Recovery method of esters in wastewater

A recovery method and technology for wastewater, applied in chemical instruments and methods, separation/purification of carboxylate, preparation of carboxylate, etc., can solve the problem of residual low-concentration isopropyl acetate isopropanol, inability to obtain purity, and many orders of magnitude. and other problems, to achieve the effect of reducing membrane area, high conversion rate and improving recycling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

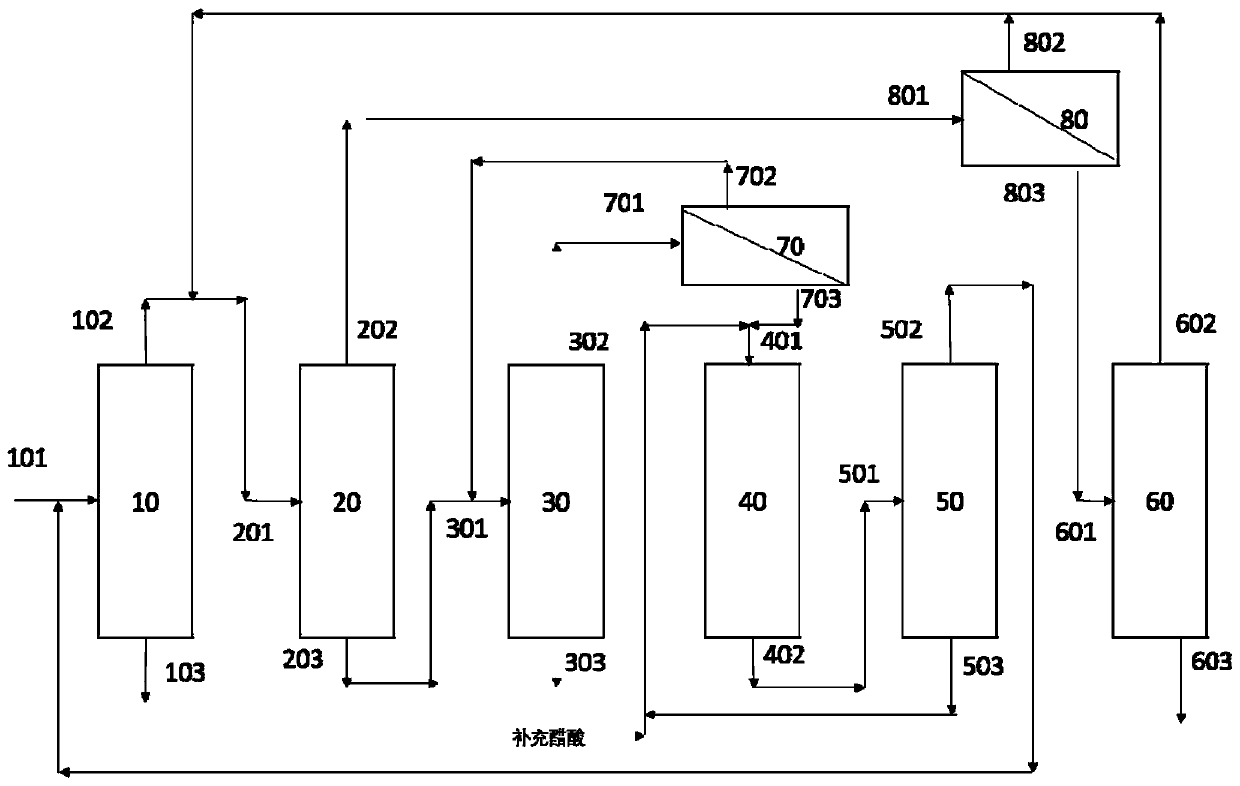

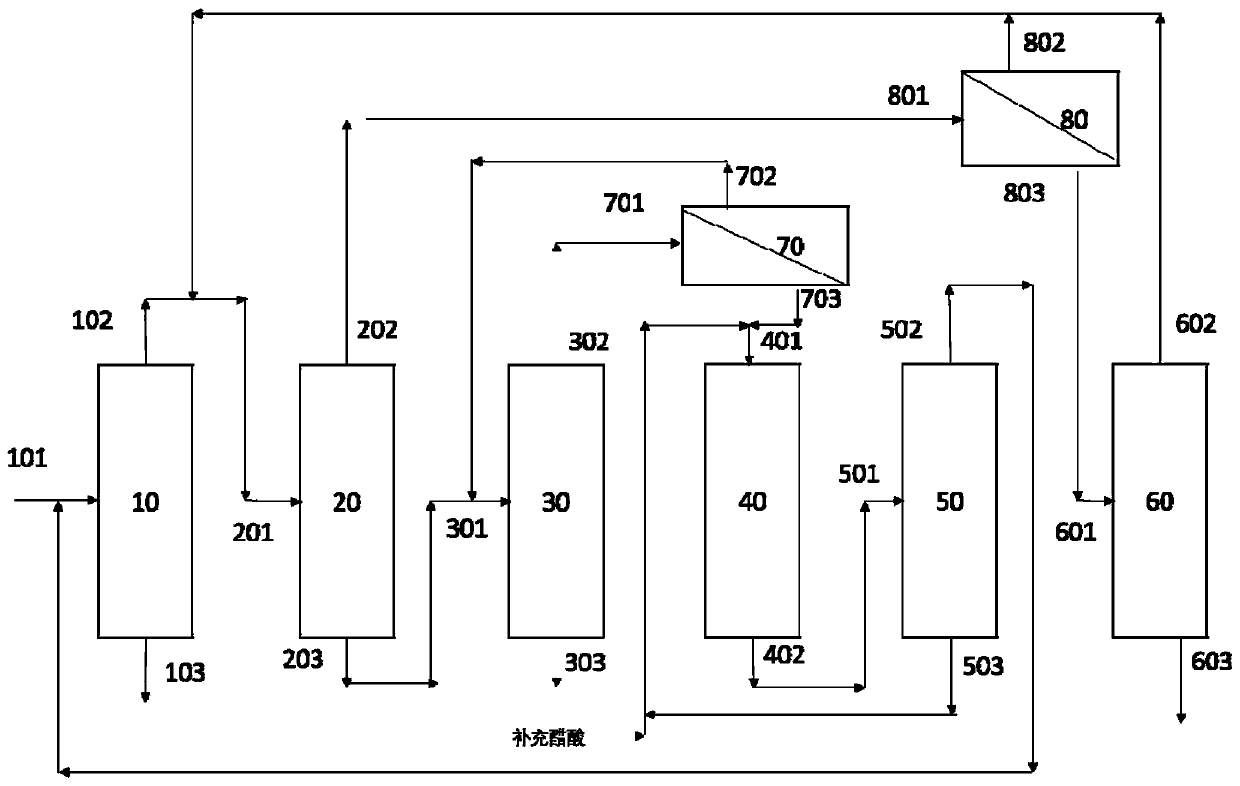

[0035] Embodiment one: the water content is about 95.5%wt in the waste water, and its technological process is as follows figure 1 shown.

[0036] An aqueous solution containing isopropyl acetate and isopropanol, wherein: isopropanol accounts for about 0.5%wt, and isopropyl acetate accounts for about 4%wt. A rectification tower 10 is used to separate most of the water. The output 103 from the tower bottom is mainly water and a small amount of residual acetic acid. The content of ester and alcohol solvent in the extraction 103 from the tower bottom is strictly controlled to <0.1%wt.

[0037] Isopropanol and water have higher boiling points, and 203 extracted from the bottom of tower 20 is isopropanol, water and azeotrope, and the content of ester solvent in 203 is strictly controlled to <0.1%wt. The output 202 at the top of the tower 20 is concentrated ester / alcohol / water mixed solvent.

[0038] 203 enters the tower 30 for further separation, 303 extracted from the bottom of ...

Embodiment 2

[0041] Embodiment two: the water content in the waste water is about 89.5%wt, and its technological process is as follows figure 1 shown.

