Patents

Literature

123 results about "Aspergillus mottae" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aspergillus mottae is a species of fungus in the genus Aspergillus first isolated from almonds and maize in Portugal. It is from the Flavi section. The species was first described in 2012.

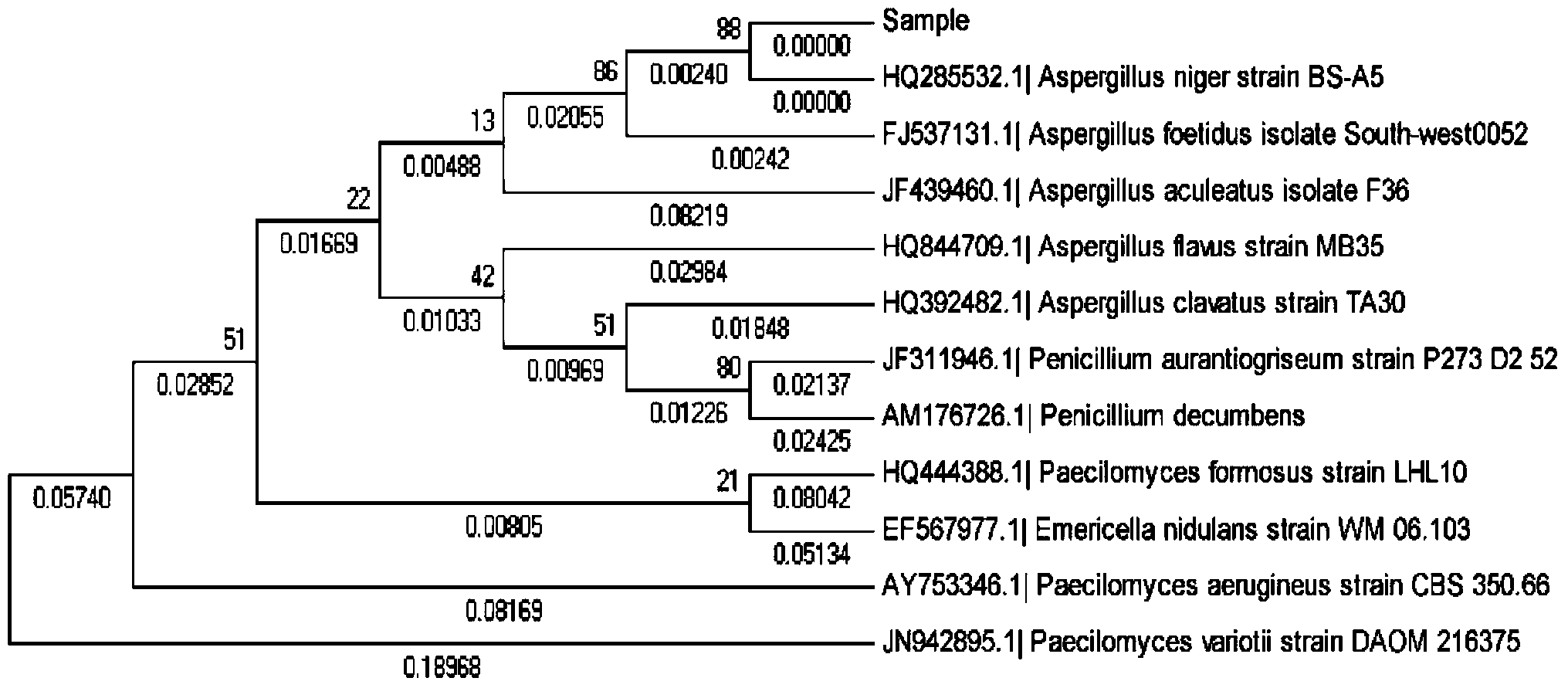

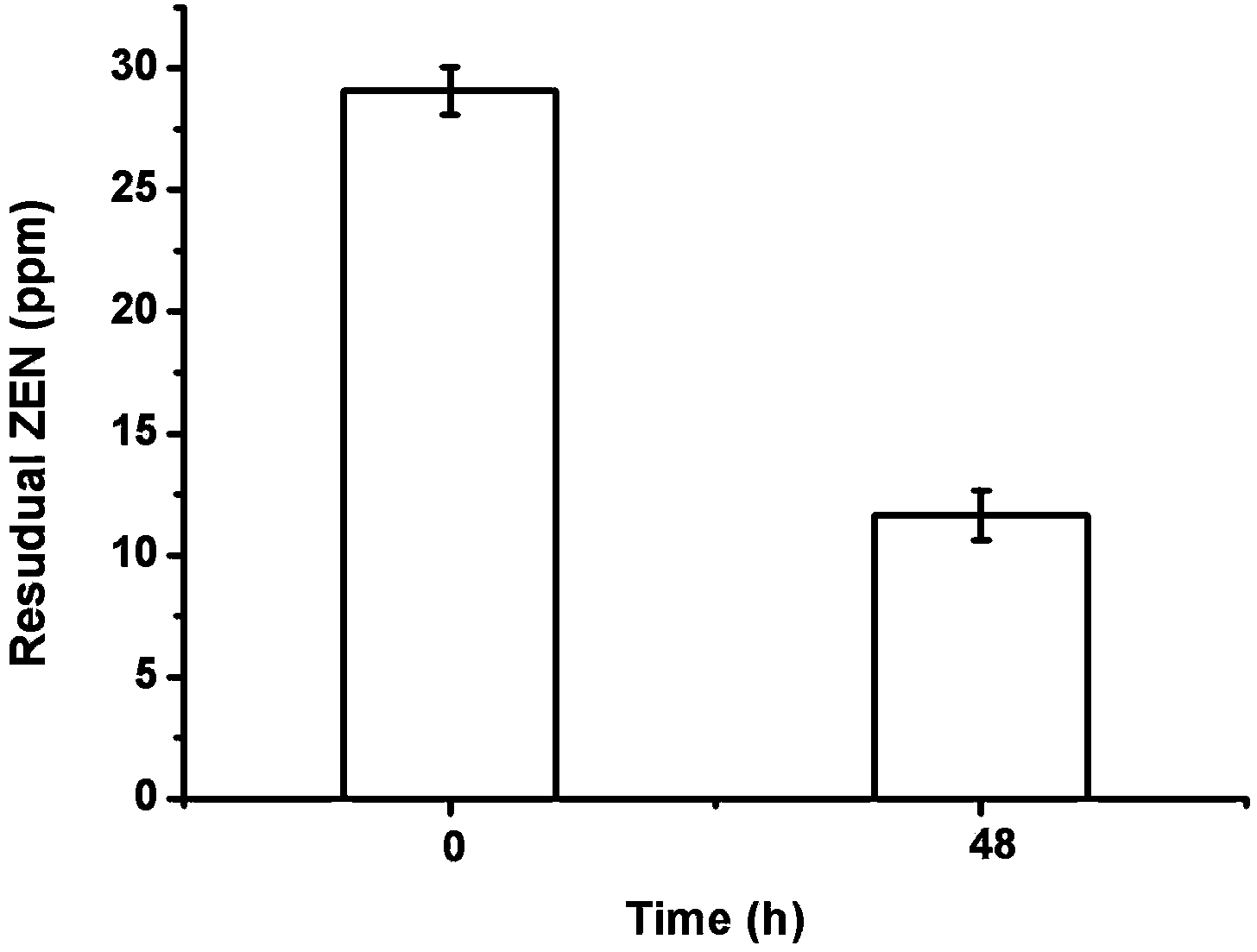

Food-grade aspergillus niger strain and application of strain in zearalenone degradation

ActiveCN103937681AReduce contentPromote degradationFungiMicroorganism based processesToxinAspergillus niger

The invention discloses a food-grade aspergillus niger strain FS-Z1 which is separated out from sauce grains and capable of preventing and treating zearalenone toxin. The collection number of the food-grade aspergillus niger strain FS-Z1 is CCTCC NO: M 2013703. The strain has excellent degradation effect on the zearalenone and the degradation rate reaches 89.56%. Besides, animal experiments in rats verify that the zearalenone in the corn steep liquor degraded by using an aspergillus niger fermentation liquor has no toxicity.

Owner:JIANGNAN UNIV

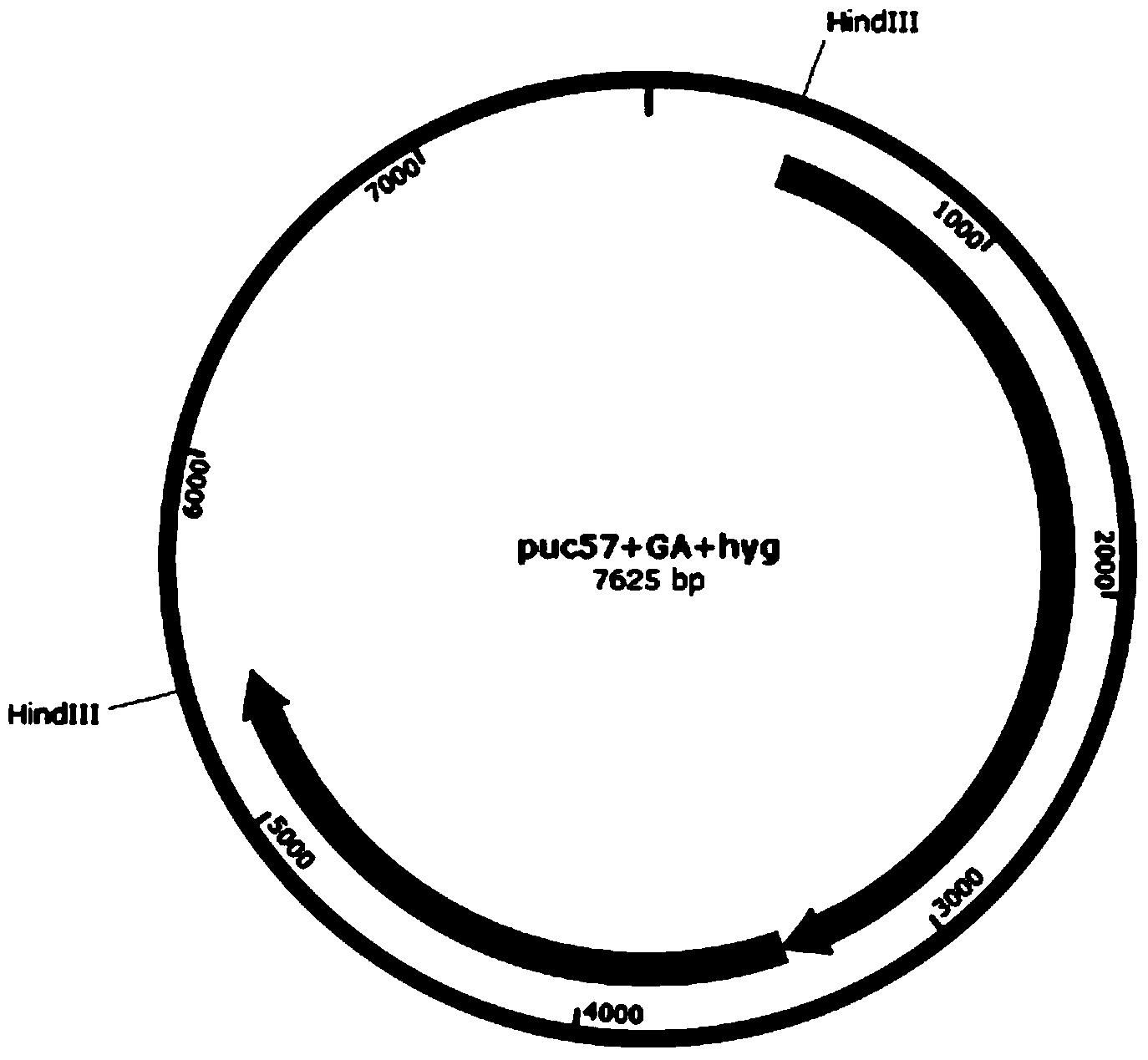

Recombination gene and method for increasing aspergillus niger expressed saccharifying enzyme

ActiveCN103937766AIncrease vitalitySave the process of screening transformantsFungiMicroorganism based processesTransformation efficiencyGene engineering

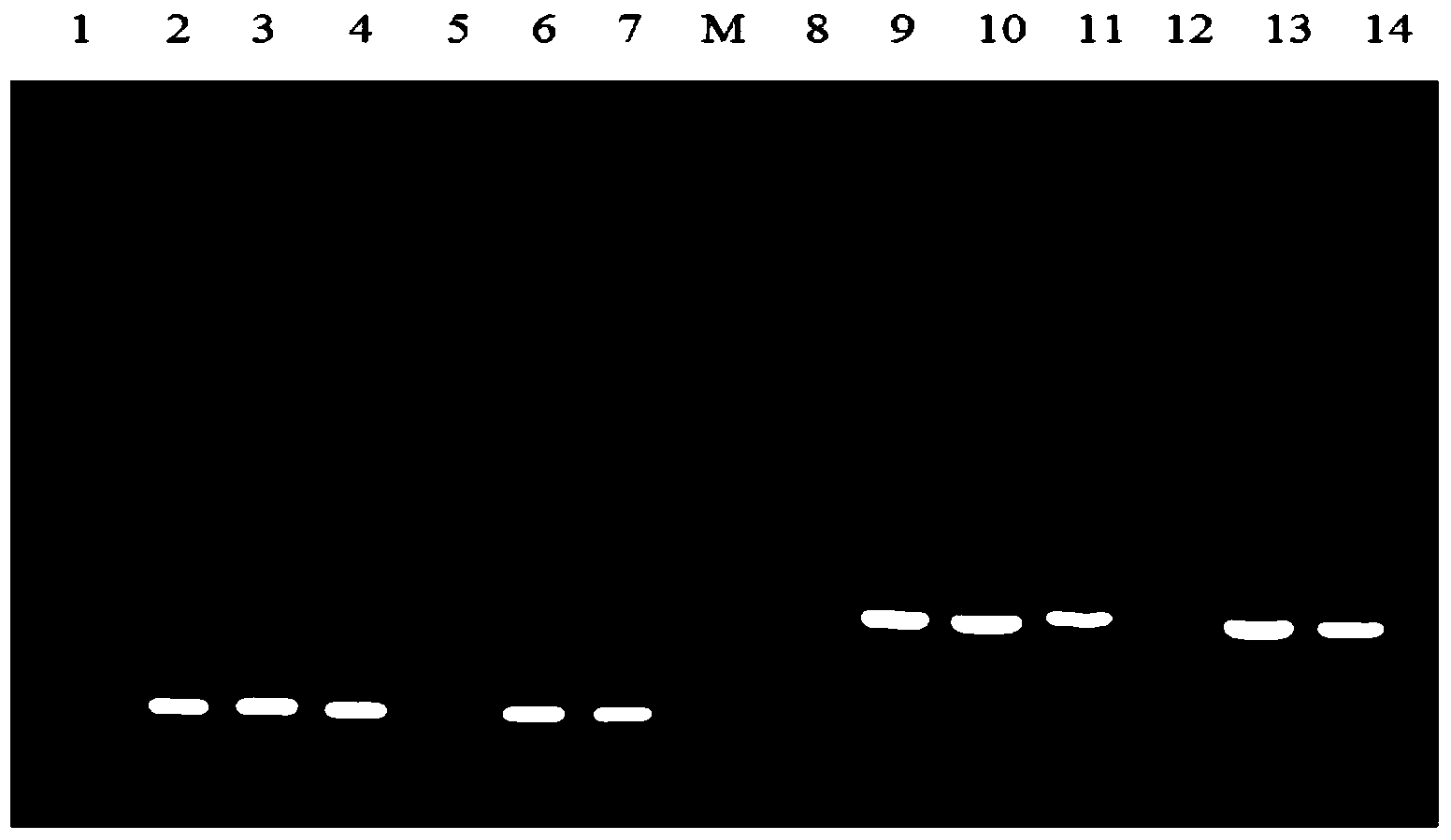

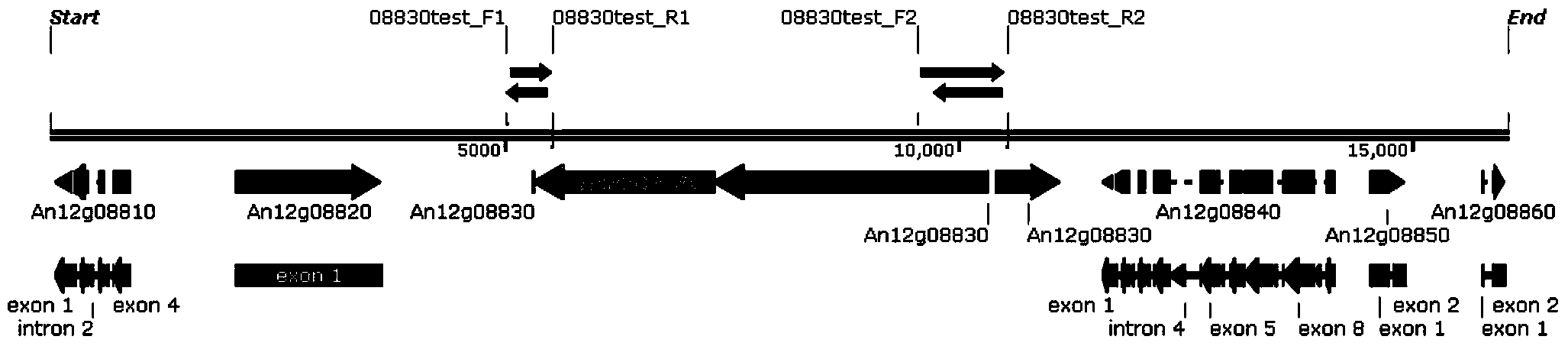

The invention belongs to the field of gene engineering, and discloses a recombination gene and a method for increasing aspergillus niger expressed saccharifying enzyme. The method for increasing aspergillus niger expressed saccharifying enzyme disclosed by the invention is as follows: by means of a homologous recombination method, a saccharifying enzyme expression cassette and selectable marker genes are integrated in an aspergillus niger An12g08830 gene locus in a targeted manner; then, saccharifying enzyme is obtained by recombining aspergillus niger through conventional resistance screening and fermentation cultivating. According to the invention, after the saccharifying enzyme expression cassette is integrated in the aspergillus niger An12g08830 gene locus in a targeted manner through the improved homologous recombination method, the conversion efficiency and the saccharifying enzyme expressing activity are obviously increased; furthermore, a lot of processes for screening converters are omitted.

