Mechatronics numerical control polishing machine tool

An electromechanical and machine tool technology applied in the field of polishing machines, which can solve problems such as inability to adjust the device and incomplete dust cleaning, and achieve the effect of reducing the pressure of the telescopic rod and ensuring normal use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

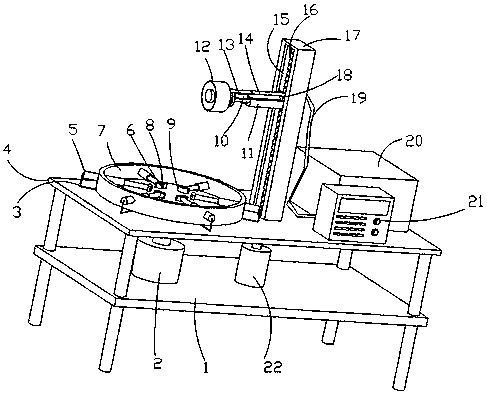

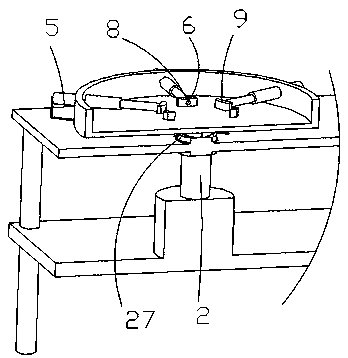

[0033] Such as figure 1 , 2 , 3 and 5, a mechatronic CNC polishing machine tool, including a base plate 1, a first rotating motor 2, a workbench 4, cables 3, a first electric push rod 5, a pressure sensor 8, a second electric push rod 10 , a vacuum cleaner 20, a controller 21, a second rotating motor 22, a polishing motor 25 and a conductive slip ring 27, the controller 21 includes a control host, a display screen and an operation keyboard, the controller 21 is electrically connected to an external power supply, and the controller 21 is respectively It is electrically connected with the first rotating motor 2, the pressure sensor 8, the second electric push rod 10, the vacuum cleaner 20, the second rotating motor 22, the polishing motor 25 and the conductive slip ring 27, and the bottom plate 1 is fixedly connected with the workbench through the support 4. The first rotating motor 2 and the second rotating motor 22 are fixedly installed on the bottom plate 1. The workbench 4 ...

Embodiment 2

[0035] Embodiment 2 is a further improvement on Embodiment 1.

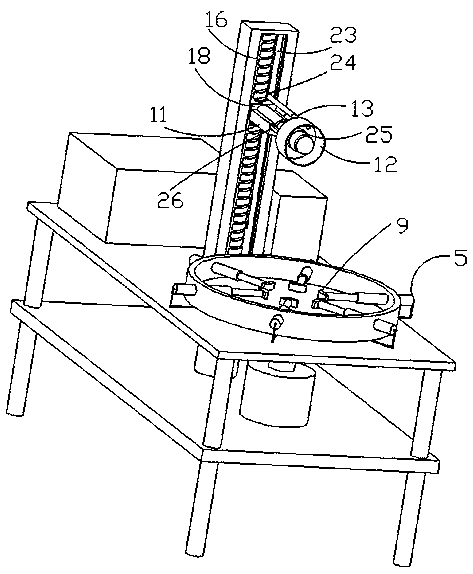

[0036] Such as figure 1 , 2 , a straight plate 17, a controller 21 and a vacuum cleaner 20 are fixedly installed on the workbench 4, a limit chute 15 is provided in the straight plate 17, and a threaded rod 16 fixedly connected with the output end of the second rotating motor 22 is provided in the limit chute 15 , the threaded rod 16 is fixedly connected with a limit slider 18, the side wall of the limit slider 18 is fixedly connected with a horizontal plate 11, and the horizontal plate 11 is fixedly installed with a second electric push rod 10 through a concave groove, and the second electric push rod The telescoping end of 10 is fixedly connected with mounting plate 28, and the side wall of mounting plate 28 is fixedly installed with polishing motor 25, and the output end of polishing motor is fixedly connected with polishing structure, cooperates by designing first electric push rod 5 and arc block 9, convenie...

Embodiment 3

[0038]Embodiment three is a further improvement on embodiment two.

[0039] Such as figure 1 , 2 4. The outer wall of the polishing motor 25 is fixedly connected with a dust collection cover 12, the dust collection cover 12 is fixedly connected with a slide tube 13, the slide tube 13 is fitted and slidably connected with a casing 14, and the limit slider 18 is attached to the limit chute 15 Sliding connection, the limit slider 18 selects dovetail block, T-shaped block or L-shaped block, the top of the limit slider 18 is fixedly connected with the installation ring 24, the sleeve 18 is fixedly installed in the installation ring 24, and the limit chute 15 The rear side wall of the rear side wall is provided with a straight hole 23 for the up and down movement of the sleeve pipe 14, the sleeve pipe 14 is fixedly connected with a hose 19, the hose 19 is fixedly connected with the input end of the vacuum cleaner 20, and the outer side of the polishing motor 25 is fixedly installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com