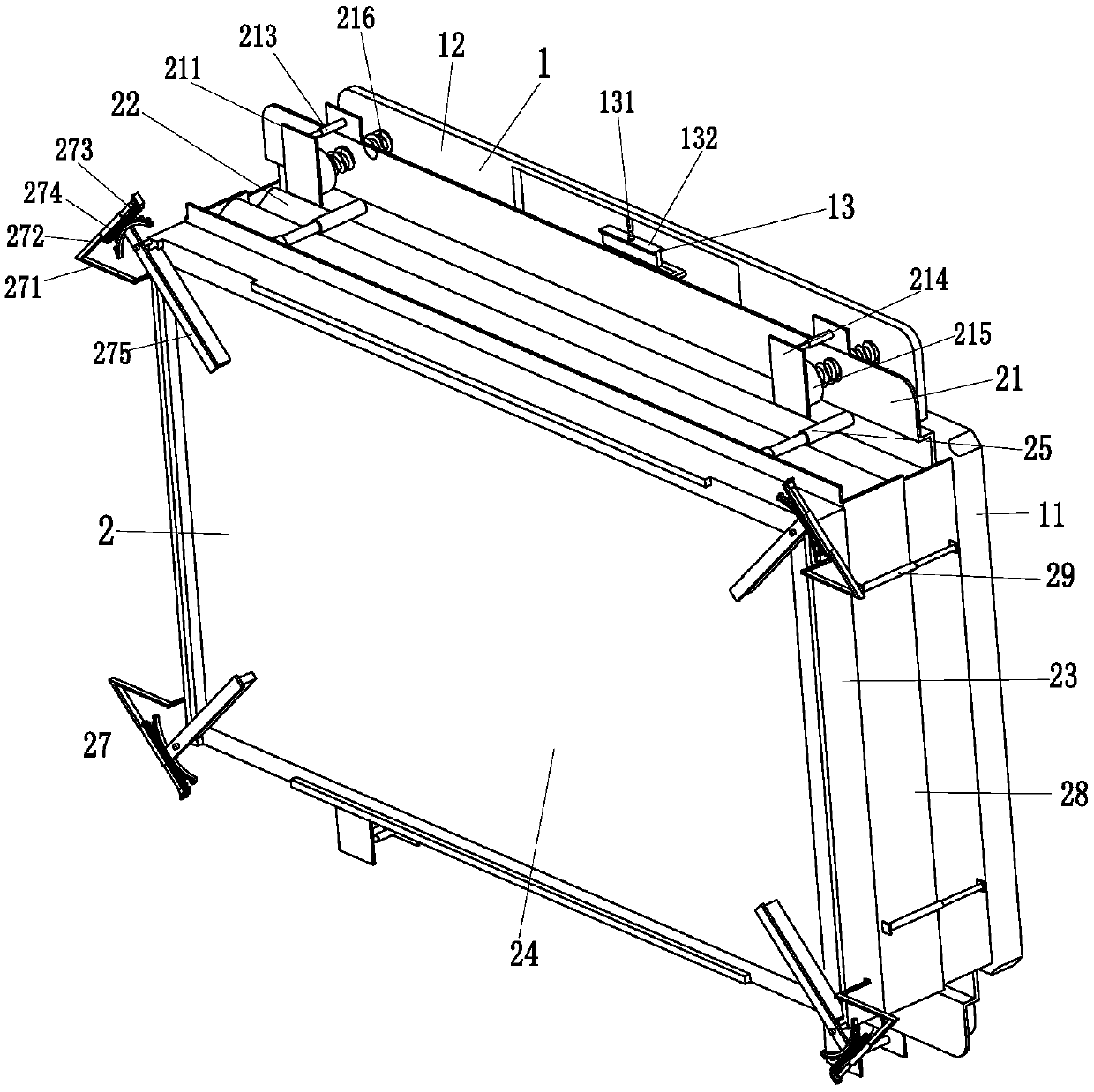

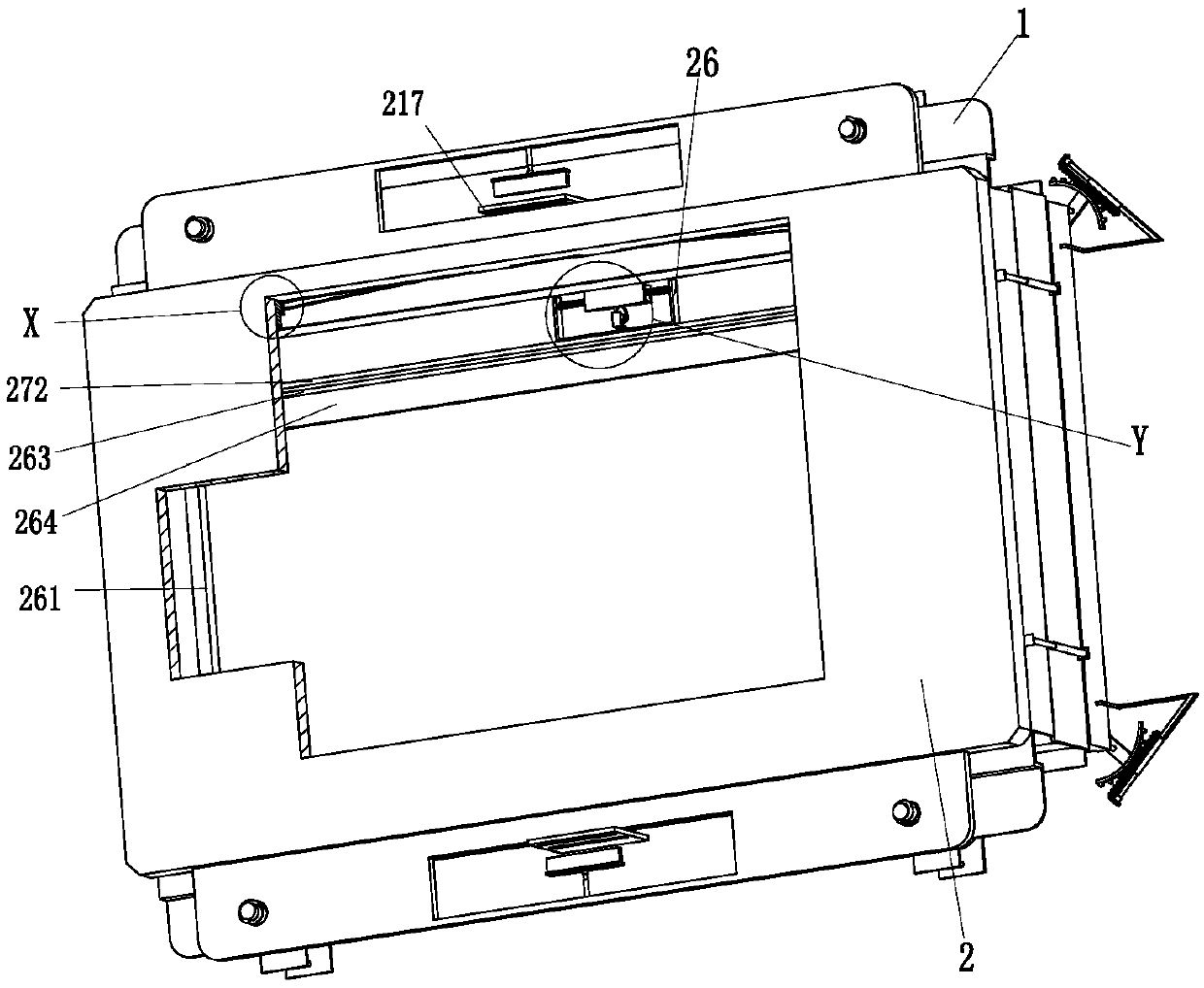

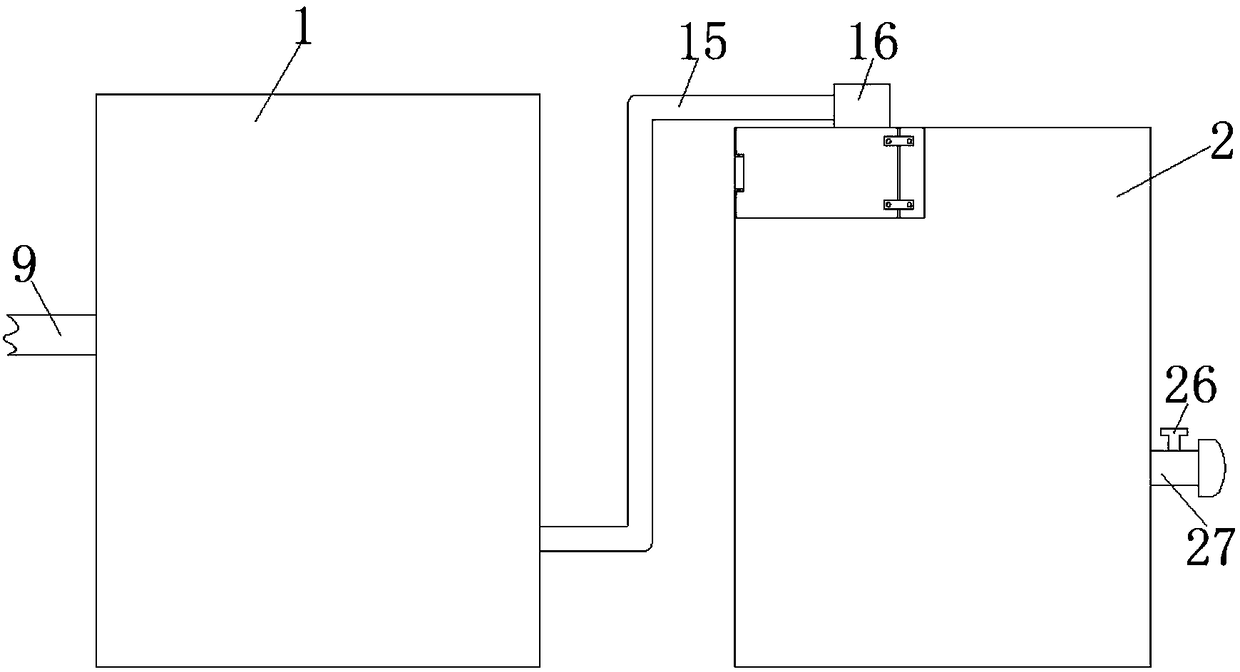

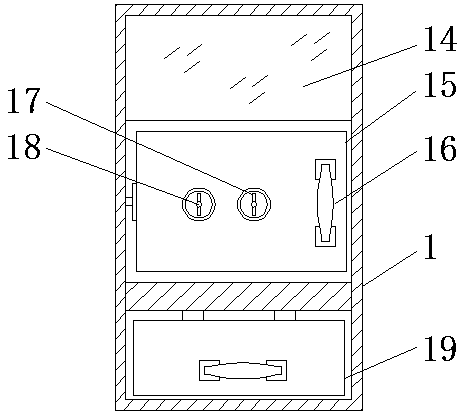

Dustproof outdoor display screen

InactiveCN109584715ARealize dustproof functionAvoid safety accidentsCleaning using toolsIdentification meansEngineeringRisk factor

The invention relates to a dustproof outdoor display screen which comprises a display screen, a dust cover and a surface ash removal device, wherein the dust cover is embedded into the front of the display screen; and the surface ash removal device is mounted at the right end of the dust cover. The dustproof outdoor display screen can solve the problems that ash easily deposits on the surface of the existing outdoor display screen; personnel are required to clean the surface of the display screen on site at regular time and have a high aerial work risk factor; complete cleaning cannot be achieved manually; in the weather that aerial work cannot be performed, the surface of the outdoor display screen is not cleaned by people for a long term to result in excessive ash deposition and unclearplaying frames; and a publicity effect is reduced. A dustproof function of the outdoor display screen can be achieved; the personal aerial work is not required; the occurrence of a safety accident isavoided; the dust cover embedded into the outdoor display screen plays a dustproof role; the ash can be removed automatically in any weather; and the publicity effect is not reduced.

Owner:济宁呱牛信息技术有限公司

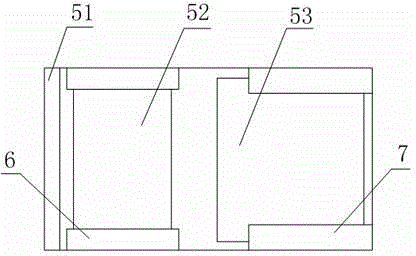

Hydraulic oil cylinder pushing type drill rod outer wall cleaning equipment

The invention relates to hydraulic oil cylinder pushing type drill rod outer wall cleaning equipment which comprises two symmetrically-arranged fixing stand plates. A guiding plate is arranged between the two fixing stand plates. A sliding block controlled by a motor is arranged on the guiding plate. The sliding block is connected with a hydraulic oil cylinder. The output end of the hydraulic oil cylinder is provided with an arc plate matched with the outer wall of a drill rod. A bent scarper in the same axial direction as the arc plate is arranged at one end of the inner side of the arc plate in the axial direction. A sponge mat is arranged at the other end of the inner side of the arc plate. A scouring pad is arranged between the bent scraper and the sponge mat. The motor is used for driving a cleaning device to move in the axial direction of the drill rod to clean the drill rod, the problem that efficiency of manual cleaning is low is avoided, the outer wall of the drill rod is cleaned through the bent scraper, the scouring pad and the sponge mat in sequence, the dirt of the outer wall of the drill rod can be completely cleared, and the problem that when an existing water spraying gun is used for cleaning, cleaning is not complete is avoided.

Owner:谭海新

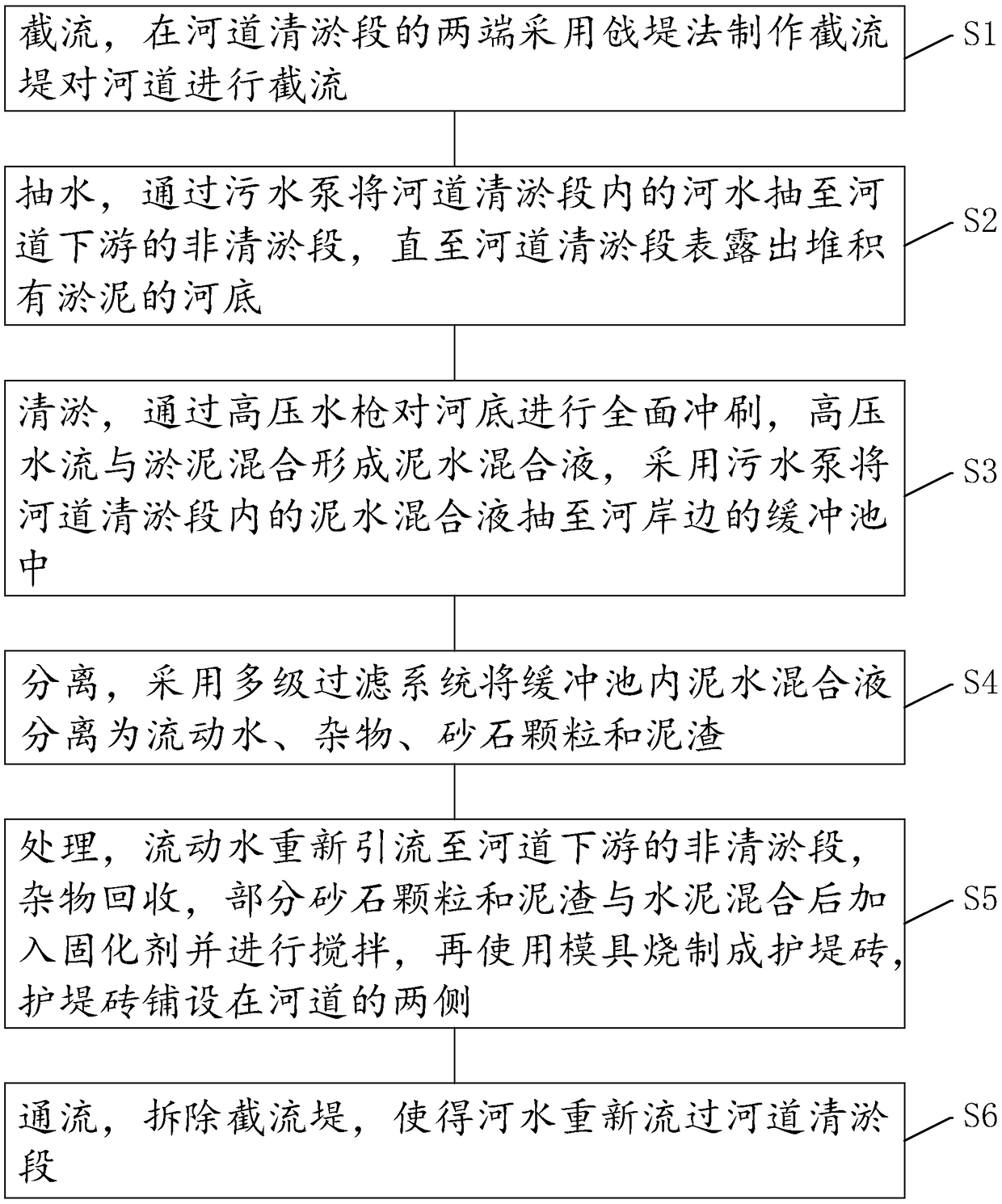

River channel comprehensive treatment method

InactiveCN108824350AImprove self-healing abilitySelf-healing long-termWater resource protectionMechanical machines/dredgersBrickSludge

The invention discloses a river channel comprehensive treatment method and relates to the technical field of river channel ecological treatment. The river channel comprehensive treatment method comprises the following steps of intercepting water flow, specifically, manufacturing cut-off dykes at the two ends of a river channel to conduct interception on the river channel; water pumping, specifically, pumping off river water in a river channel cleanout section; dredging, specifically, conducting comprehensive flushing on the river bottom through a water torch to enable water to be mixed with sludge to form mud-water mixed liquid and pumping the mud-water mixed liquid into a buffer pool; separation, specifically, separating the mud-water mixed liquid in the buffer pool into flowing water, sundries, gravel particles and sludge through a multi-stage filter system; treatment, specifically, firing part of the gravel particles and the sludge into dyke protection bricks; flow-through, specifically, dismantling the cut-off dykes. The sludge flushing and cleaning speed of high-pressure water is high, cleaning is comprehensive, and time and labor are saved. Meanwhile, water resources of non-dredging sections are utilized, and the water impounding pressure of the upstream of the river channel is also reduced. The gravel particles and the sludge are manufactured into the dyke protection bricks to protect two sides of the river channel and facilitate ecological remediation. The treatment method has the advantages of being high in efficiency, environment-friendly, capable of saving resources and beneficial to continuous remediation of the river ecology.

