Mute clamp for clutch shell body machining

A clutch housing and silent technology, which is applied in the direction of manufacturing tools, metal processing equipment, grinding workpiece supports, etc., can solve the problems of poor working environment, harsh noise, loud noise, etc., and achieve fast and complete dust cleaning and clean working environment Improvement, good effect of mute effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

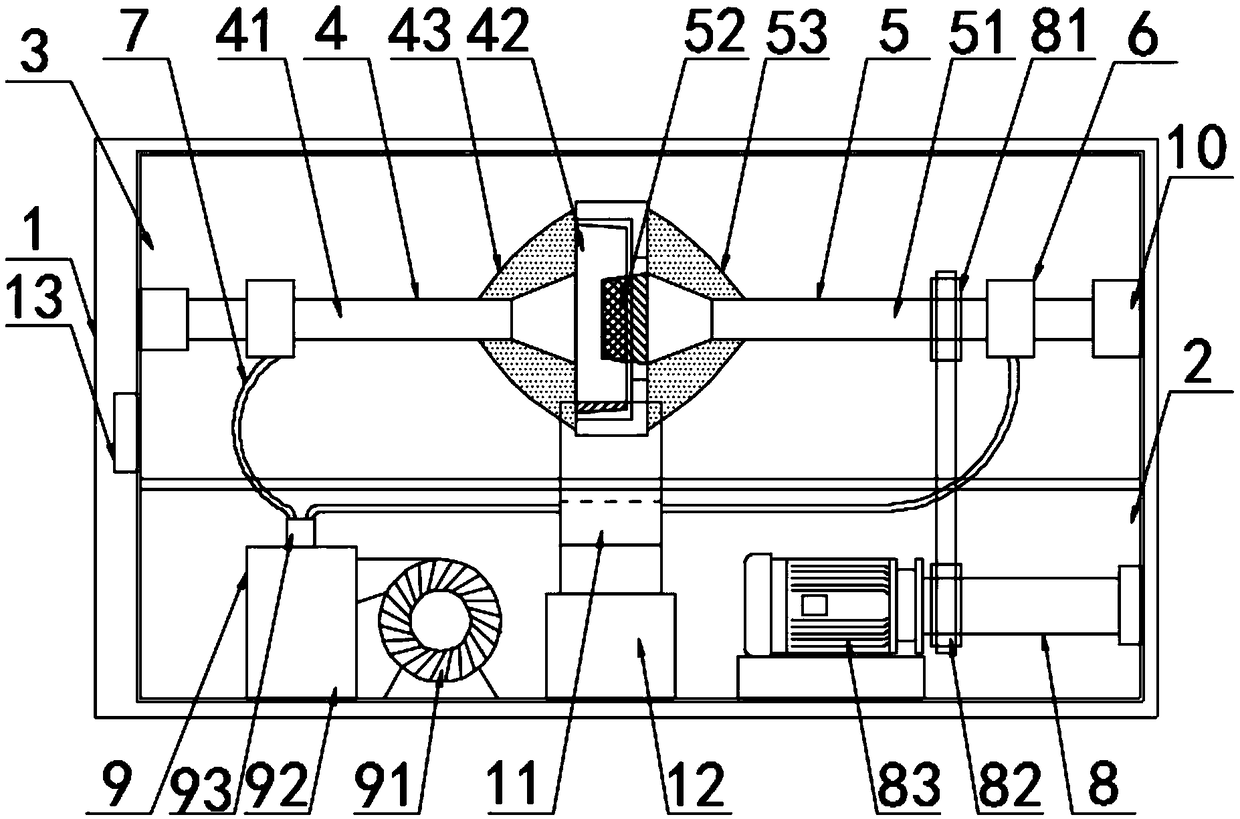

[0025] according to Figure 1-4 The shown silent fixture for clutch housing processing includes a sound-insulating body 1, a control box 2 and a processing chamber 3 are provided inside the sound-insulating body 1, and an electronic airtight door 13 is provided on the front side of the sound-insulating body 1. One side of the sound-insulating body 1 is provided with a PLC controller, the sound-insulating body 1 and the electronic airtight door 13 are both made of vacuum sound-proof glass, and the control box 2 is made of a sound-proof board, so that the whole device has a good mute effect and the working environment is improved. Improvement, the processing chamber 3 is arranged on the top of the control box 2, the inside of the processing chamber 3 is provided with a first clamping workpiece 4 and a second clamping workpiece 5, and the first clamping workpiece 4 and the second clamping workpiece 5. One end close to the inner wall of the sound-insulating body 1 is provided with...

