Hydraulic pipe orifice cleaning device

A technology for cleaning devices and pipelines, which is applied in the direction of cleaning hollow objects, cleaning methods and tools, grinding machines, etc. It can solve the problems of no protection, leakage, and labor and energy consumption of workers, so as to reduce physical exertion and improve cleaning efficiency , Improve the effect of cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

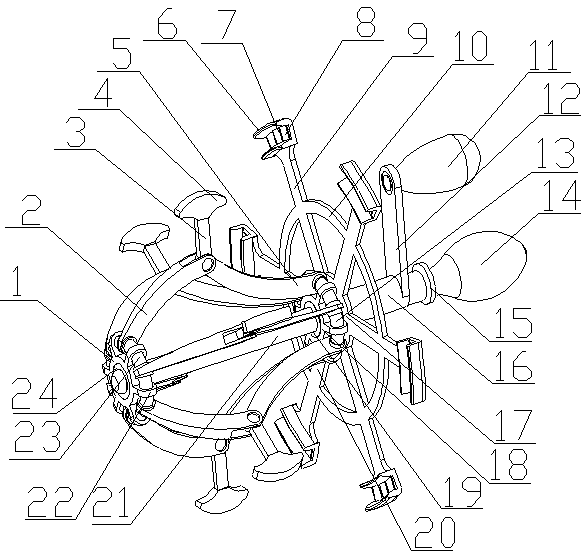

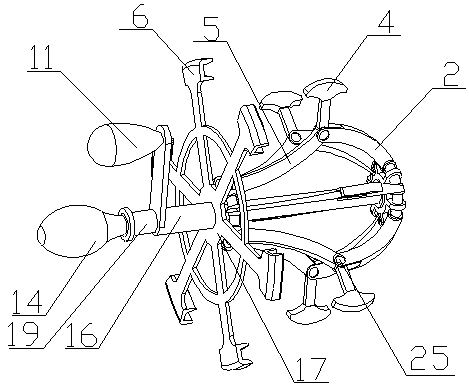

[0022] A water conservancy pipeline nozzle cleaning device of the present invention is realized in this way. When in use, the initial state of the transmission rod (2) and the connected pull rod (5) is stretched. When cleaning the nozzle of the water conservancy pipeline, first all Put the transmission rod (2) and all the pull rods (5) into the pipeline respectively, and make the U-shaped card slots on all the clamping blocks (6) respectively be stuck on the pipe nozzle, and the cleaning sheet on the wall of the U-shaped card slot ( 8) Fit the nozzle and the inner and outer walls, then hold the threaded sleeve (19) with one hand, and turn the fixed handle (14) with the other hand, because the threads on the surface of the threaded sleeve (19) and the fixed shaft (21) match , and the threaded sleeve (19) is fixed, and then the fixed shaft (21) moves out of the nozzle along the threaded sleeve (19), and drives the connecting ring (1) and auxiliary support ring (23) to move out of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com