Owner:上海景铭建设发展有限公司

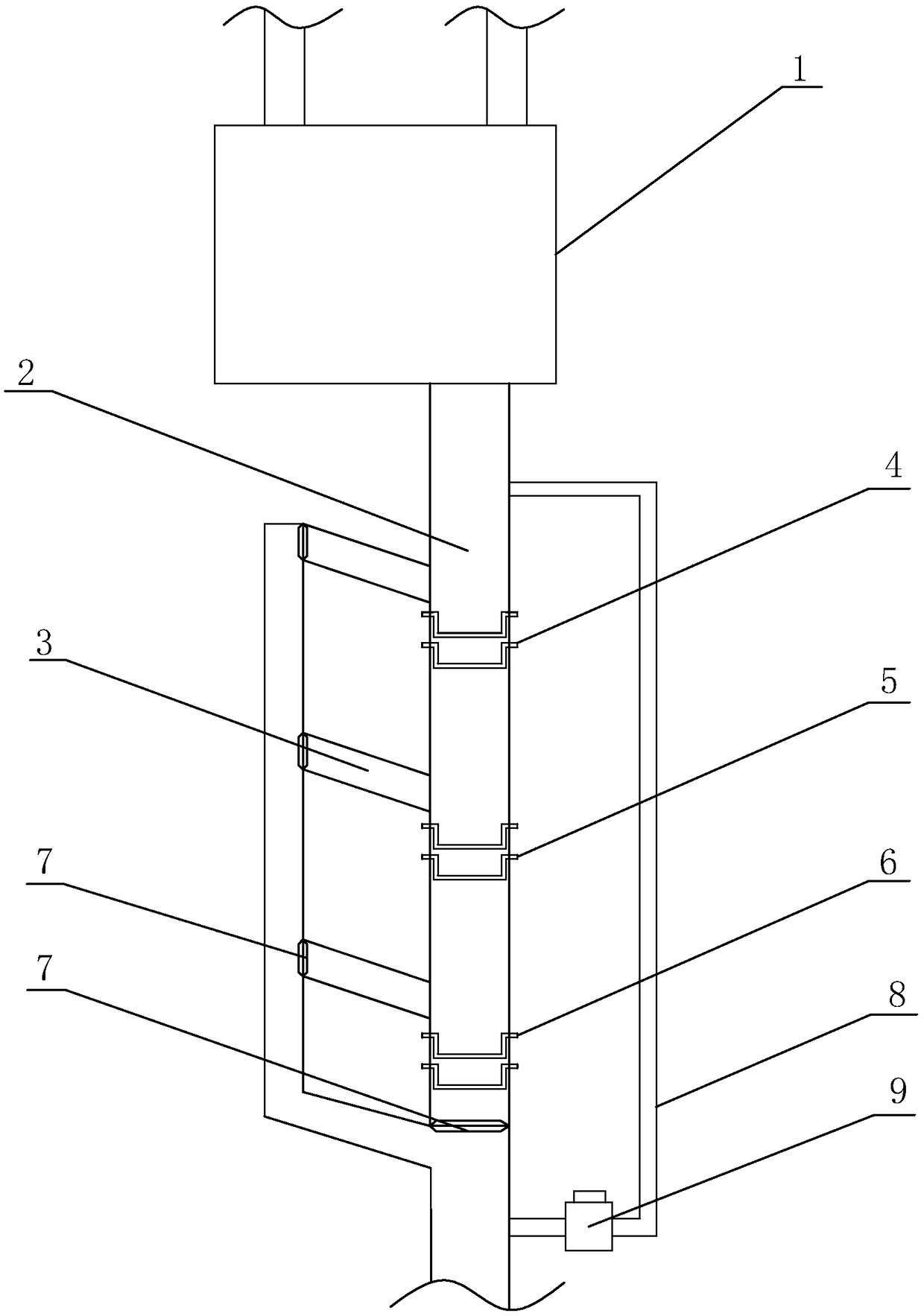

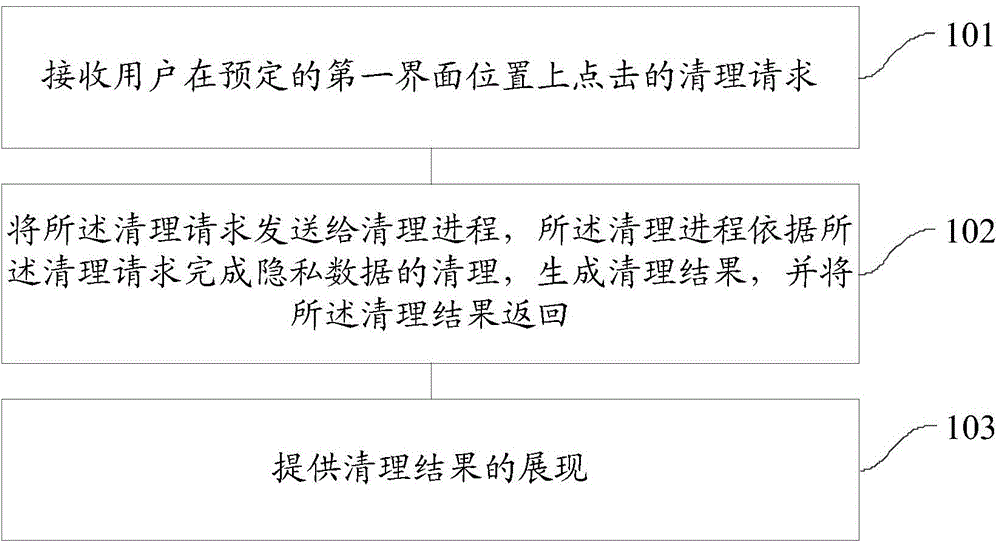

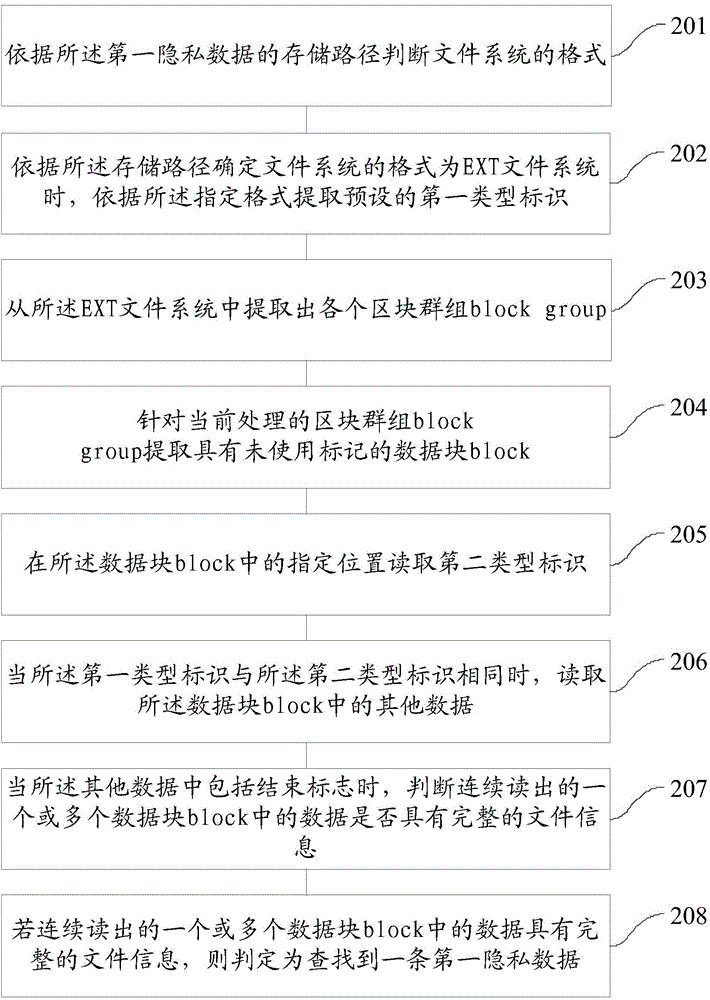

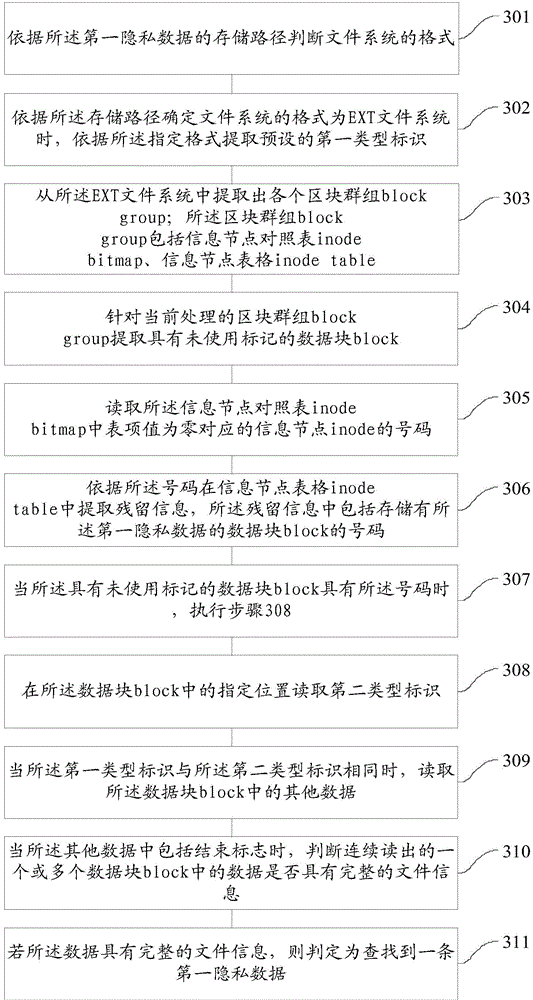

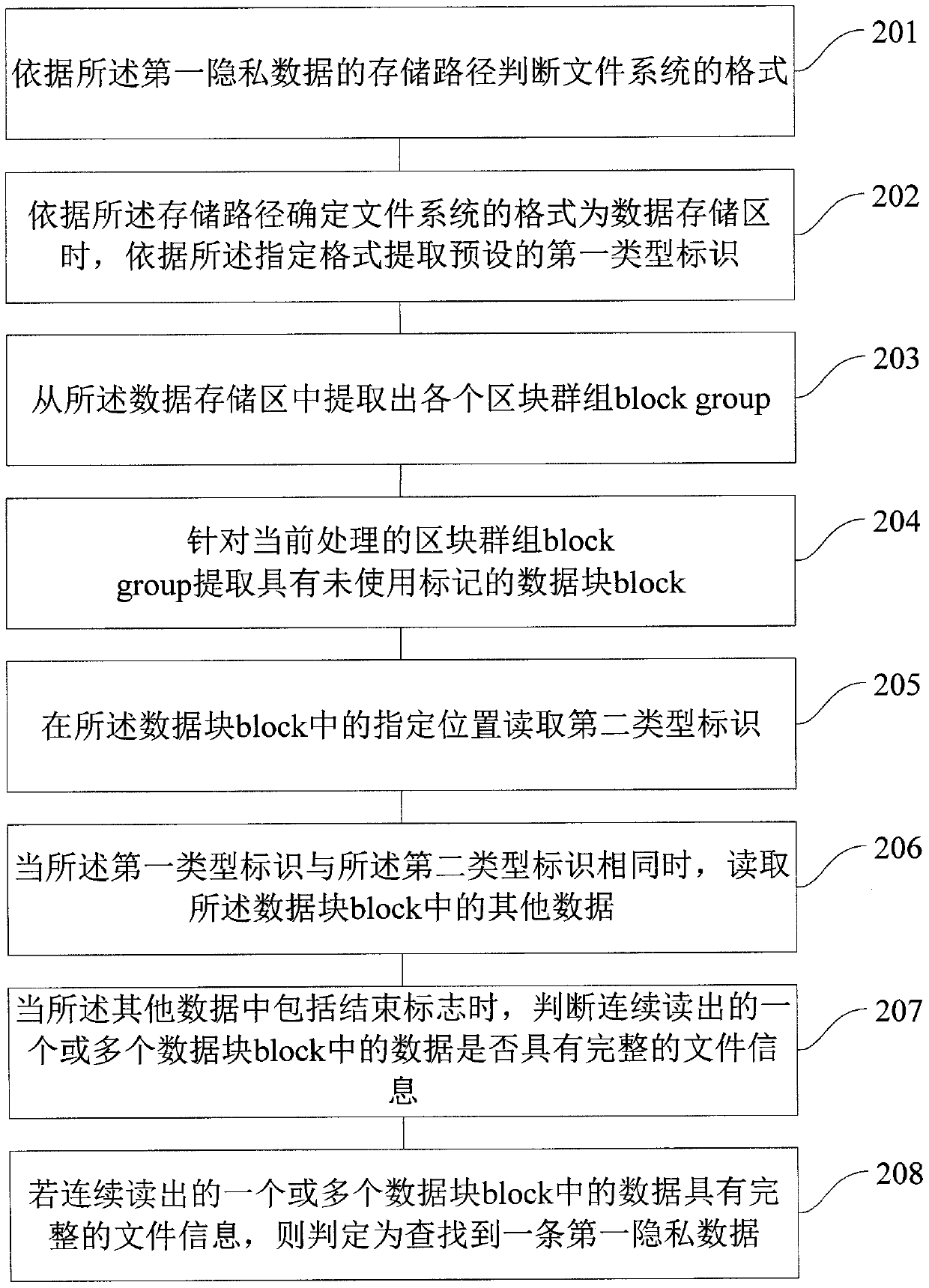

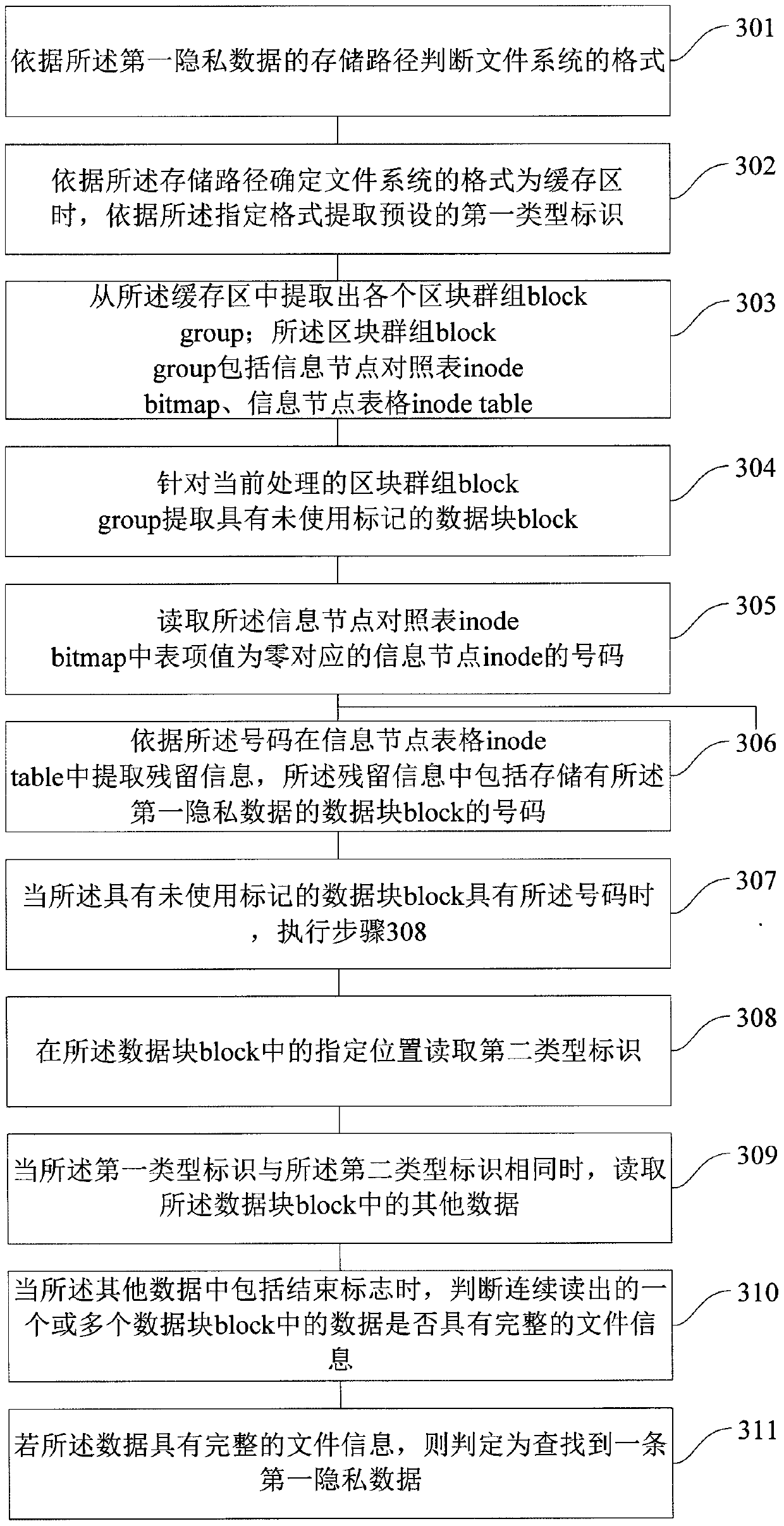

Method and device for clearing privacy data

InactiveCN104090922ASolve the problem of findingIncreased read and write lifespanSubstation equipmentSpecial data processing applicationsInternet privacyInterface position

The embodiment of the invention provides a method for clearing privacy data. The method comprises the steps of receiving a clearing request clicked by a user at a first preset interface position; sending the clearing request to a clearing program for clearing the privacy data according to the clearing request, generating a clearing result and returning the clearing result; showing the clearing result. According to the method, the clearing speed can be increased, the accuracy is improved, the manual operation is reduced, the time consumption is reduced, the read-write life span of a storage medium is prolonged, the cost is lowered, the calculation for clearing the privacy data is reduced, and the clearing efficiency is improved.