Owner:NANJING BESTZYME BIO ENG CO LTD

Aspergillus oryzae and application thereof

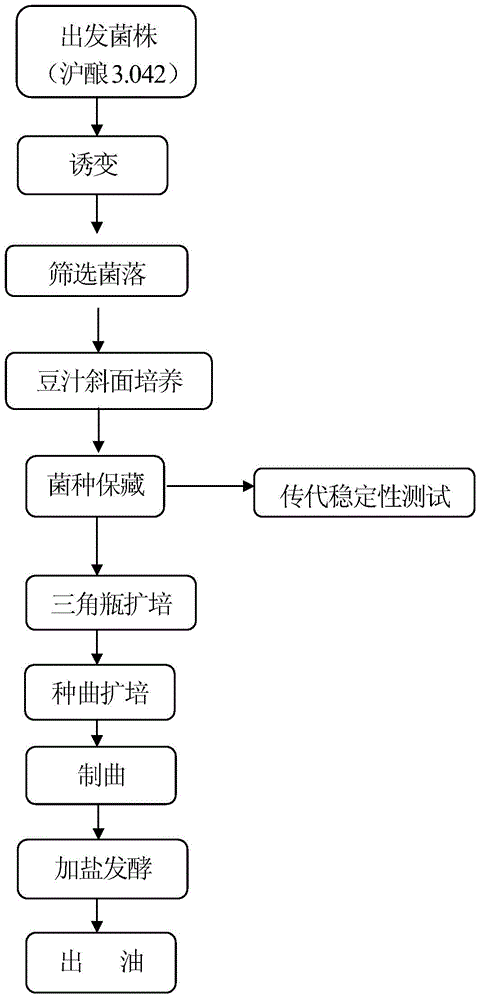

The invention discloses aspergillus oryzae zw102 with the CCTCC No. M2013386 and application of the aspergillus oryzae zw102 in preparation of soybean sauce or sauce. The embodiment proves that the bacterial strain has stable inheritance property and is easy to enlarge and culture; meanwhile the aspergillus oryzae zw102 has high activity of generating neutral protease, produces a small quantity of spores in a starter propagation stage, is beneficial to the maintenance of sanitation of workshop sites and avoids the flying of the spores; the aspergillus oryzae zw102 can be easily and uniformly mixed with saline water in a fermentation stage, so that the aspergillus oryzae zw102 is fully fermented, the utilization rate of the raw material can be increased, and the infectious microbe pollution is reduced, so that high-quality fermentative seasonings are stably obtained. The aspergillus oryzae zw102 is suitable for the large-scale industrial production of seasonings and has wide application prospect.

Owner:FOSHAN HAITIAN FLAVOURING & FOOD CO LTD +1

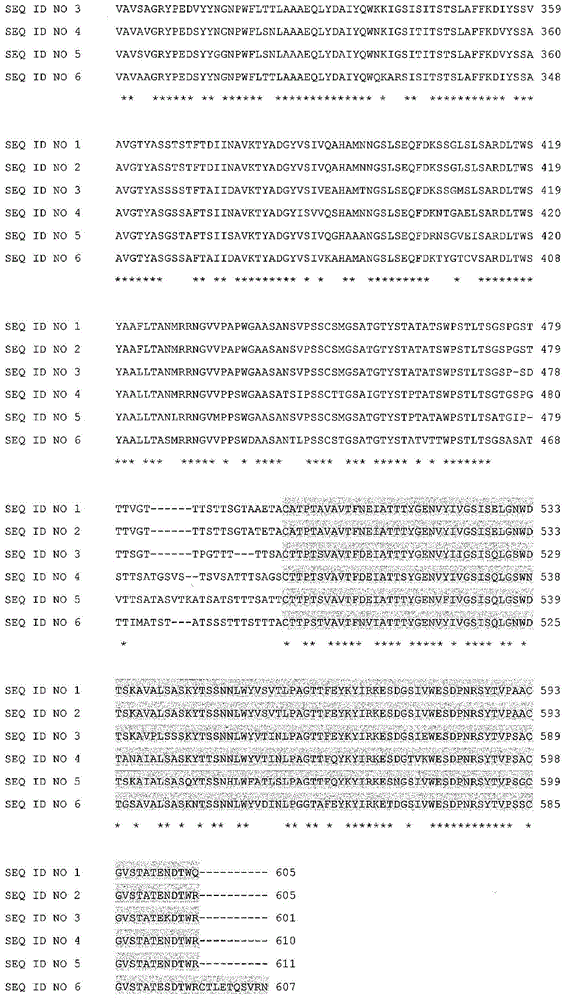

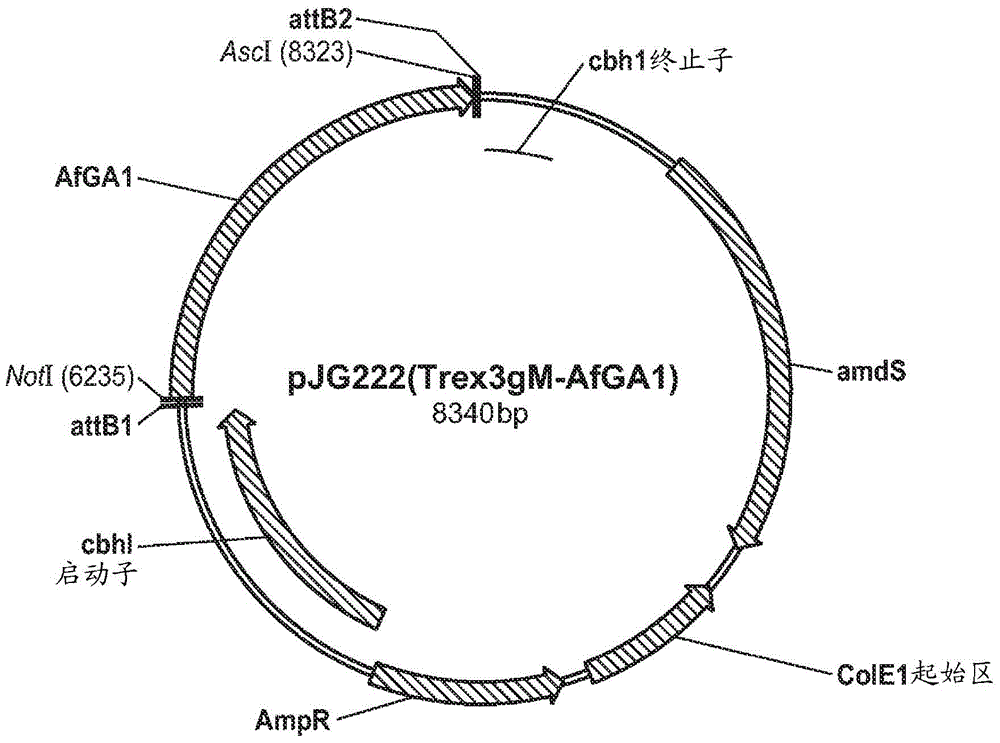

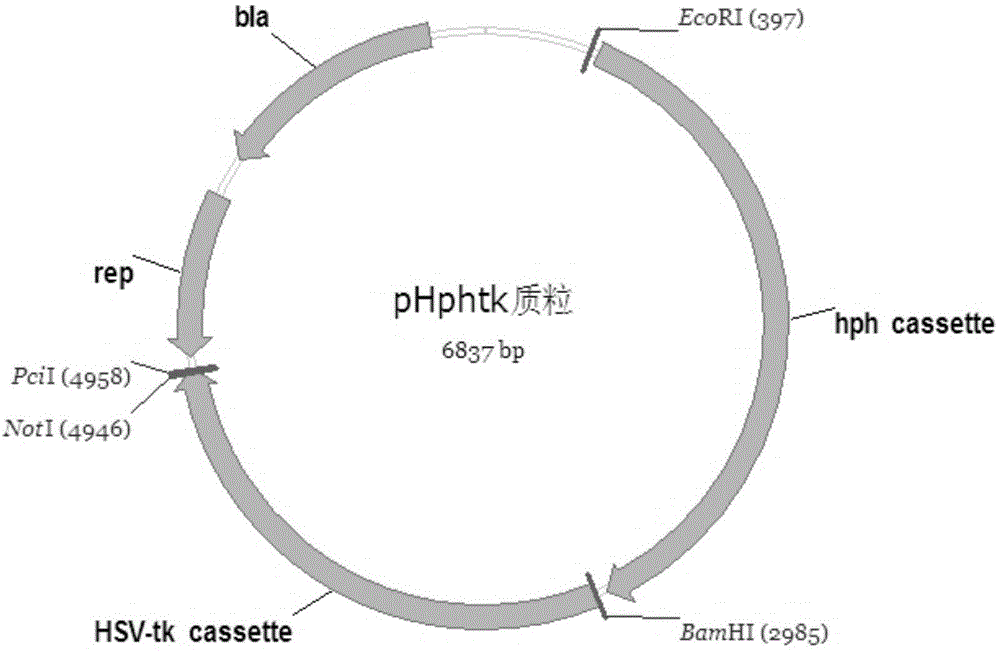

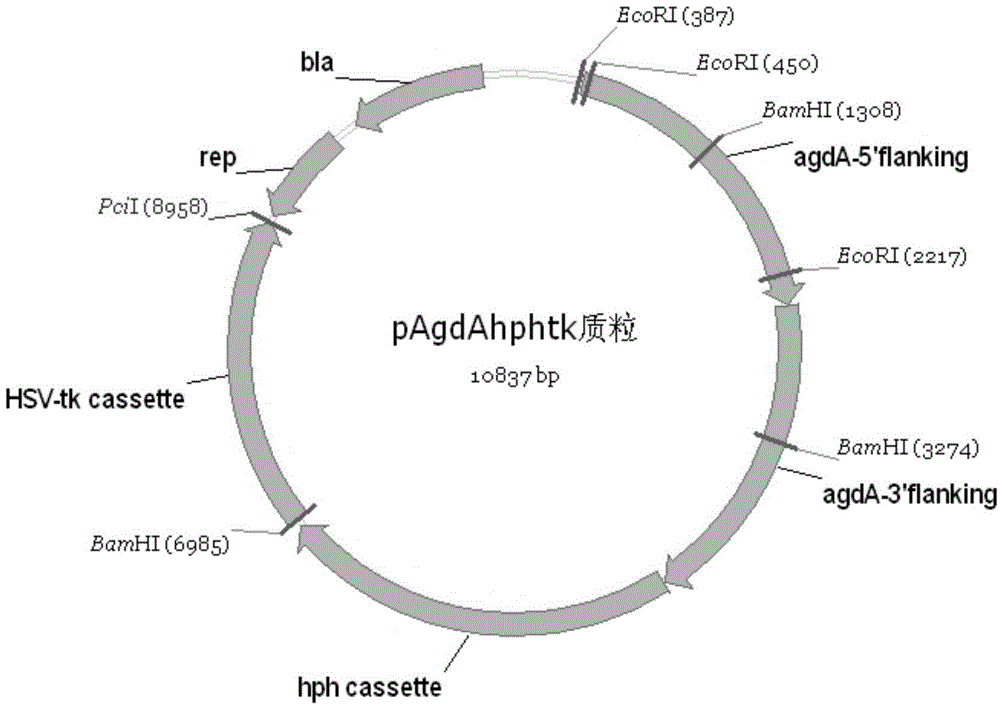

Trichoderma reesei host cells expressing a glucoamylase from aspergillus fumigatus and methods of use thereof

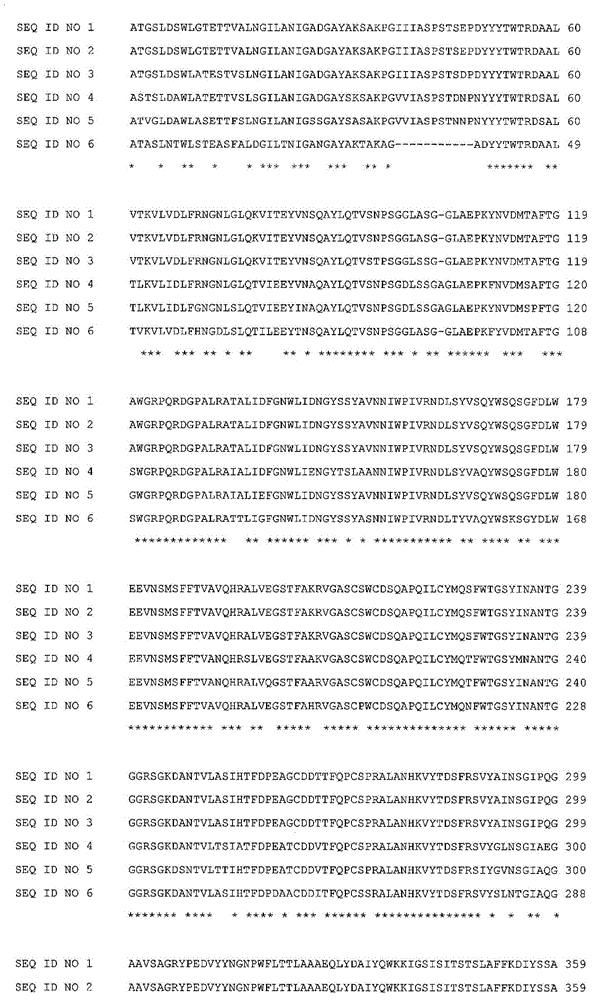

Fungal glucoamylases from Aspergillus fumigatus - expressed in Trichoderma reesei host cells (AfGATR) are provided. Trichoderma reesei host cells express AfGATRs at higher, or at least comparable, levels to natively expressed AfGA Aspergillus fumigatus. AfGATRs, including AfGA1TR and AfGA2TR, exhibit high activity at elevated temperatures and at low pH, so AfGATRs can be used efficiently in a process of saccharification in the presence of alpha-amylase, such as Aspergillus kawachii alpha-amylase (AkAA). AfGATRs advantageously catalyze starch saccharification to an oligosaccharide composition significantly enriched in DP1 (i.e., glucose) compared to the products of saccharification catalyzed by Aspergillus niger glucoamylase (AnGA) or native AfGA expressed in Aspergillus fumigatus. AfGATRs such as AfGA1TR, AfGA2TR or a variant thereof can be used at a lower dosage than AnGA and natively expressed AfGAs to produce comparable levels of glucose.

Owner:DANISCO US INC

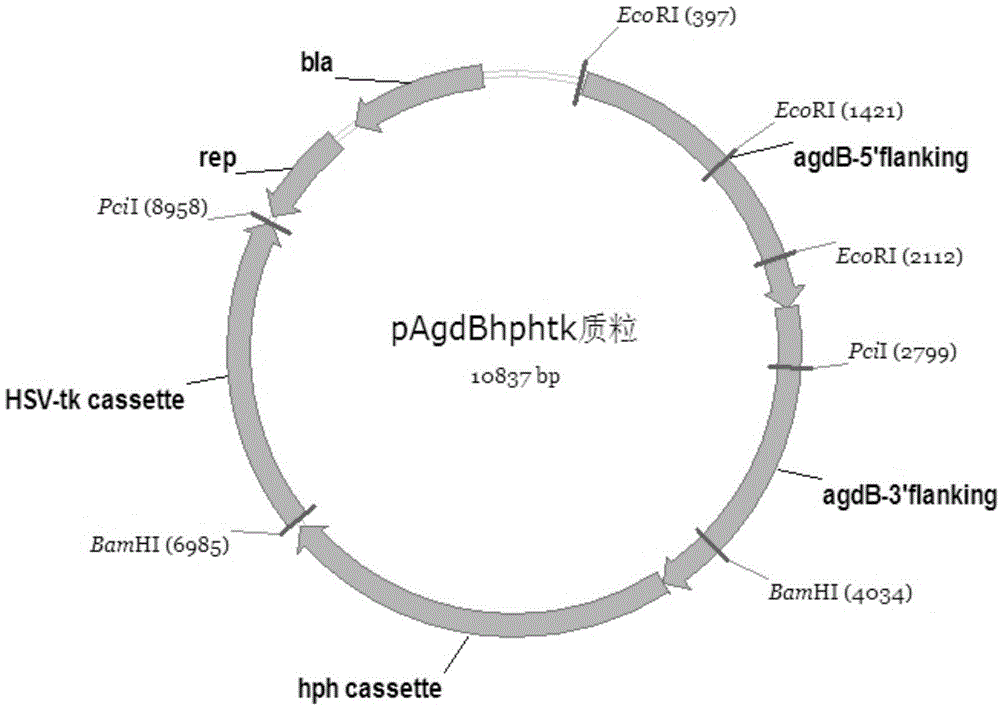

Method for enhancing glucose conversion rate of Aspergillus niger saccharifying enzyme

ActiveCN104962594AImprove conversion rateEliminate transglycosidase removal processMicroorganism based processesFermentationAlgluceraseSugar

The invention discloses a method for enhancing glucose conversion rate of an Aspergillus niger saccharifying enzyme. The composite of an agdB-gene-inactivated Aspergillus-niger-secreted saccharifying enzyme and a debranching enzyme is utilized to convert starch sugar. The alpha glucosaccharase agdB gene is inactivated to lower the saccharifying enzyme fermentation activity of Aspergillus niger, and the saccharifying enzyme can be directly compounded with the debranching enzyme to convert glucose, thereby obviously enhancing the DX value.

