Ultra low temperature super guanidine gum fracturing fluid

A technology of super guar gum and fracturing fluid, which is applied in the field of fracturing fluid, can solve problems such as loss of production stimulation effect of fracturing measures, poor shear resistance of fracturing fluid, incomplete gel breaking of fracturing fluid, etc., to ensure success Adhesive properties, lower activation energy, and thorough gel breaking effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with embodiment:

[0012] Well C 85-P Ping 33 is located in Daqing City, Heilongjiang Province, and belongs to the Chaoyanggou anticline structure of the Chaoyanggou terrace in the central depression area of the northern Songliao Basin. The perforated intervals are 840.0-832.0m, 783.0-775.0m, 732.0-725.0m and 662.0-657.0m. The temperature in the middle of the reservoir is about 30°C.

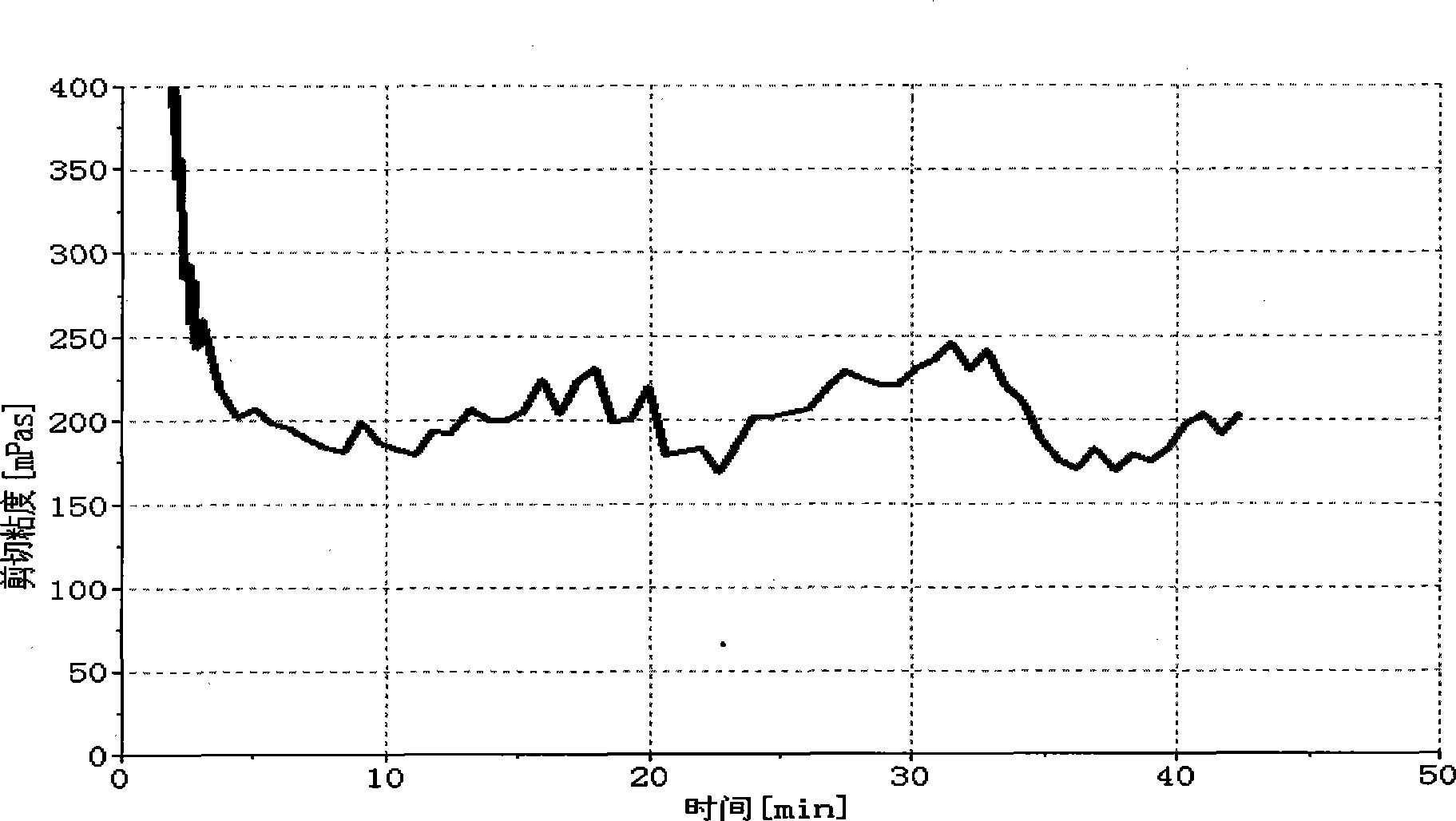

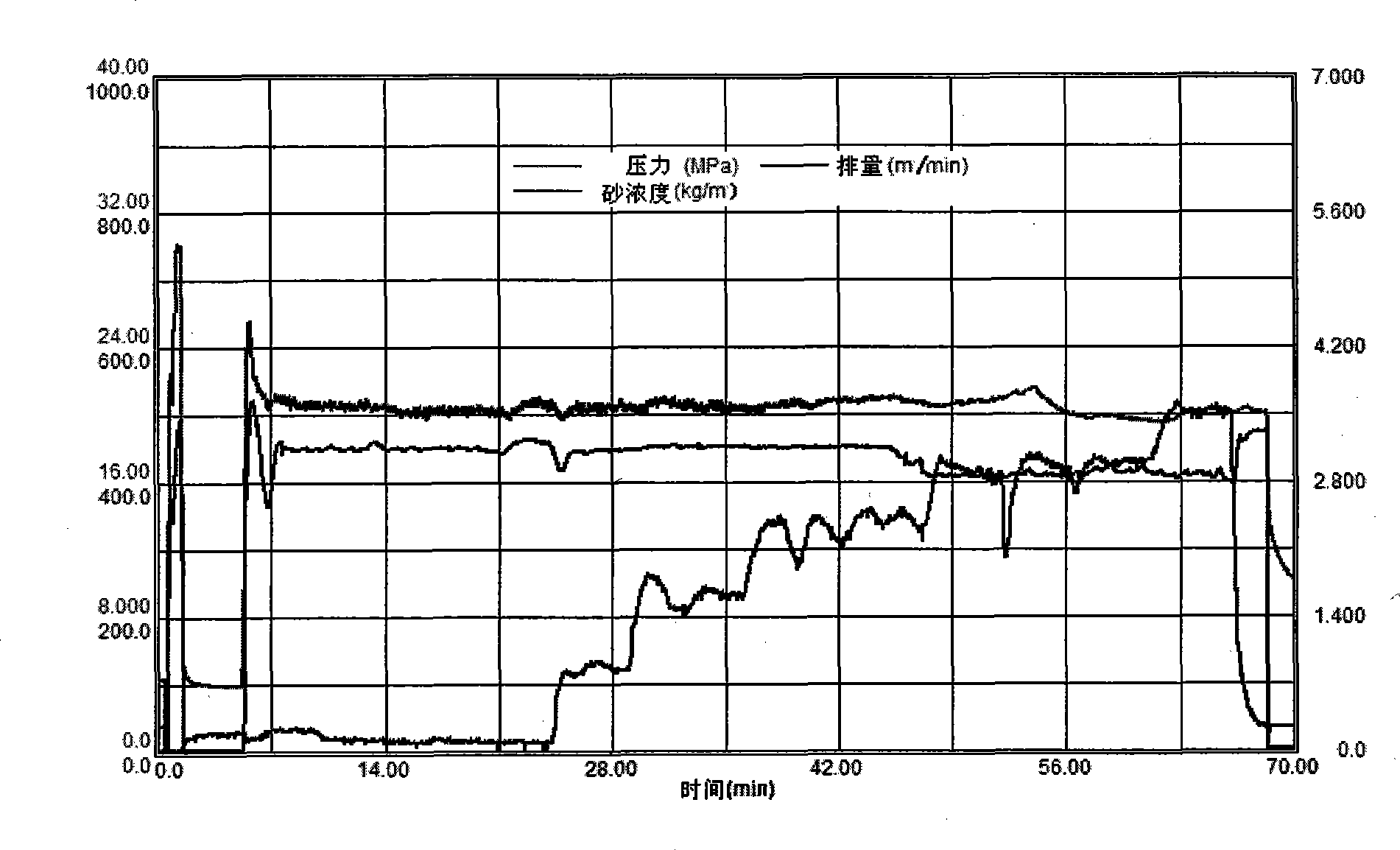

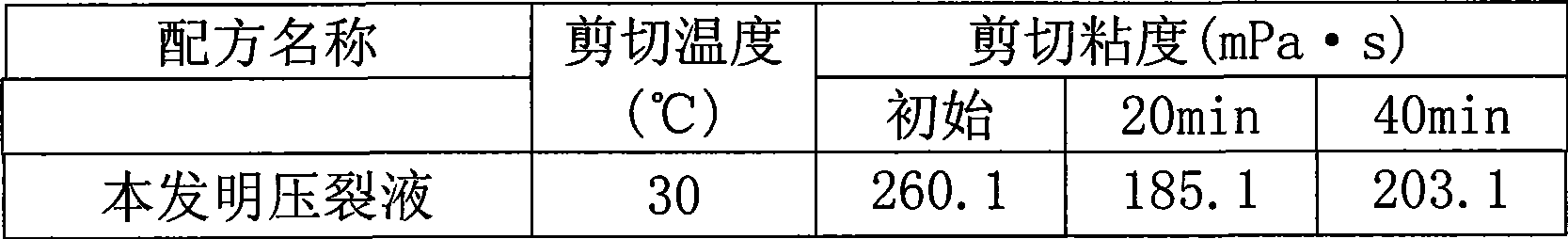

[0013] The fracturing fluid system for this layer was sheared for 40 min at 30°C, and the viscosity was 203.1 mPa.s (see Table 1, figure 1 ), and the viscosity of the fracturing fluid after 4 hours at 30°C was 3.8mPa.s, and the viscosity of the fracturing fluid base fluid prepared on site was 30.4mPa.s. In order to meet the needs of layer construction, the well was fractured in 4 intervals, and a total of 115m of proppant was added 3 , and the construction went smoothly (the construction curve of the third section o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com