Owner:BEIJING QIHOO TECH CO LTD +1

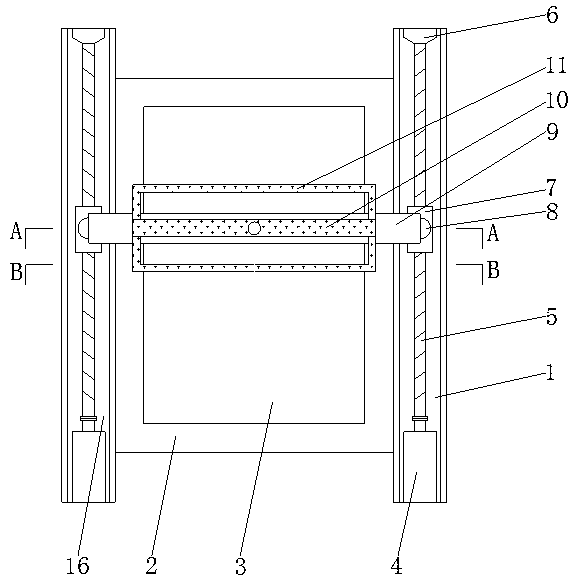

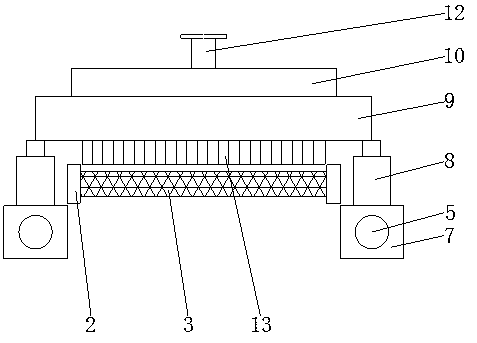

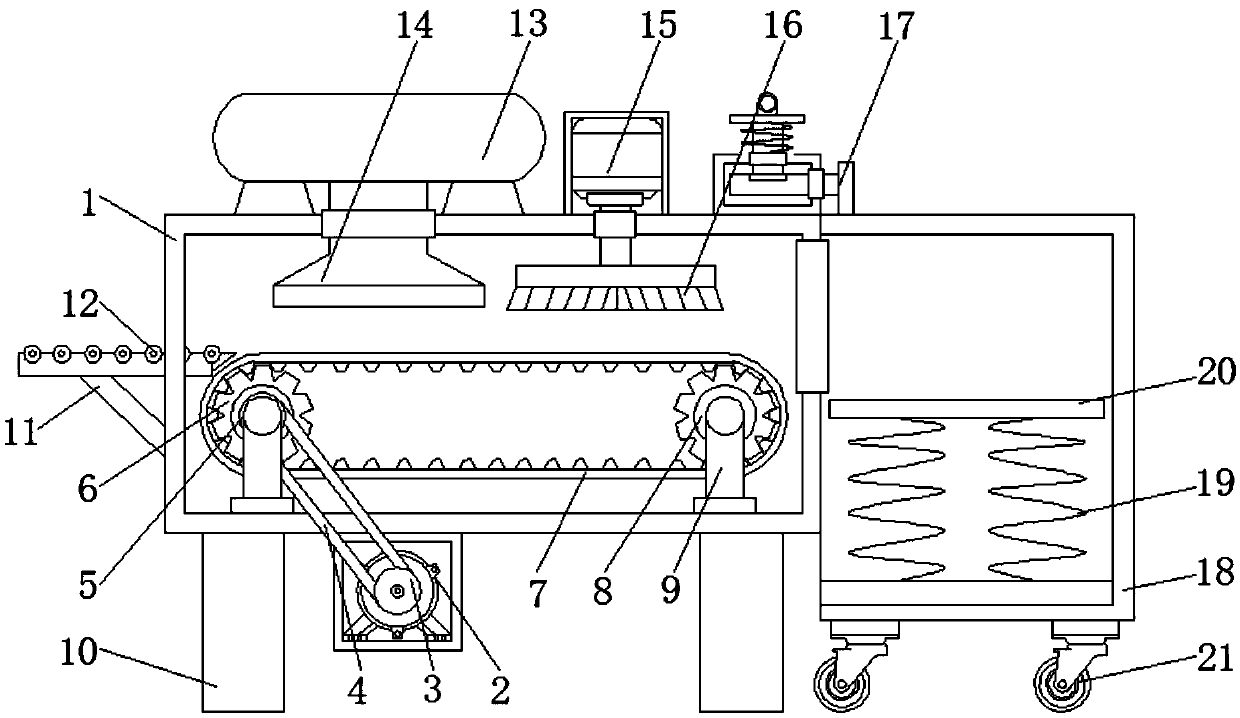

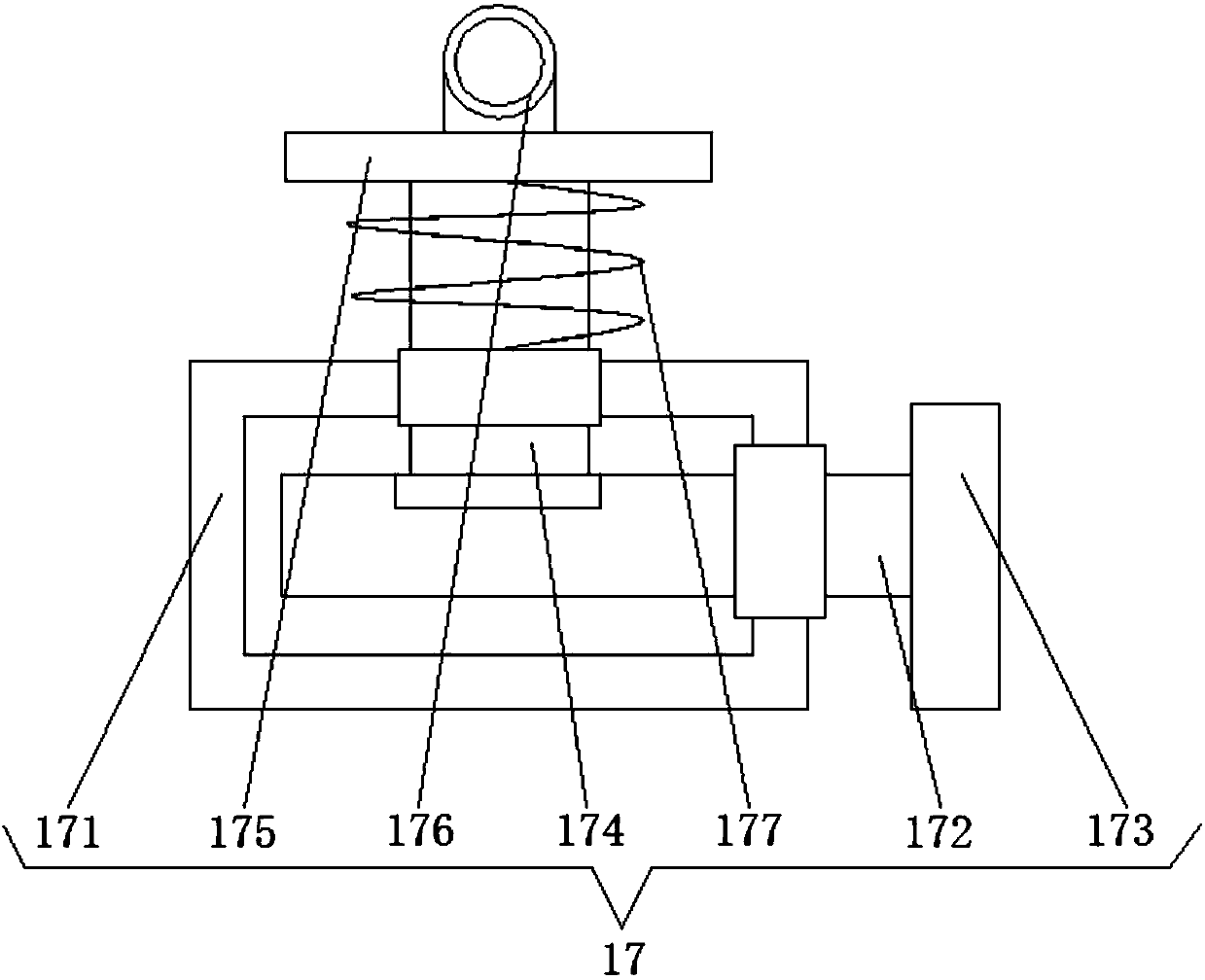

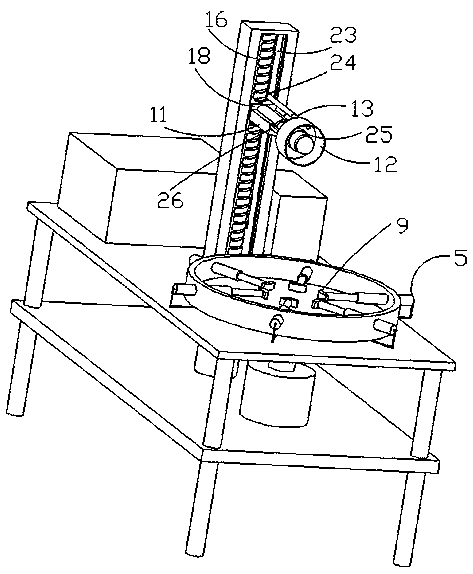

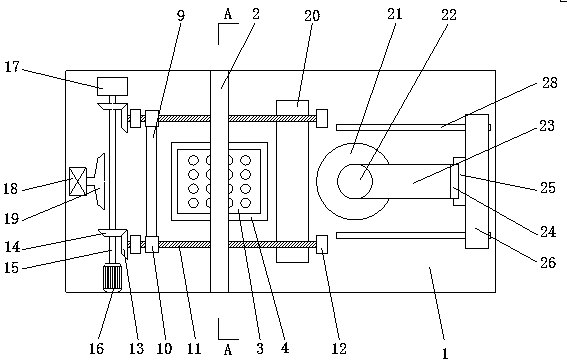

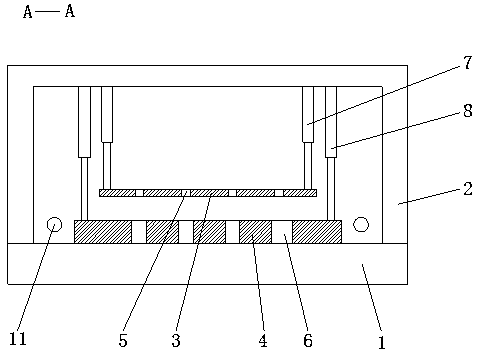

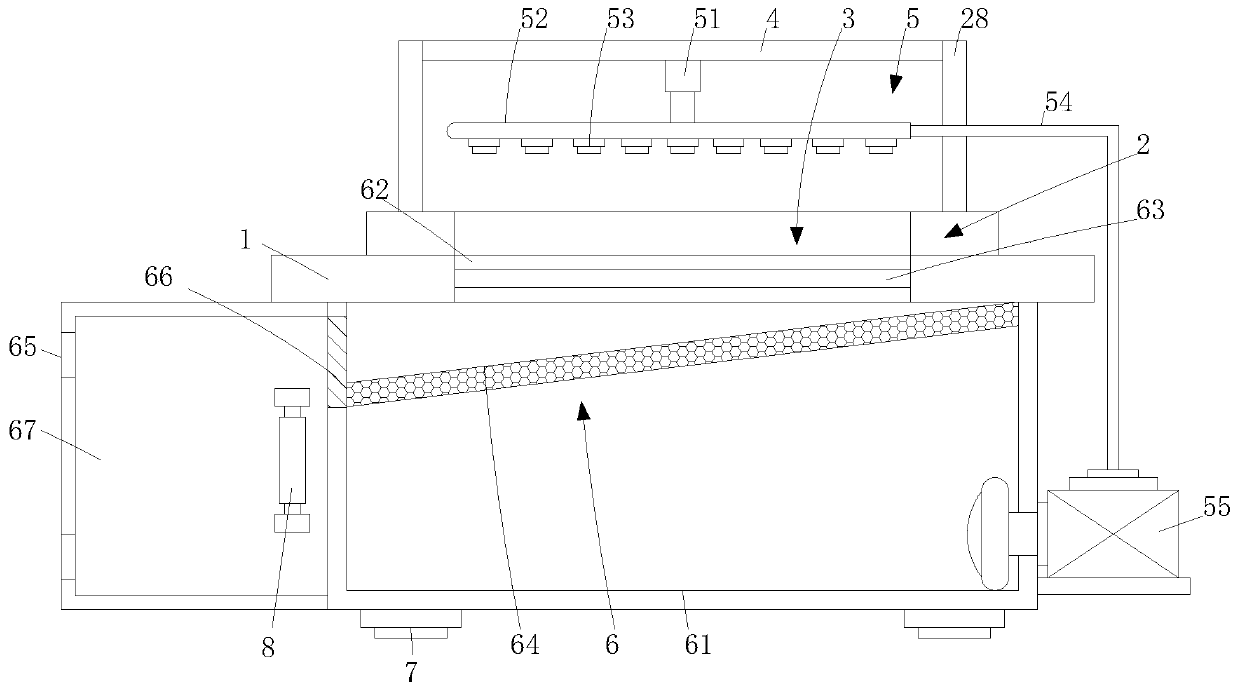

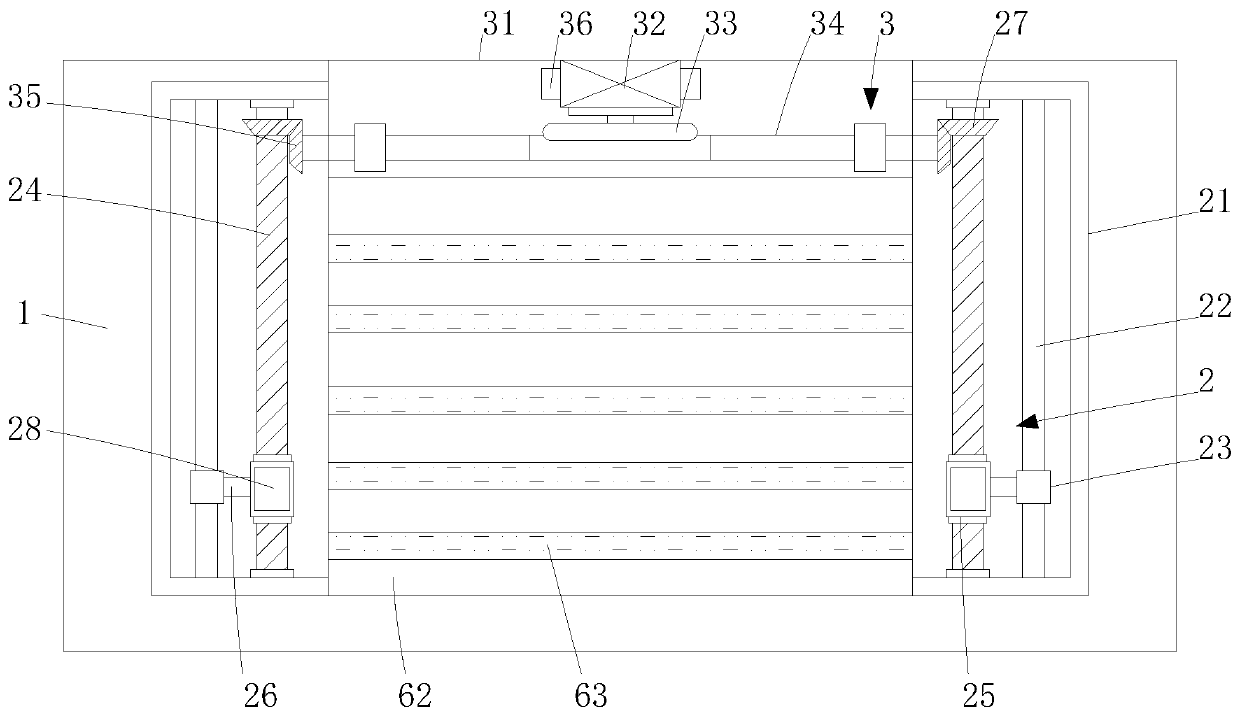

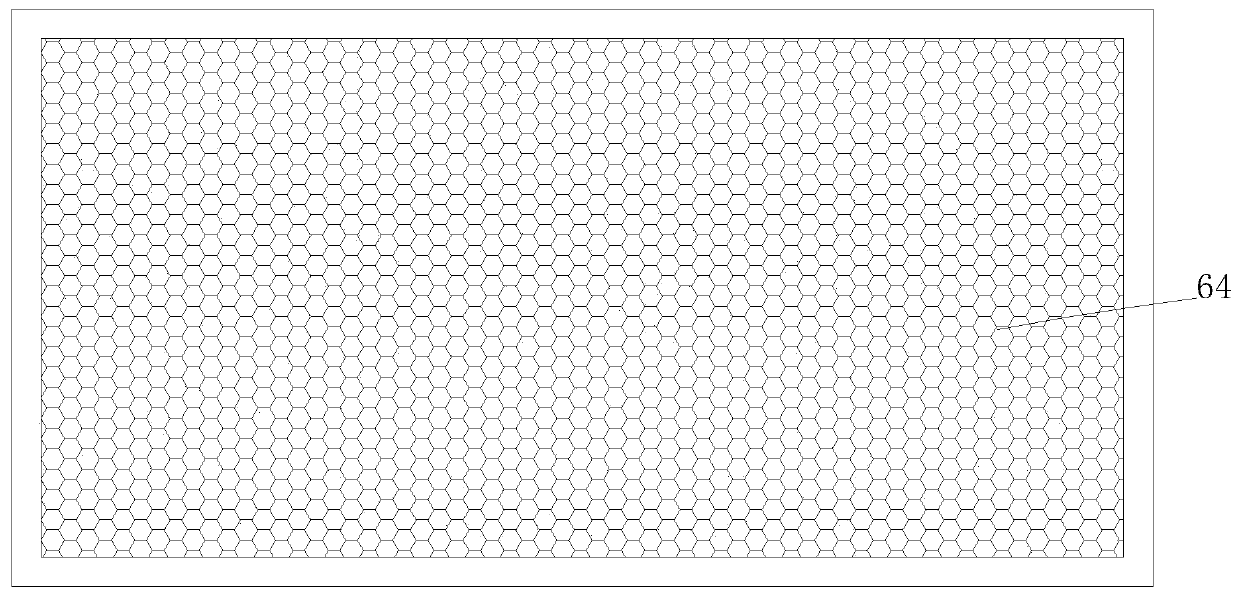

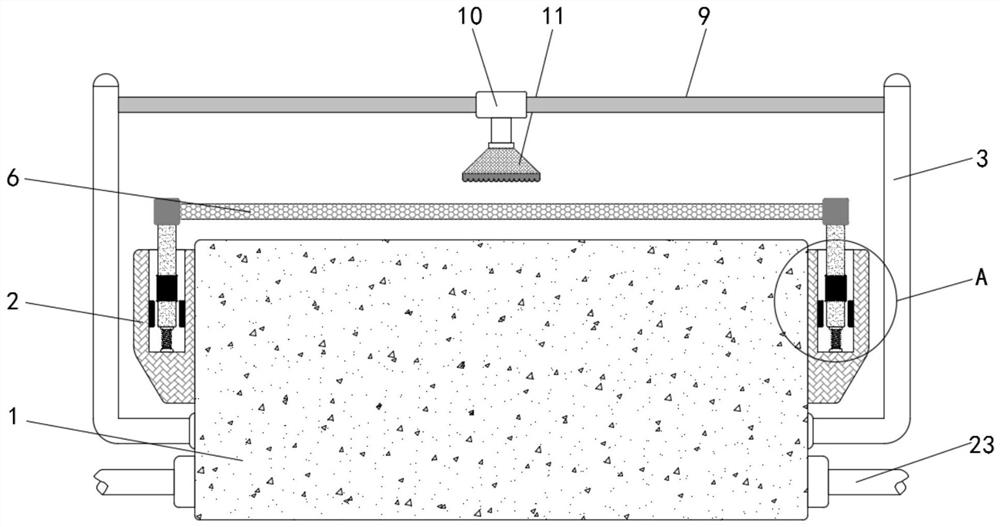

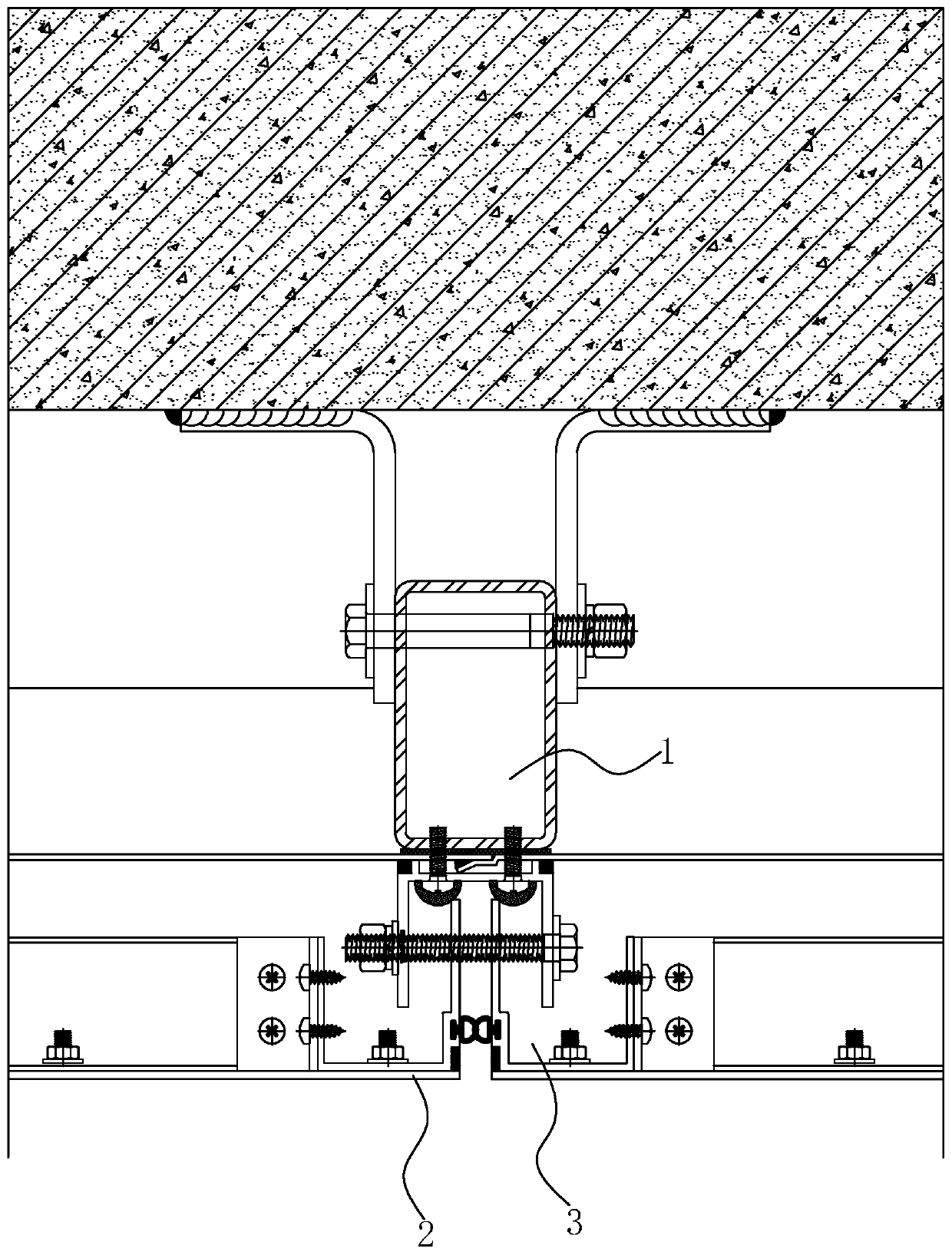

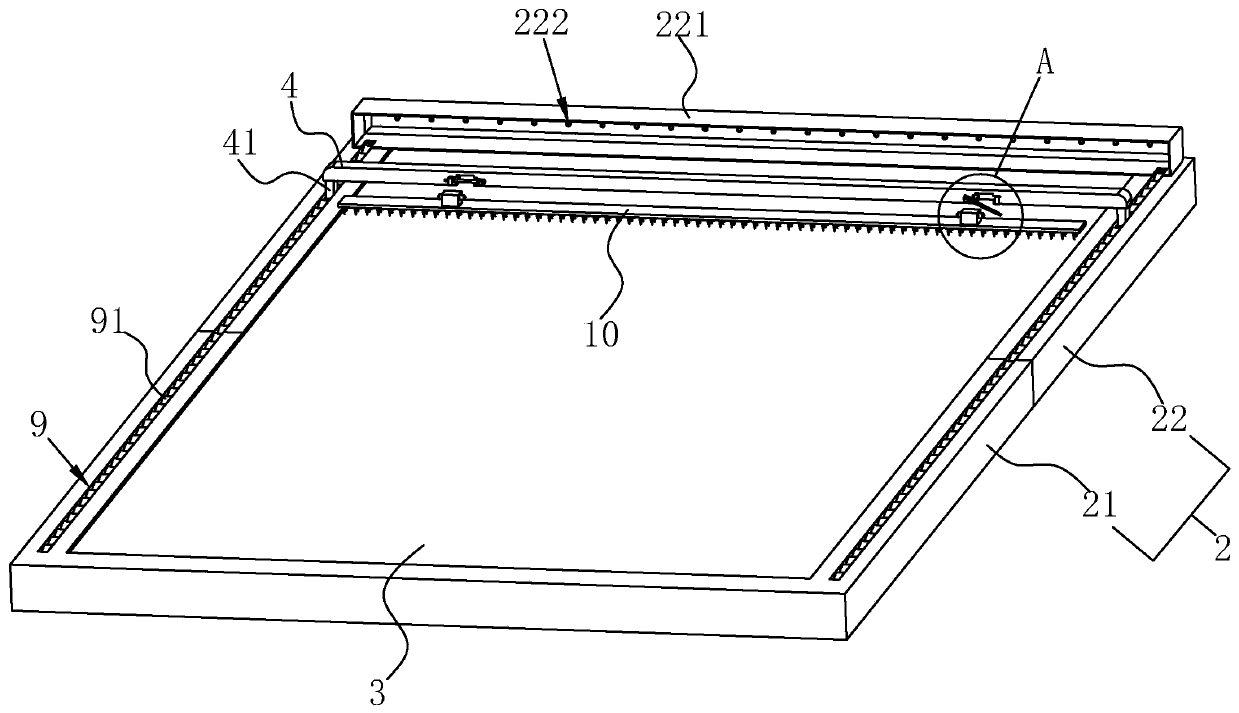

Automatic net cleaning device for vibration screen

InactiveCN108114895AHeight adjustableClean up completelySievingScreeningCouplingPulp and paper industry

The invention discloses an automatic net cleaning device for a vibration screen. The automatic net cleaning device comprises a rack, a frame is fixed to the inner side of the rack, a screen is fixed into the frame, a groove is formed in the top of the rack, a gear motor is fixed to one end of the groove, an output shaft of the gear motor is fixedly connected with one end of a screw rod through a coupler, the other end of the screw rod is rotatably connected with a bearing base fixed to the other end of the groove, the screw rod is sleeved with a nut base, an air cylinder is fixed to the top ofthe nut base, the end of a piston rod in the air cylinder is fixedly connected with the end of a mounting frame, and a main water pipe is arranged at the top of the mounting frame and is fixedly connected with the mounting frame through a pipe clamp. Through the arrangement of the screw rod, the air cylinder, a nozzle, a brush and a rotary brush, the problems that a traditional vibration screen net cleaning device is monotonous in cleaning measure, cleaning is incomplete, and the intelligence automation is insufficient are solved.

Owner:XINXIANG ZHEN YING MACHINERY EQUIP CO LTD

Lampblack cleaning device

ActiveCN103394253ANo pollution in the processPromote formationDomestic stoves or rangesLighting and heating apparatusEngineeringOil water

The invention discloses a lampblack cleaning device which belongs to the field of range hoods. The lampblack cleaning device comprises a case, a grid plate, an air outlet, an air draft device, a baffle and an oil-water separation plate, wherein the grid plate is arranged on one side of the case and inclines to the horizontal plane, the air outlet is positioned in the top of the case, the air draft device is arranged at the air outlet and on the inner side of the top of the case, the baffle is arranged in the case and corresponds to the grid plate, a lampblack channel is formed by the baffle and the grid plate, and the oil-water separation plate is fixedly arranged between the lower end of the baffle and the case, the upper end of the baffle is fixedly connected to the inner side of the top of the case, and a hole is formed in the oil-water separation plate. The lampblack cleaning device has the advantages of thorough lampblack cleaning, clean tail gas, environmental protection and simple structure.

Owner:SICHUAN HUIDATONG MACHINERY EQUIP MFG

Cleaning and binning device for ceramic tile production

PendingCN107892023AEasy to packAvoid damageCleaning using toolsPackaging protectionElectric machineryCeramic tiles

The invention discloses a cleaning and binning device for ceramic tile production, and relates to the technical field of ceramic tiles. The cleaning and binning device comprises an outer frame. The bottom of the outer frame is fixedly connected with a first motor, and one end of an output shaft of the first motor is fixedly connected with a first belt pulley. The surface of the first belt pulley is in drive connection with a second belt pulley through a belt, and the back face of the second belt pulley is fixedly connected with a first driving wheel. The surface of the first driving wheel is in drive connection with a second driving wheel through a driving belt. The axis position of the first driving wheel and the axis position of the second driving wheel are fixedly connected with the twosides of the bottom of the inner wall of the outer frame through corresponding supporting pillars separately. The right side of the top of the outer frame is fixedly connected with a locking device.According to the cleaning and binning device for ceramic tile production, the purpose of cleaning the ceramic tiles conveniently is achieved, no manual cleaning is required and the burdens on workersare relieved; and meanwhile, the cleaning effect is better, and cleaning is more thorough. Moreover, the ceramic tiles can be effectively prevented from being damaged and the practicability of the cleaning and binning device is improved.

Owner:WUXI HUIOU CERAMIC CO LTD

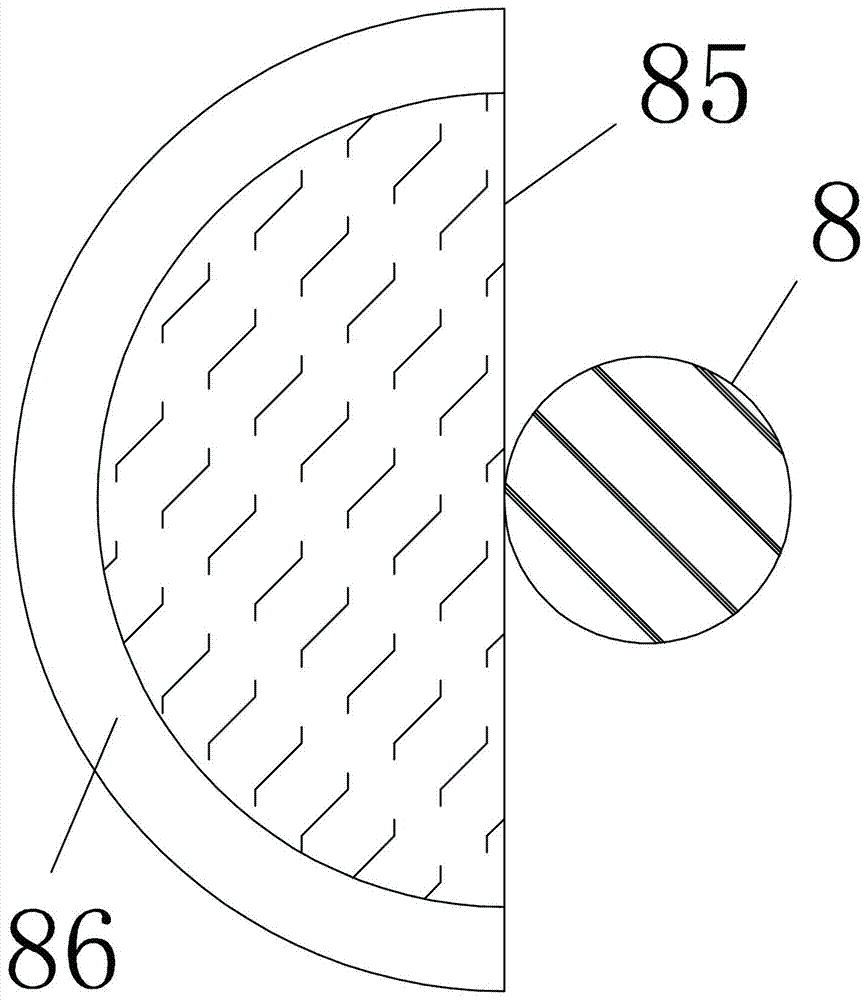

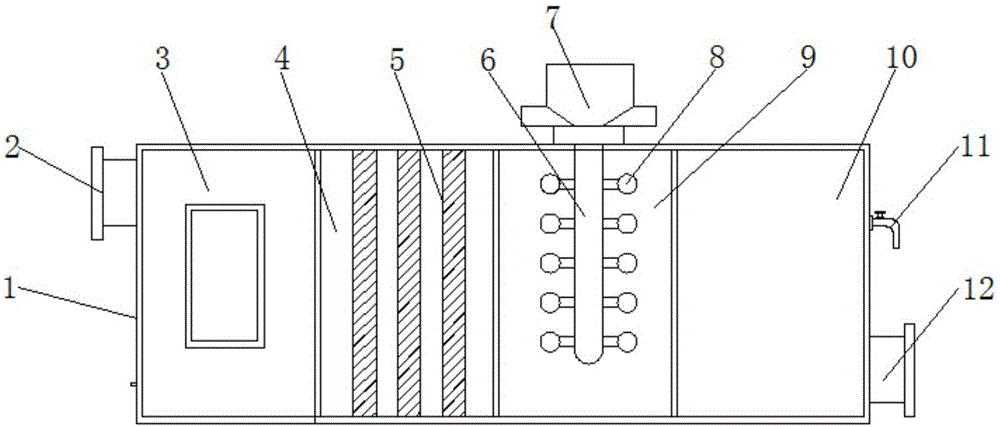

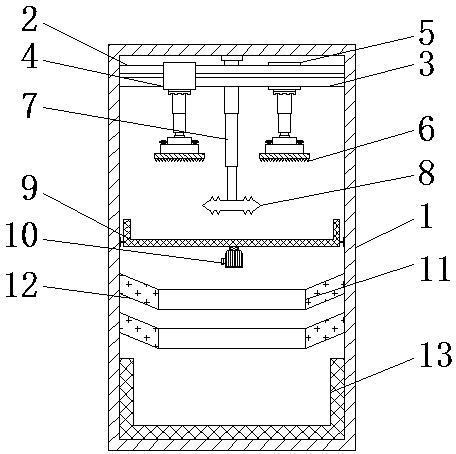

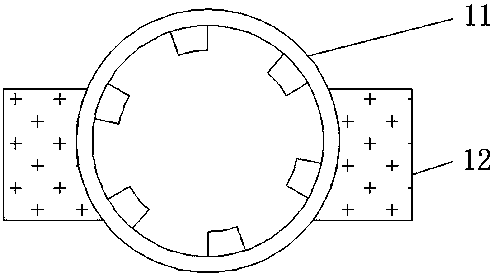

Blood filtration device for assisting in treating leukocyte diseases

The invention relates to the technical field of blood filtration, in particular to a blood filtration device for assisting the treatment of leukocyte diseases, comprising a box body, a liquid inlet pipe connected to the left side of the box body, and a liquid outlet pipe connected to the right side of the box body, the box body The inner wall of the body is connected with a circular ring, the inner wall of the circular ring is circumferentially provided with an annular chute, and a filter plate is arranged inside the circular ring, and a plurality of first sliders are circumferentially connected with the side wall of the filter plate, The first slider is slidingly connected with the annular chute, the filter plate is connected to a rotating rod in the middle of one end close to the liquid inlet pipe, the other end of the rotating rod is connected to a second bevel gear, and the first bevel gear The middle part of the lower end is connected with a rotating shaft, and the other end of the rotating shaft passes through the bottom plate of the box to reach the outside of the box and is connected with a motor. The present invention has the characteristics of simple structure, good filtering effect, good cleaning effect, and improved filtering efficiency. Substantial features and notable improvements.