Owner:NANJING BESTZYME BIO ENG CO LTD

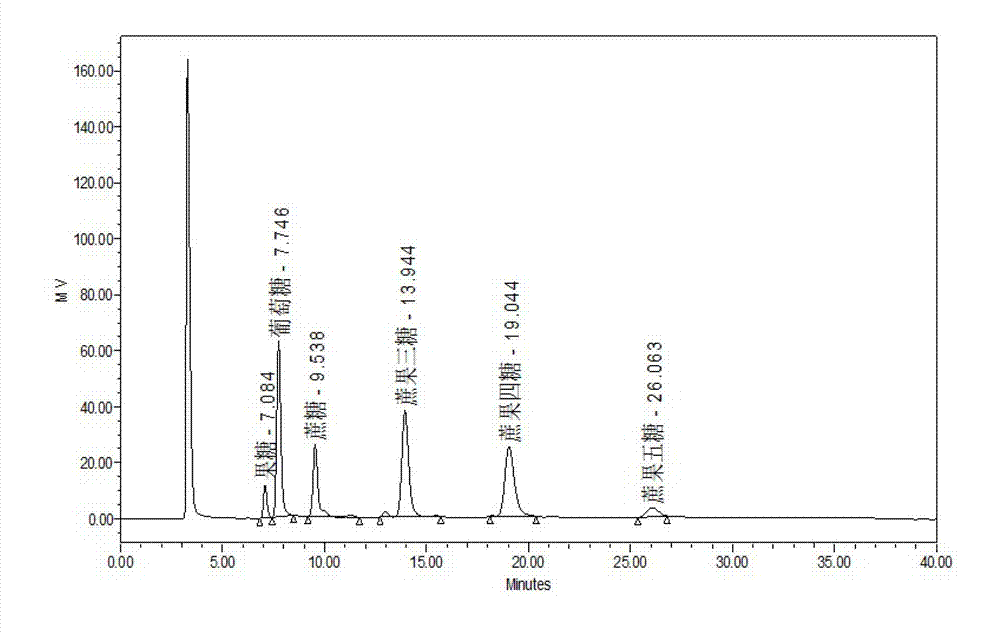

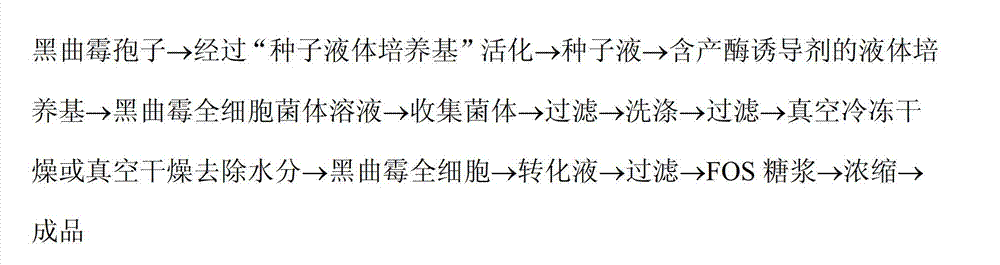

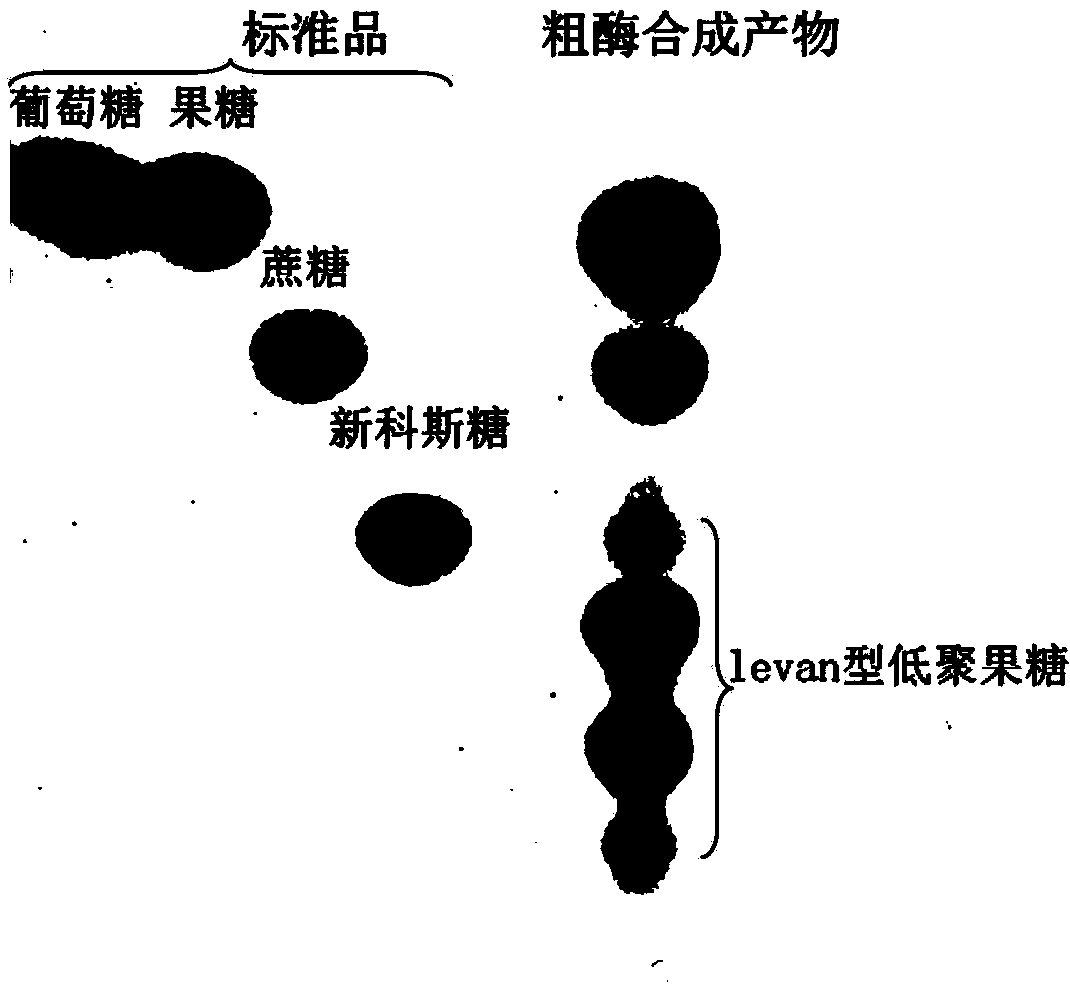

Aspergillus niger and method for catalytically producing fructo-oligosaccharide by virtue of whole-cells of aspergillus niger

ActiveCN103045489AEasy to prepareSimplify investmentFungiMicroorganism based processesTransformation efficiencyHigh pressure

The invention discloses aspergillus niger and a method for catalytically producing fructo-oligosaccharide by virtue of whole-cells of aspergillus niger. The aspergillus niger FOS-0620 is an aerobe, has black spores and milk-white hyphae, and is collected in China General Microbiological Culture Collection Centre (CGMCC for short) on September 28, 2012. The method for catalytically producing fructo-oligosaccharide by virtue of whole-cells of aspergillus niger comprises the following steps of: (1) preparing aspergillus niger whole-cells by virtue of the aspergillus niger FOS-0620 according to claim 1; and (2) catalytically producing fructo-oligosaccharide by virtue of the aspergillus niger whole-cells. The product obtained by the method disclosed by the invention is detected that the content (occupying total solids) of the fructo-oligosaccharide is not less than 50% via high-pressure liquid chromatography; and the method disclosed by the invention is simple in process, convenient to operate, high in enzymatic activity, high in conversion efficiency, and important in industrial value.

Owner:SOUTH CHINA UNIV OF TECH

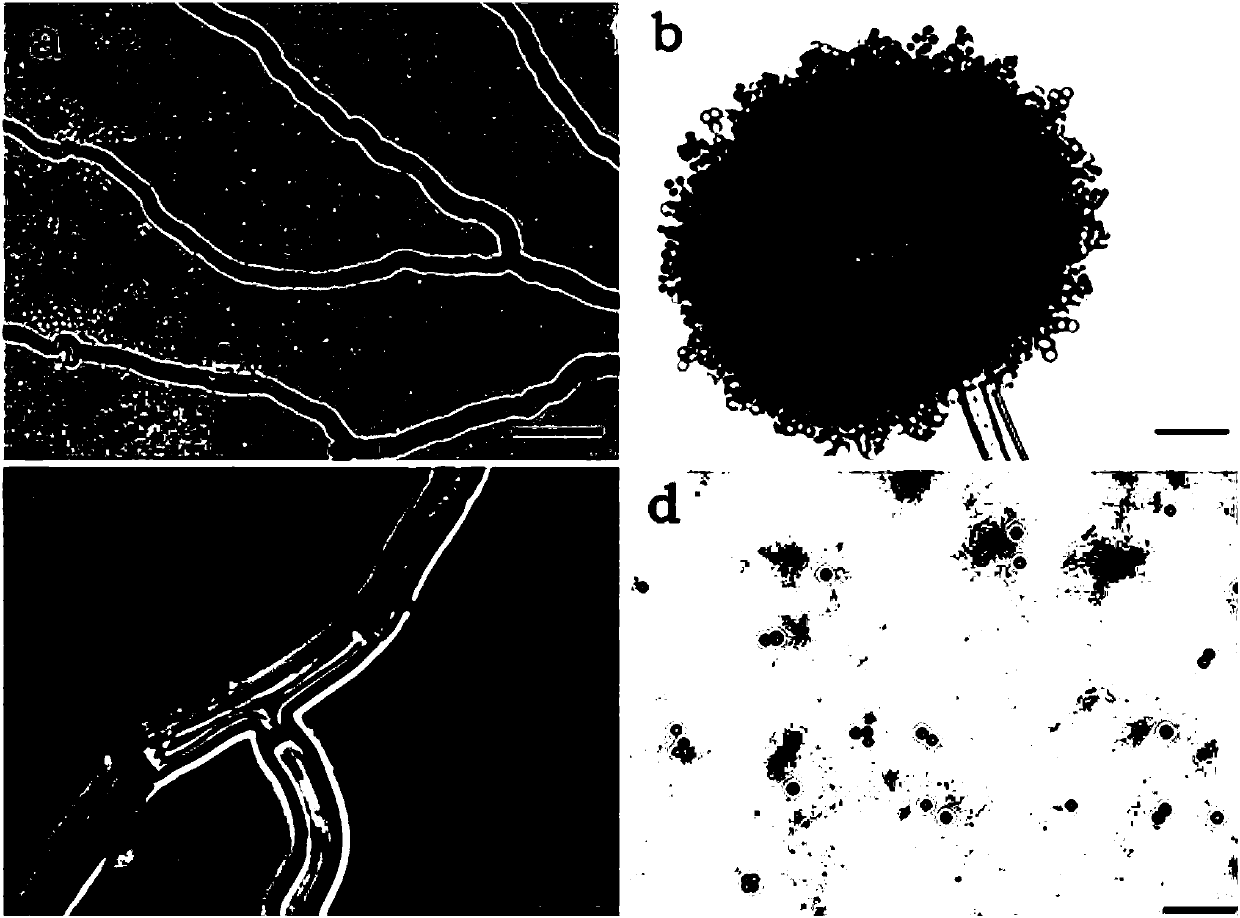

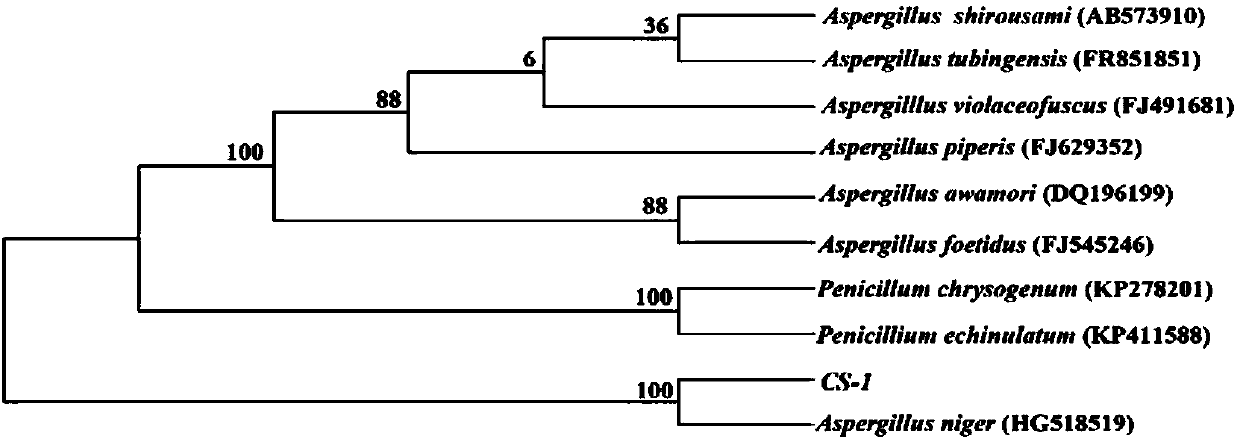

Preparation and application of aspergillus niger used for phosphate degrading, potassium degrading and cellulose degradation and microbial agent of aspergillus niger

ActiveCN107858296AEfficient phosphorus dissolving abilityEfficient Potassium Solubilizing AbilityFungiBio-organic fraction processingCelluloseMicrobial agent

The invention relates to preparation and application of aspergillus niger used for phosphate degrading, potassium degrading and cellulose degradation and a microbial agent of the aspergillus niger. The CS-1strain has the ability to degrade phosphorus and potassium and degrade cellulose efficiently; the CS-strain 1 can play a role in phosphate degrading, potassium degrading and cellulose degradation when the roots of wheat, cucumber, apple and other crops are stable; the microbial agent prepared from the strain can significantly promote the growth of the crops, can be applied to the productionof microbial fertilizers. The aspergillus niger has important significance in effectively reducing the use amount of chemical fertilizers, enhancing the soil fertility, increasing the crop yield and promoting the direct return of straw to the field.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

Production technology of aspergillus oryzae fermented soybean meal

InactiveCN103859150AIncrease crude protein contentReasonable compositionAnimal feeding stuffFiberPhytase

The invention discloses a production technology of aspergillus oryzae fermented soybean meal. The production technology comprises the following steps: (1) aspergillus oryzae strain activation; (2) aspergillus oryzae strain liquid culture; (3) aspergillus oryzae strain culture in a triangular flask; and (4) soybean meal fermentation. The production technology is simple and easy to understand, the produced soybean meal is a main protein raw material of animal feeds, and has the advantages of high crude protein content, reasonable amino acid composition, high animal digestion utilization rate and the like. Aspergillus oryzae also can produce amylase, saccharifying enzyme, cellulase, phytase and the like, and under the action of protease, nondigestible macromolecular proteins are degraded into peptone, peptides and various amino acids, and so that crude fiber, phytic acid and other matters, which are difficult to absorb, in accessories can be degraded, and the nutritional value, health function and digestive rate can be improved.

