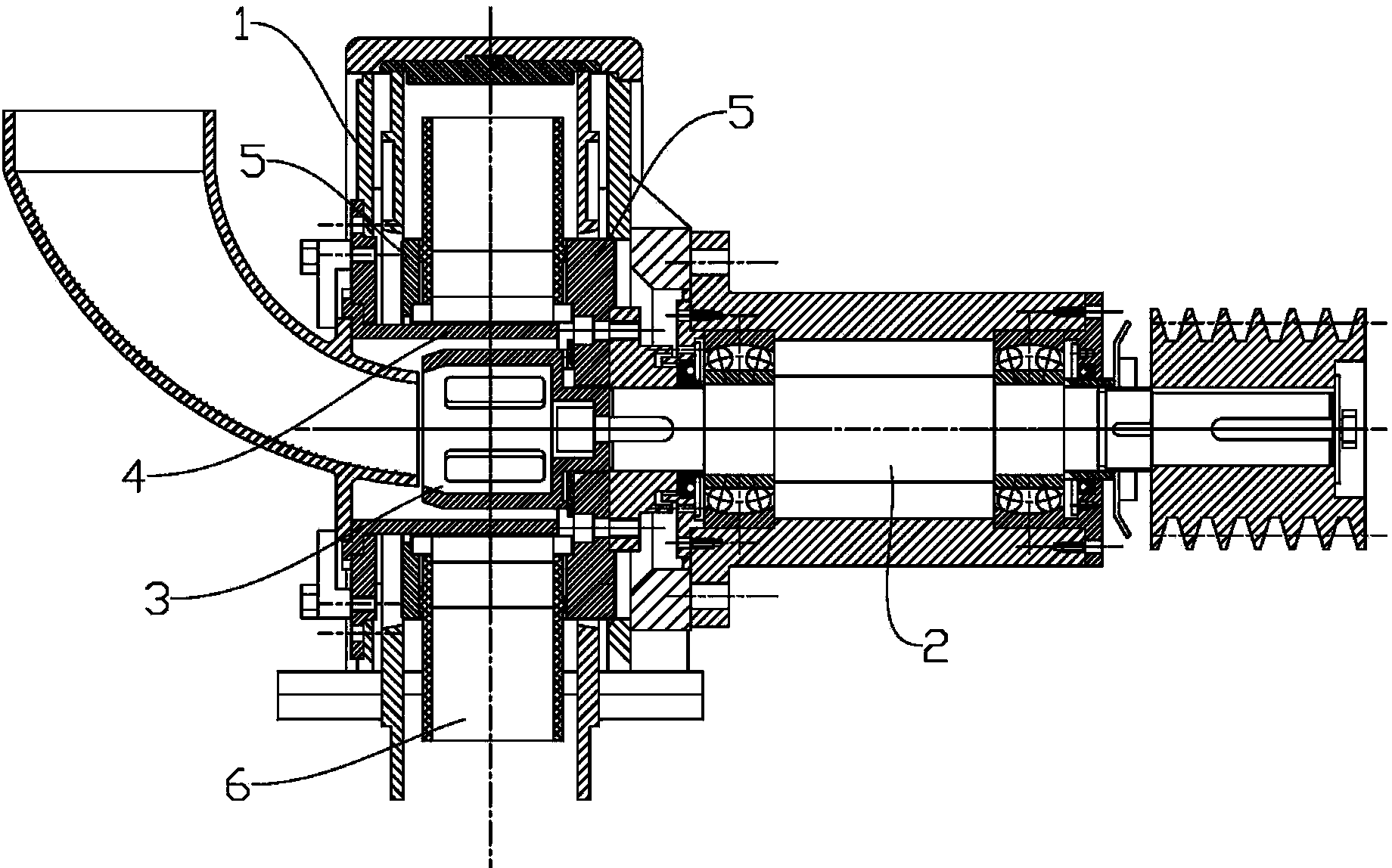

Shot blasting strengthening device and shot blasting strengthening method for engine blades

A technology of engine blades and strengthening devices, which is applied to rotor blades, explosion generating devices, impellers, etc., can solve the problems of incomplete cleaning and low strengthening quality, and achieve the effects of complete cleaning, high strengthening quality and reduced wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