Owner:张献伟

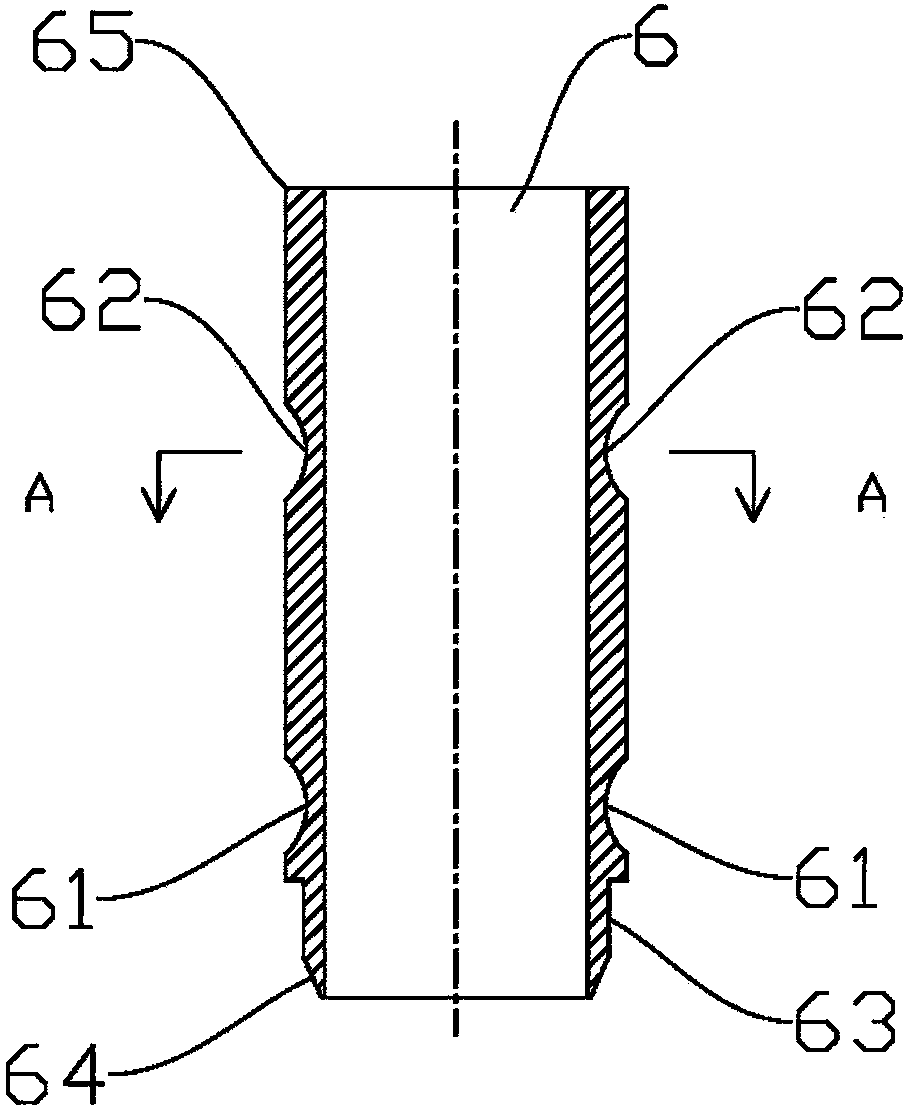

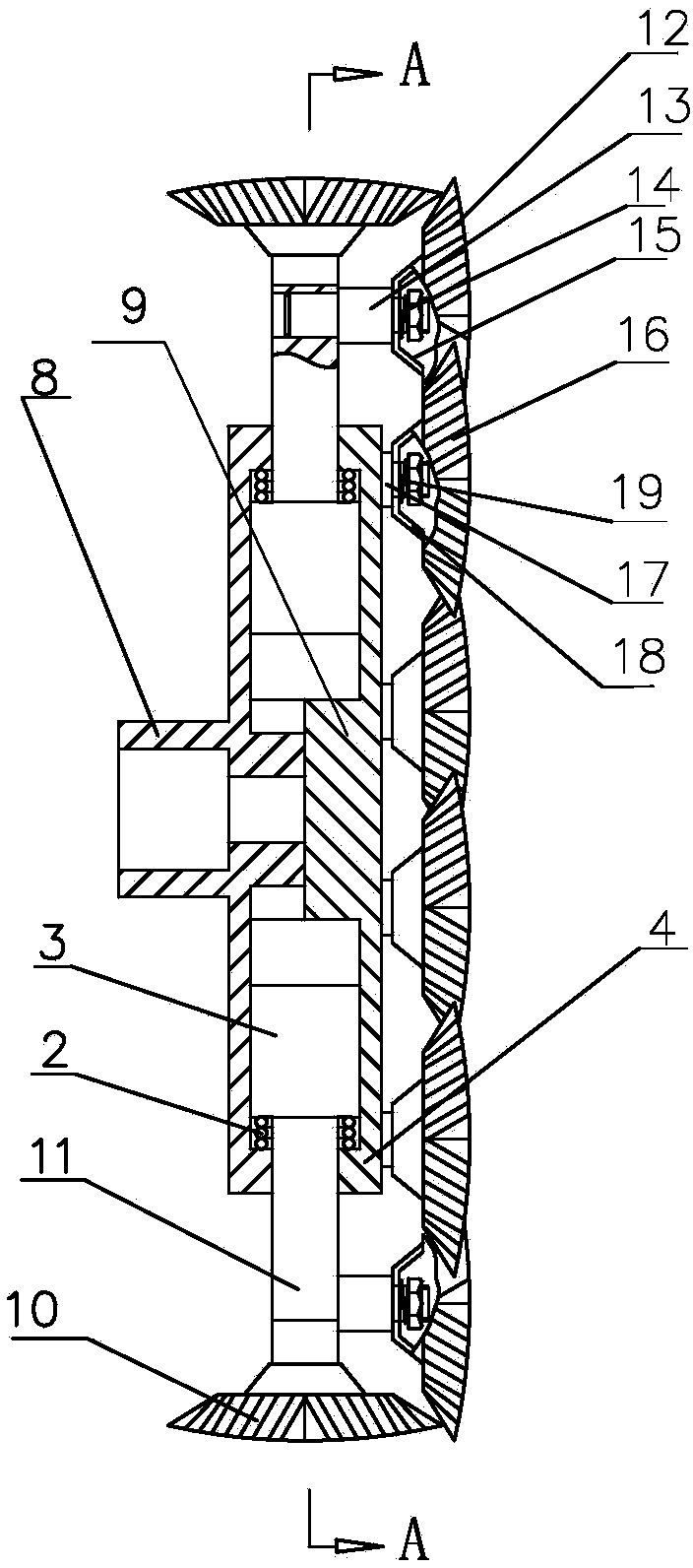

Hydraulic pipe orifice cleaning device

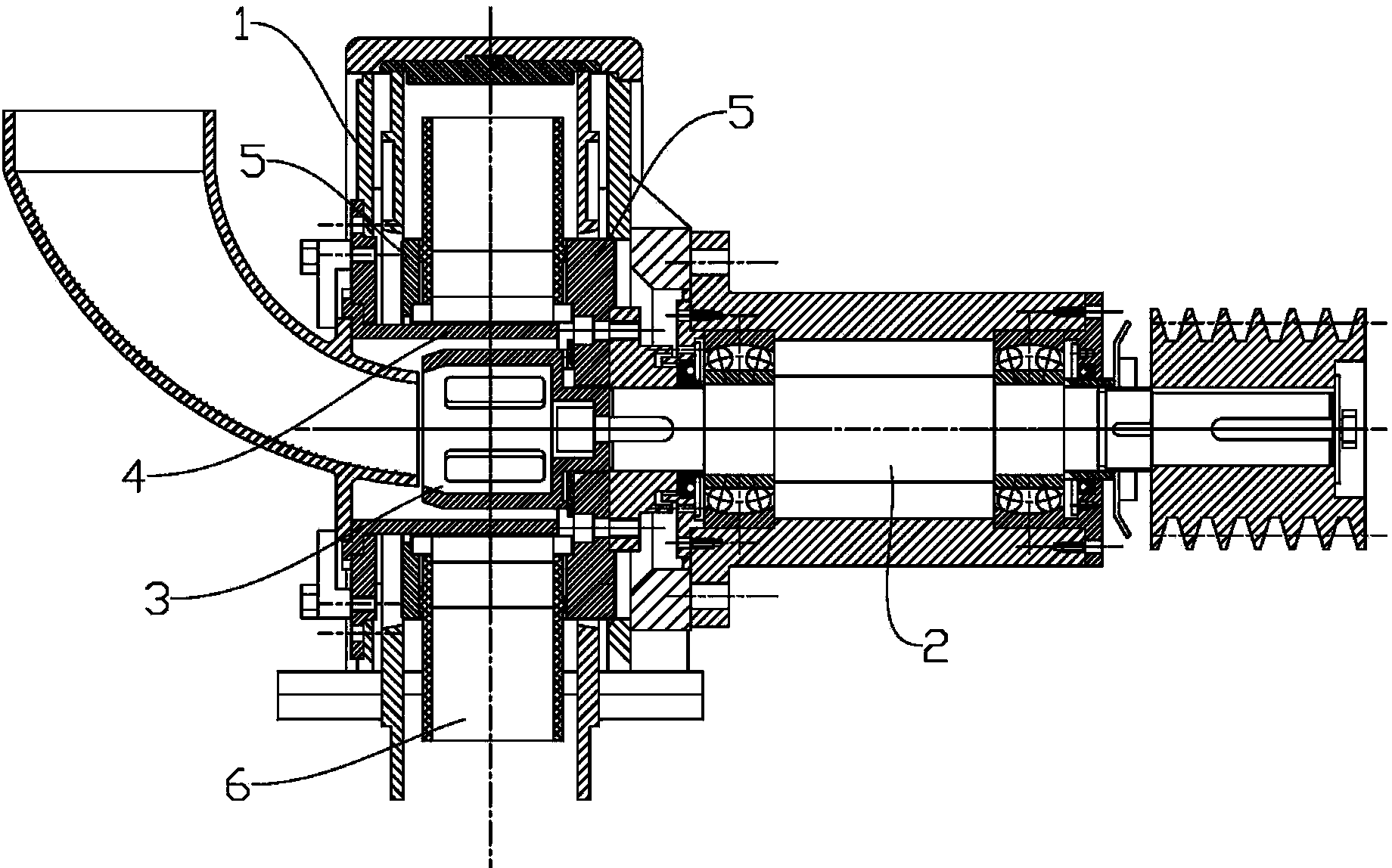

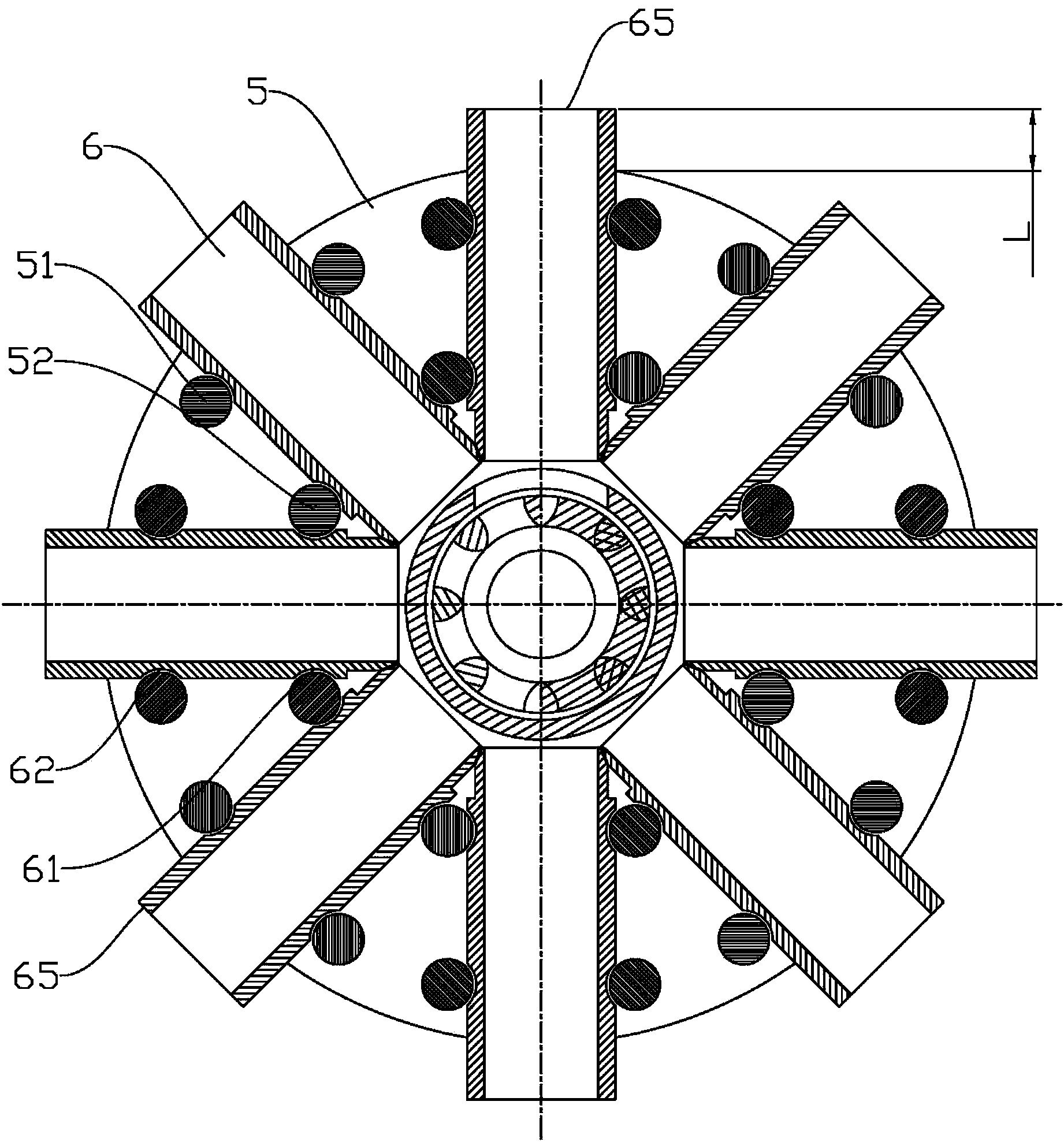

ActiveCN107617610ASo as not to damageEasy to useEdge grinding machinesHollow article cleaningEngineeringScrew thread

The invention discloses a hydraulic pipe orifice cleaning device, in particular a device for cleaning pipe orifices and the inner and outer walls of the pipe orifices through internal support of hydraulic pipes and rotation of multiple clamping blocks along the pipe orifices. The hydraulic pipe orifice cleaning device is characterized in that a fixed handle is positioned at one end of a fixed shaft; a thread is arranged on the surface of the fixed shaft; a thread sleeve sleeves the fixed shaft, and is matched with a thread on the surface of the fixed shaft; a retainer ring sleeves one end of the thread sleeve; a rotating ring is positioned at the other end of the thread sleeve; a main support ring is connected with a rotating ring through multiple fixed lugs; the distances between two adjacent fixed lugs on the main support ring are the same; a connecting ring is positioned at the other end of the fixed shaft through a bearing; an auxiliary support ring is connected with the connectingring through multiple fixed lugs; the multiple fixed lugs on the auxiliary support ring are corresponding to the multiple fixed lugs on the main support ring one to one; one ends of multiple transmission rods are positioned on the auxiliary support ring at equal intervals; and one ends of the transmission rods are positioned between two adjacent fixed lugs on the auxiliary support ring.

Owner:江苏华淼电子科技有限公司

Centrifugal sewage treatment device and operation method thereof

InactiveCN109422324AAvoid cloggingBreak up fullyWater/sewage treatment by centrifugal separationSpecific water treatment objectivesSludgeArchitectural engineering

The invention provides a centrifugal sewage treatment device, comprising a stirring tank and a centrifuging tank. A fixed base is fixedly connected to the top of the left wall of the inner cavity of the stirring tank. The right end of the fixed base is fixedly connected to the top of the right wall of the inner cavity of the stirring tank. The bottom of the fixed base is provided with a movable slot the left inner wall of which is embedded with a sliding bar. The right end of the sliding bar is embedded in the right inner wall of the movable slot, and sliding blocks are movably mounted on thesurface of the sliding bar. According to the device and the method, through arrangement of a motor case, a first motor, a stirring cylinder and breaking blocks, the first motor is turned on when sewage water in the stirring cylinder is pumped into the inner cavity of the centrifuging tank through a water discharging pipe by a water pump, and an output end of the first motor rotates to drive a stirring shaft to rotate, and therefore, sludge settled in the stirring tank is broken by the breaking blocks and is mixed with sewage, and blockage of the water discharging pipe during water pump pumpingis effectively avoided.