Owner:QINGDAO ZHONGREN PHARMA

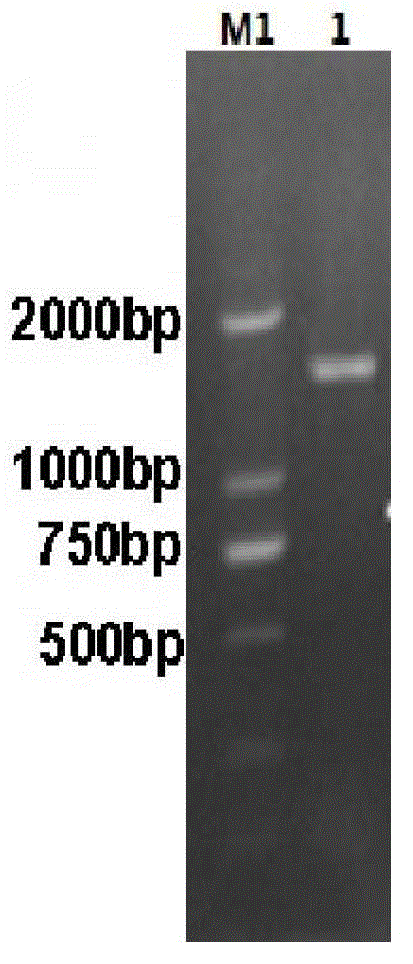

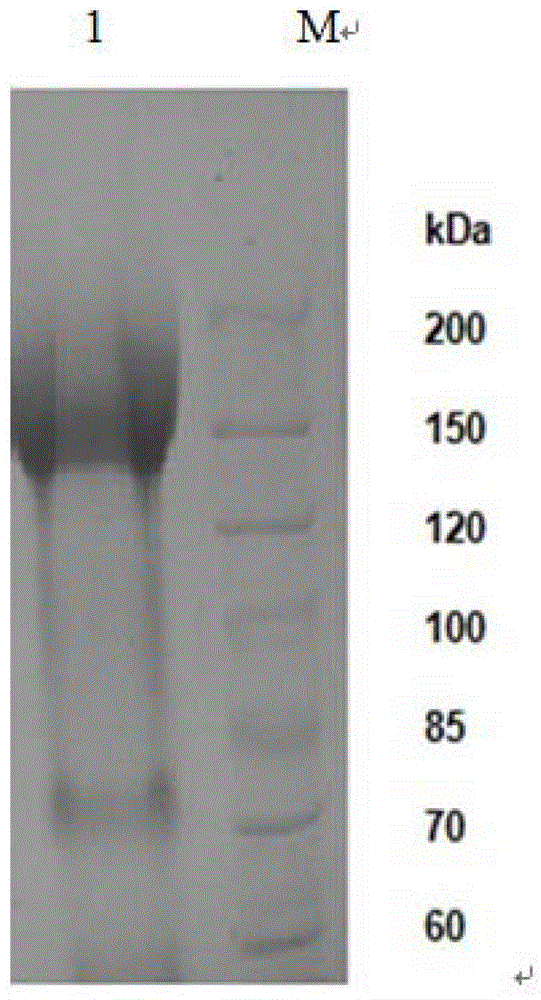

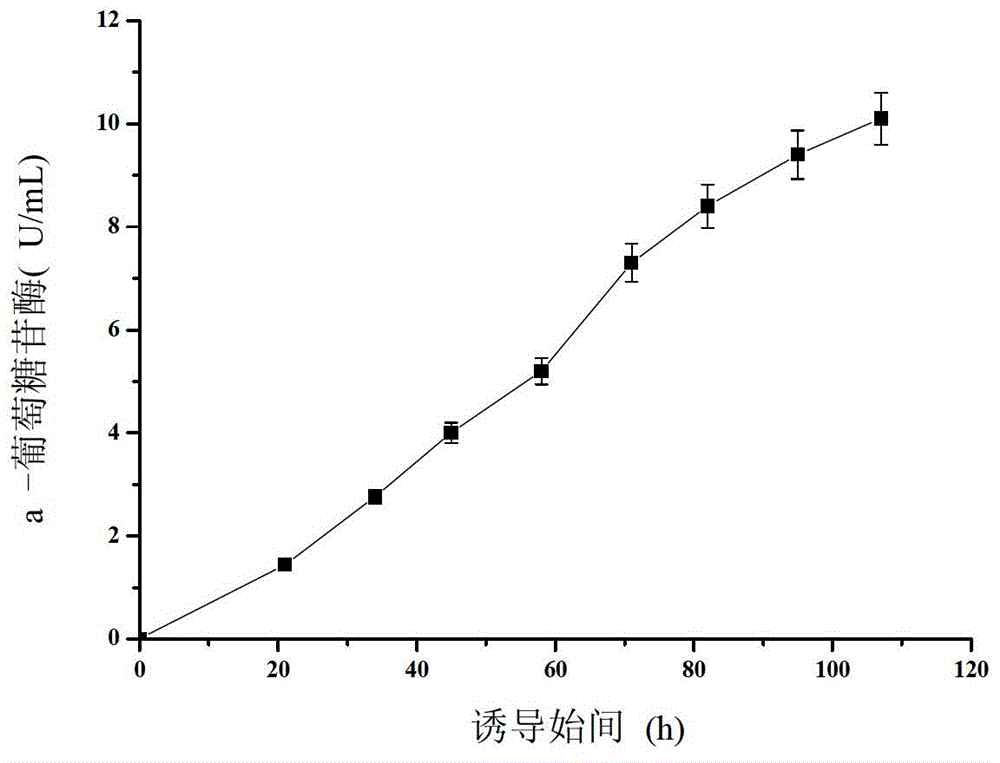

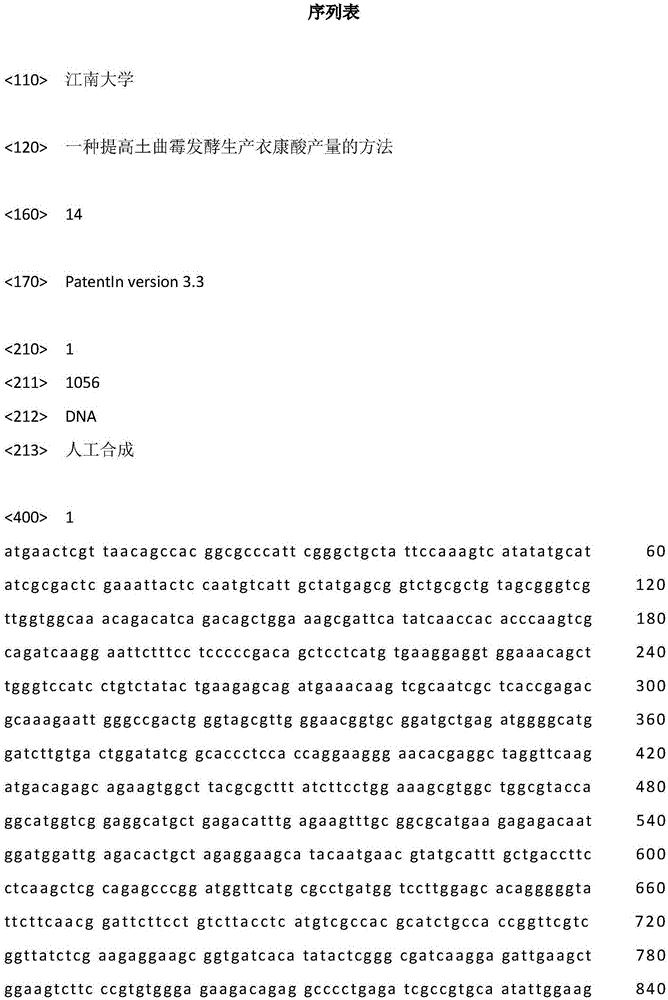

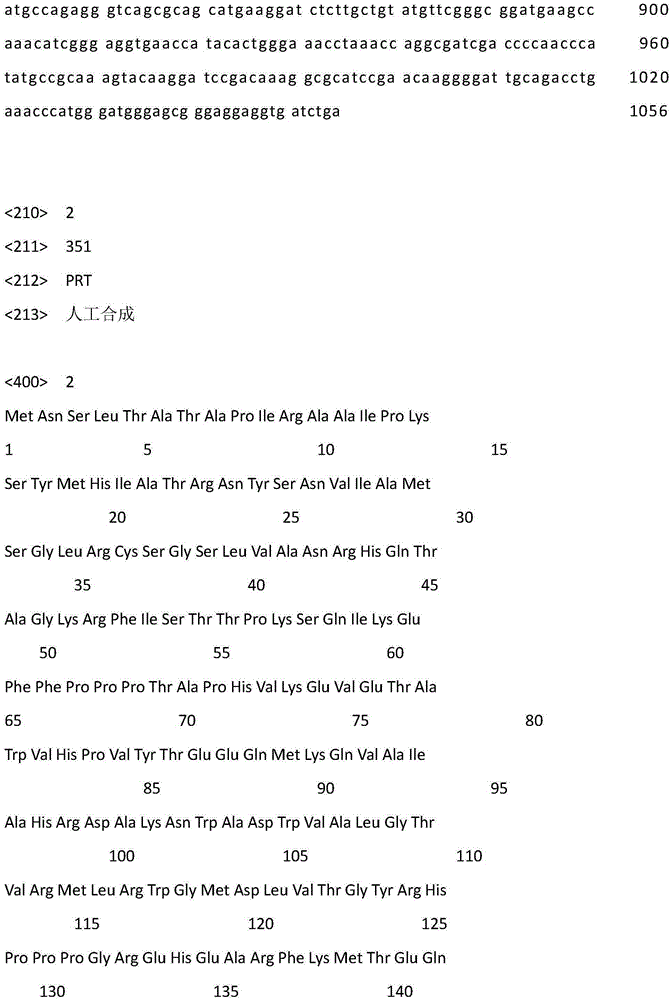

Aspergillus niger alpha-glucosidase gene and high-efficiency expression method thereof

The invention discloses an aspergillus niger alpha-glucosidase aglu<OP> and a high-efficiency expression method of the aspergillus niger alpha-glucosidase aglu<OP> in pichia pastoris. The nucleotide sequence of the optimized alpha-glucosidase gene is shown in SEQ ID No.1. The gene is constructed into a pichia pastoris expression vector, and the pichia pastoris expression vector and disulphide bond isomerase are transformed into the pichia pastoris for co-expression, and the enzyme activity of the alpha-glucosidase gene can be up to 10.1U / mL after induction is carried out for 110 hours in a 3L tank, and is 2.9 times of the enzyme cavity before optimization. The optimized alpha-glucosidase gene can be used for industrial production of the alpha-glucosidase.

Owner:JIANGNAN UNIV

Lactic acid fermented soybean paste

InactiveCN105231138AAvoid discomfortFull of nutritionNatural extract food ingredientsFood preparationYeastVillosa choctawensis

The invention discloses lactic acid fermented soybean paste. The soybean paste is prepared from, by weight, 400-430 parts of soy beans, 130-150 parts of corn germ, 10-12 parts of lactobacillus bulgaricus, 10-15 parts of aspergillus oryzae, 7-10 parts of aspergillus niger and 7-8 parts of active dry yeast. A preparation method of the lactic acid fermented soybean paste comprises the steps of firstly, using lactic acid for fermenting part of the soy beans, obtaining lactic acid soy beans which are richer in nutrition, and then fabricating the soybean paste with the lactic acid soy beans and the remaining soy beans. The soybean paste is good in taste and rich in nutrition, extracting solutions of traditional Chinese medicinal materials such as mint, kudzu vine roots, cassia twigs and momordica grosvenori are added, a certain heat-clearing and detoxifying effect is achieved, and illness caused by excessive internal heat can be avoided when the soybean paste is eaten.

Owner:合肥刘老四调味品厂

Method for producing ethyl alcohol through crop stalks by use of recombinant zymomonas mobilis

InactiveCN105368882AIncrease productionImproving the Efficiency of Using Straw to Produce EthanolMicroorganismsBiofuelsTrichoderma sp.Alcohol production

The invention provides a method for producing ethyl alcohol through crop stalks by use of recombinant zymomonas mobilis. According to the method, the crop stalks are used as a base material, aspergillus niger and trichoderma are mixed and fermented to produce a crude enzyme solution containing cellulase, the crop stalks are processed through the crude enzyme solution to enable cellulose in the crop stalks to be decomposed to produce reducing sugar, and finally recombinant zymomonas mobilis is used for fermenting the enzymatically-decomposed reducing sugar to produce ethyl alcohol. In the method, fermentation products of aspergillus niger and trichoderma are mixed according to the ratio of 1: 1 to obtain the cellulase crude enzyme solution, so that the product feedback inhibition is effectively controlled, and the cellulase crude enzyme with higher activity and yield is obtained. As zymomonas mobilis is inoculated in the enzymatically-decomposed fermentation liquor containing reducing sugar, the ethyl alcohol production efficiency through the crop stalks by use of zymomonas mobilis is greatly improved, and defects that the use range of a zymomonas mobilis substrate is narrow, and the crop stalks cannot be effectively utilized are overcome. According to the method, the conversion rate of ethyl alcohol through the crop stalks is 5%, that is, 100 g of the crop stalks can produce 5 g of ethyl alcohol.

Owner:HUBEI UNIV OF TECH

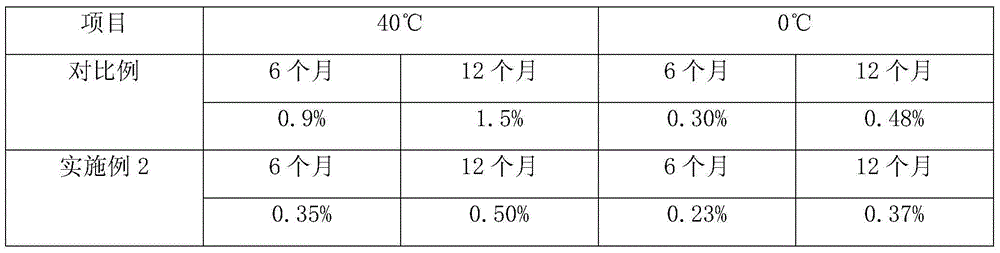

Acid protease containing compound enzyme of soy sauce and preparation method of acid protease containing compound enzyme of soy sauce

InactiveCN105524905AEnsure food safetyIncrease profitHydrolasesLyasesEscherichia coliGeneration rate

The invention discloses an acid protease containing compound enzyme of soy sauce. The acid protease containing compound enzyme of the soy sauce is prepared by taking proteases containing high-activity acid proteases and other food-grade enzymic preparations as main materials and scientifically compounding the main materials with high-activity acid proteases, mould cultures, plant extracts containing various plant enzyme systems, spice extracts, novasil, a protective agent, an activating agent, an antioxidant and the like, wherein the mould cultures have functions of inhibition of growth and propagation of aspergillus flavus and escherichia coli and decomposition of aflatoxin; the spice extracts are effective in inhibition of aspergillus flavus, bacillus subtilis, staphylococcus aureus and escherichia coli and not effective in inhibition of aspergillus niger and aspergillus oryzae and have functions of aroma enhancement and flavoring; the protective agent is capable of evidently improving storage stability of the compound enzyme of the soy sauce. The prepared compound enzyme of the soy sauce has the advantages of complete enzyme system, high enzyme activity, high stability, high potency and high food safety. The soy sauce yield can be remarkably increased by 24%, and a total nitrogen utilization rate and an amino acid generation rate of brew sauce are increased by 16.5% and 18.4% respectively.

Owner:湖南新鸿鹰生物工程有限公司

Aspergillus niger and cultivation method and application thereof

ActiveCN104130950AImprove the ability to convert into fructo-oligosaccharidesIncrease vitalityFungiTransferasesMicroorganismMicrobiology

The invention relates to an Aspergillus niger and a cultivation method and application thereof. The Aspergillus niger BLCY-02 is collected in the China General Microbiological Culture Collection Center on 15th, July in 2014 and has the collection number of CGMCC No.9449. The invention also relates to a cultivation method and application of the Aspergillus niger.

Owner:SHANDONG BAILONG CHUANGYUAN BIO TECH

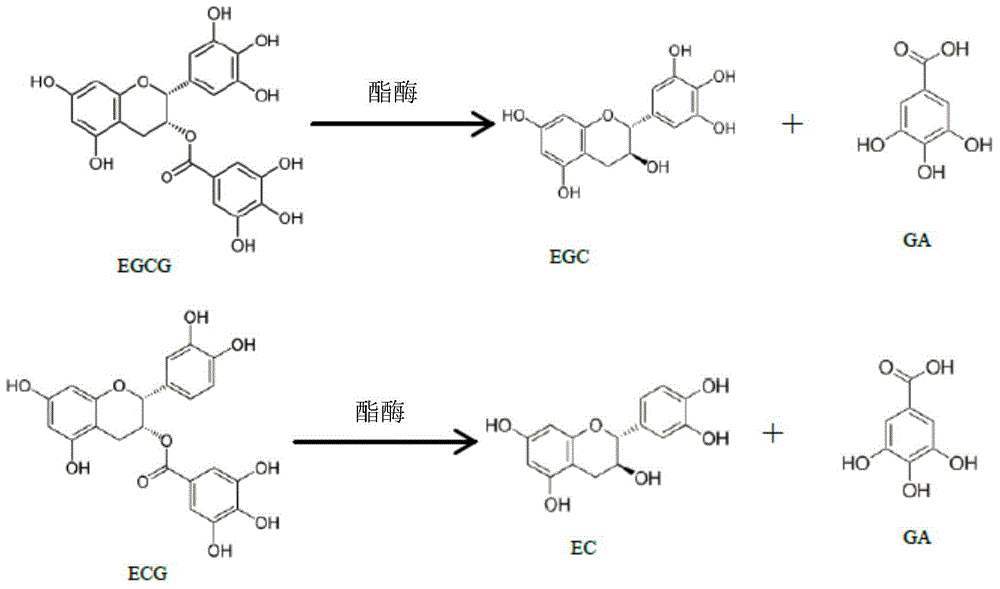

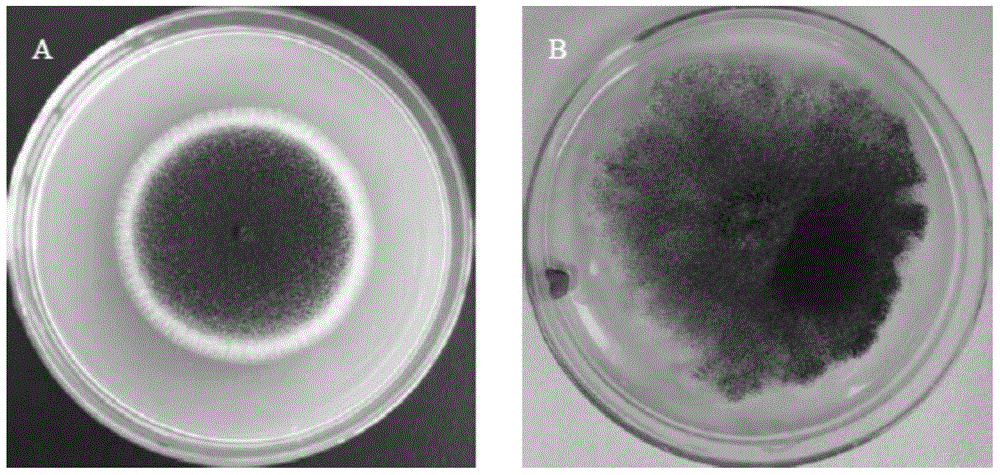

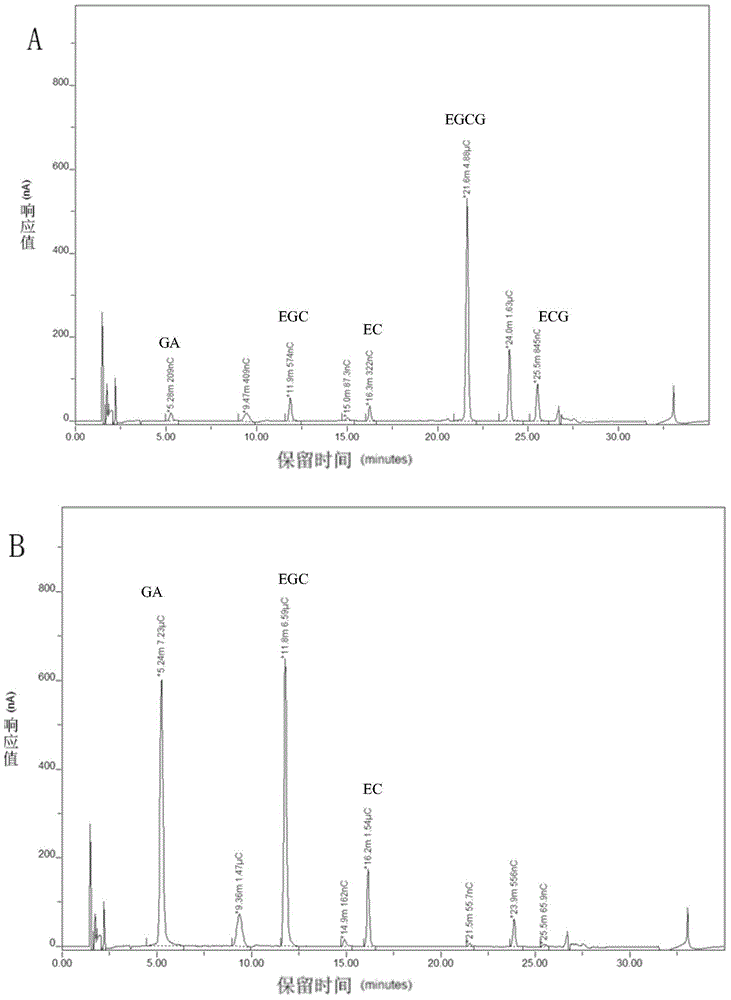

Method for producing epigallocatechin and gallic acid through transformation of aspergillus niger whole cell

