Metal product scrap and cooling liquid separation device

A technology of metal products and separation device, applied in the field of metal products, can solve the problems of affecting separation effect, waste of cooling liquid, inability to separate iron filings, etc., and achieve the effect of good separation effect and improvement of filtration effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing:

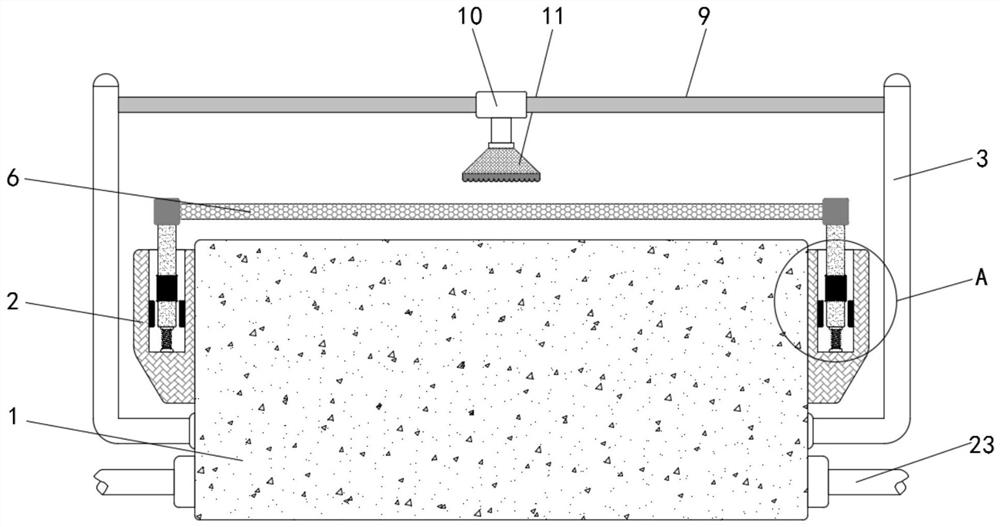

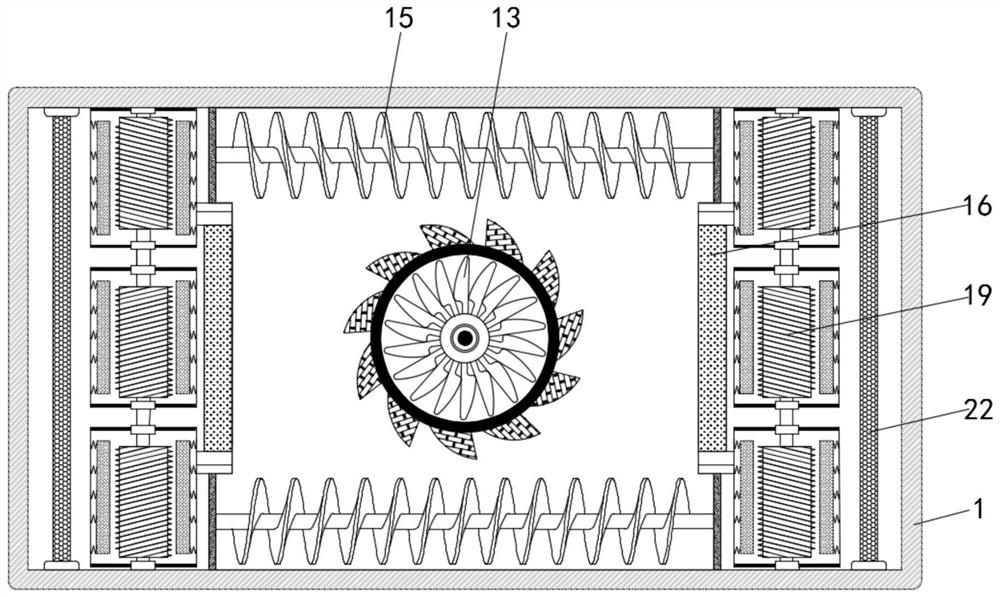

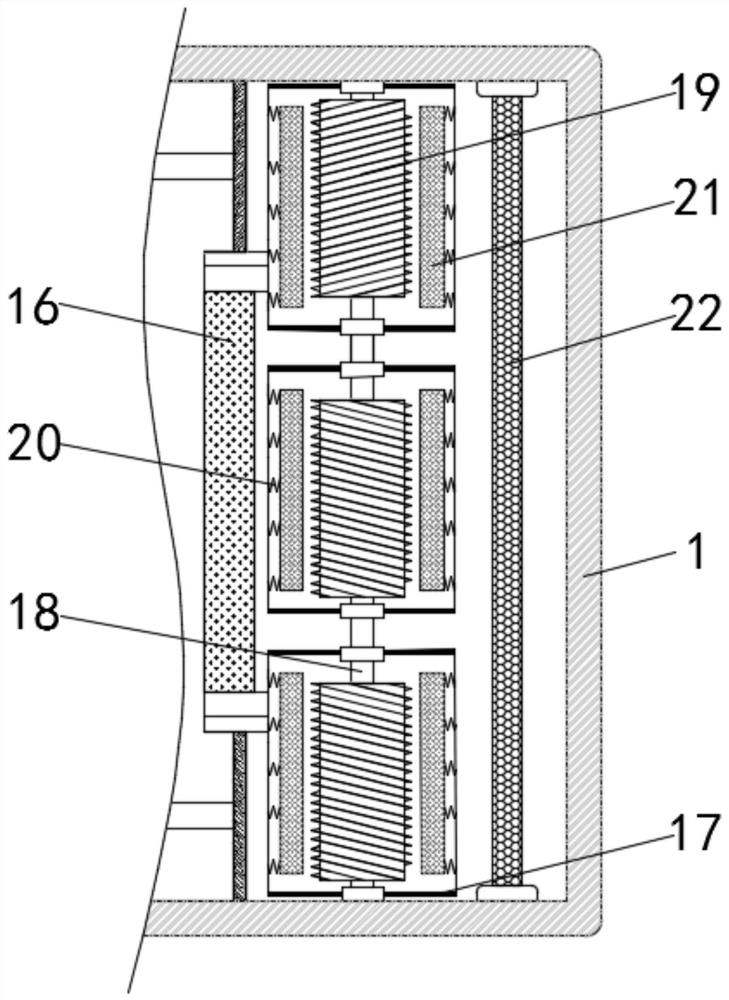

[0025] as attached figure 1 to attach Figure 5 Shown:

[0026] The present invention provides a device for separating waste chips from metal products and cooling liquid, which includes a main body 1, and the left and right sides of the main body 1 are equipped with a mounting part 2 and a fixing bracket 3, and the inside of the mounting part 2 is provided with a groove, and the The bottom of the inner wall of the groove is provided with a support spring 4, the upper end of the support spring 4 is fixedly connected with a support rod 5, the support rod 5 is provided with an induction element 7, and the inner wall of the installation part 2 is provided with an induction coil 8, an induction element 7 It is electrically connected with the induction coil 8, and the induction part 7 is in contact with the induction coil 8 to send out an electrical signal, which drives the cle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com