Owner:江苏佳鑫环保工程有限公司

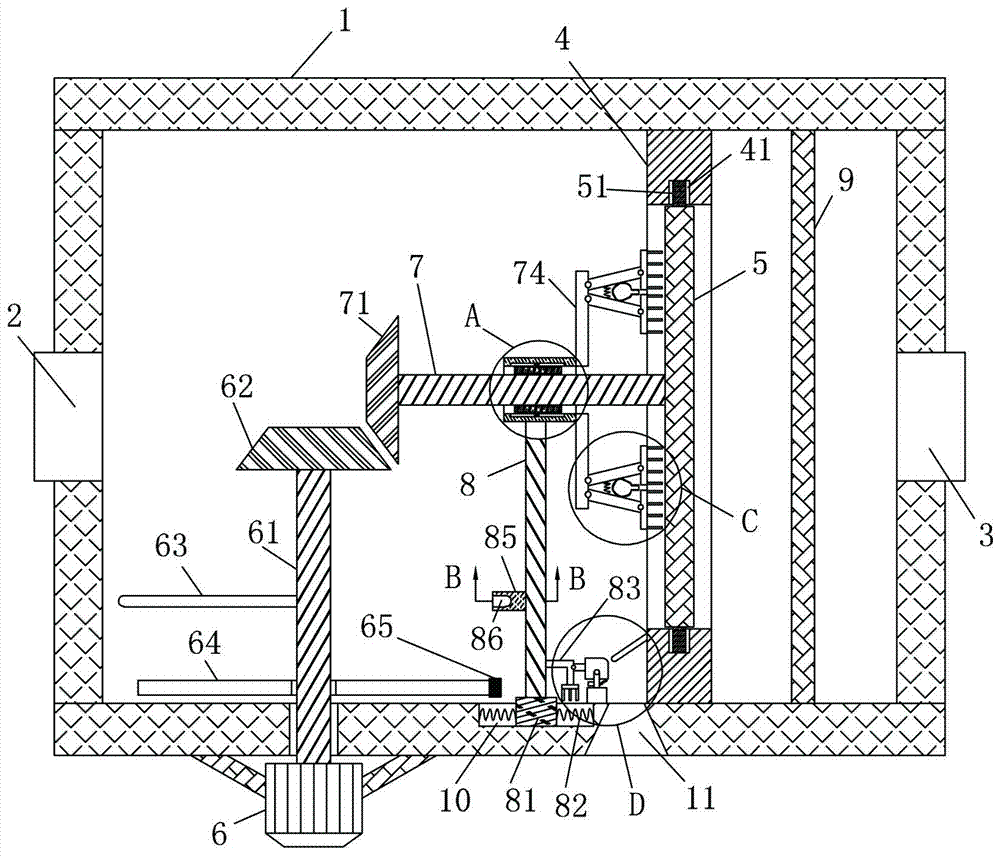

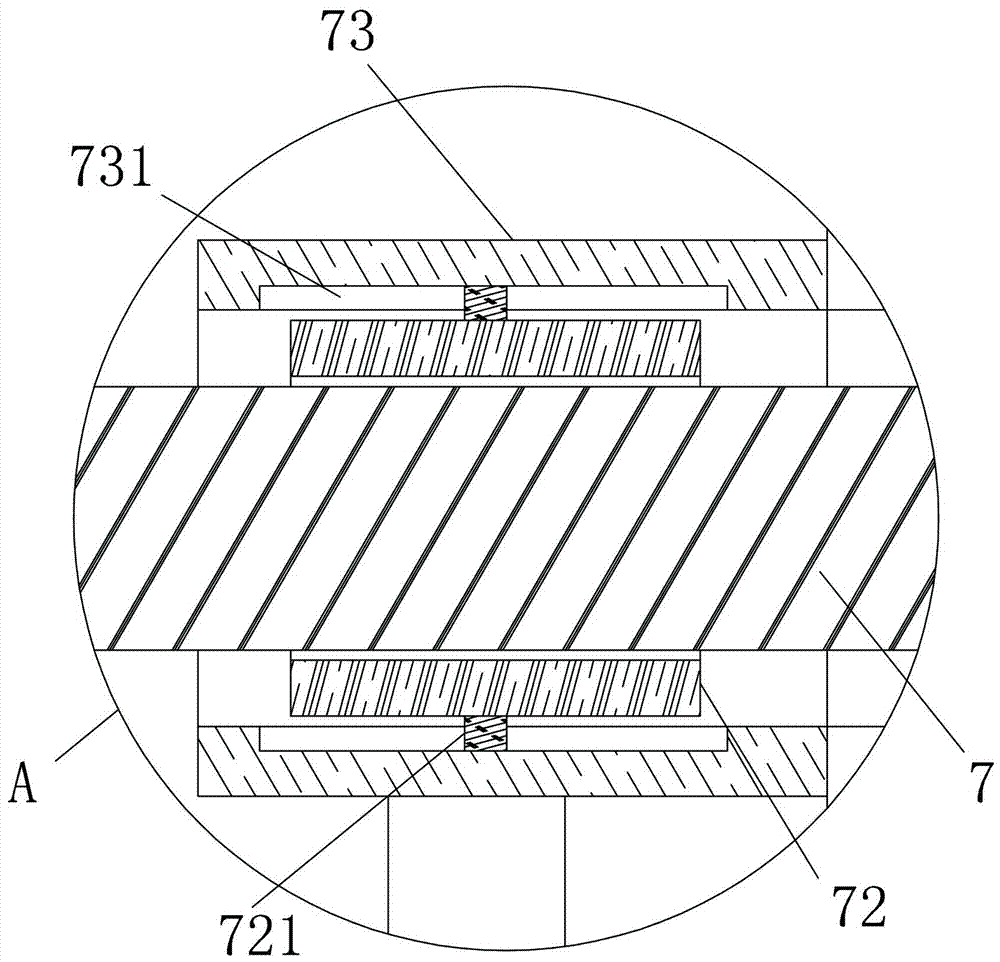

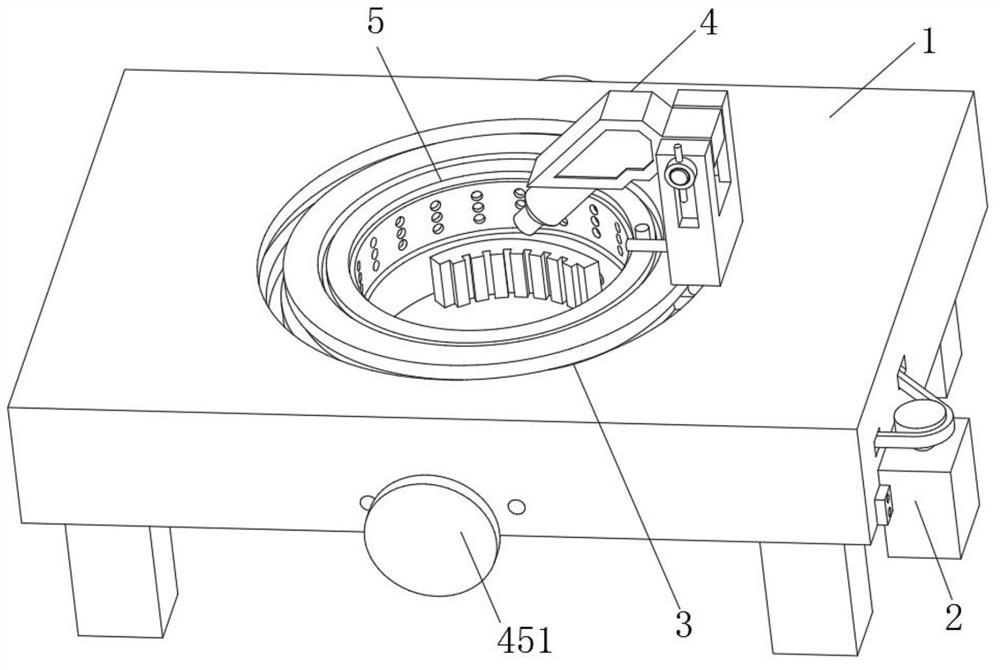

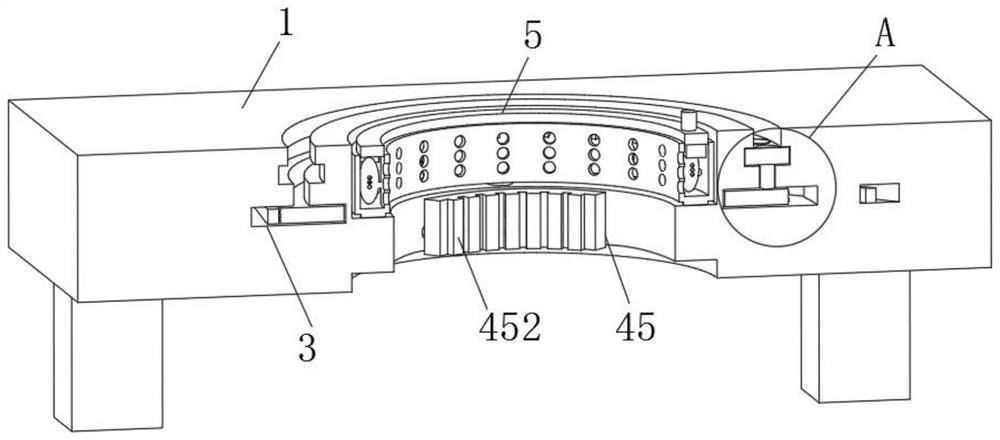

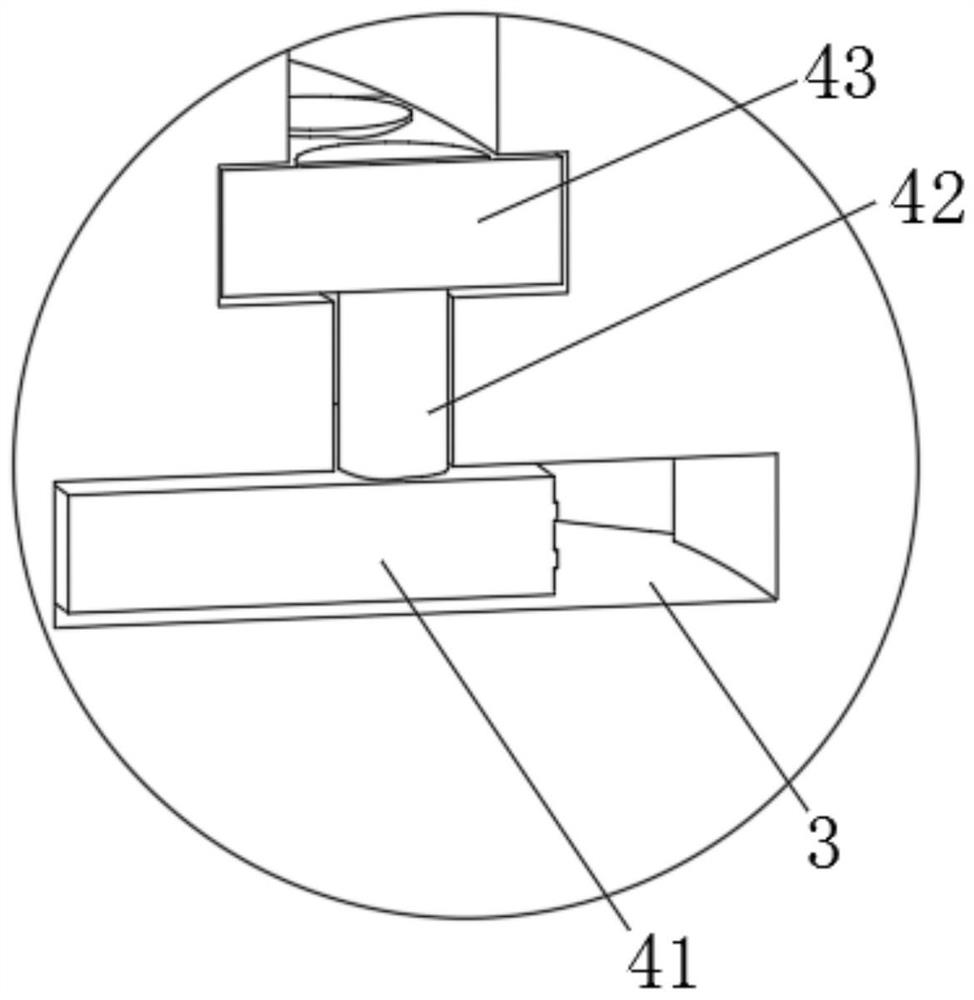

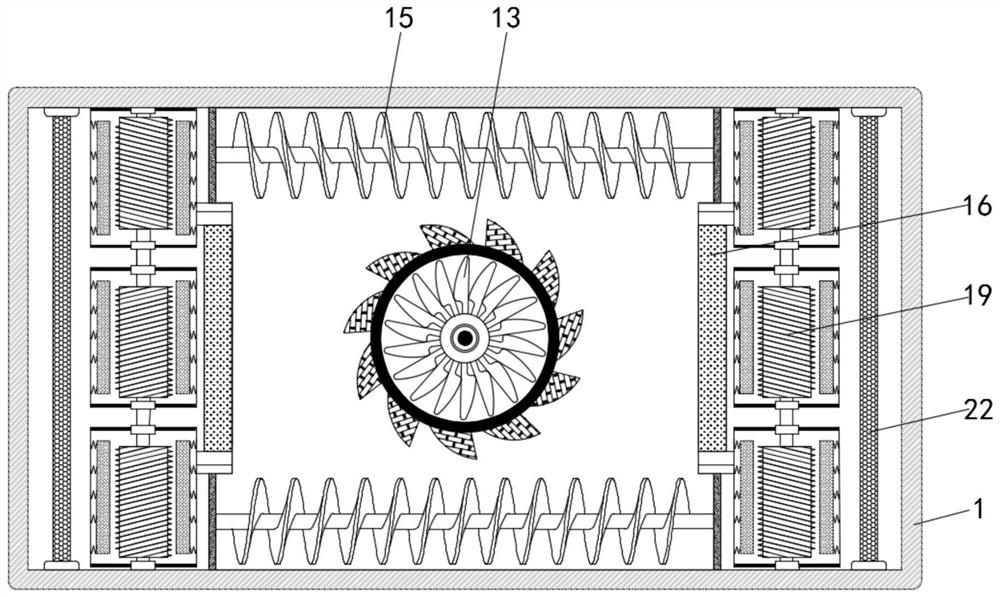

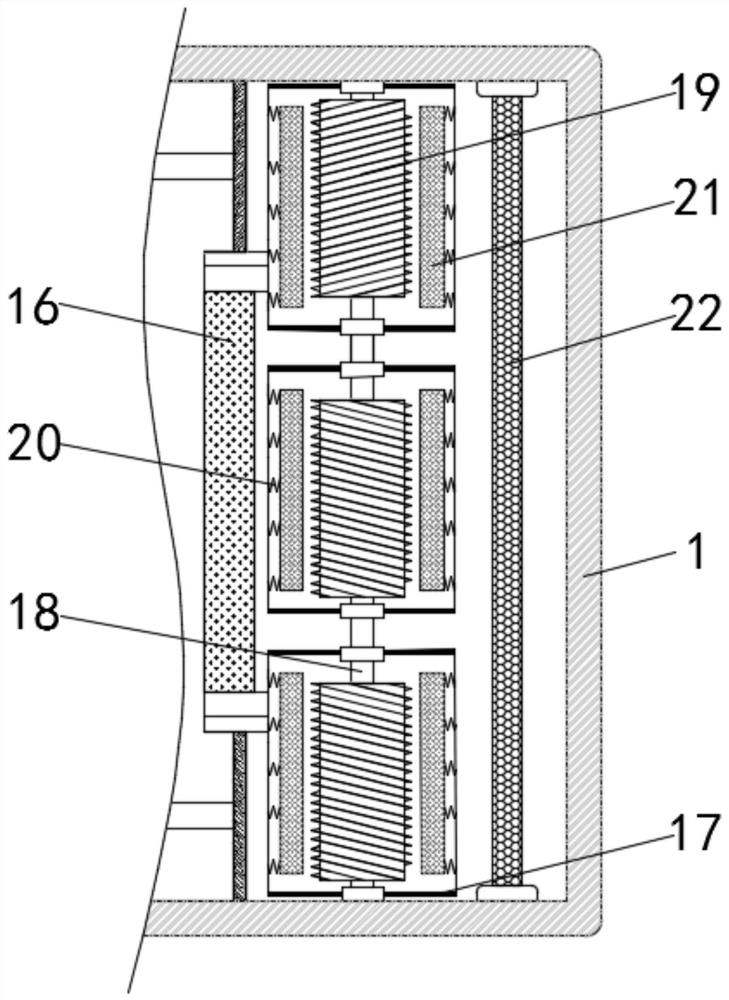

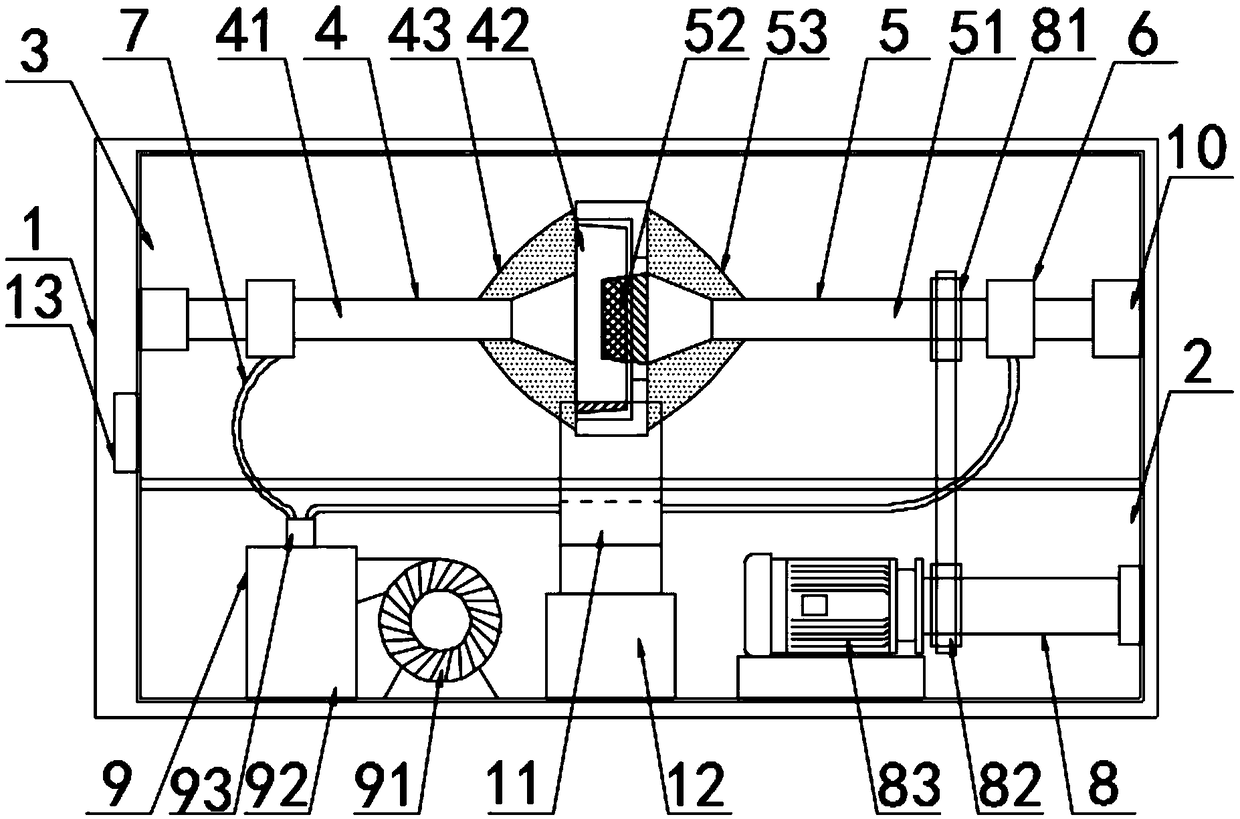

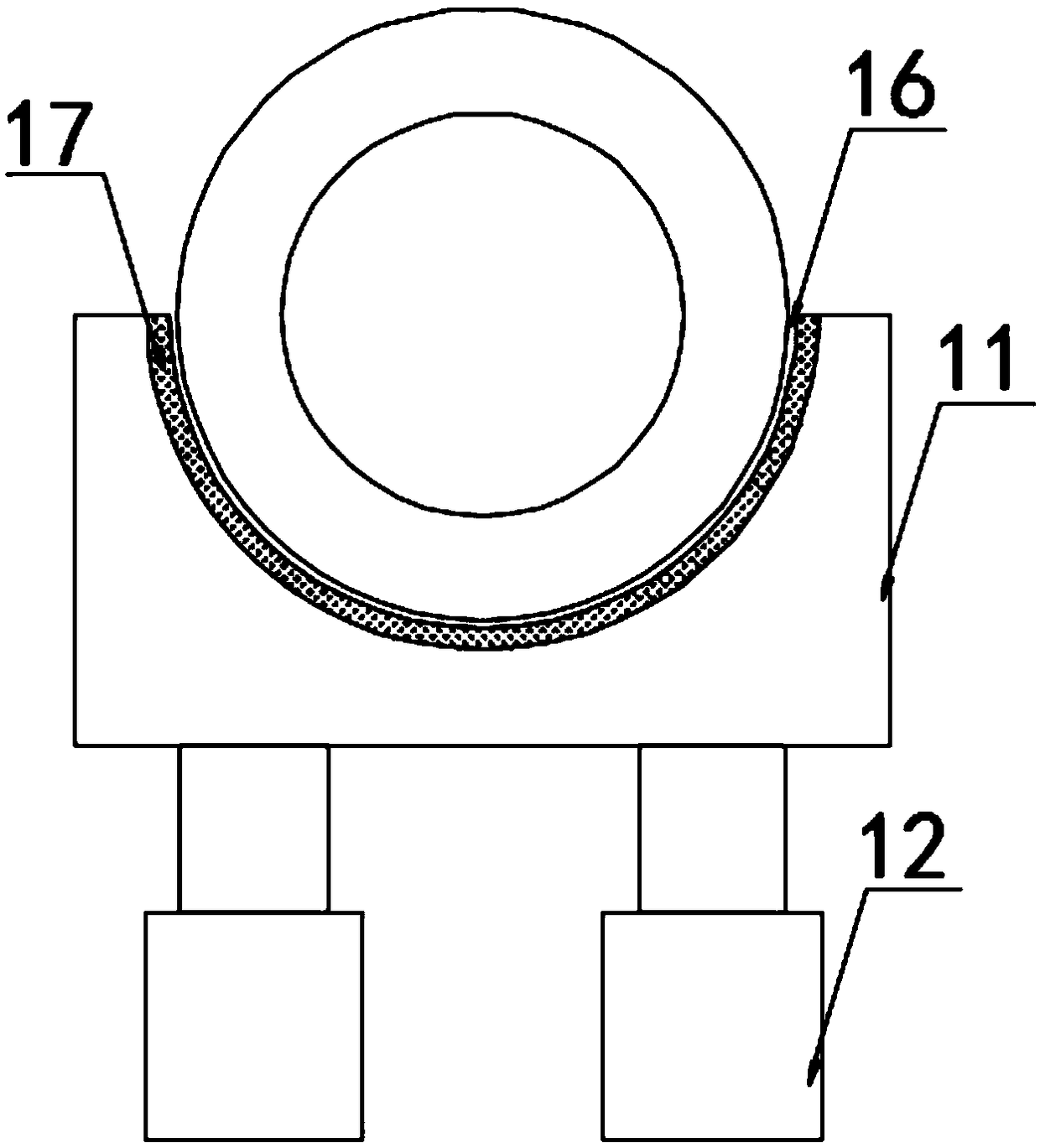

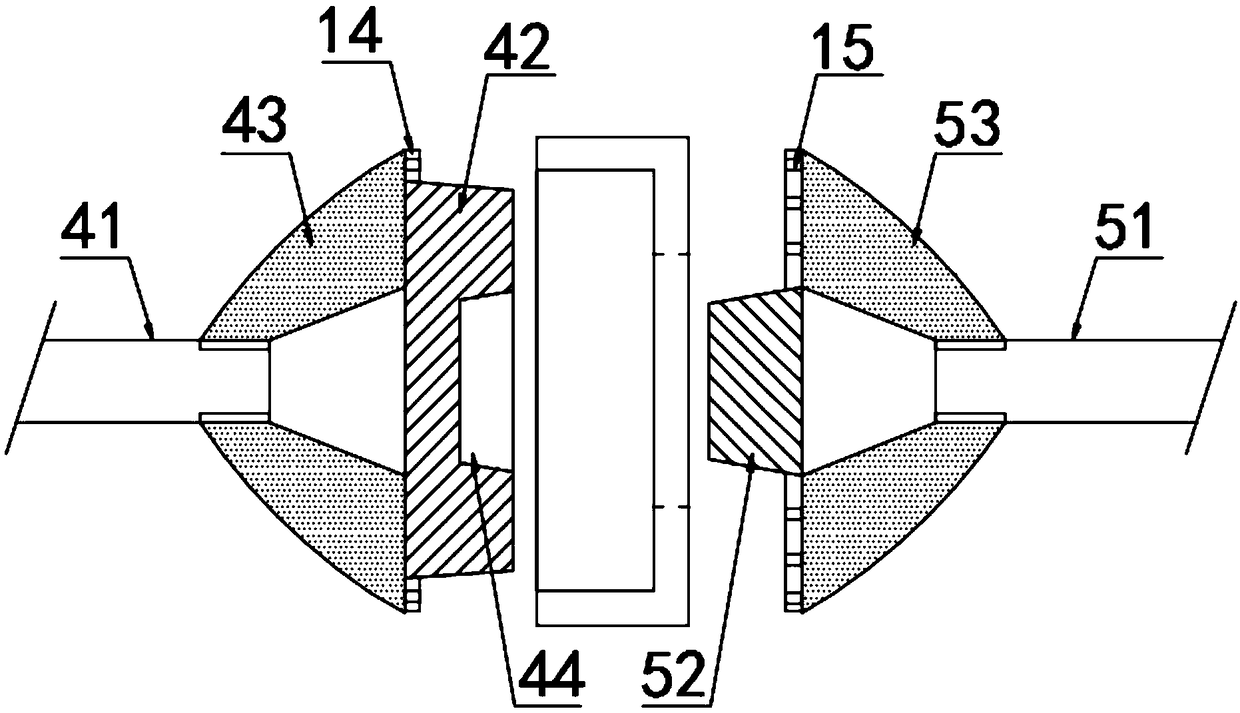

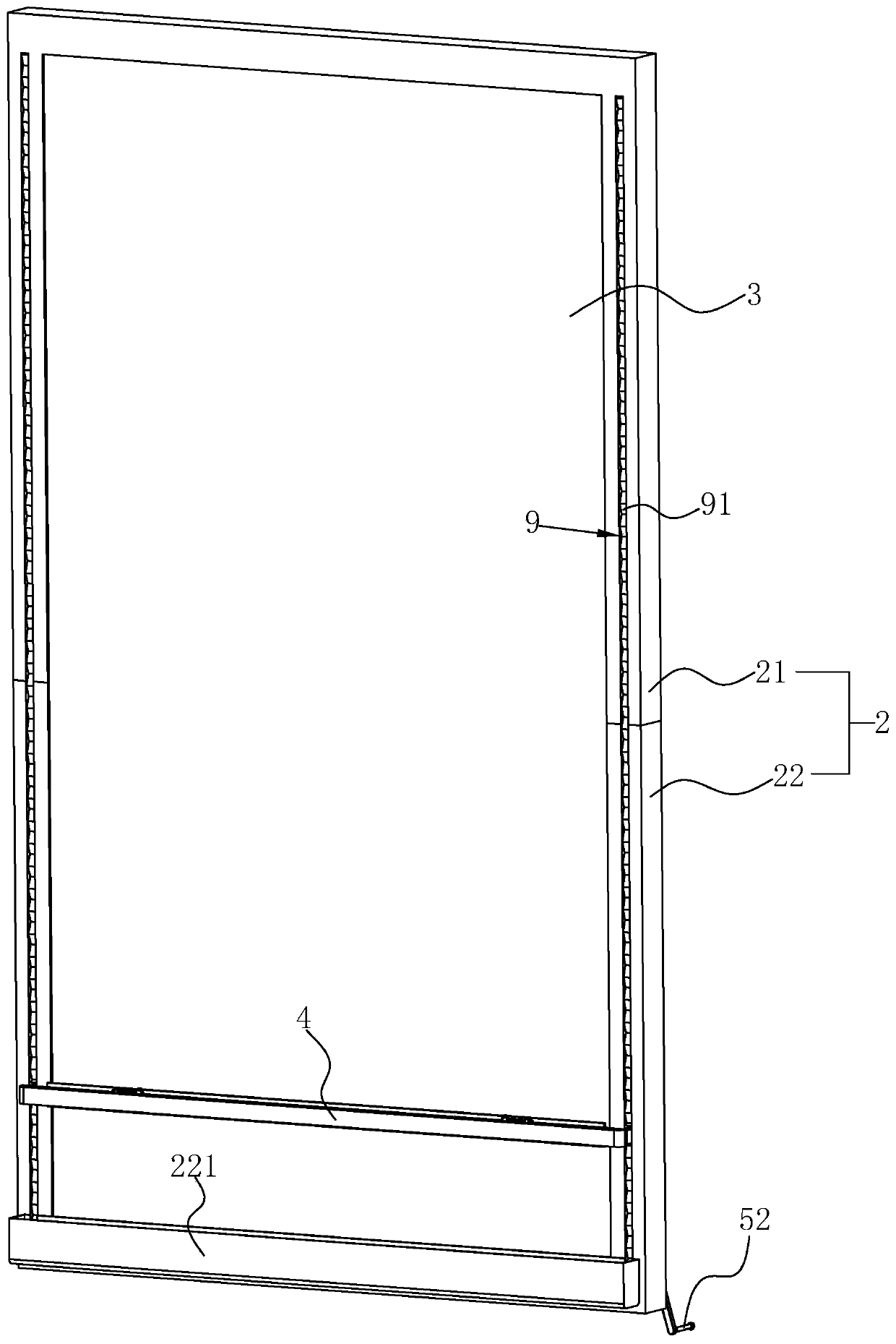

Shot blasting strengthening device and shot blasting strengthening method for engine blades

ActiveCN103522201AClean up completelyExtend your lifeImpeller wheelsRotor bladesCircular discImpeller

The invention discloses a blasting strengthening device and a shot blasting strengthening method for engine blades. The strengthening method comprises the following steps: evenly mixing five steel shots, of which the grain sizes are 1mm, 1.2mm, 1.5mm, 1.7mm and 2mm, so as to form a mixed shot material, wherein the five steel shots respectively account for 30%, 13%, 20%, 20% and 17% of the total weight of the mixed shot material; respectively blasting the mixed shot material for 30 seconds, 20 seconds, 30 seconds, 40 seconds and 30 seconds through cylindrical tube blades of an impeller head at speeds of 63.5m / s, 70m / s, 72m / s, 75m / s and 80m / s. The used impeller head is characterized in that the blades is in a shape of a cylindrical tube; arc grooves are formed in the outer surfaces of the blades; the axes of the arc grooves are vertical to that of the blades; a plurality of cylindrical near impeller fixing rods and a plurality of cylindrical far impeller fixing rods are arranged between two discs of an impeller body of the impeller head, and matched with the grooves on the blades; a thin section is arranged at the end of each blade near the impeller; an outer conical surface is arranged at the tip of each thin section; the outer conical surfaces of two adjacent blades are tightly butted together. By adopting the method, the engine blades are cleaned more completely; the strengthening quality is higher; the device is used for achieving the method; the blades have less possibility of being abraded; the blasting strengthening device is simple and reliable to install.