ActiveCN104673845AImprove toleranceEfficient conversionMicroorganism based processesFermentationGallic acid esterDipotassium phosphate

The invention discloses a method for producing epigallocatechin and gallic acid through transformation of aspergillus niger whole cell. The whole cell biotransformation is performed by adopting the aspergillus niger; the whole cell biotransformation nutrient solution is a nutrient solution containing 1-20% of tea polyphenol or EGCG; the preservative number of the aspergillus niger RAF 106 strain is CGMCC NO.9608. The whole cell biotransformation nutrient solution comprises the following ingredients: 1-20% of tea polyphenol or EGCG, 0.03-0.8% of dipotassium phosphate, 0.1-3% of monopotassium phosphate, 0.03-0.7% of manganese sulfate, 0.3-2% of sodium chloride, 0.01-0.3% of magnesium sulfate and 0.02-2% of yeast or malt extract. By adopting the nutrient solution, the whole cell is transformed in one step, the transforming efficiency is high and the transformation can be finished within 20 hours, and the killing activity of the transformed product on the colon cancer cell is high.

Owner:SOUTH CHINA AGRI UNIV

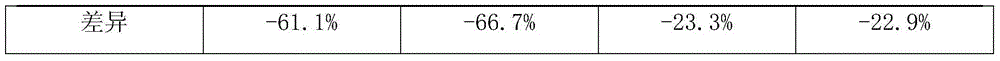

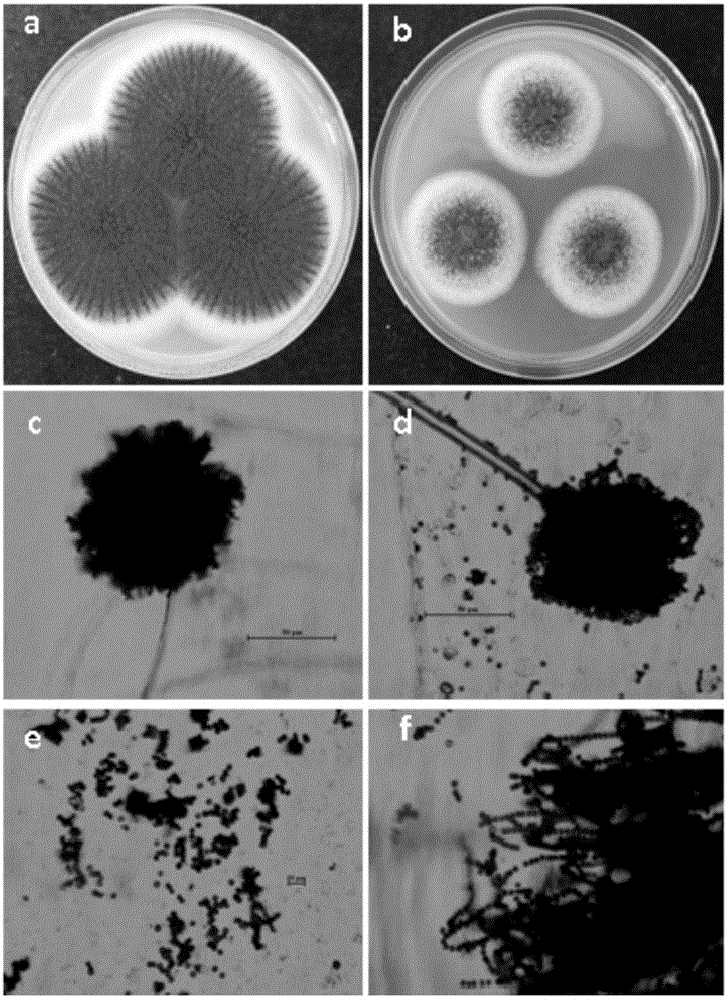

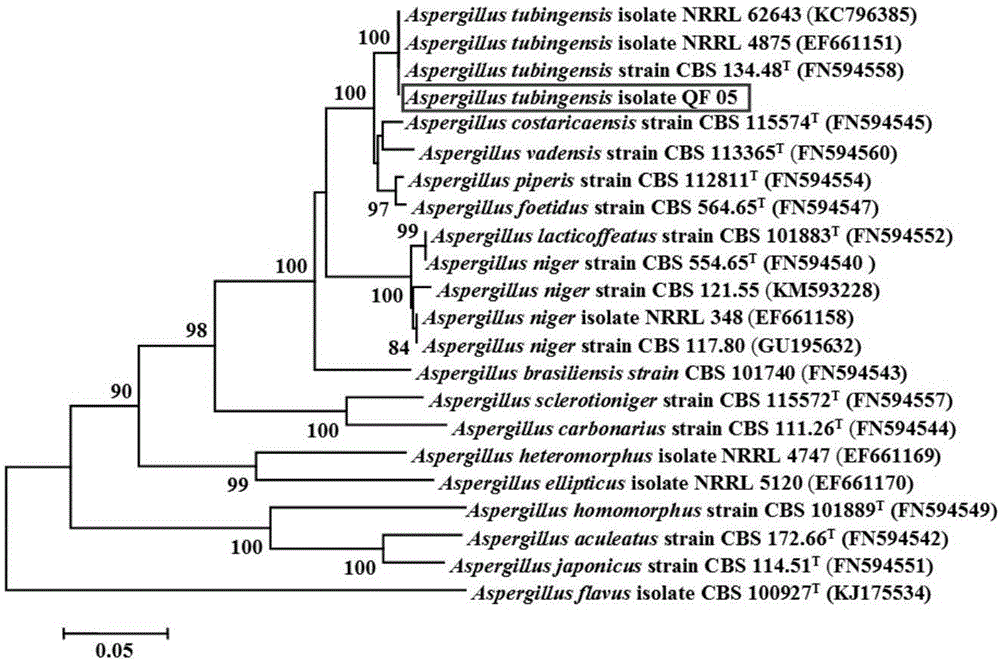

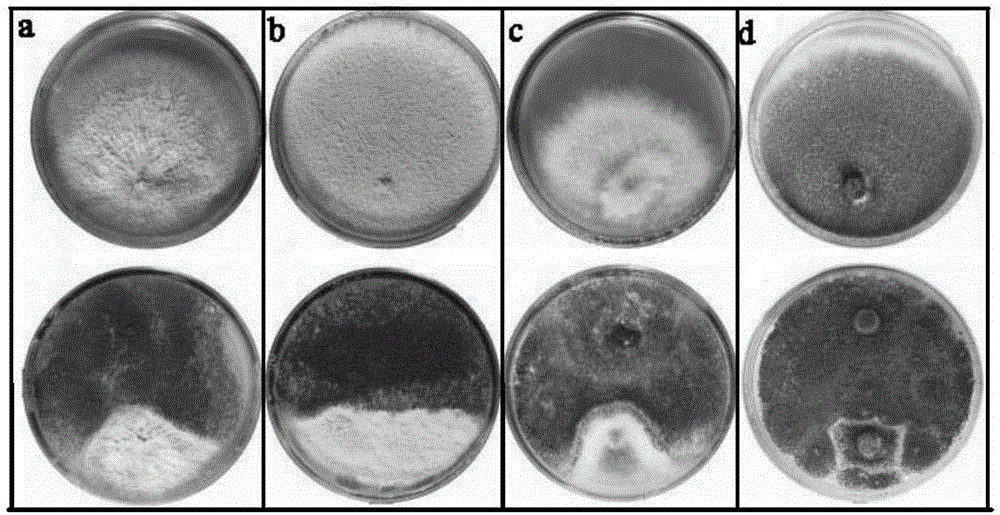

Aspergillus tubingensis with disease prevention and growth promoting functions as well as preparation and application of aspergillus tubingensis metabolites

The invention discloses aspergillus tubingensis with disease prevention and growth promoting functions as well as preparation and an application of aspergillus tubingensis metabolites. The bacterial strain No. of aspergillus tubingensis is QF05, and the registration No. of aspergillus tubingensis in CGMCC (China general microbiological culture collection center) is CGMCC No.13563. Aspergillus tubingensis QF05 has an inhibition function on botrytis cinerea, colletotrichum capsici, fusarium wilt of cucumbers, alternaria solani and pseudomonas syringae pv.lachrymans. Sterile fermentation filtrate of aspergillus tubingensis QF05 can remarkably increase the germination rate of pepper seeds and promote elongation of radicle. Aspergillus tubingensis QF05 metabolites containing bacteria effectively promote growth of true leaves of cucumbers and effectively increase the plant height and the yield of the cucumbers.

Owner:北京奥沃伽科技有限公司

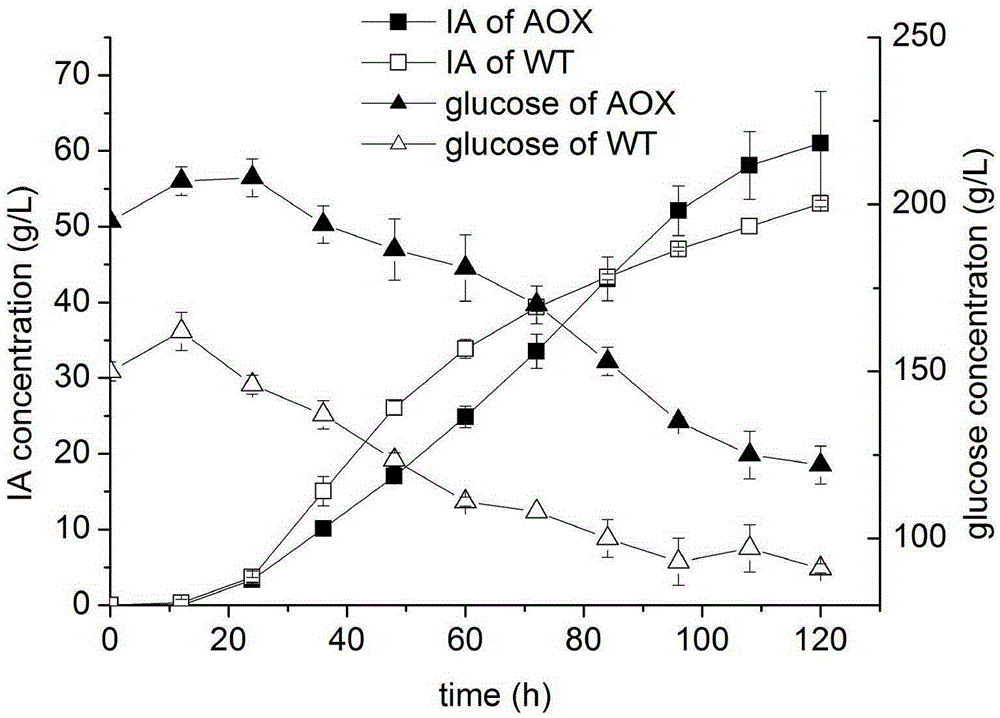

Method for increasing yield of itaconic acid produced by fermentation of aspergillus terreus

ActiveCN105274153AIncrease productionEnhanced Glycolytic PathwayFungiMicroorganism based processesItaconic acidFermentation

The invention belongs to the technical field of bioengineering and discloses a method for increasing yield of itaconic acid produced by fermentation of aspergillus terreus. By adoption of acid-induced promoters derived from aspergillus niger, lateral respiratory chain protein AOX of the aspergillus niger is introduced into the aspergillus terreus to improve supply of an intracellular NAD+ bank, and accordingly glycolytic pathway can be enhanced to realize increase of itaconic acid yield. The itaconic acid yield of recombinant aspergillus terreus strains obtained by the method is increased by about 20% to reach 60g / L. The method provides a fresh idea for itaconic acid production.

Owner:JIANGNAN UNIV

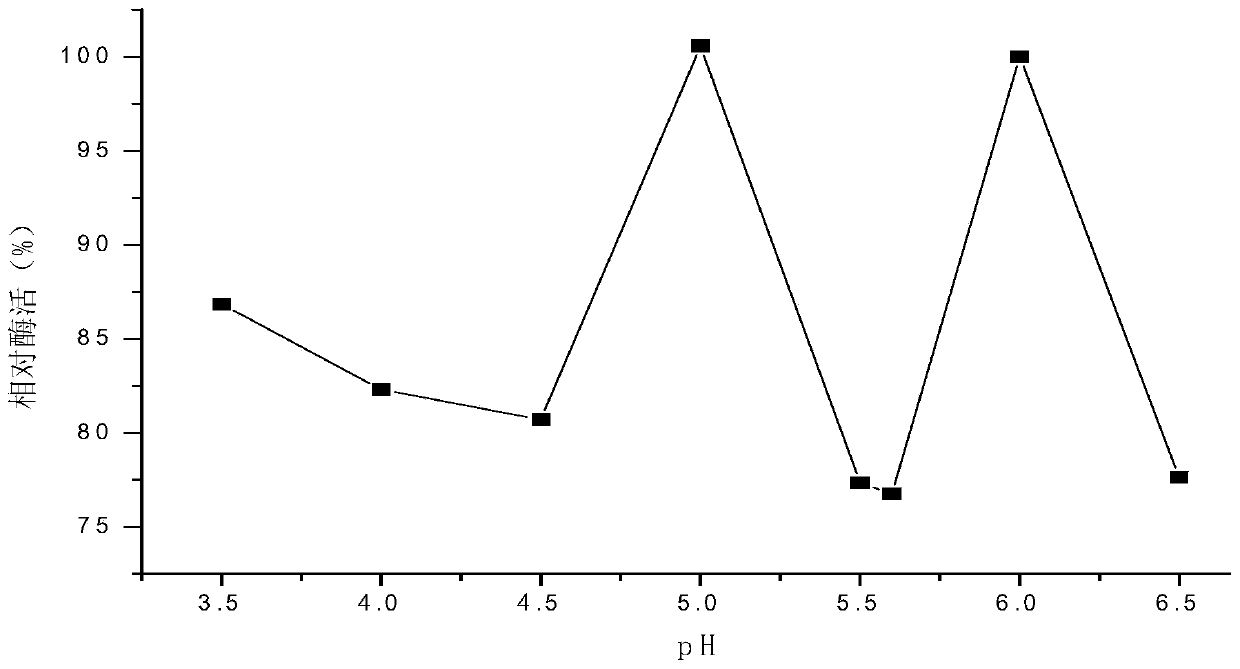

High xylanase yield Aspergillus niger and application thereof

ActiveCN103992954AImprove toleranceIncrease vitalityFungiMicrobiological testing/measurementEnzyme inhibitionReaction temperature

The present invention discloses high xylanase yield Aspergillus niger and an application thereof, wherein the Aspergillus niger SM24 / a has the preservation number of CGMCC No.8671. According to the present invention, the Aspergillus niger SM24 / a can produce xylanase providing good tolerance for ethanol, acetic acid, furfural, vanillin, ferulic acid and a mixture of the above materials, the xylanase production activity of the strain is high, the solid fermentation enzyme activity of the xylanase can be up to 10801 IU / g (catalysis production of 1 [mu]mol of xylose within 1 min is defined as an enzyme unit), the optimum pH value is 5.6, the optimum reaction temperature is 37 DEG C, and the 50 DEG C enzyme activity remaining rate is 79.01%; and 5-hydroxymethyl furfural provides an inhibition effect for the enzyme, and the concentration and the enzyme inhibition rate present a certain linear relationship when the 5-hydroxymethyl furfural exists in a separate or mixed manner, such that the xylanase can further be used as the qualitative even quantitative indicator of the 5-hydroxymethyl furfural concentration.