Embodiment 2

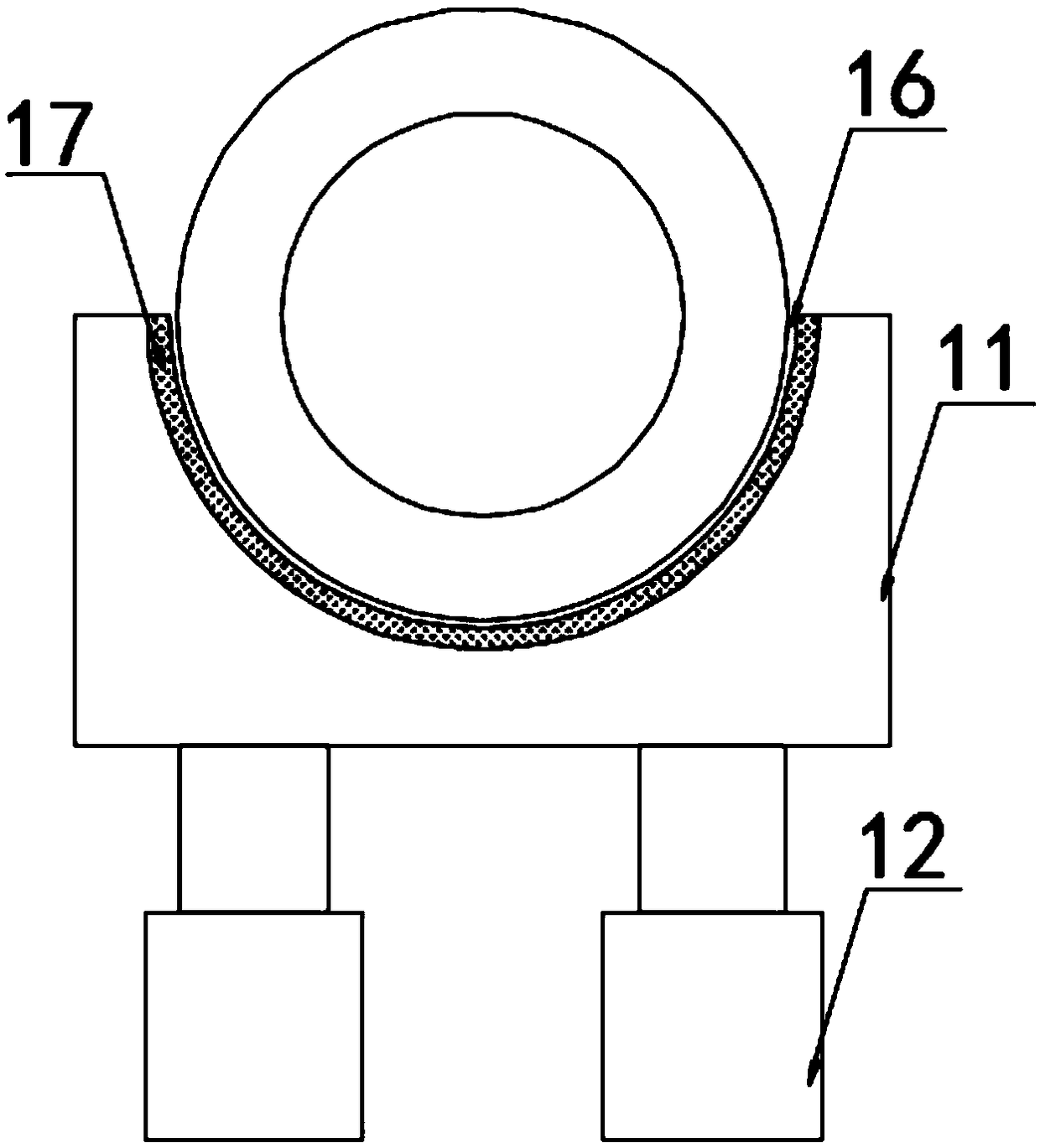

[0028] according to figure 2 As shown in the silent fixture for clutch housing processing, the top of the grinding workpiece 11 is provided with a semicircular groove 16, and the inner wall of the semicircular groove 16 is fixed with grinding sandpaper 17, and the clutch housing and the semicircular groove 16 are movably clamped. ;