Owner:山东开泰工业科技有限公司

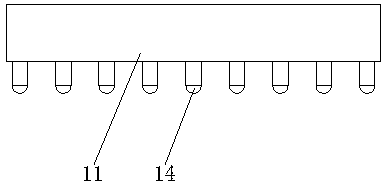

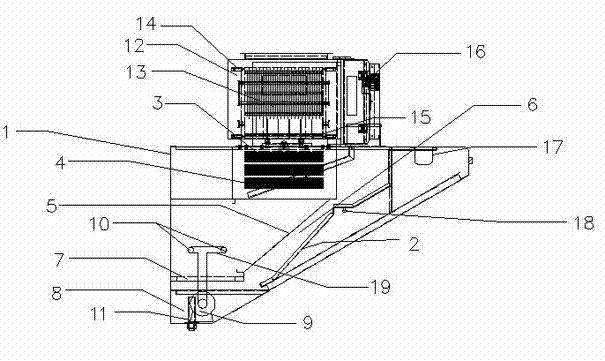

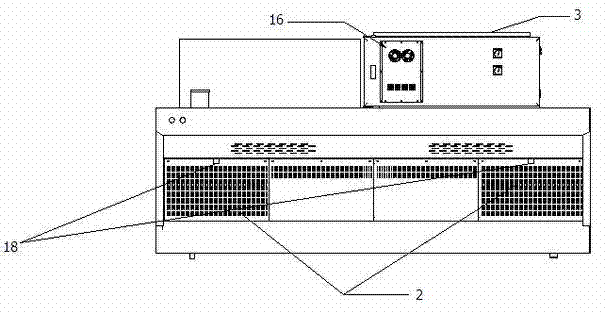

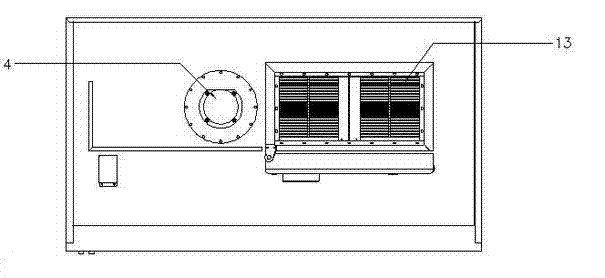

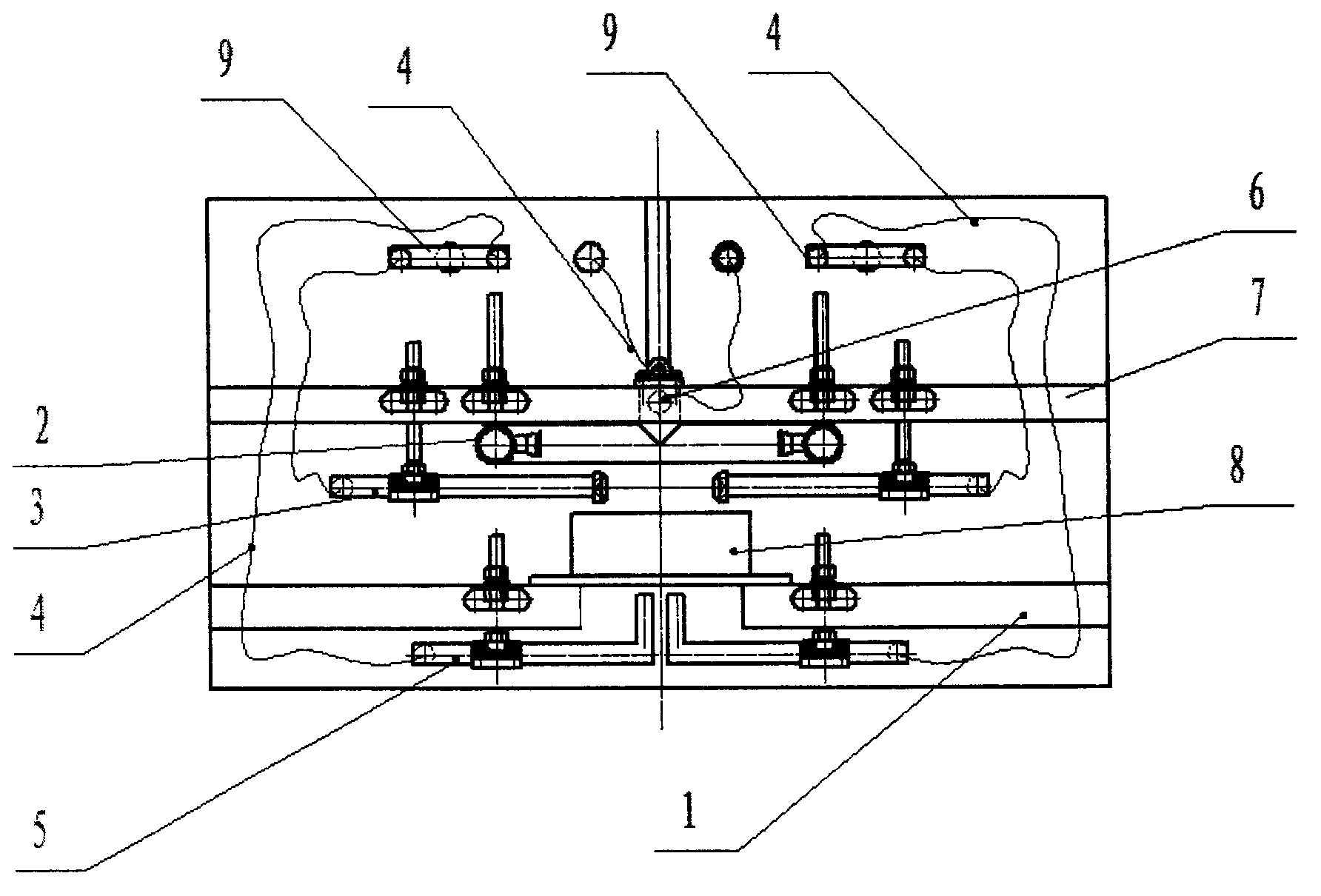

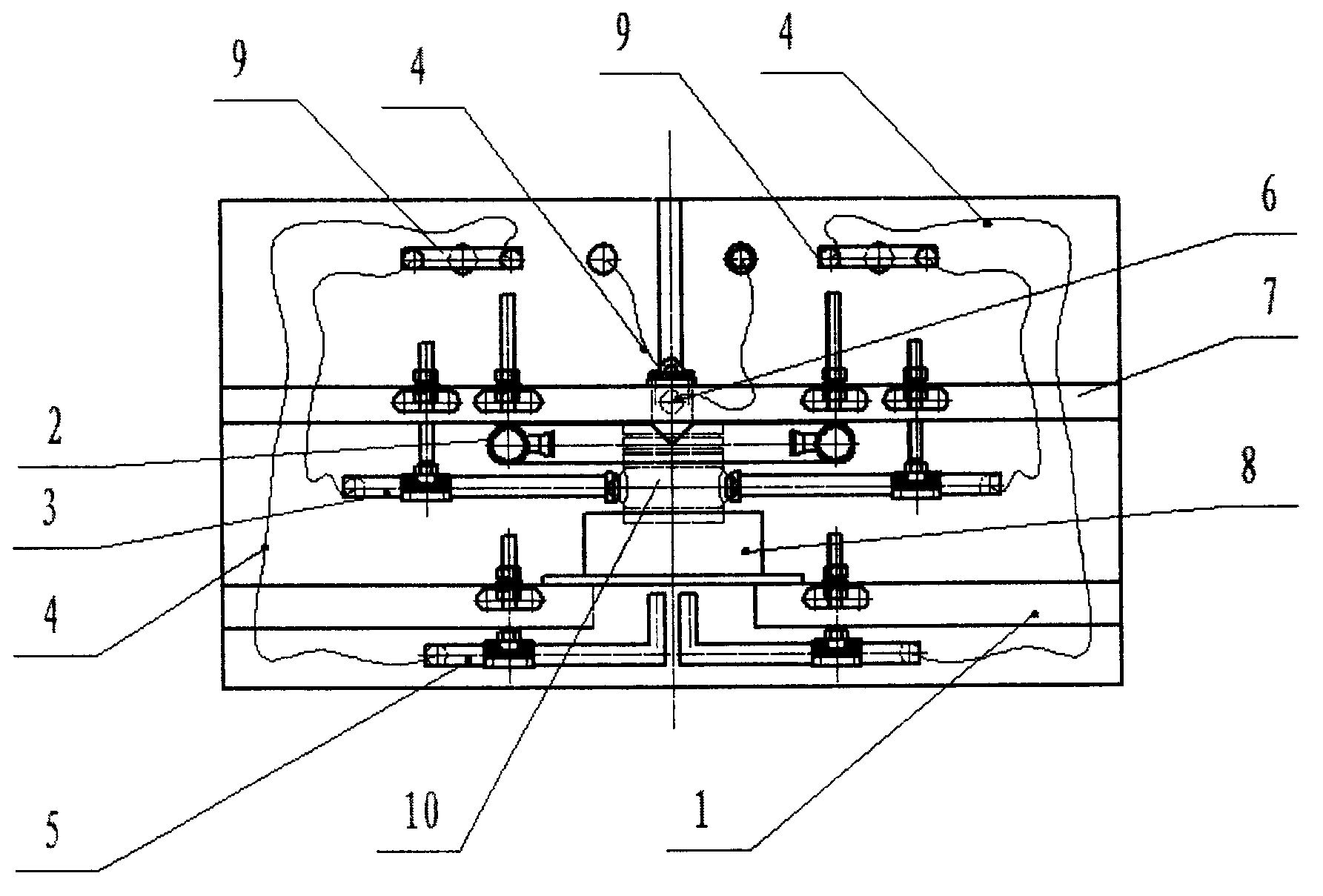

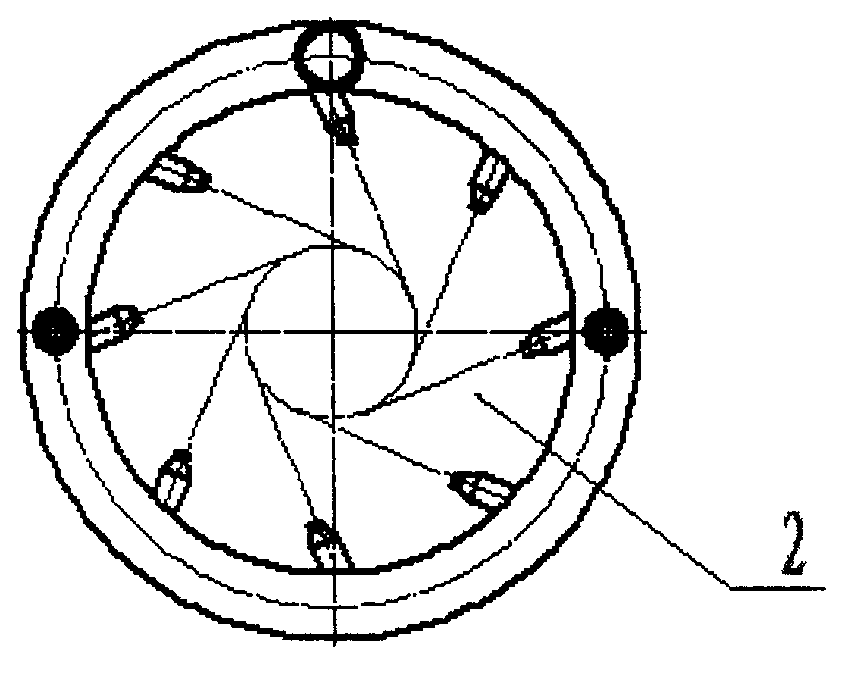

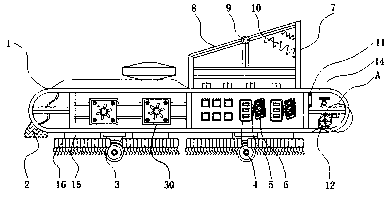

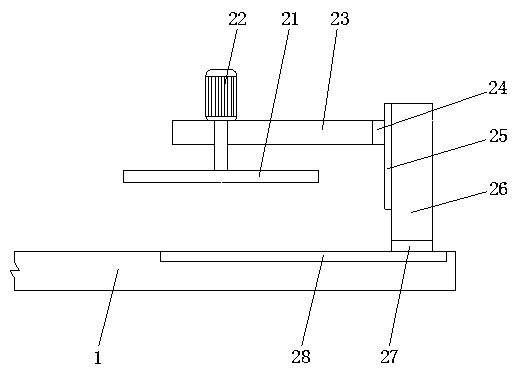

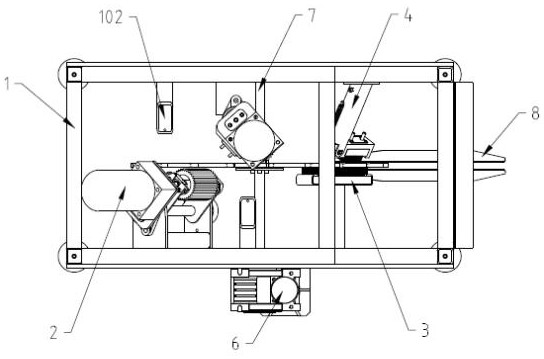

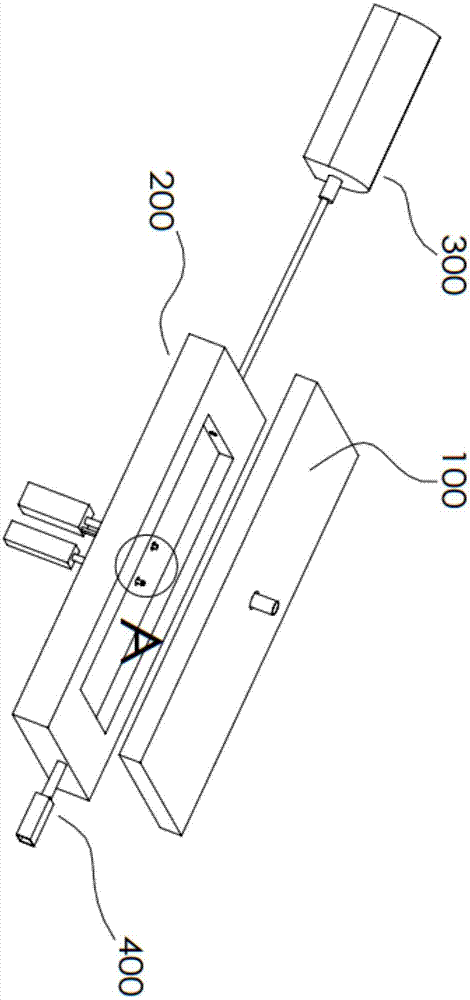

Multi-spray-nozzle air-pressure pulse chip clearing system for piston chip clearing and control method

InactiveCN103008288AEfficient chip removalPrevent blowing dead angleCleaning using gasesSpray nozzleEngineering

The invention discloses a multi-spray-nozzle air-pressure pulse chip clearing system for piston chip clearing and a control method. The system comprises oil hole spray nozzles, pin hole spray nozzles, annular groove spray nozzles and a spark plug hole spray nozzle, wherein the oil hole spray nozzles are installed on a rack A and the direction of the air outlet ends of the oil hole spray nozzles is in parallel with the axis direction of a piston supporting seat; the pin hole spray nozzles are installed on a rack B and the direction of the air outlet ends of the pin hole spray nozzles is perpendicular to the axis direction of the piston supporting seat; the annular groove spray nozzles are installed on the rack B and the direction of the air outlet ends of the annular groove spray nozzles is perpendicular to the axis direction of the piston supporting seat; and the spark plug hole spray nozzle is installed on the rack B and the direction of the air outlet end of the spark plug hole spray nozzle is in parallel with the axis direction of the piston supporting seat. The control method comprises six process steps in the actual working process. The multi-spray-nozzle air-pressure pulse chip clearing system for piston chip clearing and the control method aim at clearing chips produced during piston machining and preventing cross pollution of the chips on different machining surfaces during chip clearing process.

Owner:湖南省三联环保科技有限公司

Snow removal device for electrical equipment

ActiveCN108539597AGuarantee job stabilityAvoid damageSubstation/switching arrangement casingsCleaning using toolsSurface layerProtection mechanism

The invention discloses a snow removal device for electrical equipment, and belongs to the field of electrical equipment maintenance devices. The snow removal device comprises a supporting lifting mechanism, a limiting protection mechanism, a moving mechanism and an ice and snow removal mechanism, wherein the limiting protection mechanism comprises a limiting rod and a rotary cutting disc; the rotary cutting disc can be driven to rotate and horizontally move; the ice and snow removal mechanism mainly comprises a spacing roller, a dislocation roller and a scraper roller; an ice shaving knives are distributed on the spacing roller and the dislocation roller; an ice scraping knife is arranged on the scraper roller; the distance between the bottom of each roller and the rotary cutting disc isequal to that between the bottom of a limiting sleeve and the top of a limiting rod; the rollers and the limiting sleeve move synchronously; collecting holes penetrating through corresponding knife bodies and communicated with corresponding rollers are formed in the ice shaving knives and the ice scraping knife; and a suction ventilator communicated with a corresponding roller is mounted at one end of each roller. The snow removal device is accurate in mechanism travel control, can prevent the surface layer of the electrical equipment from being damaged, is high in ice and snow removal efficiency and good in effect, and can further prevent snow water from permeating the electrical equipment after ice and water are molten.

Owner:李慧

Sewage treatment device for rapid cleaning

InactiveCN107434317AReduce water momentumImprove work efficiencyTreatment involving filtrationMultistage water/sewage treatmentSewage treatmentSewage

The invention discloses a quick-cleaning sewage treatment device, which comprises a sewage treatment body. The shells on both sides of the sewage treatment body are respectively connected with water inlets and water outlets. The interior of the sewage treatment body is equally spaced Open the sedimentation bin, filter bin, reaction bin and clean water bin. The inside of the sedimentation bin is welded with an equalizing plate at the junction of the water inlet. The inside of the sedimentation bin is welded with a sedimentation sloping plate. The bottom of the sedimentation bin is fixed with a sludge suction pump. , and the sludge suction pump communicates with the outside of the sewage processor body shell through the sewage pipe, three filter membranes are welded equidistantly inside the filter chamber, and a material injection port is welded on the top of the reaction chamber. In the present invention, first of all, by providing a uniform flow plate, the impulse force of the water flow can be reduced, and at the same time, a settling sloping plate is provided to keep the water body stable and accelerate the settling, thereby significantly improving the working efficiency of the settling bin and making the settling effect better .

Owner:CHENGDU KECHUANGCHENG TECH

File monitoring method and device, electronic device and storage medium

PendingCN112269762AClean up completelySafe cleanupHardware monitoringFile/folder operationsUser identifierEngineering

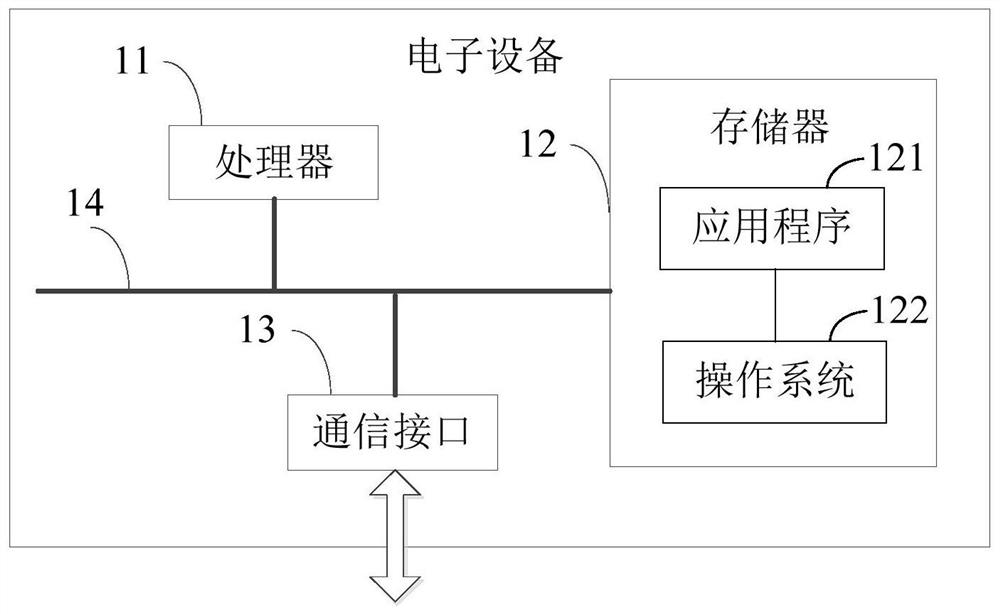

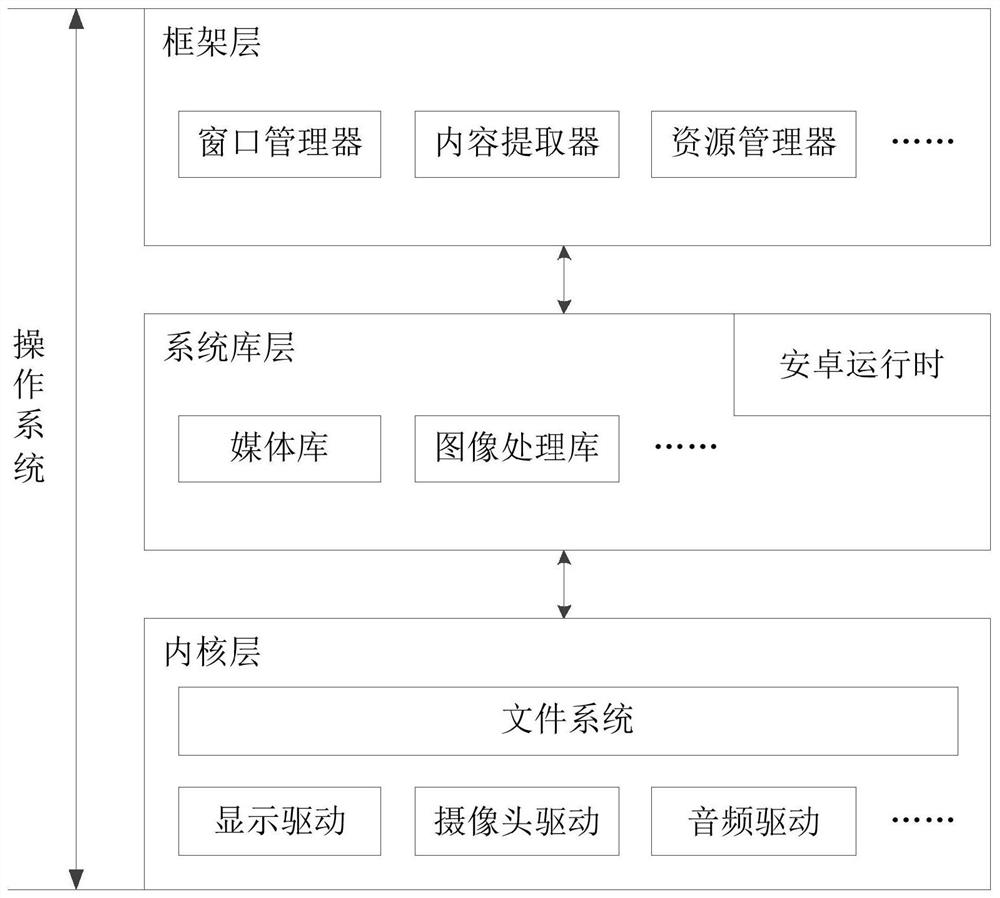

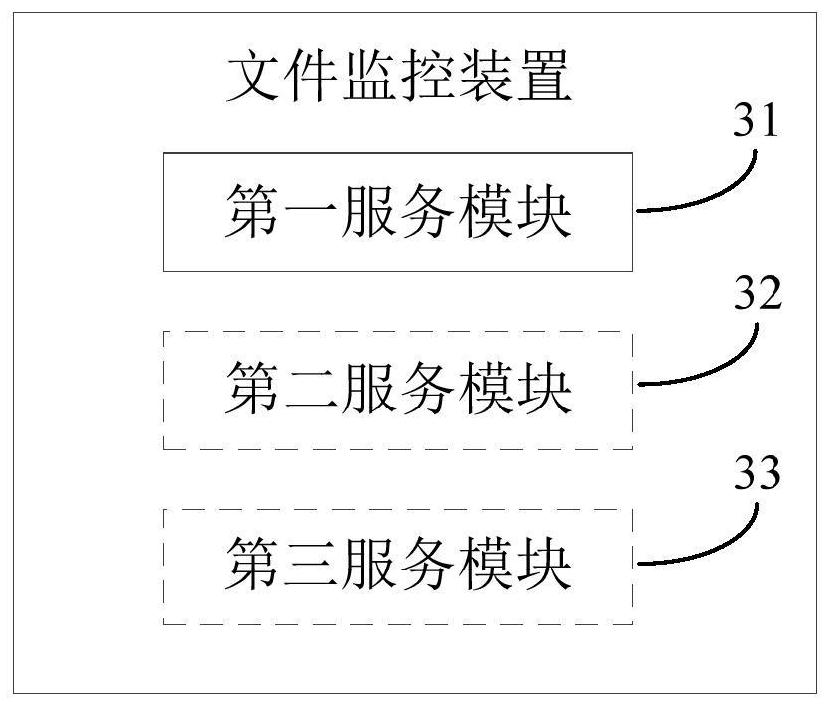

The embodiment of the invention relates to the technical field of computers, in particular to a file monitoring method and device, an electronic device and a storage medium. In the embodiment of the invention, the method comprises the steps of configuring a first service in advance, and registering a notification event in a file system in advance so as to monitor a plurality of behavior interfacesof the file system based on the first service; after the behavior is monitored by the first service, analyzing a user identifier, a process identifier and the path information corresponding to the behavior based on the first service; generating the content information of the notification event based on the first service, wherein the content information comprises the behavior information, the useridentifier, the process identifier and the path information; and reporting the notification event carrying the content information based on the first service so as to execute an unloading or cleaningoperation subsequently based on the content information carried in the reported notification event, thereby realizing the complete and safe cleaning.

Owner:MEIZU TECH CO LTD

Mechatronics numerical control polishing machine tool

InactiveCN111015491ARelieves Stress on Telescoping RodsGuaranteed normal useGrinding carriagesPolishing machinesPolishingEngineering

The invention relates to a mechatronics numerical control polishing machine tool in the technical field of polishing machines. The mechatronics numerical control polishing machine tool comprises a bottom plate and a workbench. A first rotating motor and a second rotating motor are arranged on the bottom plate; the first rotating motor is provided with a support cylinder; the support cylinder has afirst electric push rod; the first electric push rod has an arc-shaped block; a straight plate, a controller and a dust collector are arranged on the workbench; a limiting sliding groove is formed inthe straight plate; a threaded rod is arranged in the limiting sliding groove; a limiting sliding block is arranged on the threaded rod; the limiting sliding block is provided with a transverse plate; the transverse plate is provided with a second electric push rod; the second electric push rod is provided with a mounting plate; the mounting plate is provided with a polishing motor; the polishingmotor is provided with a dust collection cover; the dust collection cover is provided with a sliding pipe; the sliding pipe is provided with a sleeve; the sleeve is provided with a hose; and the hoseis connected with a dust collector. The mechatronics numerical control polishing machine tool is convenient to adjust so as to polish cylindrical workpieces with different diameters.

