Lampblack cleaning device

A cleaning device and oil fume technology, applied in the direction of oil fume removal, household heating, heating methods, etc., can solve the problems of evolutionary function failure, failure to achieve separation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

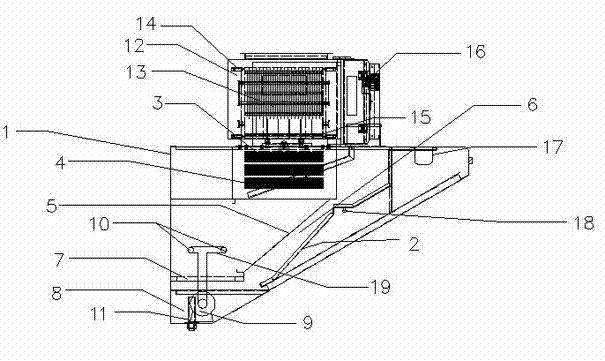

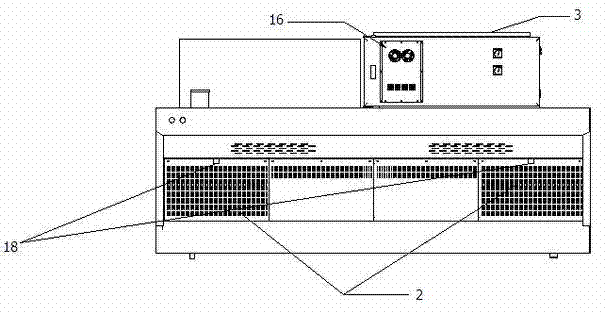

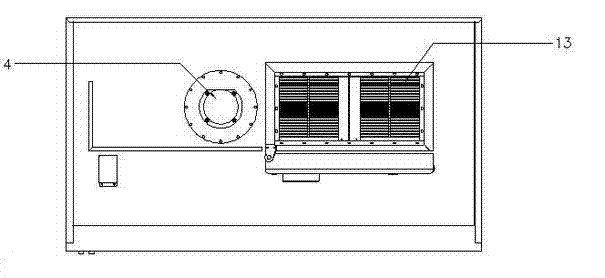

[0042] An oil fume cleaning device, comprising a chassis, a grid plate located on one side of the chassis, the grid plate is arranged inclined to the horizontal plane, an air outlet located on the top of the chassis, and an exhaust device located at the air outlet and arranged on the inner side of the top of the chassis. The baffle plate corresponding to the grid plate in the case, the baffle plate and the grid plate form a fume passage, and also includes an oil-water separation plate fixedly arranged between the lower end of the baffle plate and the chassis, and the upper end of the baffle plate is fixedly connected to the On the inner side of the top of the case, the oil-water separation plate is provided with holes.

Embodiment 2

[0044] An oil fume cleaning device, comprising a chassis, a grid plate located on one side of the chassis, the grid plate is arranged inclined to the horizontal plane, an air outlet located on the top of the chassis, and an exhaust device located at the air outlet and arranged on the inner side of the top of the chassis. The baffle plate corresponding to the grid plate in the case, the baffle plate and the grid plate form a fume passage, and also includes an oil-water separation plate fixedly arranged between the lower end of the baffle plate and the chassis, and the upper end of the baffle plate is fixedly connected to the On the inner side of the top of the case, the oil-water separation plate is provided with holes. The diameter of the hole in the present invention is 5mm.

Embodiment 3

[0046] An oil fume cleaning device, comprising a chassis, a grid plate located on one side of the chassis, the grid plate is arranged inclined to the horizontal plane, an air outlet located on the top of the chassis, and an exhaust device located at the air outlet and arranged on the inner side of the top of the chassis. The baffle plate corresponding to the grid plate in the case, the baffle plate and the grid plate form a fume passage, and also includes an oil-water separation plate fixedly arranged between the lower end of the baffle plate and the chassis, and the upper end of the baffle plate is fixedly connected to the On the inner side of the top of the case, the oil-water separation plate is provided with holes. The diameter of the hole in the present invention is 15mm. The present invention also includes a water tank arranged under the oil-water separation plate, a water pump located in the water tank, the water pump is connected with a spray pipe, the spray pipe passe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com