Hydraulic oil cylinder pushing type drill rod outer wall cleaning equipment

A technology for hydraulic cylinders and cleaning equipment, applied in cleaning methods and tools, cleaning methods using tools, chemical instruments and methods, etc., can solve problems such as low work efficiency, incomplete cleaning of drill pipes, etc., to avoid low efficiency and overcome The effect of incomplete cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

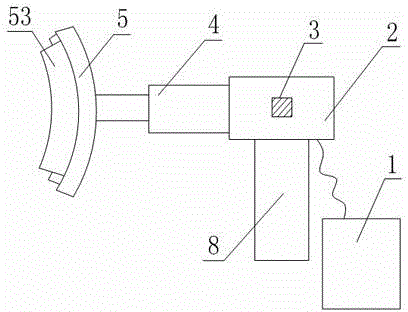

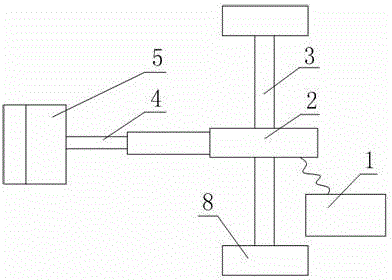

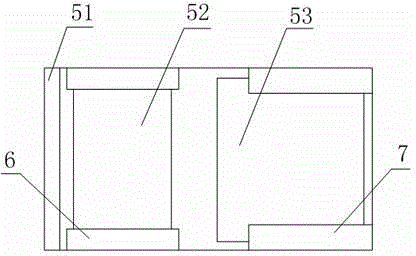

[0018] Such as Figure 1 to Figure 3 As shown, a hydraulic cylinder pushing type drill pipe outer wall cleaning equipment includes two symmetrically arranged fixed vertical plates 8, a guide rail 3 is arranged between the two fixed vertical plates 8, and a slider 2 controlled by a motor 1 is arranged on the guide rail 3 , the slider 2 is connected with a hydraulic cylinder 4, and the output end of the hydraulic cylinder 4 is provided with an arc-shaped plate 5 matched with the outer wall of the drill pipe. The arc length of the arc-shaped plate 5 is 1 / 3 of the circumference of the outer wall of the drill pipe. One end of the inner side of the plate 5 in the axial direction is provided with a curved scraper 51 which is axially consistent with the arc plate 5. The thickness of the curved scraper 51 is 3mm, and the other end is provided with a sponge pad 53, and the sponge pad 53 passes through the The two baffles II7 arranged at the radially upper end of the arc-shaped plate 5 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com