Owner:彭青珍

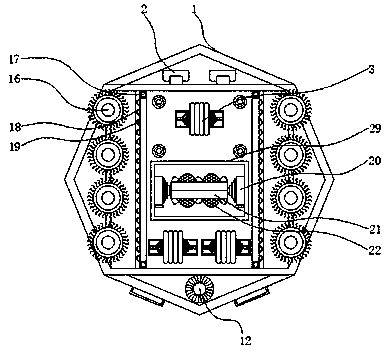

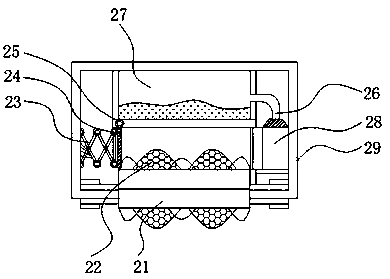

Artificial intelligence domestic floor sweeping robot

PendingCN109480703APlay a protective effectAvoid fragile phenomenaAutomatic obstacle detectionTravelling automatic controlContact failureEngineering

The invention relates to an artificial intelligence domestic floor sweeping robot. The robot comprises a main robot body, a dustbin, a fan, an ash sticking plate and a hydraulic rod, a collision avoidance sensor is installed below the left side of the main robot body, the main robot body is fastened with the collision avoidance sensor through nuts, universal wheels are installed below the main robot body and movably connected with the main robot body, a charging interface is formed in the side face of the main robot body, and a rubber strip is connected to the right side of the charging interface. The artificial intelligence domestic floor sweeping robot has the advantages that a rubber plug is arranged, in the process of using the sweeping robot, the rubber plug can protect the charging interface to a certain degree, and the occurrence of the phenomenon that a charging structure is easily damaged after being collided is avoided; meanwhile, the charging interface exposed outside achieves a certain effect of shielding ash, and thus the situation when the robot runs, the ash easily enters the inner wall of the interface, and poor contact on the interface is easily caused is avoided.

Owner:杜都

Electronic component pin lead cutting device

InactiveCN110253071AClean up completelyFree height adjustmentShearing machinesFeeding apparatusEngineeringPortal frame

The invention discloses an electronic component pin lead cutting device which comprises a worktable face. A portal frame is fixed to the left end of the worktable face. First electric telescopic rods and second electric telescopic rods are fixed to the bottom of a cross beam of the portal frame. A limiting plate is fixed to the bottoms of the first electric telescopic rods, and lead through holes are formed in the limiting plate. A bottom plate is fixed to the bottoms of the second electric telescopic rods. The bottom plate is provided with electronic component containing through holes matched with the lead through holes. By means of the electronic component pin lead cutting device, due to the fact that a scraping plate, screw rod sleeves, screw rods, first bearing seats, first bevel gears, second bevel gears, a rotating shaft, a first motor, a second bearing seat, a draught fan, an air cover and a waste chip through hole are arranged, the problems that a traditional electronic component pin lead cutting device cannot be used for removing lead waste chips in time, consequently pin leads which are cut off fall into the electronic component containing through holes, placement of electronic components is not flat, and the cutting precision is affected are solved.

Owner:马鞍山秉信光电科技有限公司

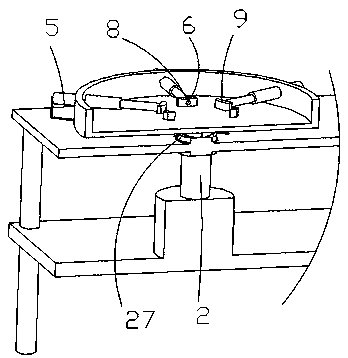

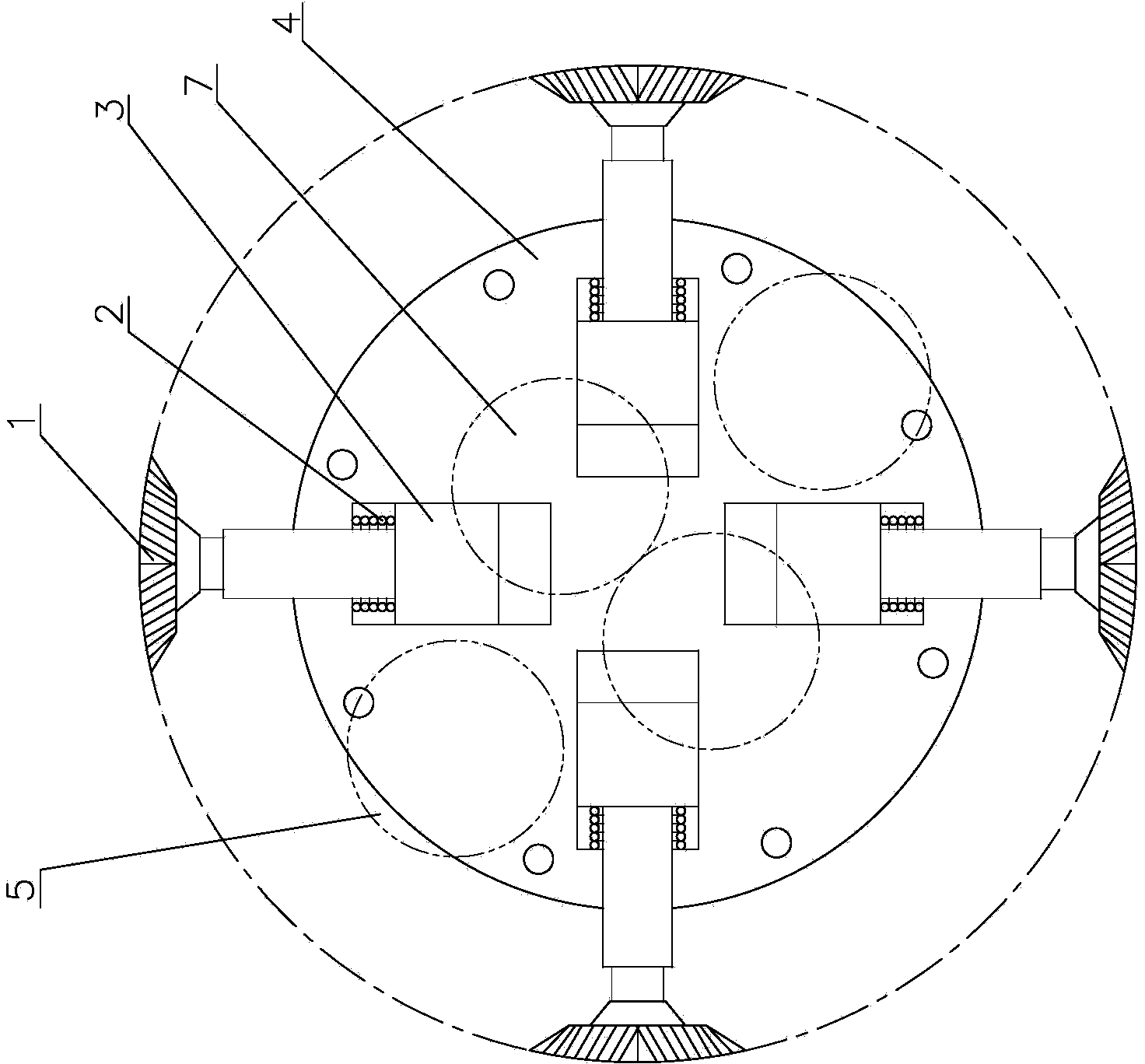

Positioning welding device for high-end equipment manufacturing

InactiveCN113523559AEasy to useShorten the timeWelding/cutting auxillary devicesAuxillary welding devicesElectric machineryWorkbench

The invention discloses a positioning welding device for high-end equipment manufacturing, and relates to the technical field of high-end equipment manufacturing. The positioning welding device for high-end equipment manufacturing comprises a workbench, wherein a round opening is formed in the center of the top of the workbench and penetrates to the bottom of the workbench; a motor is fixedly installed at the position, close to the front face, of the right side of the workbench; a movable groove is formed in the inner side of the workbench; a welding device is arranged at the right end of the top of the workbench; an air blowing device is arranged in the center of the inner side of the workbench; and the welding device comprises a rotating ring, a fixing column, a movable block, a welding piece and a fixing piece. According to the positioning welding device for high-end equipment manufacturing, through arranging the welding device and the air blowing device, a tubular machined workpiece is completely welded, and burnt metal oxide is blown away from the surface of the workpiece in the welding process, so that the time for manually adjusting the workpiece and cleaning the surface of the workpiece is saved, and the positioning welding device is more convenient to use.

Owner:王清富

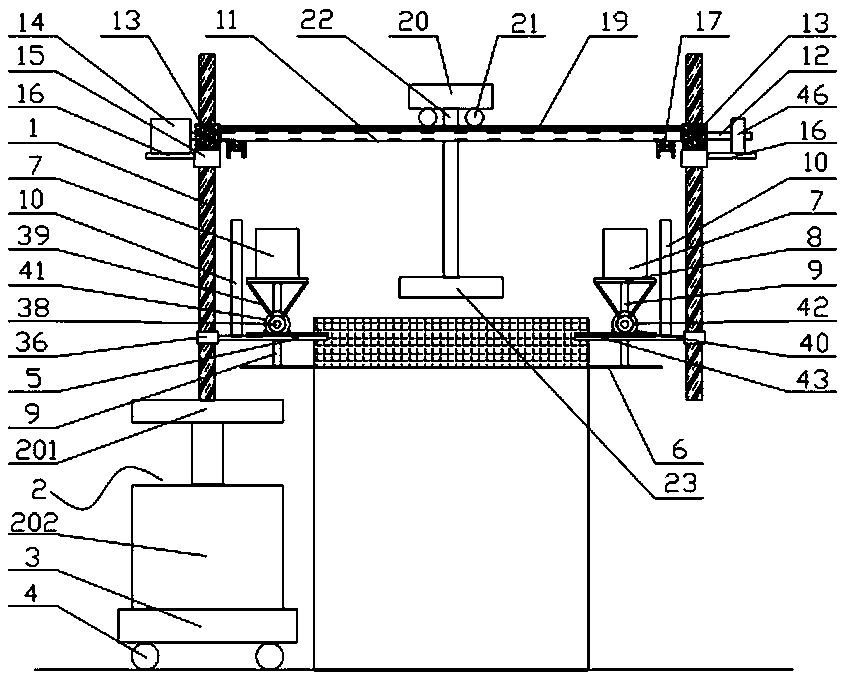

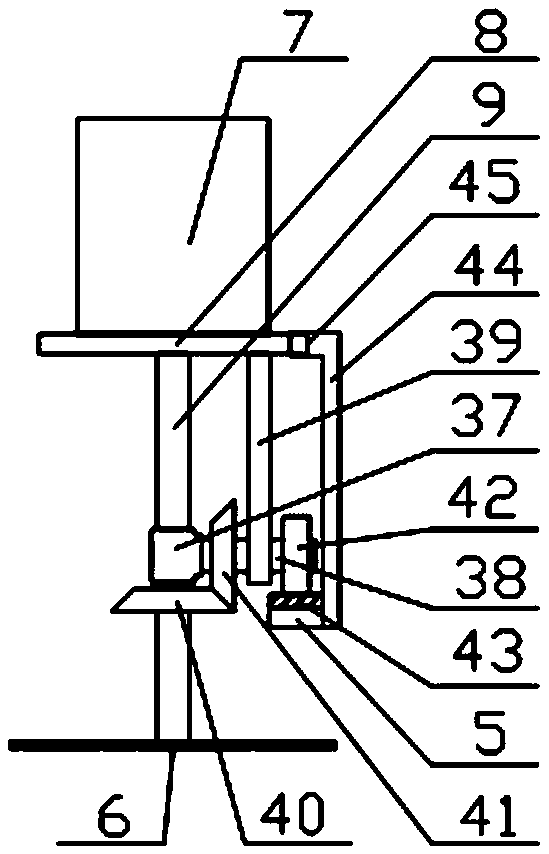

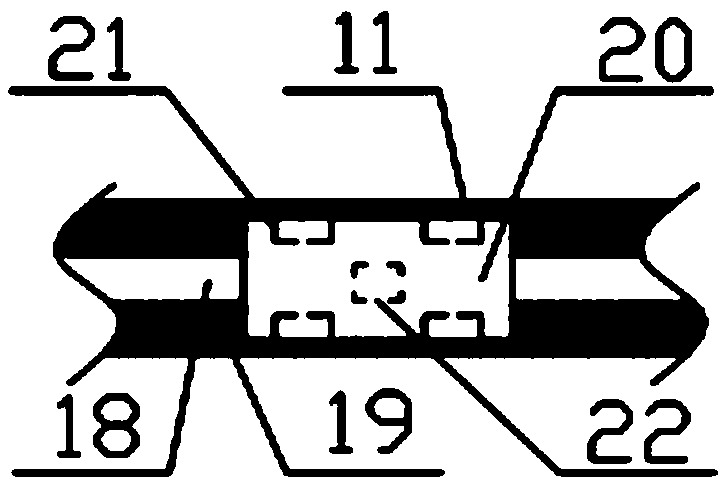

Aluminum alloy template cleaning equipment

ActiveCN109779254AHigh speed cleaningEfficient and fast impactForm treatmentHigh pressure waterEngineering

The invention relates to the technical field of aluminum alloy templates, and discloses aluminum alloy formwork cleaning equipment, comprising an operation table, walking mechanisms, a transmission mechanism, a cross beam plate, a cleaning mechanism, a recycling mechanism, a base and a handle, two sides of the top of the operation table are connected with the bottoms of two walking mechanisms respectively, the two walking mechanisms are in transmission connection through the transmission mechanism, and the bottom of the transmission mechanism is connected with the back face of the top of the operation table. According to the invention, a high-pressure water pump and a high-pressure nozzle are combined, high-speed rotary jet flow can be generated through a plane cleaner, concrete on the aluminum alloy template is impacted efficiently and quickly, and the aluminum template can be quickly cleaned through one working procedure in cooperation with the recycling mechanism, it is guaranteed that concrete and other attached sundries on the surface of the aluminum template can be completely cleaned, and therefore the purposes that the cleaning cost is low, the speed is high, the cleaning rate is high, cleaned objects are not damaged, the application range is wide, and the environment is not polluted are achieved.

Owner:南京淼洁高压清洗设备科技有限公司

Waste shell environment-friendly treating device in nut production

InactiveCN107940467AImprove work efficiencyExpand the scope of workIncinerator apparatusEnvironmental resistanceManual handling

The invention discloses an environmental protection treatment device for discarded shells in nut production, which includes a main body, a pressing knife, a telescopic rod, a turning machine, a perspective window, a handle and a second pull plate. The top of the main body is equipped with a first sliding column. The telescopic rod is installed in the middle of the pressing knife, and the bottom of the telescopic rod is connected with a rotating knife, the rotating machine is connected with the main body through a screen, and the lower part of the rotating machine is equipped with a burner, and the outside of the burning machine is connected with a connecting column , and the lower part of the connecting column is provided with a garbage area, the see-through window is installed on the outside of the telescopic rod, and the lower part of the see-through window is provided with a first pull plate, the handle is connected to the outside of the first pull plate, and the first pull The surface of the board is provided with a first switch and a second switch. The use of the waste husk environmental protection treatment device in the production of nuts, the main body, the pressing knife and the burner enables the device to effectively treat the husk, avoid manual treatment, increase work efficiency, and reduce pollution at the same time.

Owner:林少明

Drum brushing device for steel drum renovation

InactiveCN103480617AImprove cleaning effectExtended service lifeHollow article cleaningBrush deviceEngineering

The invention discloses a drum brushing device for steel drum renovation. The drum brushing device is capable of polishing the inner wall of a steel drum evenly and good in cleaning effect. The drum brushing device comprises a connecting plate and a plurality of drum wall polishing brushes. Each drum wall polishing brush comprises a drum wall brush rod and a drum wall brush head which are fixedly connected. The connecting plate includes a front connecting plate and a rear connecting plate which are detachably connected. Cavities respectively corresponding to the drum wall polishing brushes are formed in the connecting plate. Through holes communicated with the cavities and respectively corresponding to the drum wall polishing brushes are formed along the periphery of the connecting plate. A slider is mounted in each cavity, and each drum wall brush rod penetrates the corresponding through hole to be fixedly connected with the corresponding slider. A wall drum brush head reset spring is mounted between the outer side of each slider and the inner wall of the corresponding cavity. By the reset springs, the drum wall brush head can adapt to the uneven inner wall of a drum body, polishing miss is avoided, and cleaning effect is increased.

Owner:TIANJIN LYUBOTE ENVIRONMENTAL PROTECTION EQUIP MFG

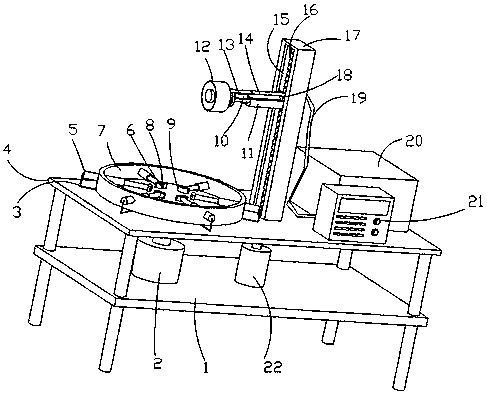

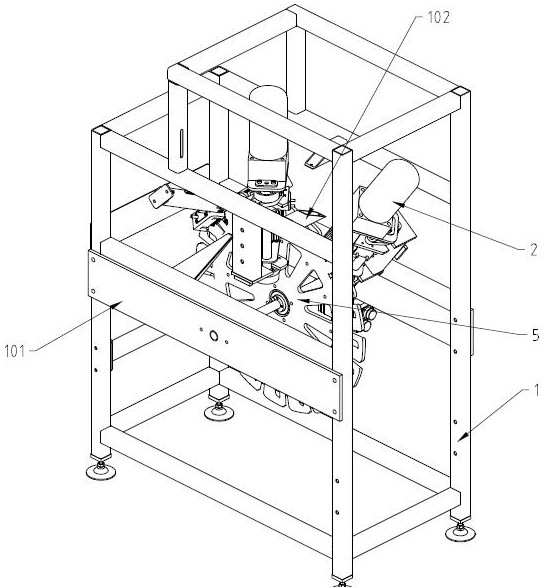

Automatic grinding and scraping machine for yellow skin of poultry gizzard

ActiveCN111771955AEfficient removalHighly integratedPoultry processingElectric machineryGrinding wheel

An automatic grinding and scraping machine for yellow skin of poultry gizzard, comprises a machine frame, gizzard-grinding assemblies and a friction roller. The friction roller is placed vertically, the outer edge of the friction roller is provided with a plurality of inlets and outlets for poultry gizzard, the middle of the friction roller is provided with a first rotating shaft, both ends of thefirst rotating shaft are assembled on the machine frame, one end of the first rotating shaft is connected with a first motor, at least one gizzard-grinding assembly is arranged on both sides of the fraction roller respectively, the positions of the two sides of the gizzard-grinding assemblies are not coincident, the gizzard-grinding assemblies are connected on the machine frame, the gizzard-grinding assembly comprises gizzard-grinding wheel and a second motor, the gizzard-grinding wheel is driven by the second motor, the rotation direction of the gizzard-grinding wheel is opposite to the rotation direction of the friction roller, and when the friction roller rotates forward, the gizzard-grinding wheel can contact with the yellow skin of poultry gizzard and carry out reverse grinding and scraping. The automatic grinding and scraping machine for yellow skin of poultry gizzard integrates the functions of gizzard-grinding and gizzard-scraping, the yellow skin at the esophageal position ofchicken gizzard or duck gizzard can be effectively removed, the effect of removing yellow skin is better, and the arrangement of personnel for secondary processing is not in need completely.

Owner:JIANGSU DEEPAGRI INTELLIGENT TECH CO LTD

Metal product scrap and cooling liquid separation device

InactiveCN112495584AEfficient use ofImprove filtering effectMagnetic separationMaintainance and safety accessoriesEngineeringCooling fluid

The invention provides a metal product scrap and cooling liquid separation device, which comprises a main body, wherein mounting components and fixing brackets are arranged on the left side and the right side of the main body, grooves are formed in the mounting components, supporting springs are arranged at the bottoms of the inner walls of the grooves, supporting rods are fixedly connected to theupper ends of the supporting springs, and a filter screen is mounted on the opposite side of the supporting rod. According to the invention, a second driving bearing drives a filtering mechanism to rotate while a second adsorption plate is made to generate electric adsorbability, the second adsorption plate is used for adsorbing fine scrap iron in primarily-filtered cooling liquid again to filterthe cooling liquid again, so that the filtering effect of the device on cooling liquid is further improved, and the device achieves the effect of good separation effect; and the filtered cooling liquid enters a circulating pipeline through a filtering baffle, so that the cooling liquid is effectively utilized.

Owner:广州一纪电子商务有限公司

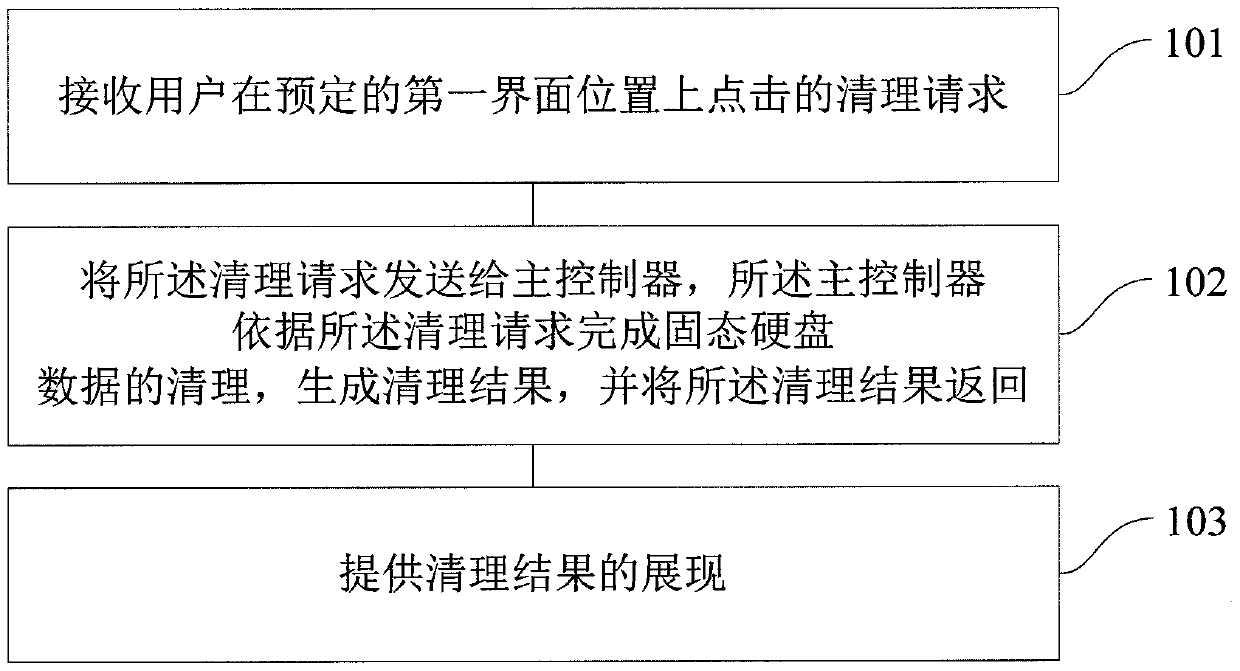

Method and device for cleaning up data of solid state disk based on cloud

InactiveCN107621924ASolve the problem of findingIncreased read and write lifespanInput/output to record carriersSolid-state driveMaster controller

Embodiments of the invention provide a method for cleaning up data of a solid state disk based on a cloud. The method comprises the following steps of receiving a cleaning request which is clicked ona predetermined first interface position by a user; sending the cleaning request to a master controller, wherein the master controller is used for completing cleaning of the data of the solid state disk according to the cleaning request, generating a cleaning result and returning the cleaning result; and showing the cleaning result. According to the method and the device, the cleaning speed can beaccelerated, the accuracy can be improved, the manual operation can be reduced, the elapsed time can be reduced, the read-write life of a storage medium can be prolonged, the cost can be reduced, theoperation during cleaning of the data of the solid state disk can be reduced, and the cleaning efficiency can be improved.

