Closed type air washing machine

A washing machine and a closed-type technology, applied in the field of washing machines, can solve the problems of insufficient air supply of an air compressor, poor sterilization and disinfection effect, poor washing effect, etc., so as to reduce the complexity of the mechanical structure, improve the uniform washing effect, and have a good mute effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

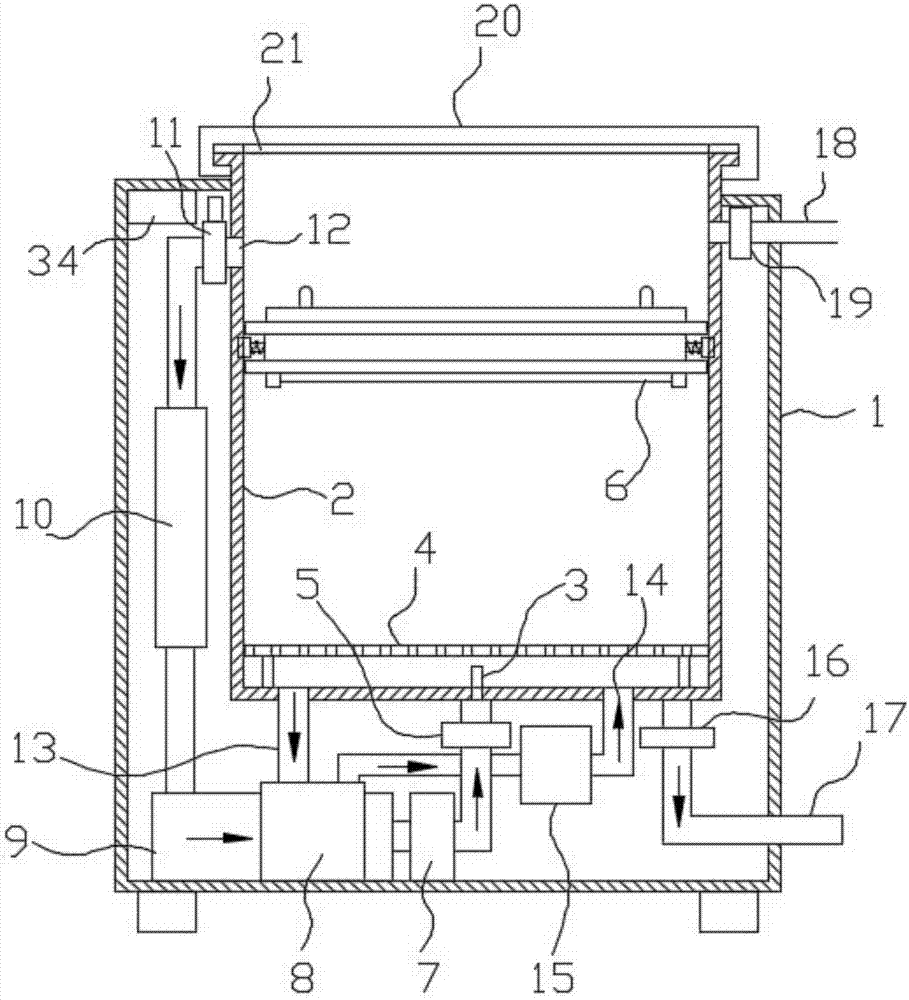

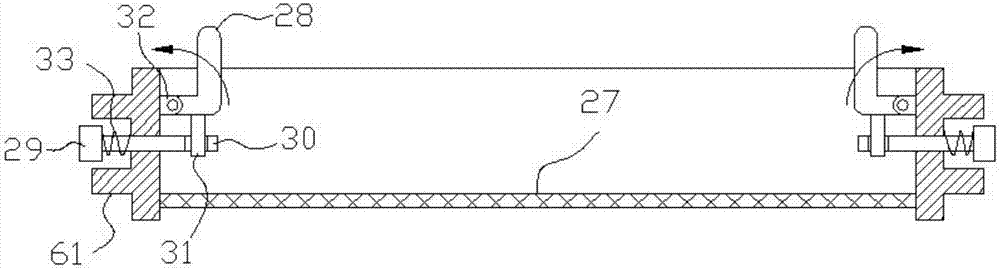

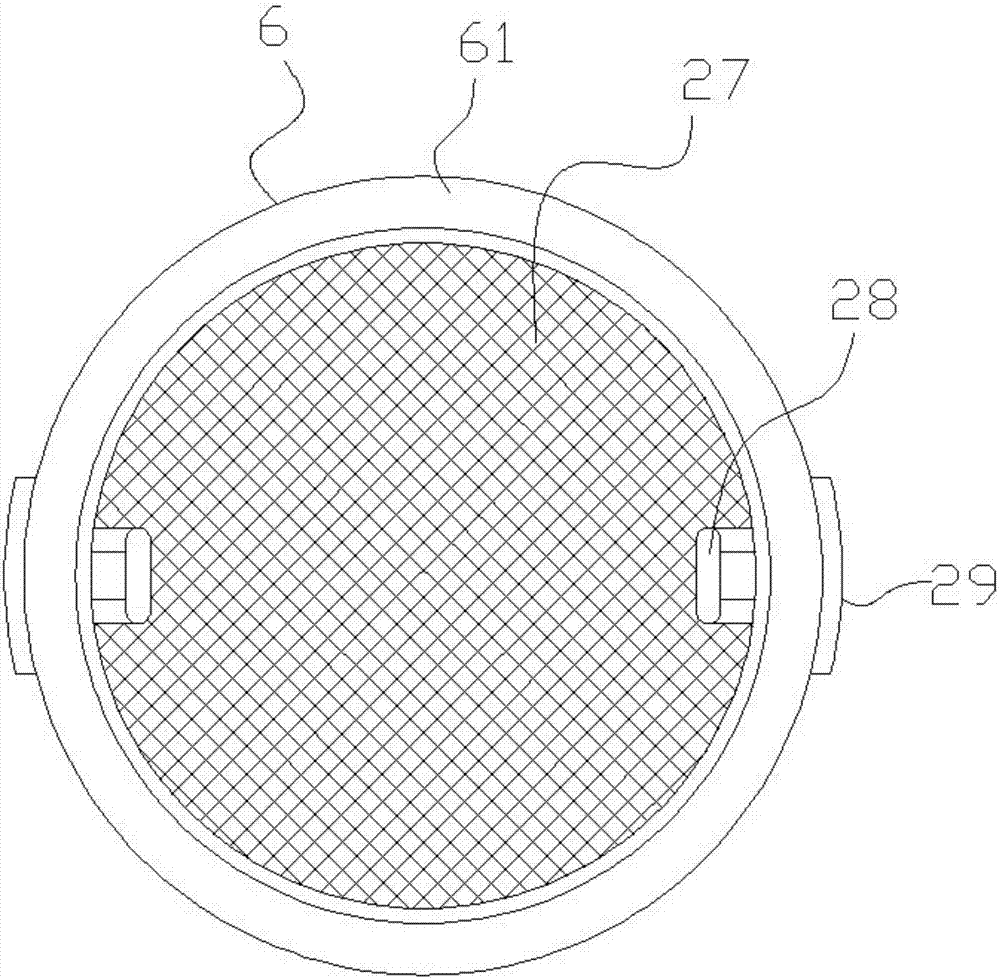

[0029] like Figure 1-Figure 7 As shown, the specific structure of the present invention is: a closed air washing machine, which includes a washing bucket 2 arranged in the outer box 1, the upper end of the washing bucket 2 is equipped with a sealing cover 20; The damping mesh cover 6 that can adjust the position up and down arbitrarily; the damping mesh cover 6 is provided with a damping mesh 27; the center of the bottom of the washing bucket 2 is provided with a spiral atomizing nozzle 3; Connect the air compressor 9 with the pipeline, and the pipeline between the spiral atomizing nozzle 3 and the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com