Temperature-resistant salt-resistant quick-dissolving thickening agent used for seawater-based fracturing fluid and preparation method thereof

A technology of temperature resistance, salt resistance and thickener, which is used in the fields of fine chemistry and oilfield chemicals, and can solve the problem that the temperature and shear resistance of thickener solutions are difficult to improve, the hydration and swelling of conventional thickeners are incomplete, and the thickening It can improve the effect of reservoir reconstruction, reduce the damage of residues, and break the glue without residues.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The synthetic optimization scheme of association intermediate provided by the present invention:

[0049] Add p-vinylbenzenesulfonic acid, NaOH, hydroquinone and deionized water to the monomer reactor in sequence, stir for 1.5h, then add NaHCO 3 , control the pH value to 8.5, then add allyl chloride dropwise to the solution, react for 8 hours after the dropwise addition, heat up to 90°C, react for 4 hours, cool to room temperature, filter to obtain a light yellow association intermediate, and store it for later use;

[0050] In the above reaction system, taking the total reaction system mass as 100%, p-vinylbenzenesulfonic acid accounts for 24% of the total mass, NaOH accounts for 6% of the total mass, hydroquinone accounts for 0.1% of the total mass, NaHCO 3 Accounting for 8% of the total mass, allyl chloride accounts for 8% of the total mass, and the rest is deionized water.

[0051] The performance of the product obtained by this synthesis scheme is excellent, so this...

Embodiment 2

[0053] Thickener colloid synthesis optimization scheme provided by the present invention:

[0054] Add acrylic acid, sodium hydroxide and deionized water to the polymerization reactor in sequence, mix and dissolve and neutralize the acrylic acid to a neutralization degree of 90%, then add acrylamide, maleic acid, 2-acrylamide-2 - Dimethylpropanesulfonic acid (AMPS), octadecyl methacrylate accounts for the total mass and the synthesized association intermediate, after controlling the temperature of the mixed reaction system at 20 ° C and feeding nitrogen into the reactor for 2 hours, Stop the nitrogen flow, and heat the reactor to increase the temperature of the reactant to 23°C, add the initiator, and react for 6 hours when the reactant starts to polymerize to obtain the colloid of the thickener.

[0055] In the above reaction system, taking the total reaction system mass as 100%, acrylic acid accounts for 6% of the total mass, sodium hydroxide accounts for 5% of the total mas...

Embodiment 3

[0058] The post-treatment optimization scheme of the colloid provided by the invention:

[0059] After the step reaction in Example 2 is completed to generate the thickener colloid, the temperature of the reaction kettle is heated to 95°C and kept for 6 hours, and then the colloid is granulated, fluidized bed dried, and air-flow pulverized, and the thickened colloid with a size of 80 mesh or more is sieved. Agent granules, packaged to obtain a heat-resistant, salt-resistant instant thickener that can be used in seawater-based fracturing fluids.

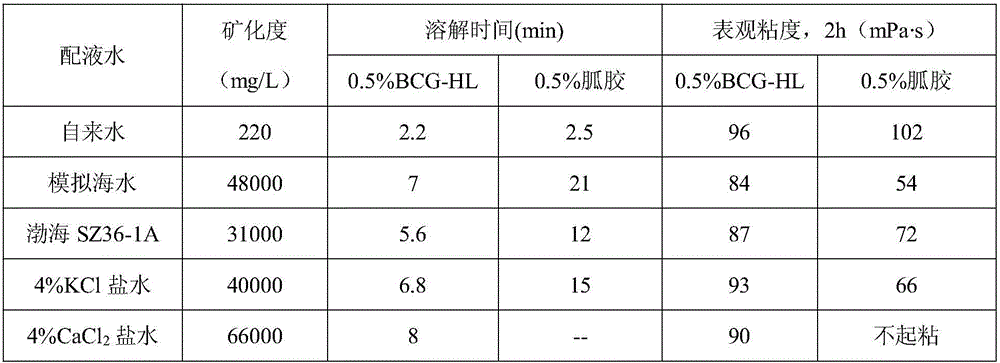

[0060] The product obtained by this solution is in the form of white powder, with the best performance test. Therefore, this product is used as a temperature-resistant and salt-resistant instant thickener that can be used in seawater-based fracturing fluids. It will be replaced by the code BCG-HL below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com