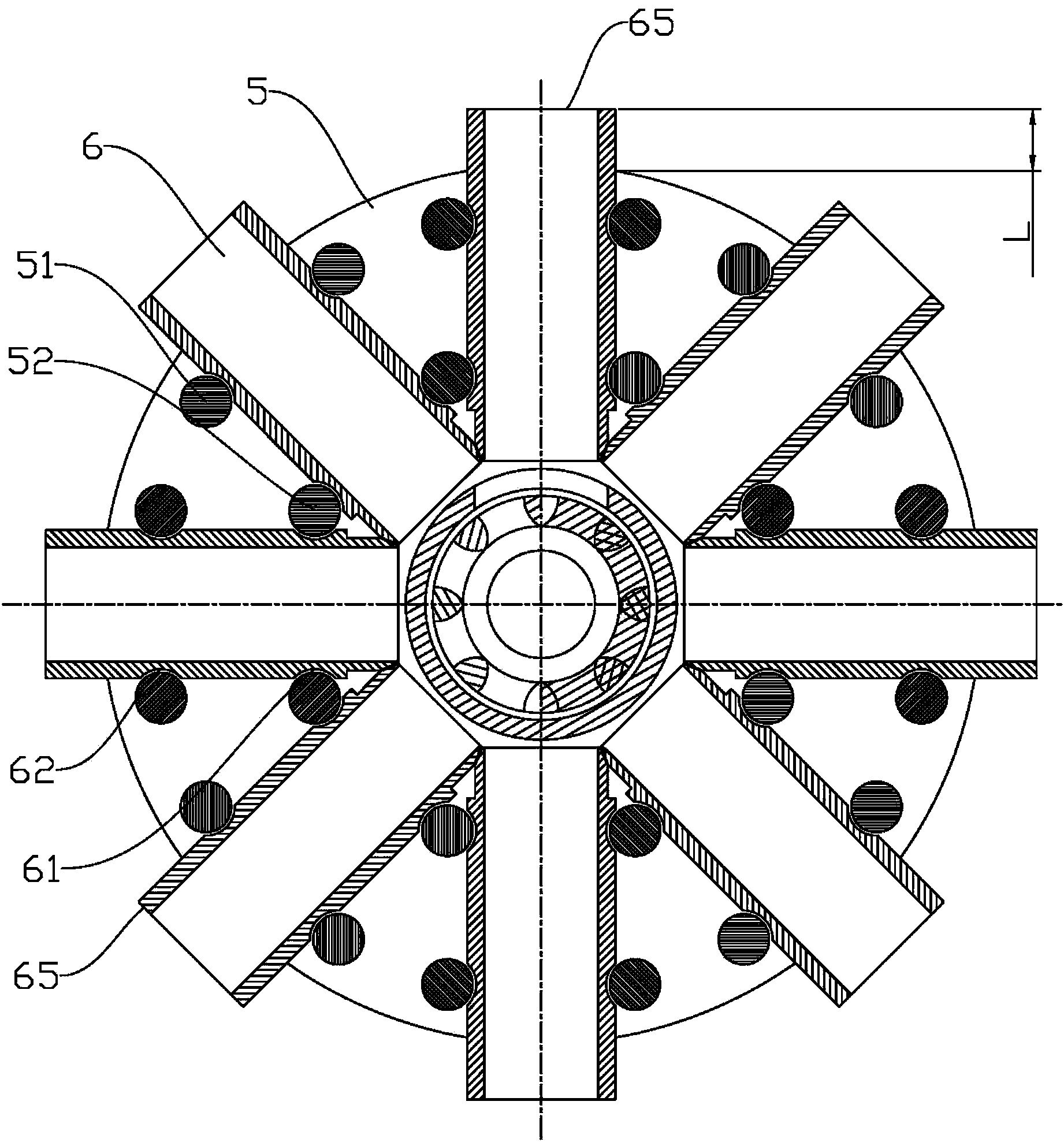

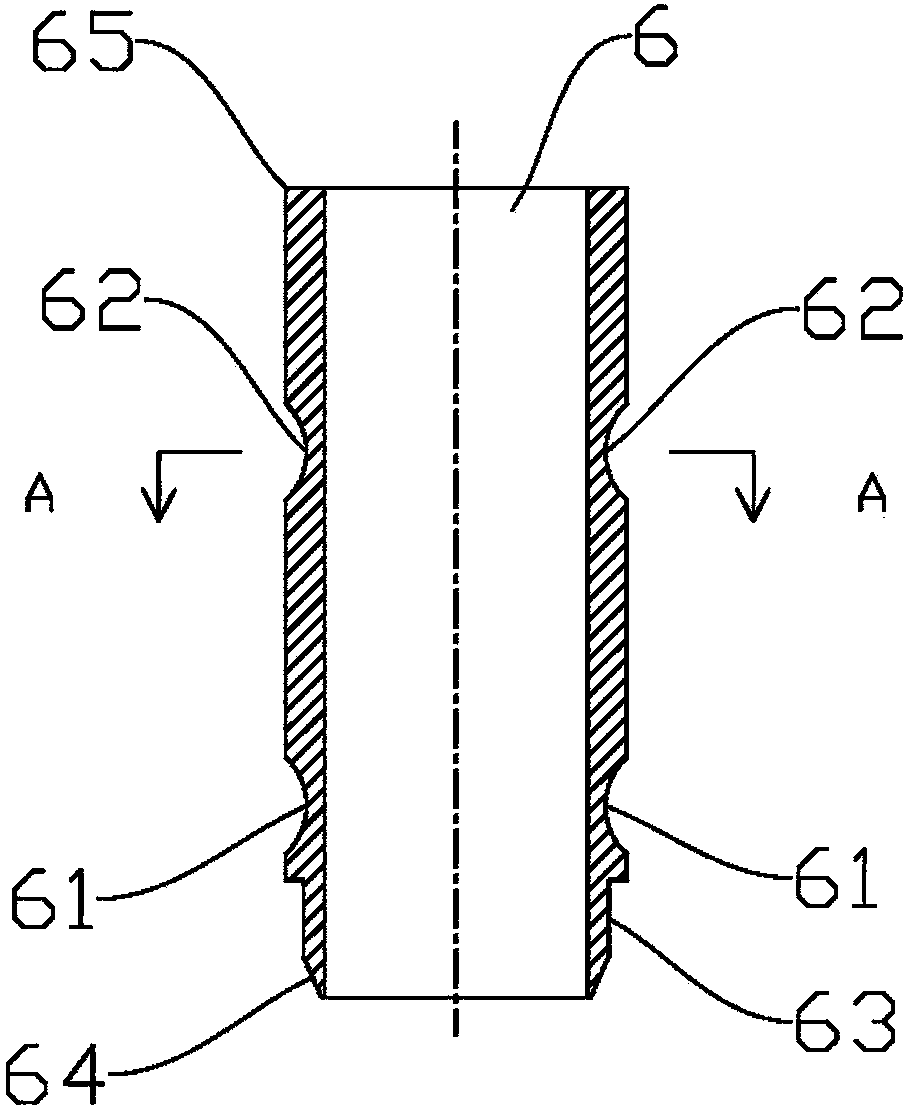

Method used

Image

Examples

Embodiment Construction

[0024] The shot blasting strengthening method of engine blades, the special features of this method are:

[0025] Select the first type of steel shot with a particle size of 1 mm, the second type of steel shot with a particle size of 1.2 mm, the third type of steel shot with a particle size of 1.5 mm, the fourth type of steel shot with a particle size of 1.7 mm, and a particle size of 2 mm. Millimeters of the fifth steel shot are mixed evenly to form a mixed shot; wherein the first steel shot, the second steel shot, the third steel shot, the fourth steel shot, and the fifth steel shot respectively account for the total amount of the mixed shot 30%, 13%, 20%, 20%, 17% of the weight;

[0026] Throw the mixed shot through the cylindrical tubular blade of the shot blaster at a speed of 63.5m / s, and then hit the engine blade for 30s;

[0027] Then throw it at a speed of 70m / s, and hit the engine blade for 20s;

[0028] Then throw it at a speed of 72m / s, and hit the engine blade f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com