Drum brushing device for steel drum renovation

A technology for brushing barrels and steel barrels, which is applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc. It can solve the problems of uneven grinding, affecting the cleaning effect, and missing beating, so as to achieve uniform distribution and improve the cleaning effect , the effect of preventing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

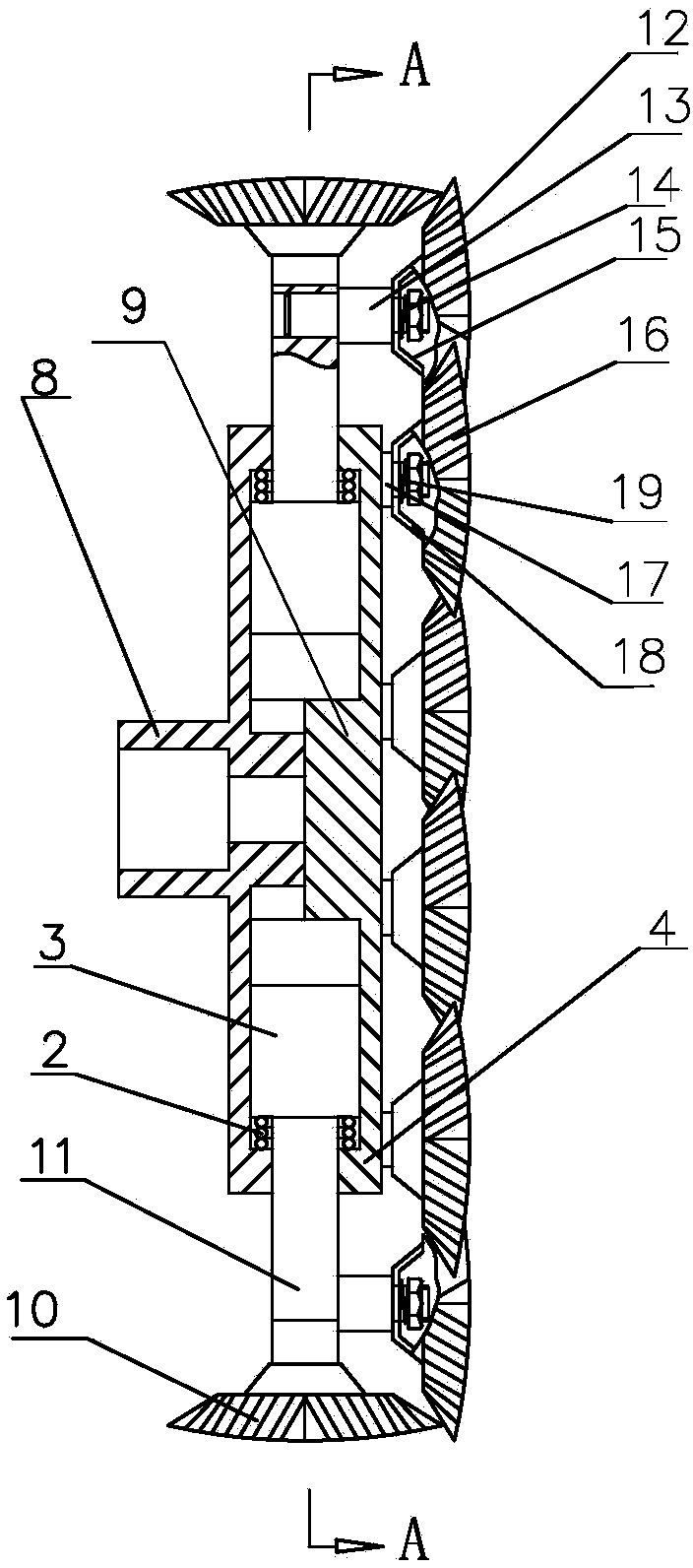

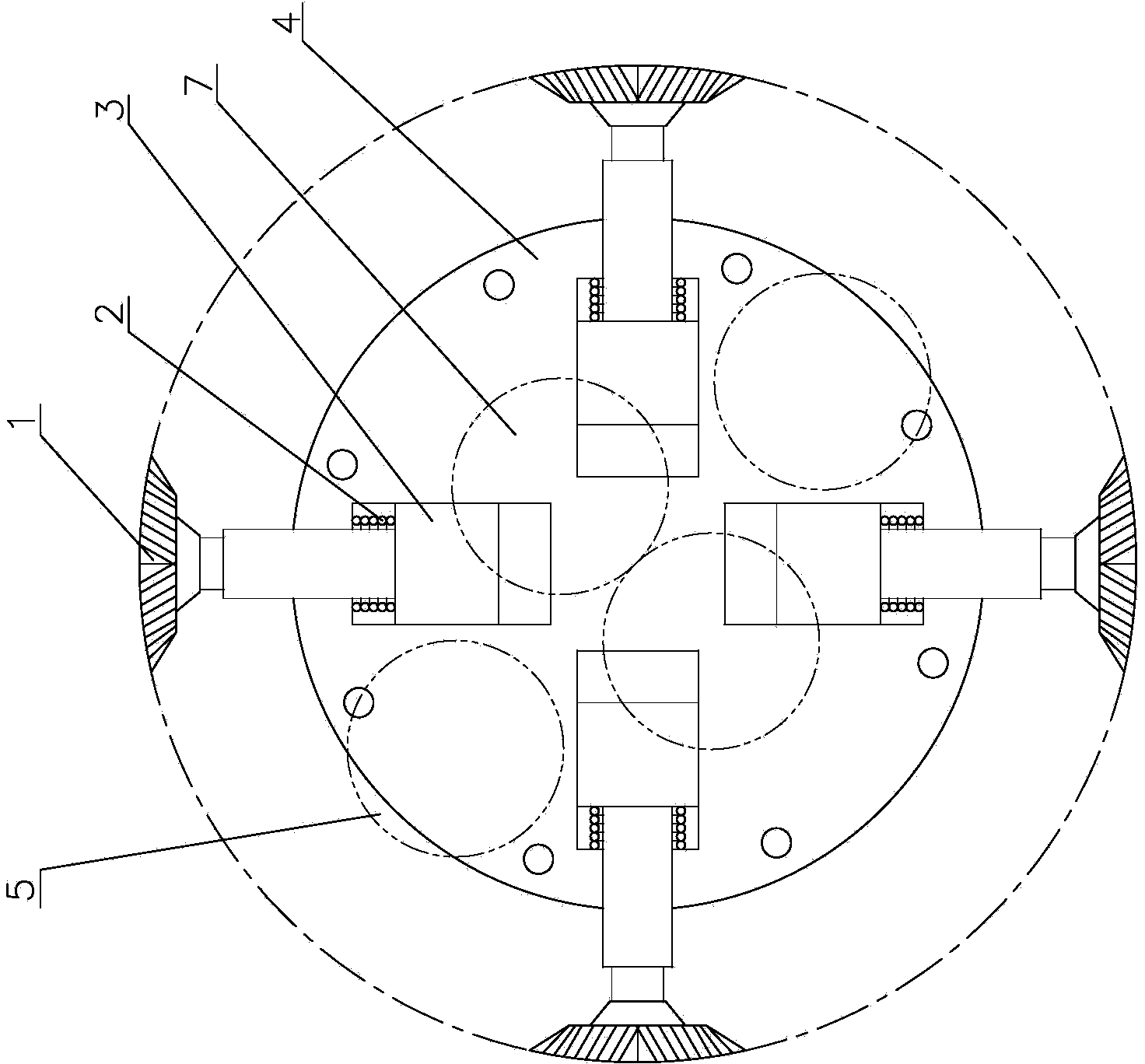

[0020] The schematic diagram of the drum refurbishment brushing device of the present invention is as figure 1 and figure 2 As shown, it includes a connection plate and a plurality of bucket wall grinding brushes 1 . The barrel wall grinding brush 1 is composed of a barrel wall brush rod 11 and a barrel wall brush head 10, and the barrel wall brush head 10 is fixedly connected with the barrel wall brush rod 11. The connecting plate is composed of the front connecting plate 8 and the rear connecting plate 4, which can be connected by bolts. A cavity is provided at a position corresponding to each of the barrel wall grinding brushes in the connecting plate, and a cavity corresponding to each of the barrel wall grinding brushes is respectively provided in the connecting plate along the circumferential direction. Each cavity is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com