A hydrogel preparation method

A technology of hydrogel and cross-linking agent, which is applied in the field of preparing hydrogel, can solve the problems of low heating efficiency, uneven heating, temperature reduction, etc., and achieve the effects of saving energy, speeding up preparation, and heating uniformly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0010] The method for preparing hydrogel of the present invention is described in detail as follows in conjunction with embodiment:

[0011] The method of the present invention comprises the following steps:

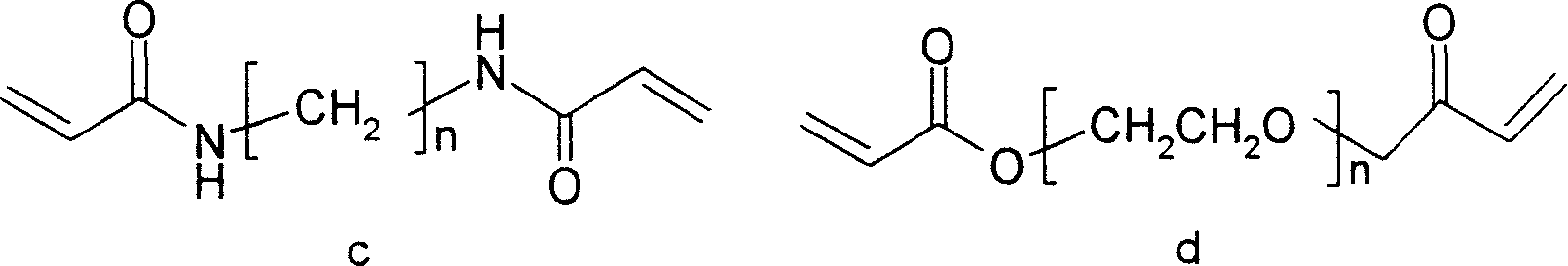

[0012] 1) After mixing vinyl monomers, crosslinking agents and initiators, dissolve them in a solvent to make a reaction system. The weight ratio of each component in the reaction system is: monomer: crosslinking agent: initiator: solvent=100: 2-50: 0.2-1: 1-10;

[0013] 2) It is obtained by irradiating and heating the reaction system by using microwaves with a frequency of 2450MHz or microwaves with frequency conversion of 300MHz-300GHz.

[0014] The power of the microwave or variable-frequency microwave can be 75 watts to 10,000 watts, and the irradiation heating takes 1-30 minutes.

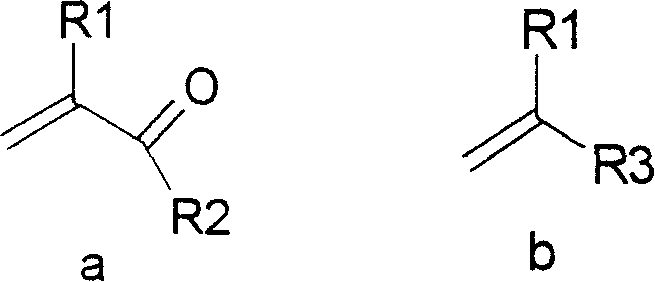

[0015] The structural formula of the ethylenic monomer can be a or b:

[0016]

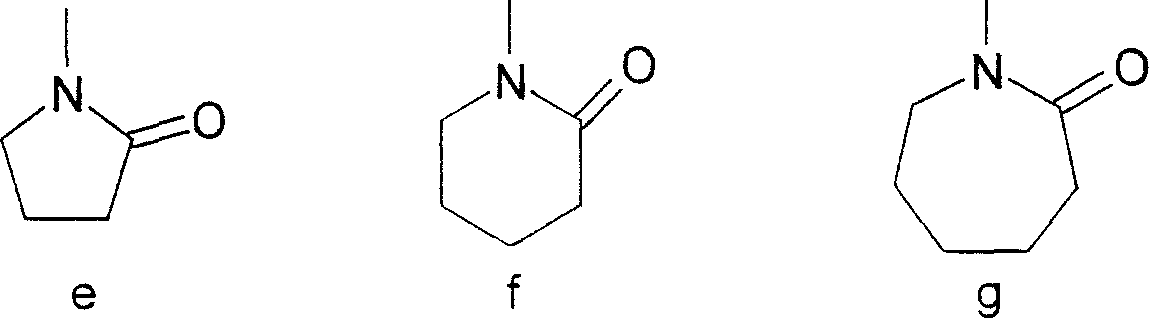

[0017] where R1 = H, CH 3 ; R2=OR4, NR4R5; The structural formula of R3 is e, f or g:

[0018] ...

Embodiment 1

[0026] Dissolve 10g of acrylamide, 0.5g of N,N'-methylenebisacrylamide and 10mg of azobisisobutyronitrile in 40ml of water, blow in high-purity nitrogen, vacuumize, repeat degassing three times, and seal the tube under vacuum. Then put the sealed tube into a microwave oven with a frequency of 2450 MHz and select an output power of 340 watts to irradiate for 2 minutes. The obtained hydrogel was washed with water and dried. Yield 90%.

Embodiment 2

[0028] Mix 10g acrylamide, 2g acrylic acid, 0.5g N,N'-methylenebisacrylamide and 10mg azobisisobutyronitrile, dissolve in 50ml water, degas three times with high-purity nitrogen, seal the tube under vacuum, and then Put the sealed tube into a microwave oven and irradiate it with 75W microwaves with a frequency in the range of 300MHz-300GHz for 20 minutes. Wash, tumble dry. Yield 88%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com