Owner:杨凌未来中科环保科技有限公司

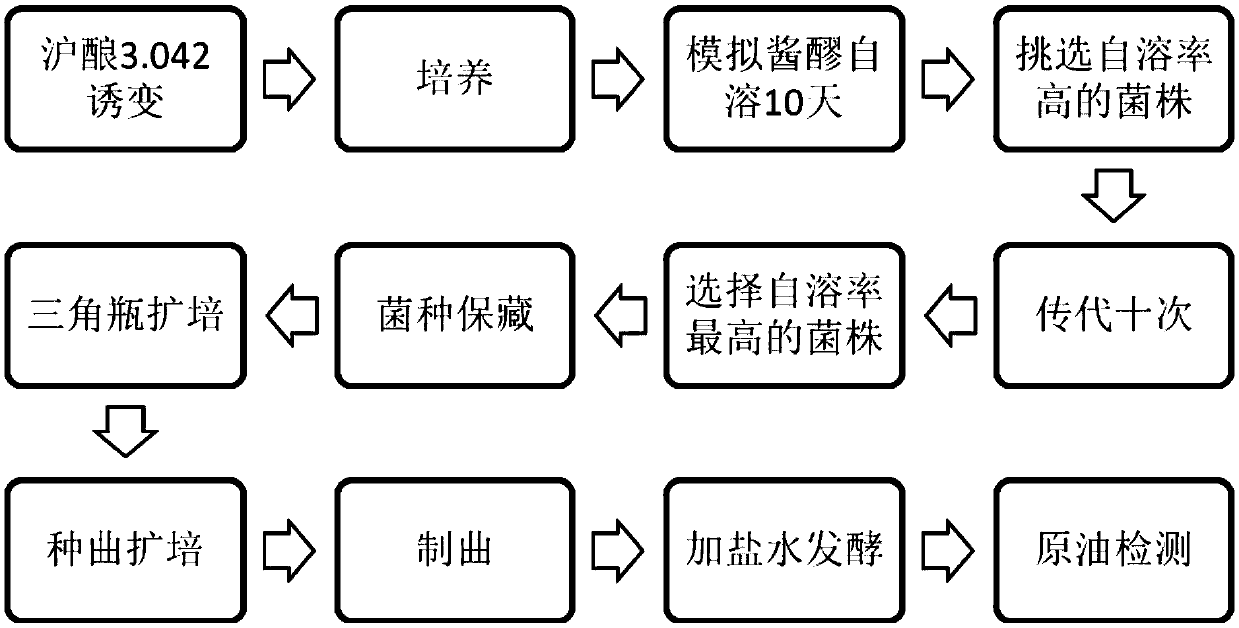

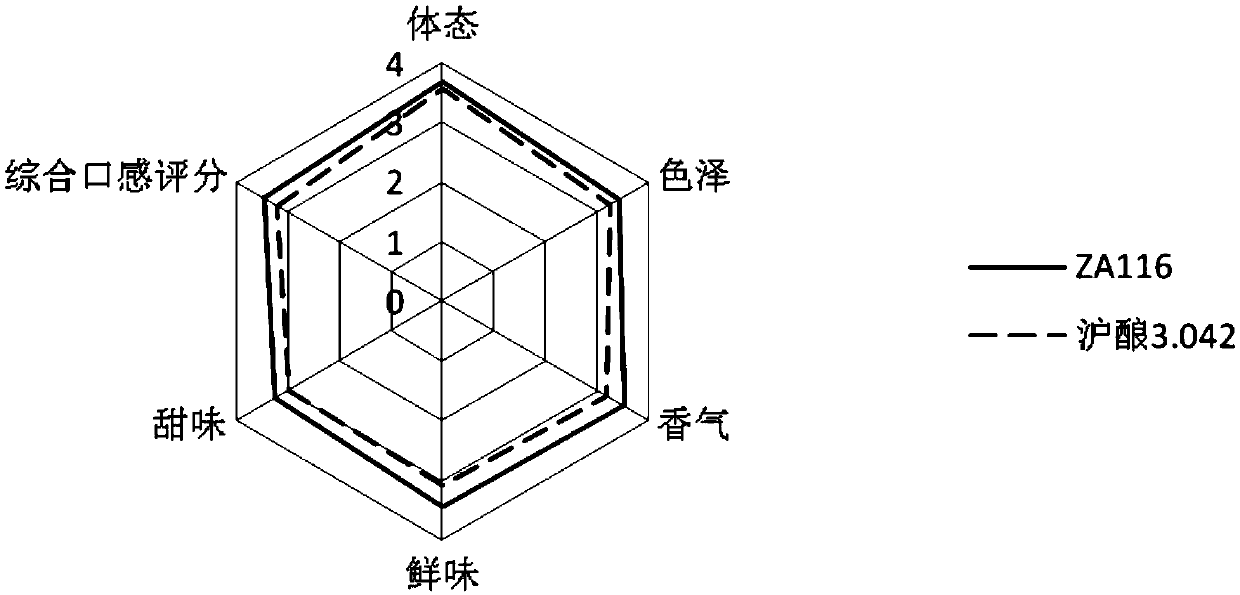

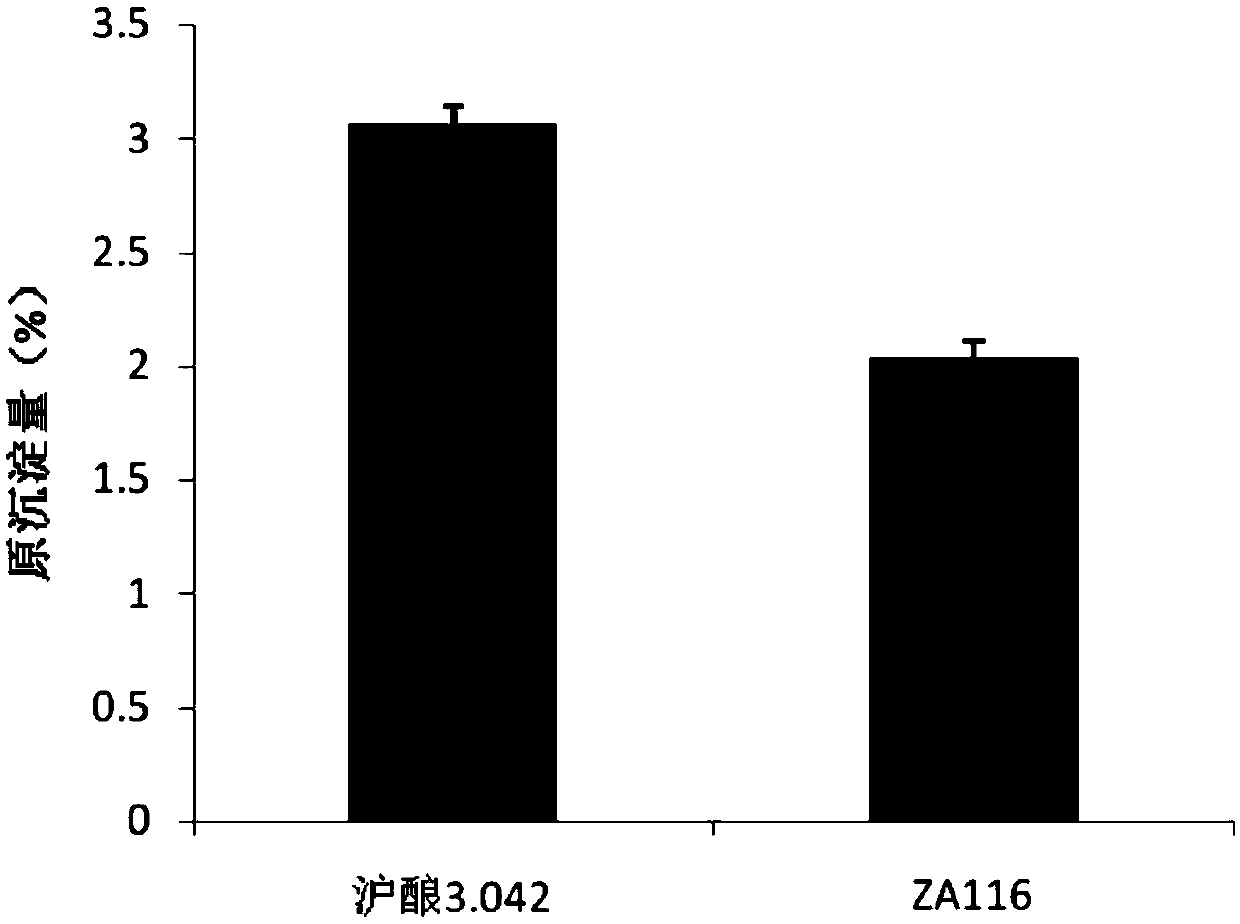

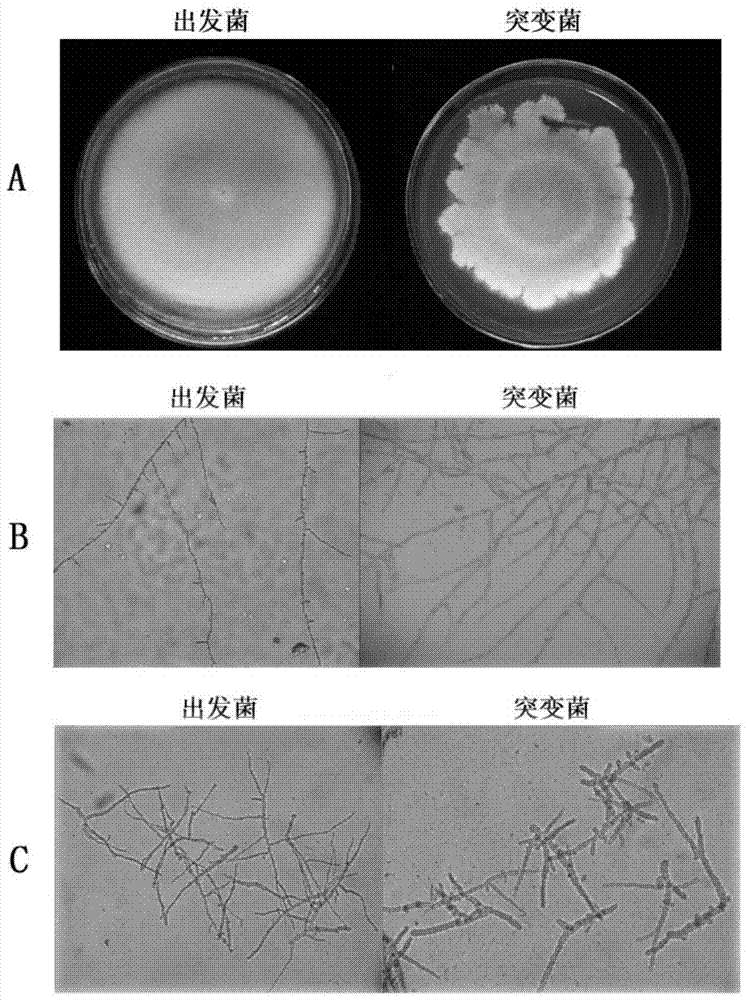

Aspergillus oryzae ZA116 bacterial strain and application thereof

ActiveCN109666593AHigh autolysis rateRich in sporesFungiMicrobiological testing/measurementBiotechnologyBacterial strain

The invention discloses a strain of Aspergillus oryzae ZA116. The Aspergillus oryzae ZA116 is preserved in Guangdong Microbiological Culture Collection Center on November 15, 2018, the preservation number is GDMCC 60479, and the preservation address is 59 building, No. 100 Courtyard, Xianlie Middle Road, Guangzhou. The invention further provides application of the Aspergillus oryzae ZA116 in foodfermentation or koji making or soy sauce making. The strain ZA116 obtained through mutagenesis screening is high in autolysis rate in the fermentation stage, high in glutamic acid content in soy sauceand clearer in crude oil; the Aspergillus oryzae ZA116 with the high autolysis rate is adopted for improving the quality of soy sauce by fully releasing enzymes and nutrients in bacteria, the changeof an existing production process and replacement of production equipment are not involved, the production cost is low, and industrialized popularization is facilitated.

Owner:FOSHAN HAITIAN GAOMING FLAVORING & FOOD +2

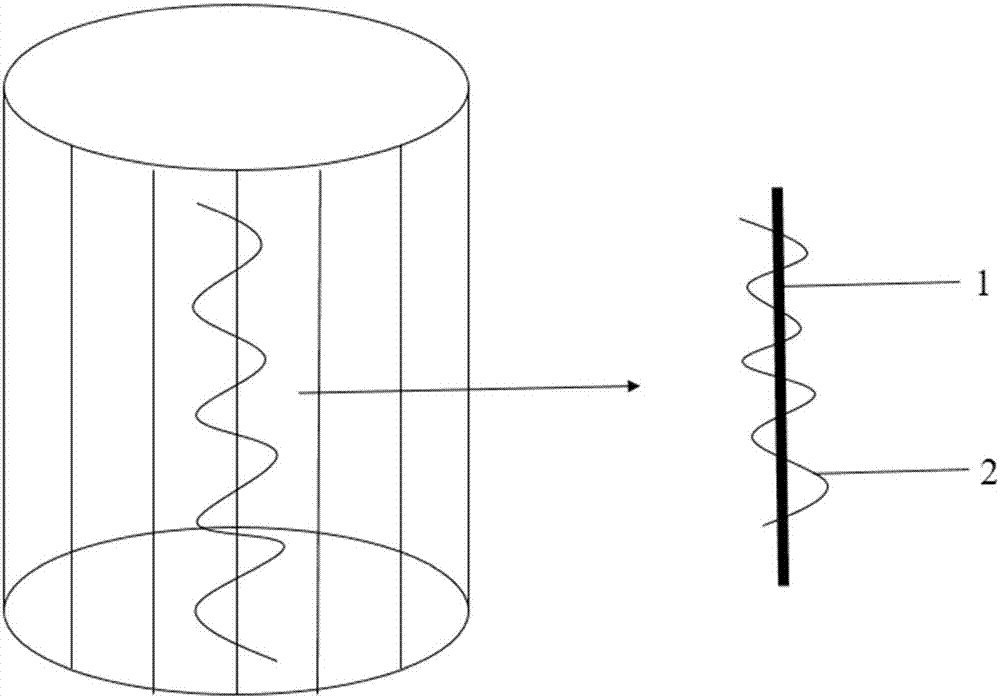

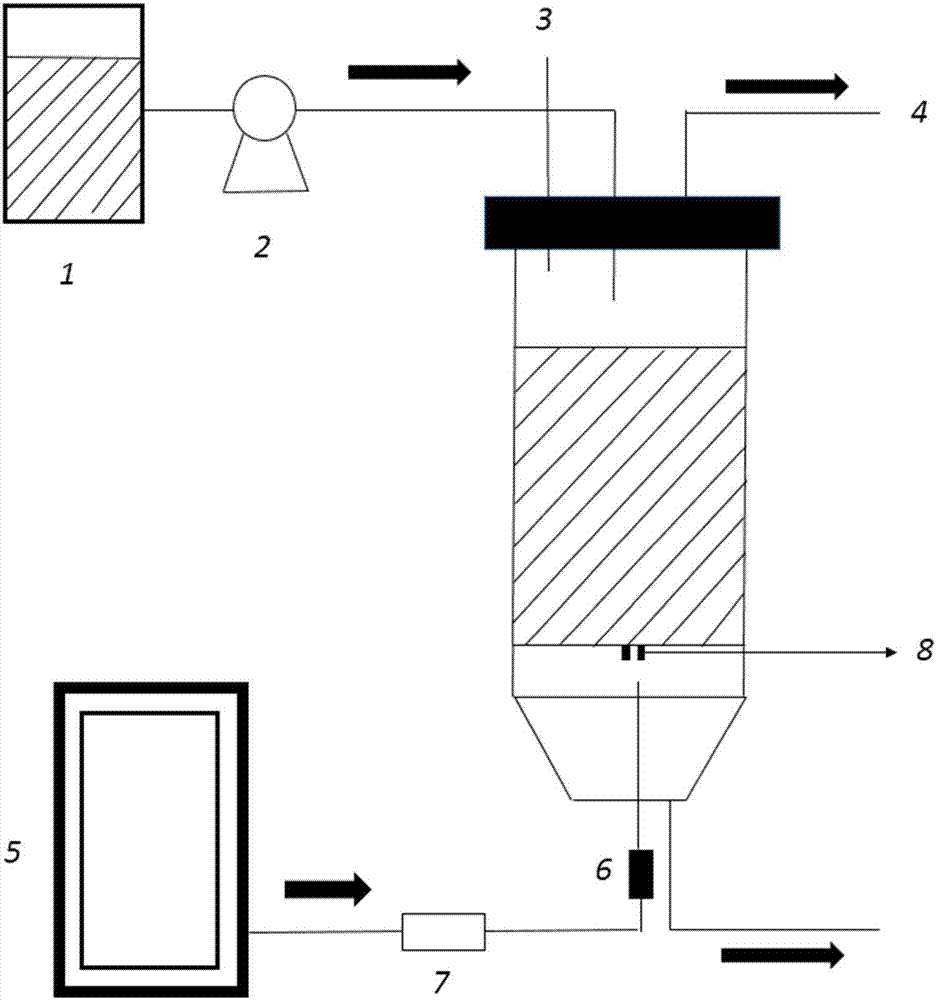

Immobilization method of Aspergillus niger

The invention discloses an immobilization method of Aspergillus niger. According to the immobilization method, a pretreated fibrous material is used as an immobilization medium, the Aspergillus niger is activated and then cultured in a fermentation container containing the immobilized medium, and the strain is adsorbed on the fibrous material in the culturing process. When an airlift-type fiber bed reactor with polyester fiber as the immobilization medium is used for continuously producing citric acid for 15 batches, the acid producing level is not reduced and the fermentation process is stable. Ultimately, the citric acid yield is 88.65g / L, the fermentation rate is 1.06g / L / h, and the yield rate (citric acid yield / glucose consumption) is 93.3% (w / w). Compared with free fermentation, the yield of immobilized fermentation is obviously increased, the fermentation period is shortened, the number of mycelia in a fermentation broth is obviously reduced, and the viscosity is decreased therewith, so that separation of a product and the mycelia at a later period is facilitated.