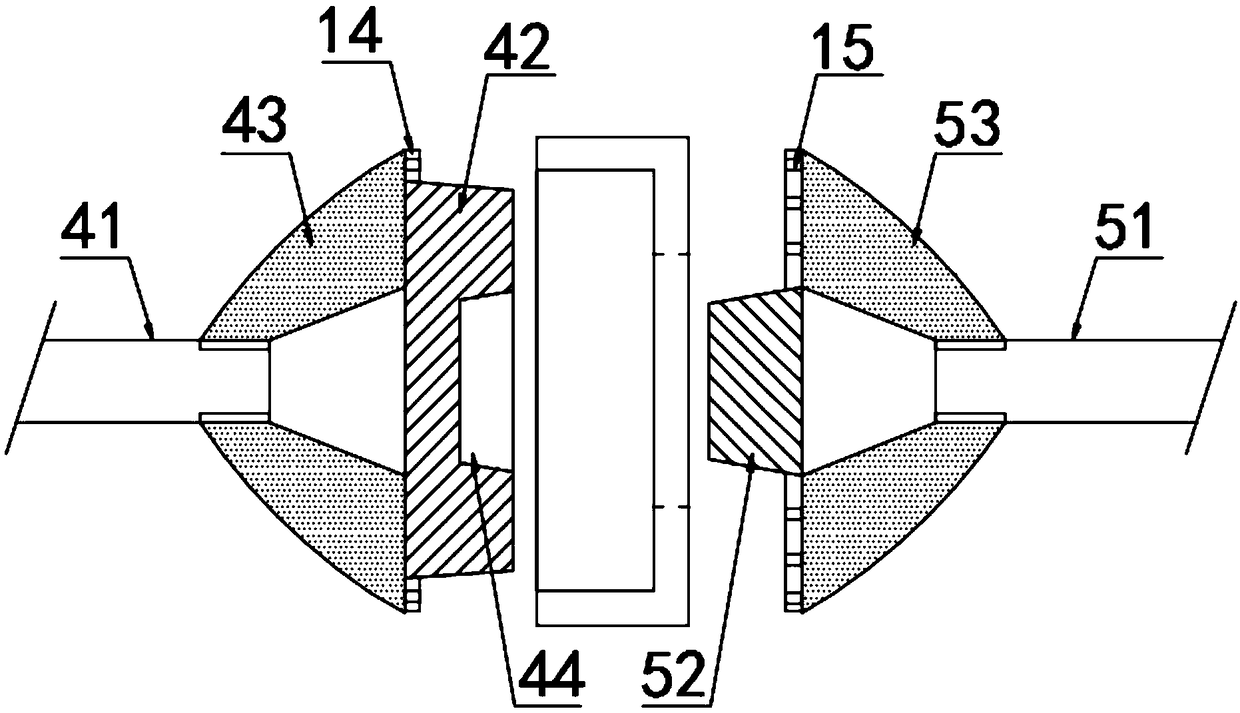

[0029] according to image 3 As shown in a silent clamp for clutch housing processing, the first clamping workpiece 4 includes a first empty tube 41, and the first empty tube 41 communicates with the bearing 6 at the end, and the first empty tube The end of 41 is fixed with a first clamping head 42, and the outside of the first clamping head 42 is fixed with a first dust cover 43, and the end surface of the first clamping head 42 is provided with a slot 44. The first clamping head 42 is set in the shape of a circular platform, which is convenient for insertion into the hollow groove of the clutch housing. The second clamping workpiece 5 include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com