[0042] An aqueous solution containing isopropyl acetate and isopropanol, wherein: isopropanol accounts for about 1.5%wt, and isopropyl acetate accounts for about 9.0%wt. A rectification tower 10 is used to separate most of the water. The output 103 from the tower bottom is mainly water and a small amount of residual acetic acid. The content of ester and alcohol solvent in the extraction 103 from the tower bottom is strictly controlled to <0.1%wt.

[0043] Isopropanol and water have higher boiling points, and 203 extracted from the bottom of tower 20 is isopropanol, water and azeotrope, and the content of ester solvent in 203 is strictly controlled to <0.1%wt. The output 202 at the top of the tower 20 is concentrated ester / alcohol / water mixed solvent.

[0044] 203 enters the tower 30 for further separation, 303 extracted from the bottom o...

Embodiment 3

[0047] Embodiment three: water content is about 83%wt in the waste water, and its technological process is as follows figure 1 shown.

[0048] An aqueous solution containing ethyl acetate and ethanol, wherein: ethanol accounts for about 12%wt, and ethyl acetate accounts for about 17.0%wt. The tower 10 is used to separate most of the water, and the 103 extracted from the tower kettle is mainly water and a small amount of residual acetic acid, and the content of ester and alcohol solvents in the 103 is strictly controlled to <0.1%wt.

[0049] The 203 extracted from the bottom of the tower 20 is ethanol, water and azeotrope, and the content of the ester solvent in the 203 is strictly controlled to <0.1%wt. The output 202 at the top of the tower 20 is concentrated ester / alcohol / water mixed solvent.

[0050] 203 enters tower 30 for further separation, 303 extracted from the bottom of the tower is water, and 302 extracted from the top of the tower is an azeotropic composition of e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com