Owner:NANJING UNIV OF TECH

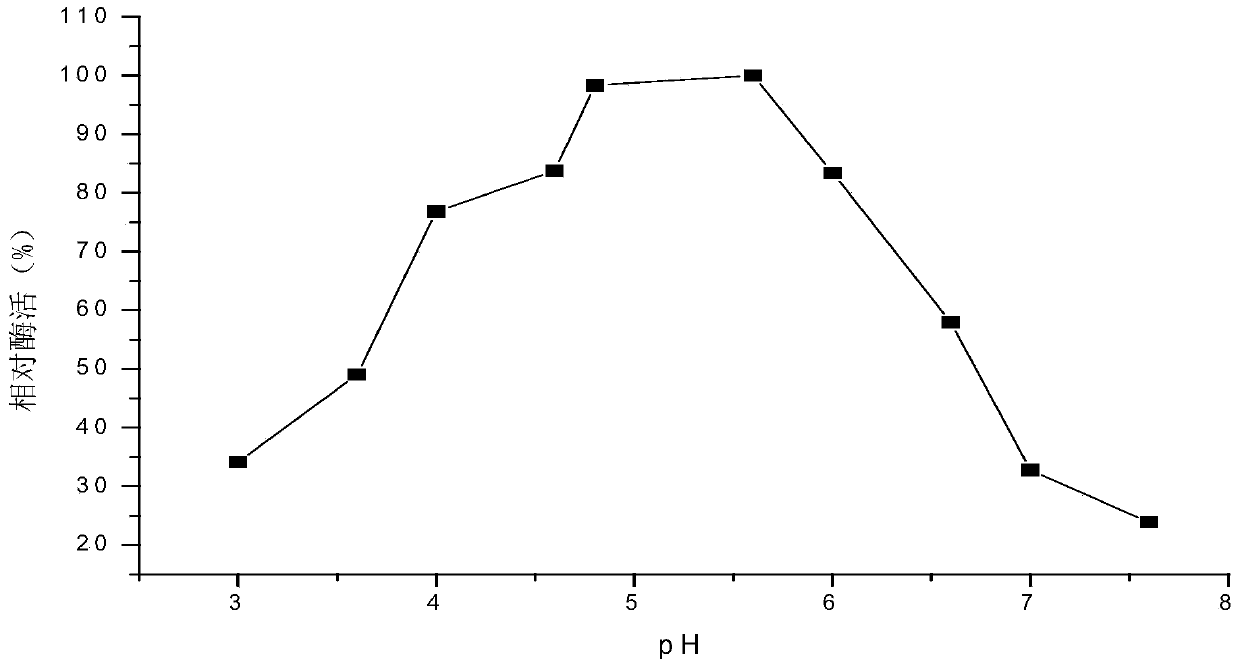

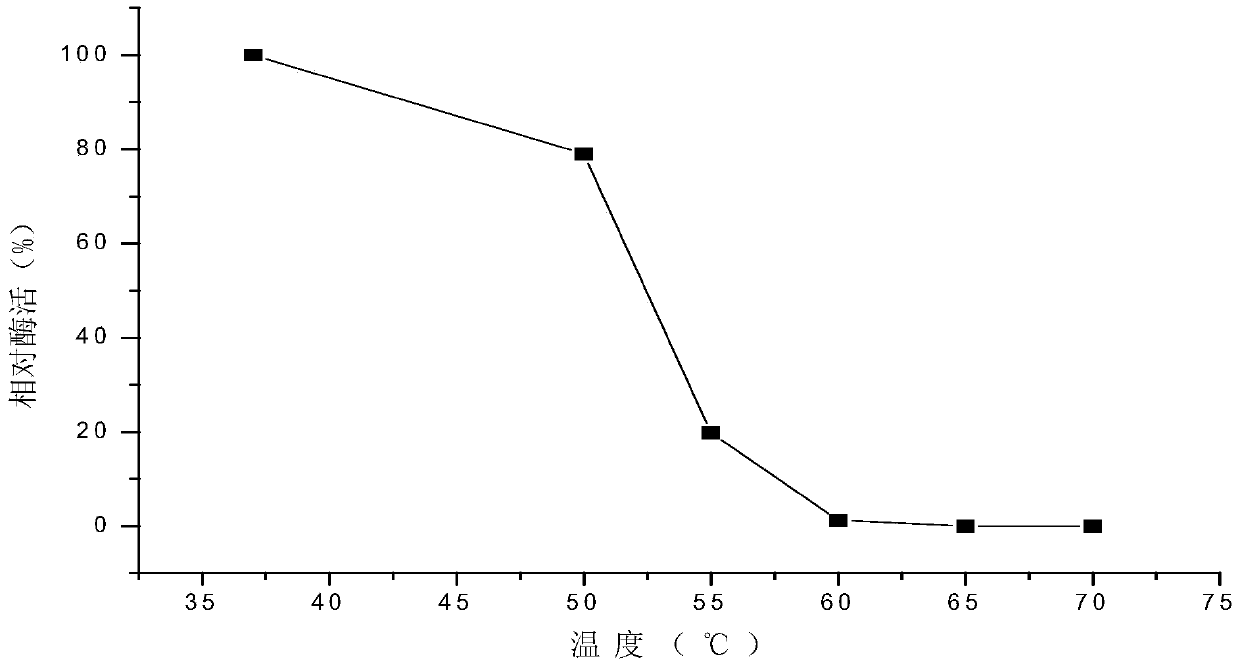

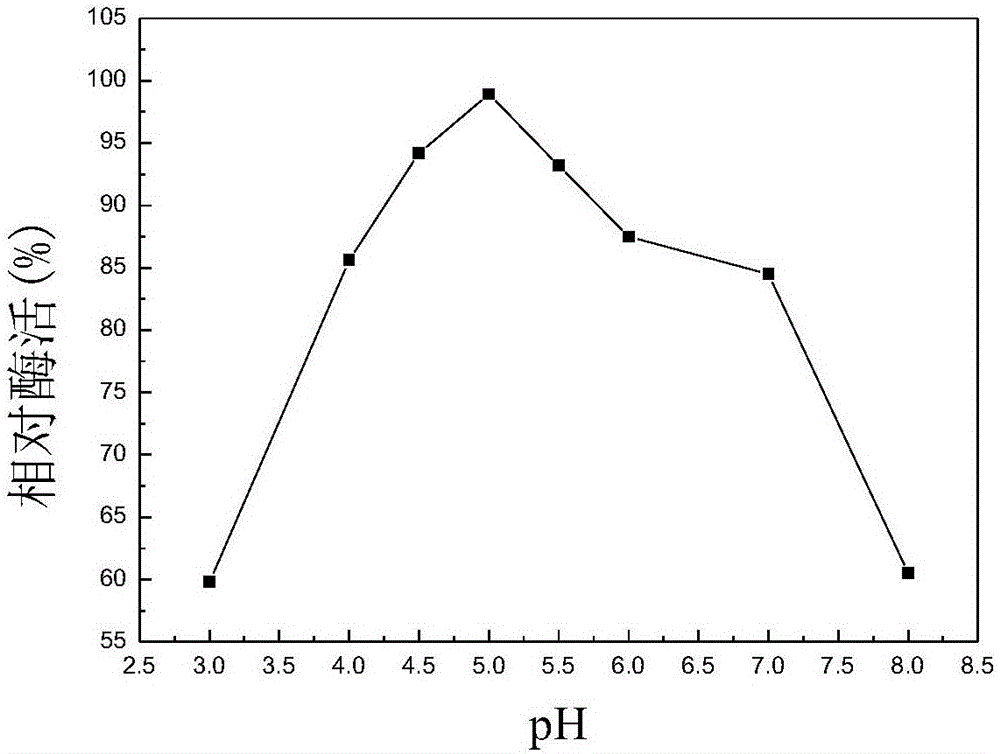

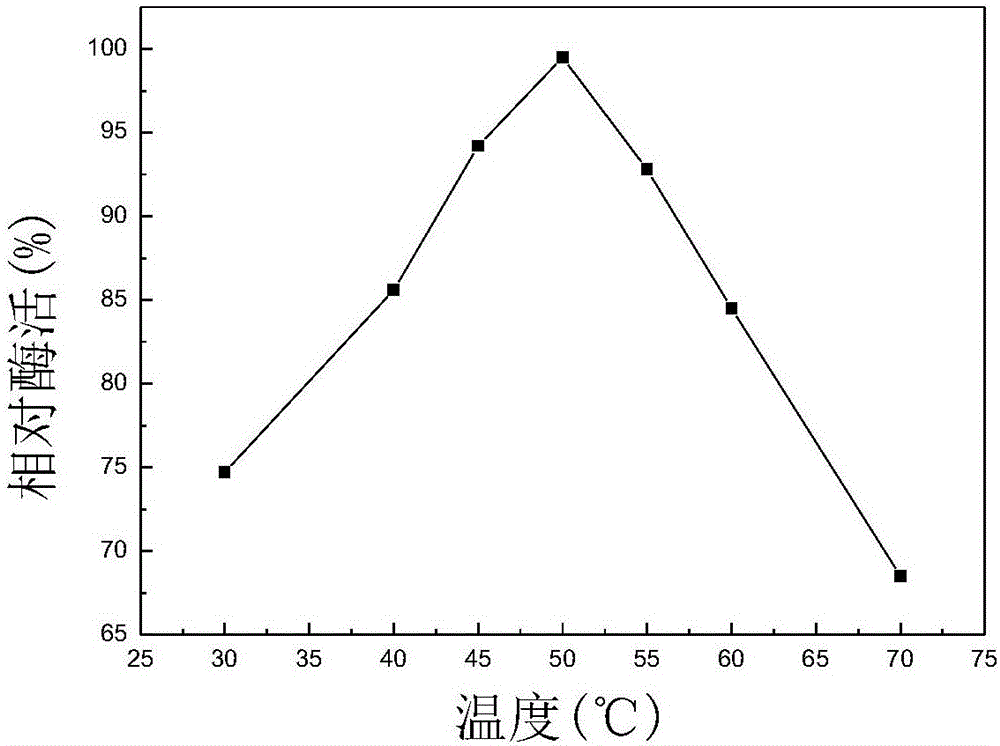

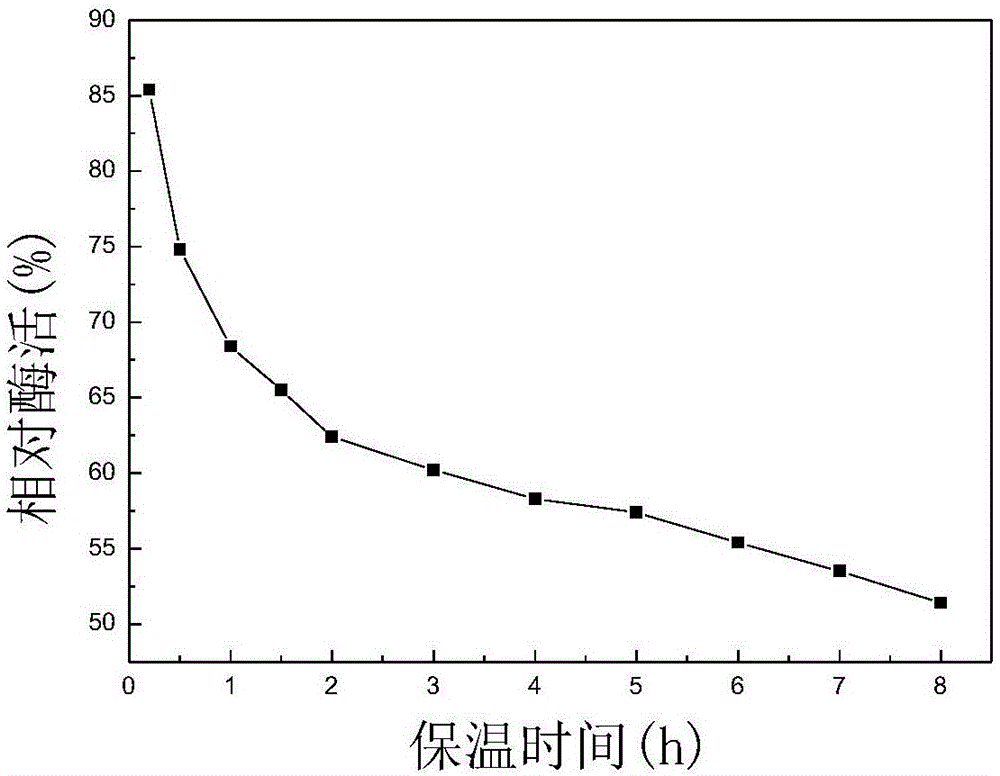

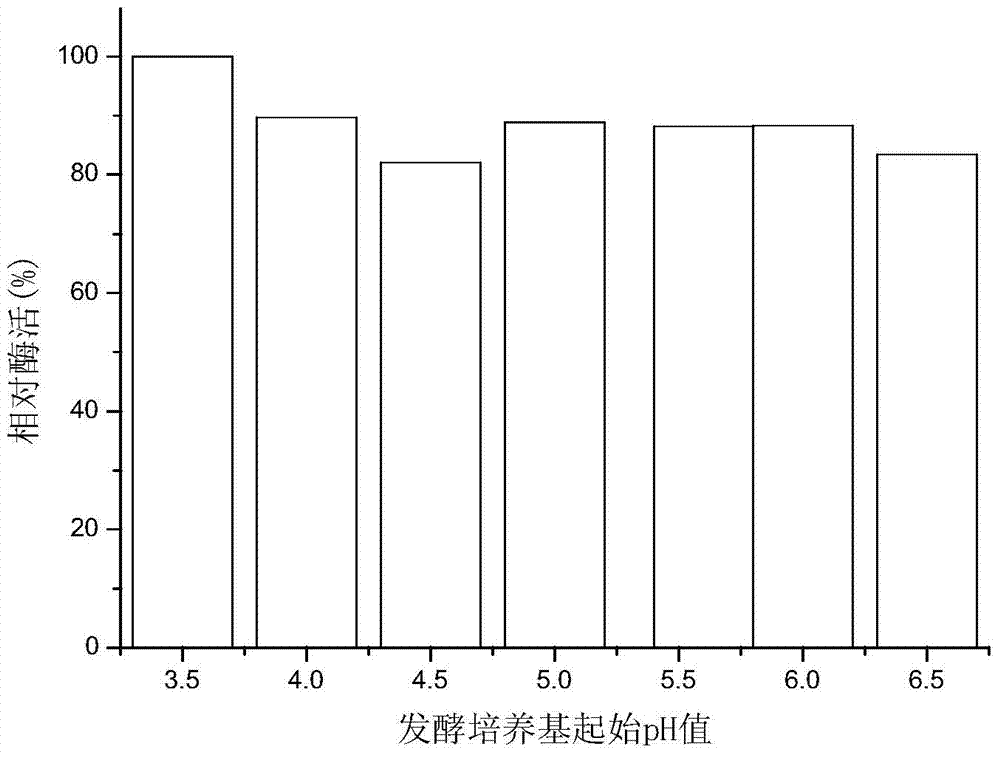

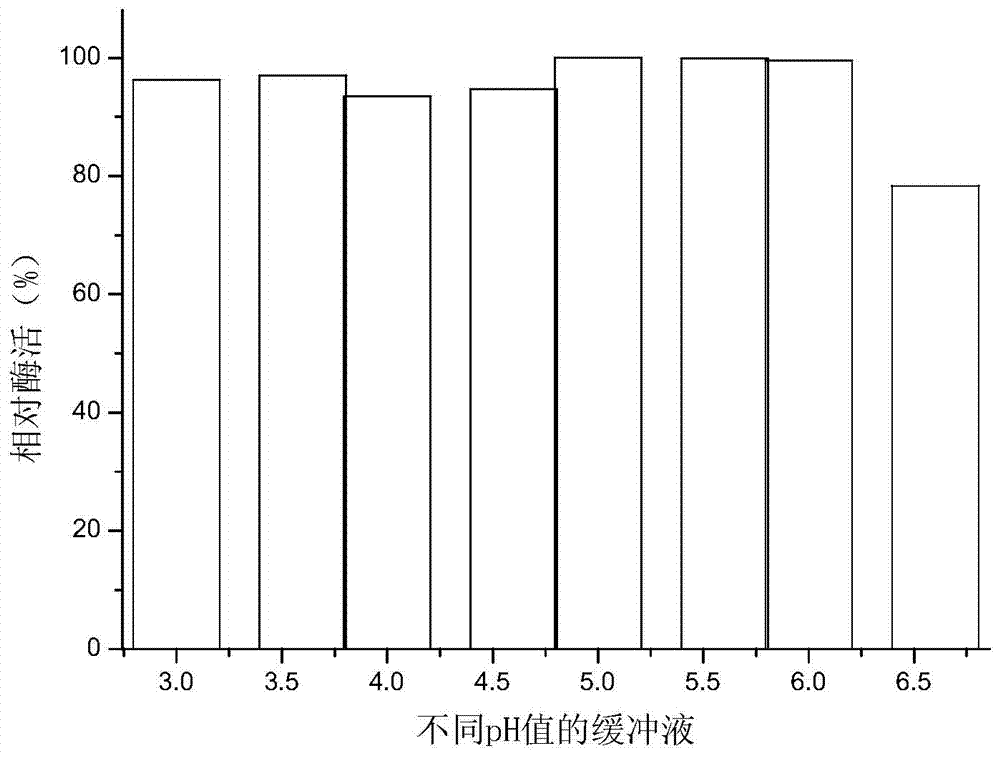

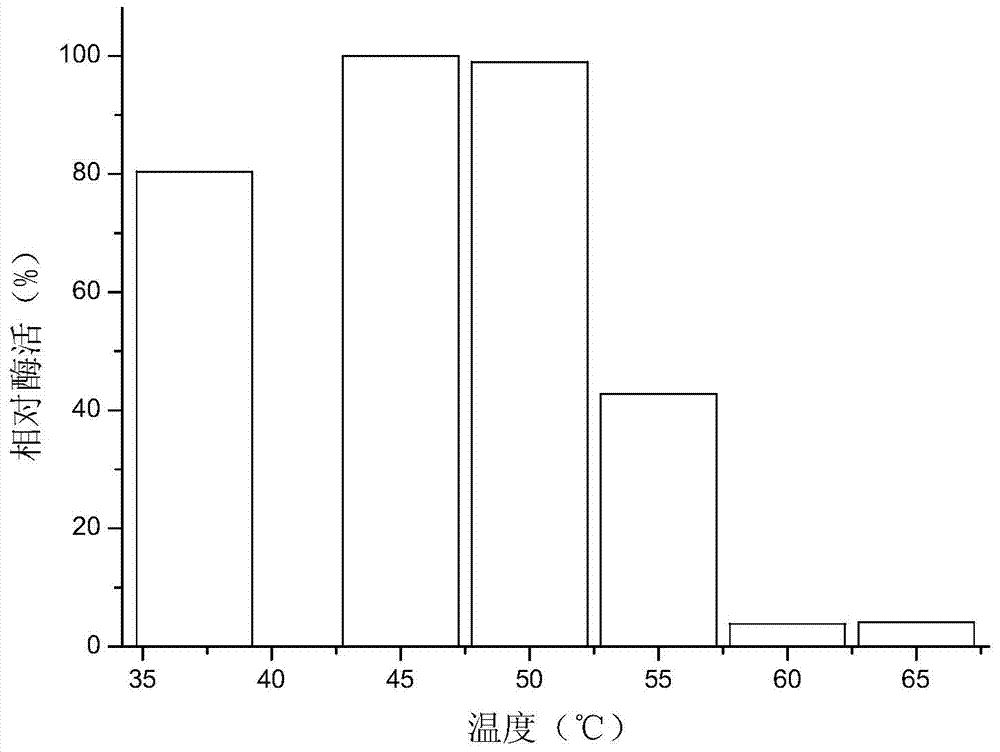

Aspergillus niger strain with high yield of beta-D-fructofuranosidase and liquid-state fermentation and enzyme production method of aspergillus niger strain