Owner:FUTUREPATH TECH

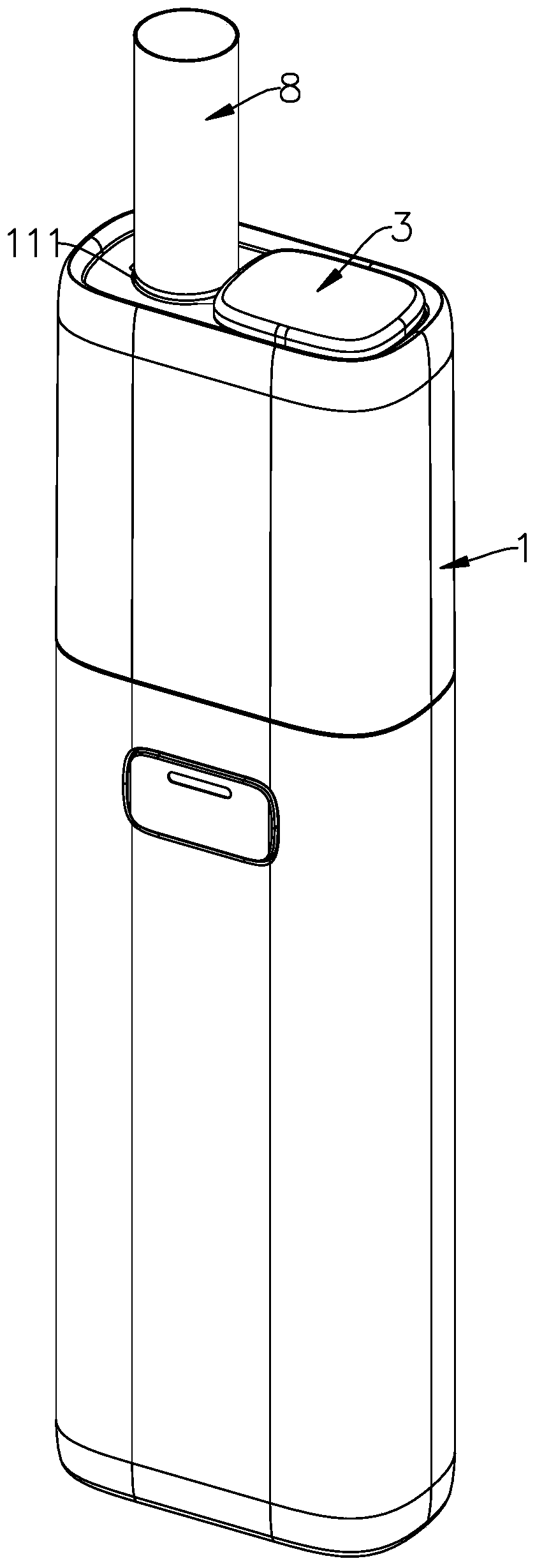

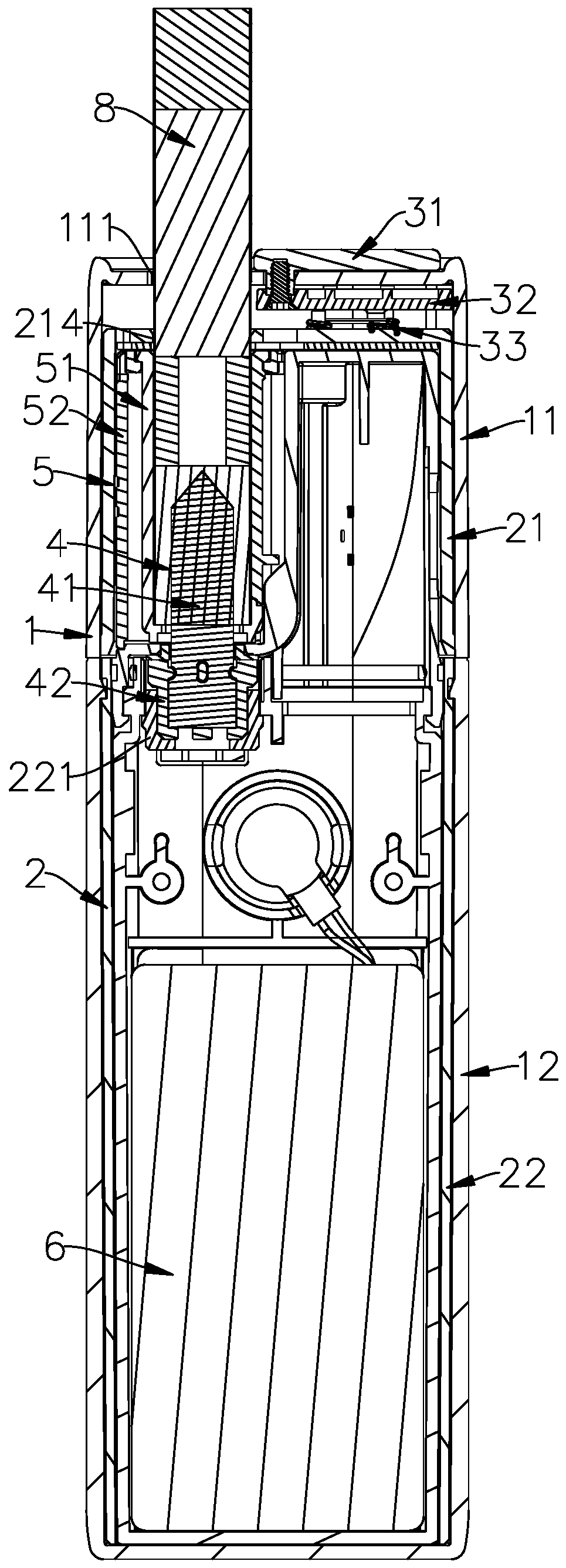

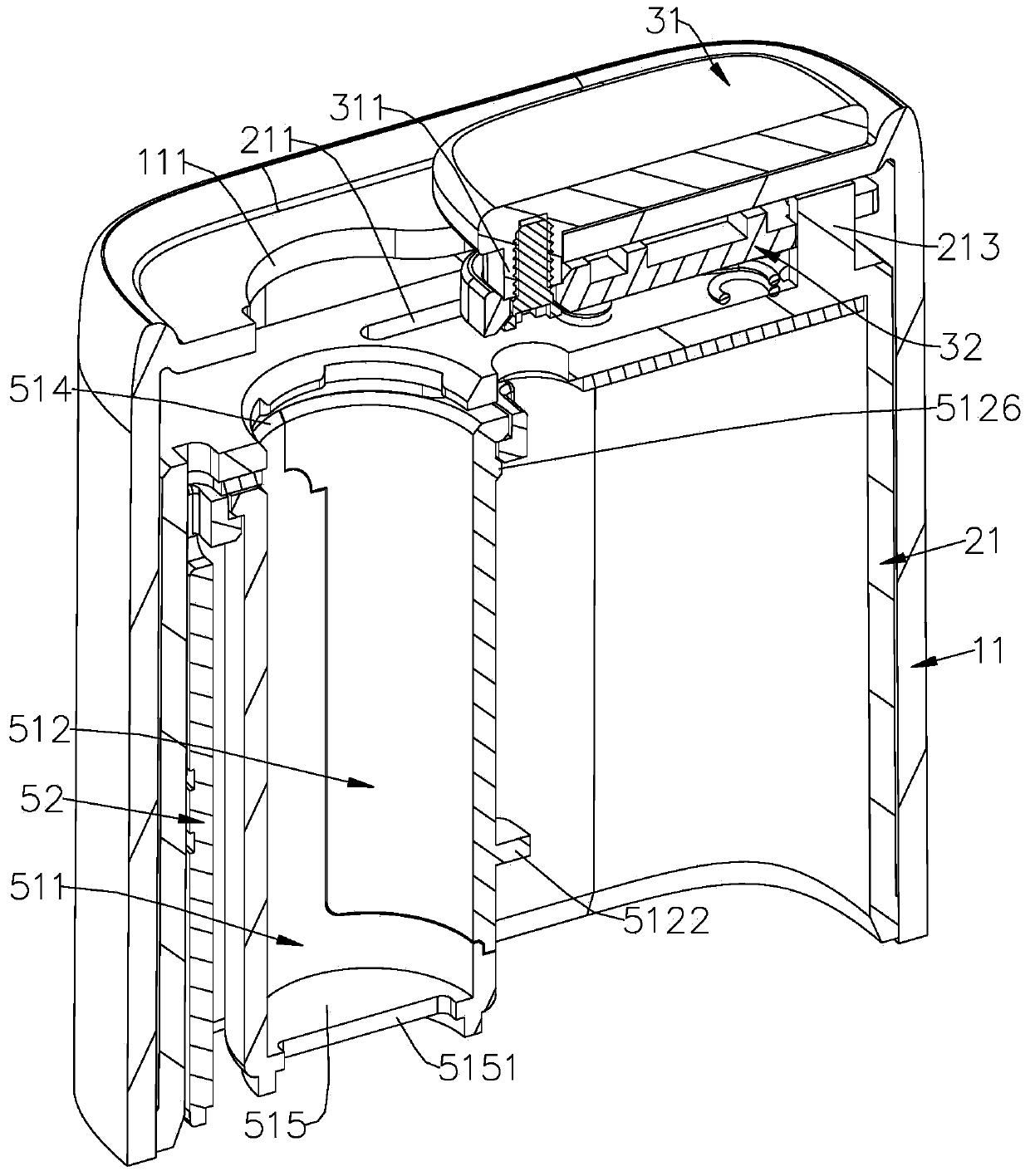

Low-temperature baking smoking set and split type push pipe structure thereof

PendingCN110604342AEasy to cleanConvenience for subsequent useTobacco devicesEngineeringMechanical engineering

The invention relates to a low-temperature baking smoking set and a split type push pipe structure thereof. The split type push pipe structure comprises a push pipe, wherein an accommodating cavity for accommodating a cigarette body is formed in the push pipe; and the push pipe comprises a first part and a second part, wherein the second part can move back and forth relative to the first part between a working position used for accommodating the cigarette body and a cleaning position used for cleaning the push pipe. When the push pipe is in the cleaning position, the inner wall surface of thepush pipe can be conveniently cleaned, the operation space is increased, and the cleaning is more complete.

Owner:SHENZHEN SMOORE TECH LTD

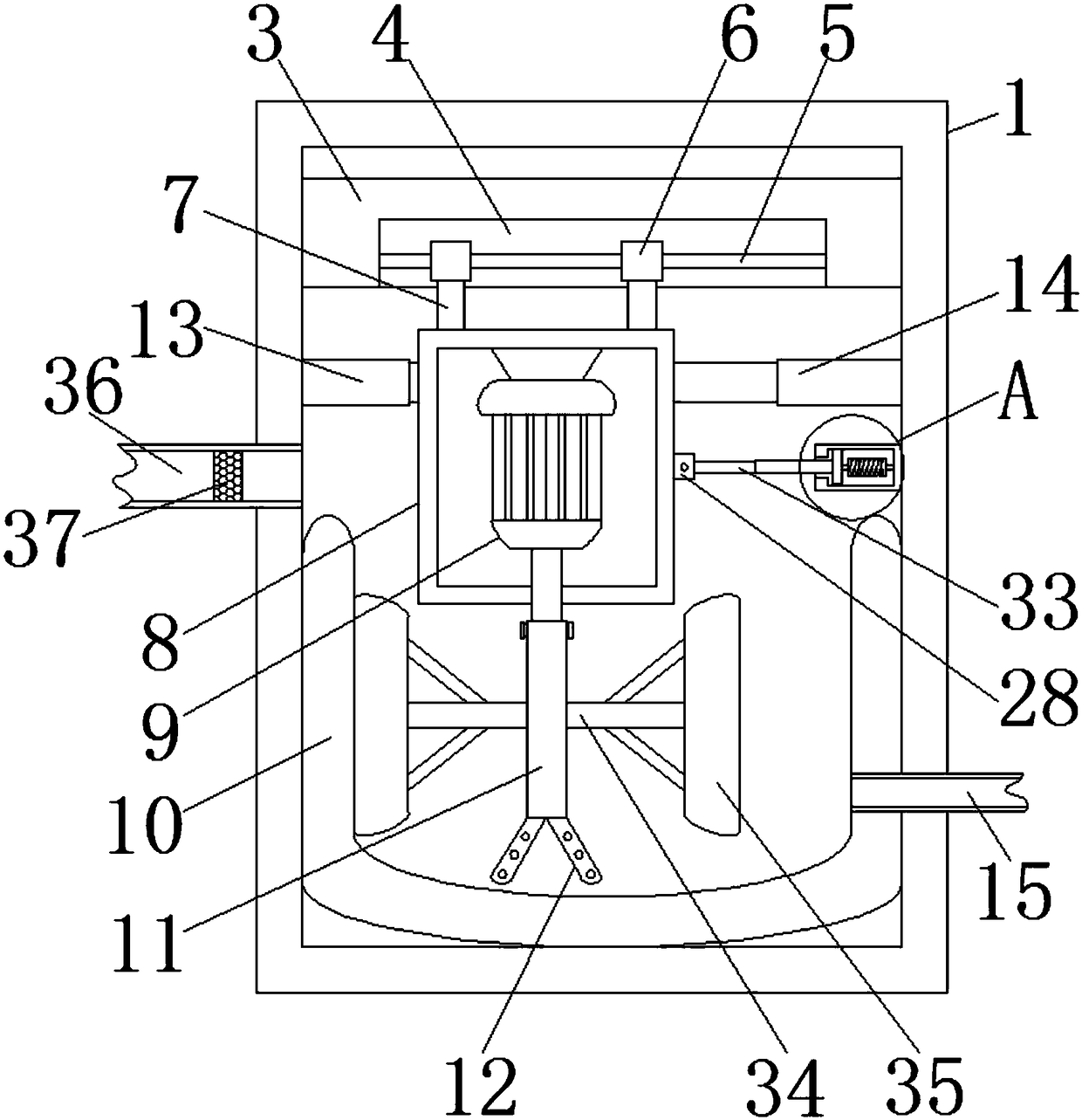

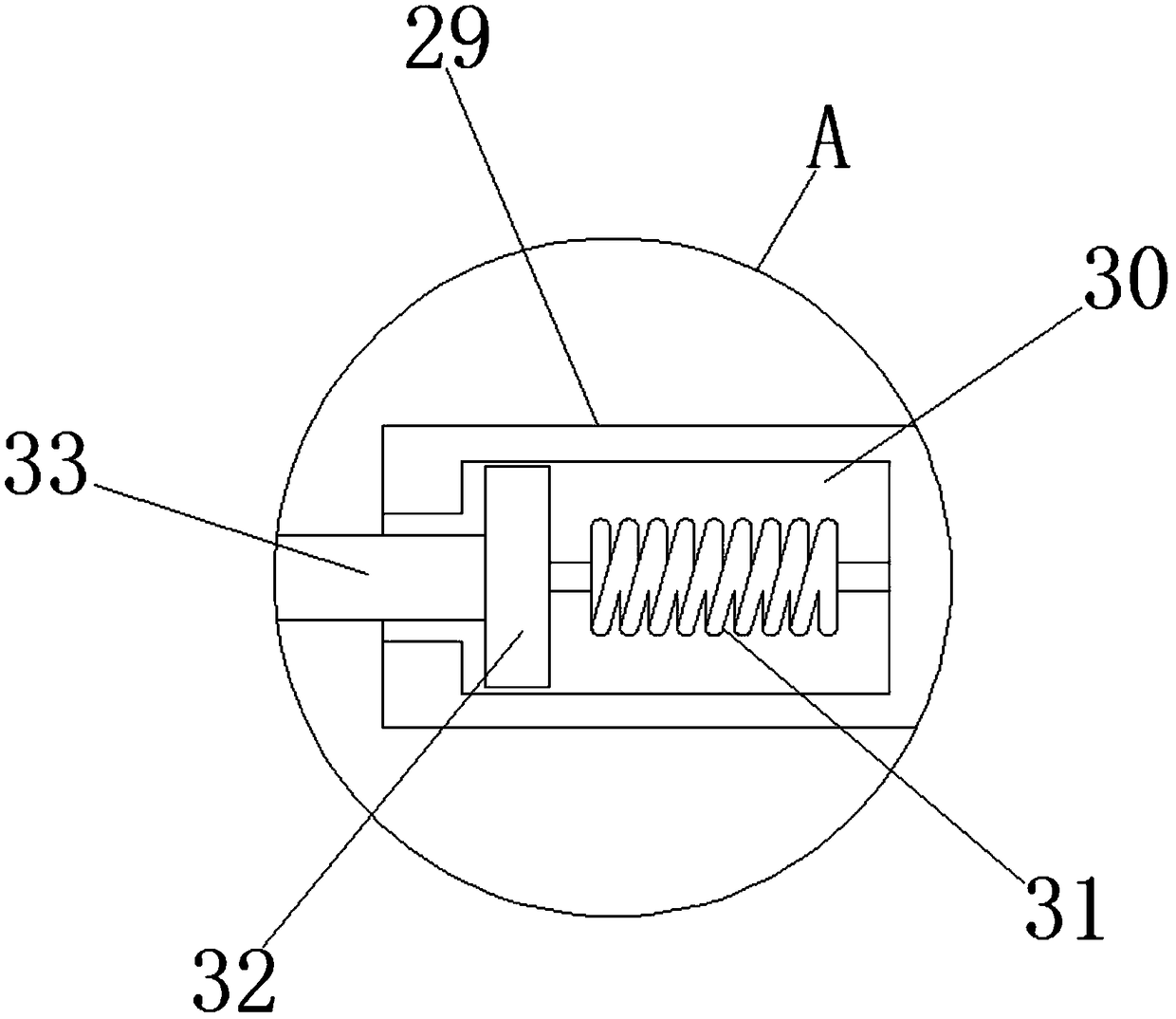

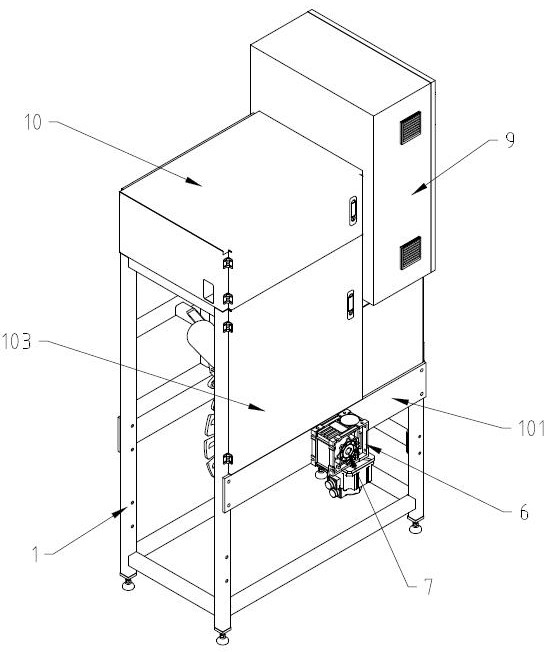

Mute clamp for clutch shell body machining

ActiveCN109262383AImprove mute effectImprove working environmentRevolution surface grinding machinesGrinding drivesWorking environmentEngineering

The invention discloses a mute clamp for clutch shell body machining. The clamp comprises a sound insulation device body, a control box and a machining cavity are arranged in the sound insulation device body, and the machining cavity is formed in the top of the control box; a first clamping workpiece and a second clamping workpiece are arranged in the machining cavity, bearings are arranged at theends, close to the inner wall of the sound insulation device body, of the first clamping workpiece and the second clamping workpiece, and the bottoms of the bearings are connected with an air pumpingpipe; pneumatic cylinders are fixedly arranged at the ends of the bearings and fixedly connected with the inner wall of the sound insulation device body, one end of the air pumping pipe is connectedwith a dust collection mechanism, and the dust collection mechanism is arranged in the control box. Control elements of the whole mute clamp are installed in the control box, therefore noises generated during machining of a clutch shell body are primarily insulated, in addition, the external sound insulation device body insulates noises generated from work of control elements again, and the polishing noise is insulated, the muting effect of the whole mute clamp is good, and the work environment is greatly improved.

Owner:YUEXI SHENGHONG IND & TRADE

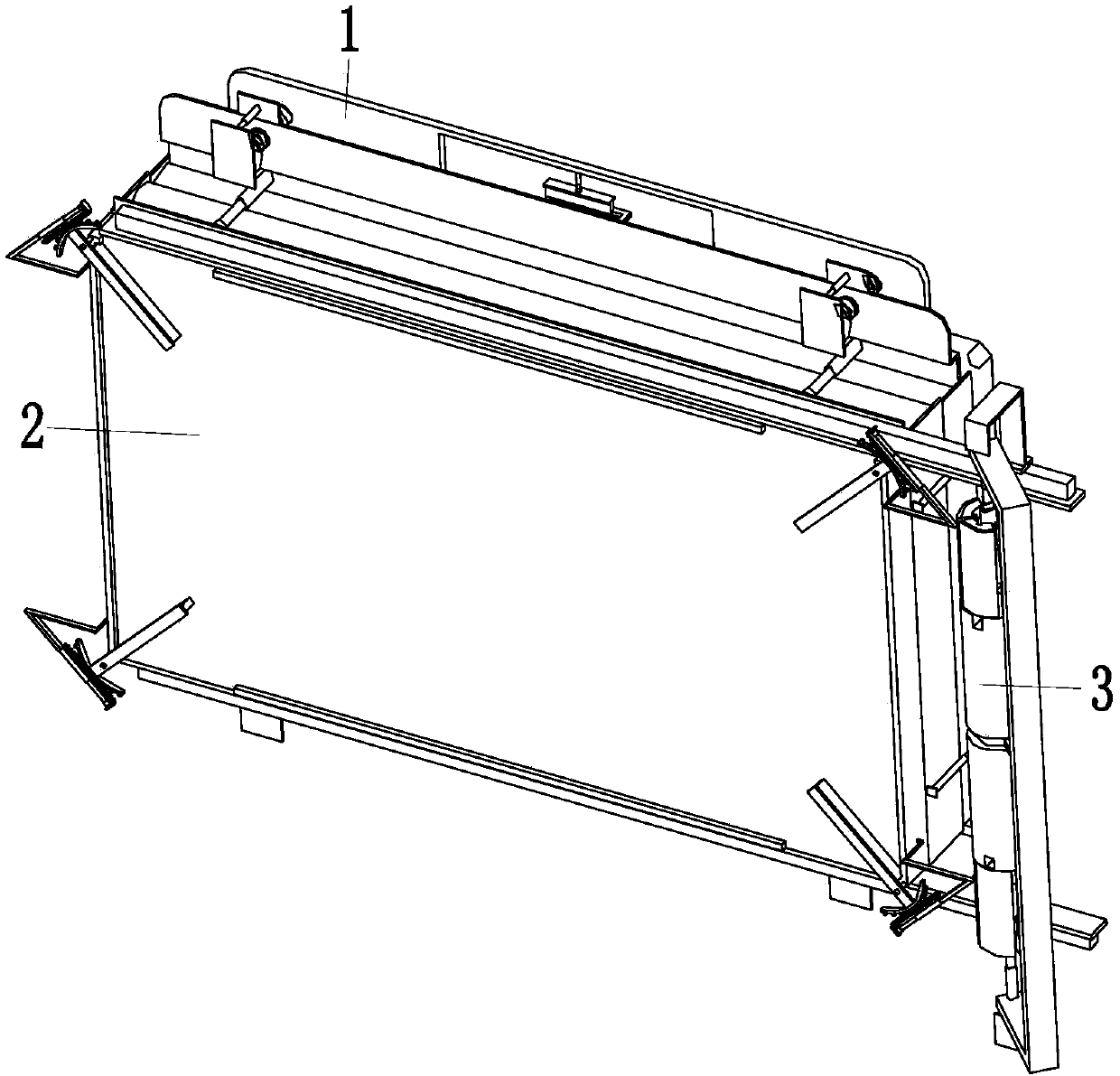

Open aluminum curtain wall structure

The invention relates to an open type aluminum plate curtain wall structure, and relates to the technical field of curtain walls. The open type aluminum plate curtain wall structure comprises a curtain wall stand column, an aluminum alloy frame arranged on the curtain wall stand column and a curtain wall plate in the aluminum alloy frame. The aluminum alloy frame comprises an upper aluminum alloyframe and a lower aluminum alloy frame, a sliding rod is slidably arranged on the outdoor side of the curtain wall plate in the vertical length direction of the aluminum alloy frame and is located onthe aluminum alloy frame, a cleaning piece for cleaning the outdoor side surface of the curtain wall plate is arranged on the sliding rod, and a manual driving piece for driving the sliding rod to slide in the vertical direction of the aluminum alloy frame is arranged on the side wall, near the room, of the curtain wall plate and is located on the aluminum alloy frame. The manual driving piece isstarted, the sliding rod slides in the vertical direction, and the cleaning piece cleans the wall surface, near the outside, of the curtain wall plate. As the outdoor wall of the curtain wall plate can be cleaned indoors during cleaning, the safety factor during cleaning is improved to a certain extent.

Owner:四川华厦建辉门窗幕墙装饰有限公司

Cutting die with automatic waste clearing function

The invention relates to a cutting die with an automatic waste clearing function. The cutting die comprises a male die plate, a female die plate, a gas device and a waste discharge device. The female die plate is positioned below the male die plate, the upper surface of the female die plate is provided with a concave cavity for placement of a to-be-machined workpiece, the concave cavity is provided with a first through hole and at least one second through hole, a first positioning pin is arranged in the first through hole, a second positioning pin is arranged in each second through hole, the lower side of the first positioning pin is connected with a telescopic rod of a first air cylinder, and the lower side of each second positioning pin is connected with a telescopic rod of a second air cylinder. The gas device comprises a first gas valve in horizontal arrangement and at least one second gas valve in vertical arrangement, the first gas valve is fixed to a first side of the female die plate, and gas outlets of the first gas valve and each second gas valve face the concave cavity. The waste discharge device comprises a suction cavity and a waste collection box, and the waste collection box is communicated with the suction cavity. The cutting die has the advantage that small-particle wastes can be cleared thoroughly.

Owner:CHANGSHU MUTUAL TEK CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com