ActiveCN106754411AIncrease productivityReduce manufacturing costFungiMicroorganism based processesAspergillus nigerMicrobiological culture

The invention discloses an aspergillus niger strain with a high yield of beta-D-fructofuranosidase and a liquid-state fermentation and enzyme production method of the aspergillus niger strain and belongs to the field of microorganisms or enzymes. The aspergillus niger strain is aspergillus niger QL-225 and the preservation number is CGMCC (China General Microbiological Culture Collection Center) No.13168; liquid deep-layer fermentation is carried out through a 50L fermentation tank; meanwhile, materials are supplemented and fermented and cultured for 120h to 140h; finally, the enzyme activity of fermentation liquid can reach 19000U / ml to 20000U / ml. According to the established method for producing the beta-D-fructofuranosidase through liquid fermentation, the most suitable operation pH (Potential of Hydrogen) of the produced beta-D-fructofuranosidase is 4.0 to 7.0, and the most suitable operation temperature range is 40 DEG C to 60 DEG C; the residual enzyme activity is 51.4 percent after heat is preserved at 70 DEG C for 8h; the aspergillus niger strain has good acid resistance and heat resistance and can be widely applied to the industrial fields of foods, medicines, wine brewing and the like.

Owner:SHANDONG LONGKETE ENZYME PREPARATION

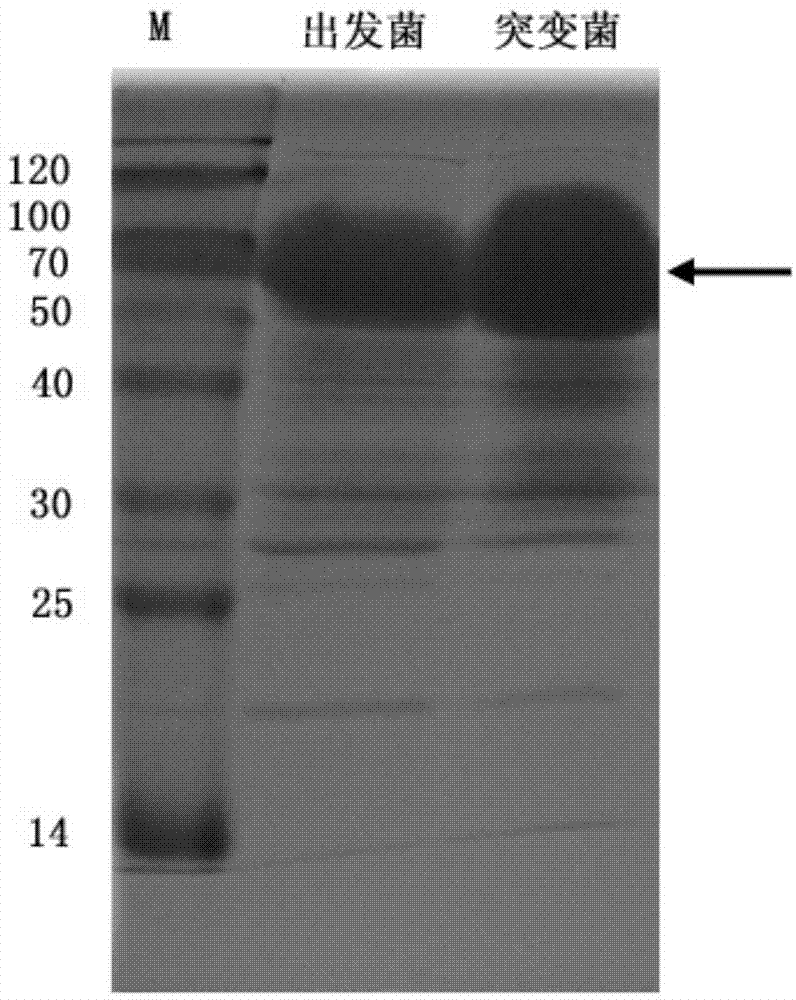

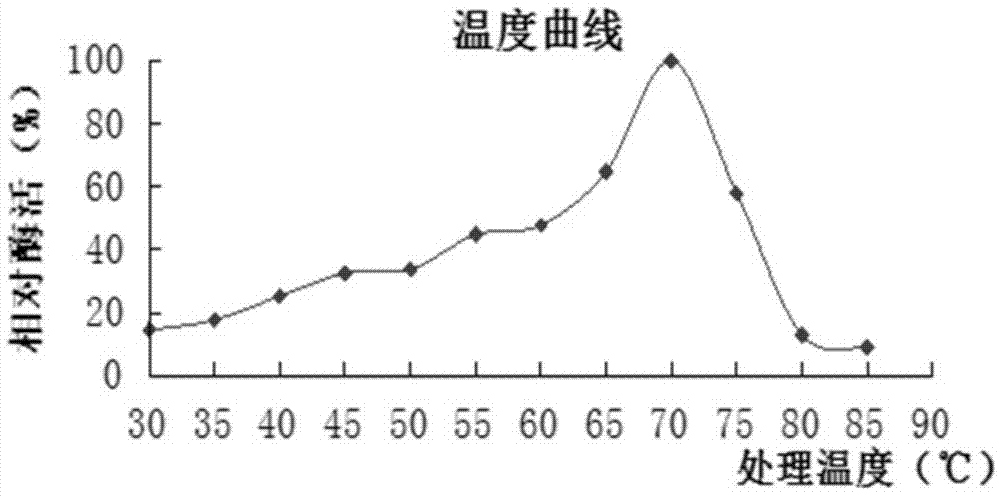

Trichoderma reesei bacterial strain for expressing saccharifying enzyme

ActiveCN103614303AHigh catalytic efficiencyReduce manufacturing costFungiMicroorganism based processesBacterial strainTrichoderma reesei

The invention aims at providing a trichoderma reesei bacterial strain for producing saccharifying enzyme. The trichoderma reesei bacterial strain is trichoderma reesei HDGAU-1 (Trichoderma reesei HDGAU-1) with a preservation number of CCTCC (China Center for Type Culture Collection) NO: M2013584. The trichoderma reesei bacterial strain disclosed by the invention can efficiently express the saccharifying enzyme, and fermentation enzyme activity is as high as 4000 U / ml which is improved by 54% in comparison with that before mutation, and protein amount exceeds 2.1 g / L which is improved by about 50% in comparison with that before mutation. According to the invention, production cost of the saccharifying enzyme can be greatly lowered by utilizing the trichoderma reesei bacterial strain to produce the saccharifying enzyme, and wide application of the saccharifying enzyme is facilitated. Moreover, the saccharifying enzyme recombinant and expressed by the trichoderma reesei bacterial strain disclosed by the invention has an optimum acting temperature of 70 DEG C and an optimum acting pH of 5.5, has catalytic efficiency higher than that of the common saccharifying enzyme from aspergillus niger at present, is more high temperature resistant, can effectively shorten saccharifying time and can lower production cost.

Owner:QINGDAO VLAND BIOTECH GRP

Method for preparing yeast culture through distillers' grains and application of yeast culture

ActiveCN110384175APromote autolysisAlternate consumption of large amounts of molassesFungiBacteriaPhytaseAspergillus niger

The invention discloses a method for preparing a yeast culture through distillers' grains and an application of the yeast culture. The method comprises the following steps of S1, supplementing a carbon source to distillers' grains to obtain pretreated distillers' grains, inoculating mixed bacterium liquid to the pretreated distillers' grains, adding mixed enzyme liquid, preparing a fermentation base material, and performing fermentation culture for 96-120h; and S2, after fermentation is completed, performing inoculation with bacillus subtilis, continuing to perform fermentation culture for 24h, and performing baking, crushing and screening so as to obtain the yeast culture, wherein the mixed bacterium liquid comprises 3 strains of saccharomyces cerevisia, lactic acid bacteria and aspergillus niger, and the mixed enzyme liquid comprises liquefying amylase, glucoamylase, phytase and proteases. According to the method disclosed by the invention, the distillers' grains are used as substrates, the mixed bacterium liquid and the mixed enzyme liquid are added for heap fermentation, so that the yeast culture is obtained; and the distillers' grains are turned into wealth from waste, and besides, a feed rich in nutrient components is provided for animals, so that improvement of the immunity of the animals can be facilitated.

Owner:HUAZHONG AGRI UNIV +1

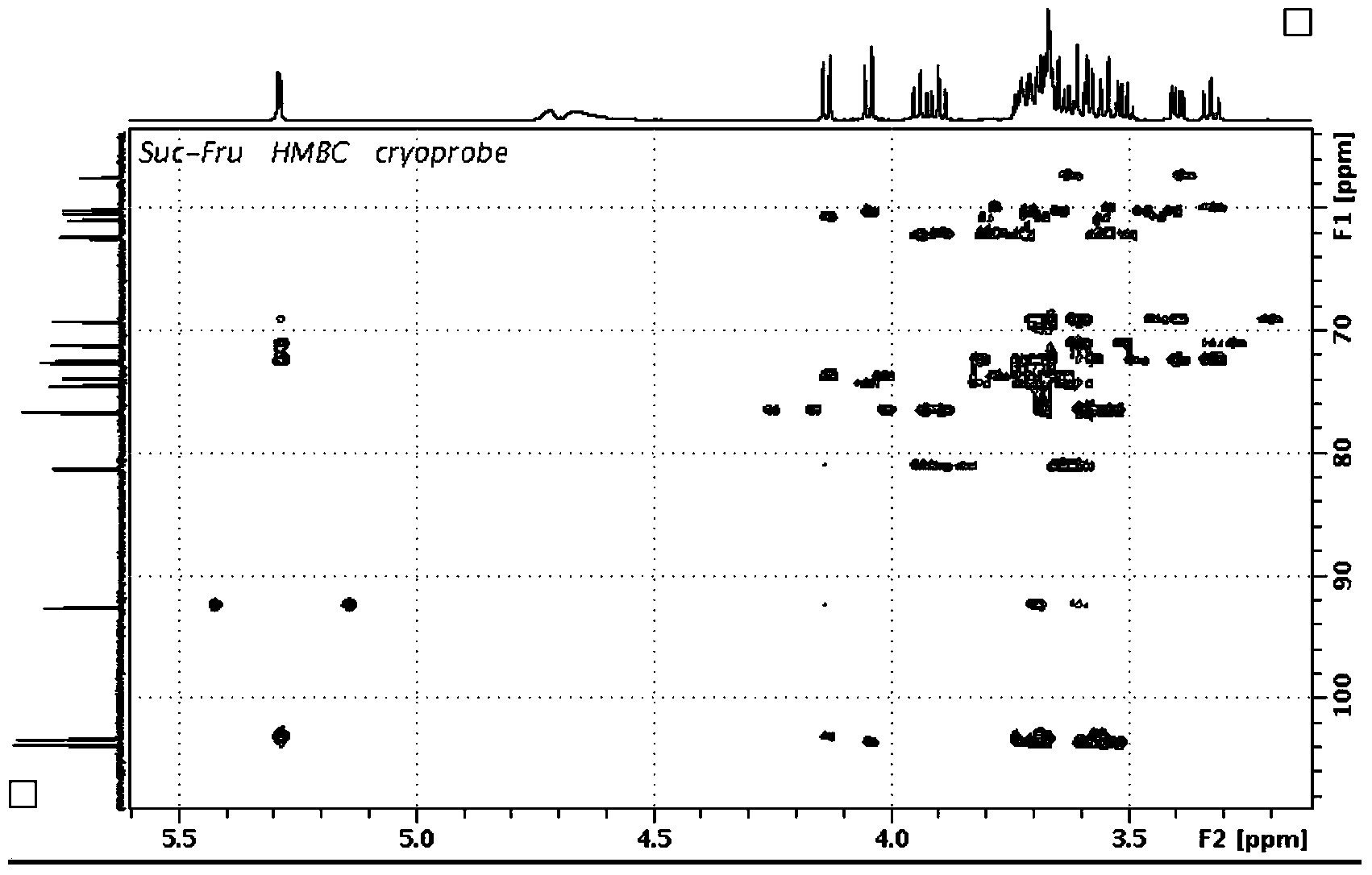

Aspergillus oryzae strain capable of producing beta-fructofuranosidase, as well as culture method and application thereof

The invention relates to an aspergillus oryzae strain capable of producing beta-fructofuranosidase, as well as a culture method and application thereof. An aspergillus oryzae FS4 strain is collected in China General Microbiological Culture Collection Center (CGMCC) on April 24, 2014, with the collection number of CGMCC No. 9087 and the address of Institute of Microbiology, Chinese Academy of Sciences, Building 3, NO.1 Beichen West Road, Chaoyang District, Beijing. The invention further relates to the culture method and application of the aspergillus oryzae strain. The aspergillus oryzae FS4 strain obtained by screening has the advantages of simple culture, stable genetic nature, high synthesis efficiency and stable enzyme activity, can be applied to the field of synthesis of levan type oligofructoses and the like by a modern bio-engineering technical enzyme method, and further has broad application prospects.

Owner:SHANDONG UNIV

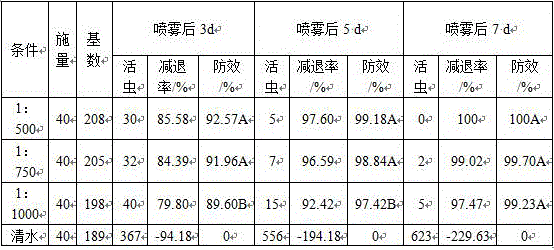

Aspergillus parasiticus and preparation method and application thereof

The invention provides aspergillus parasiticus which is Aspergillus parasiticus RWSF001-02 which is preserved in Guandong Microbiological Culture Collection Center with the preservation number being GDMCC NO: 60080. The aspergillus parasiticus is screened from naturally dead aphids as a result of fungal parasitism. The aspergillus parasiticus and conidial powder containing the aspergillus parasiticus can be used for preparing an insecticide, and particularly has a relatively high preventing and treating rate on aphids, and the strain is good in production trait and fast to grow. The sporulation quantity of culture in a solid culture medium within 3-5 days can reach 8*10<8> / g.

Owner:鹤壁市人元生物技术发展有限公司

Method for manufacturing lactobacillus fermented soybean rich in gamma-aminobutyric acid

InactiveCN106174040AAdd flavorIncrease nutritionLactobacillusFood scienceFlavorGamma-Aminobutyric acid

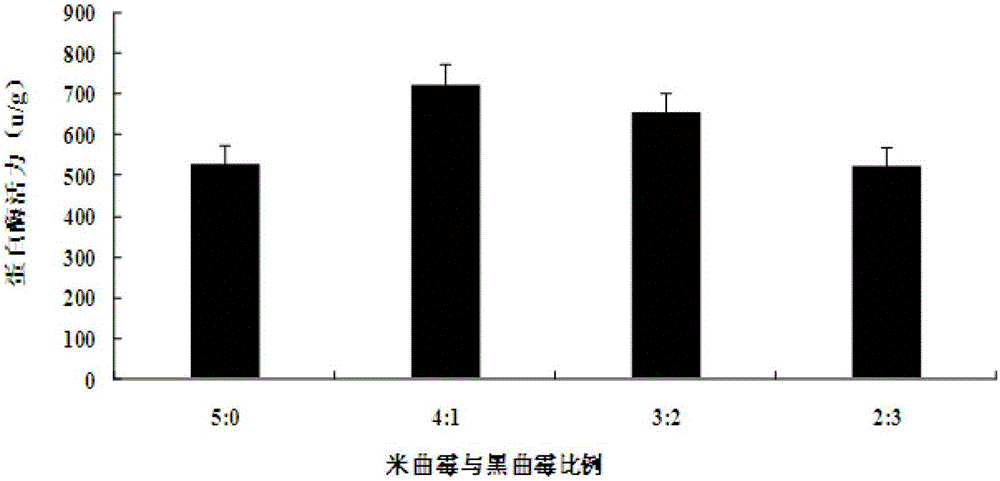

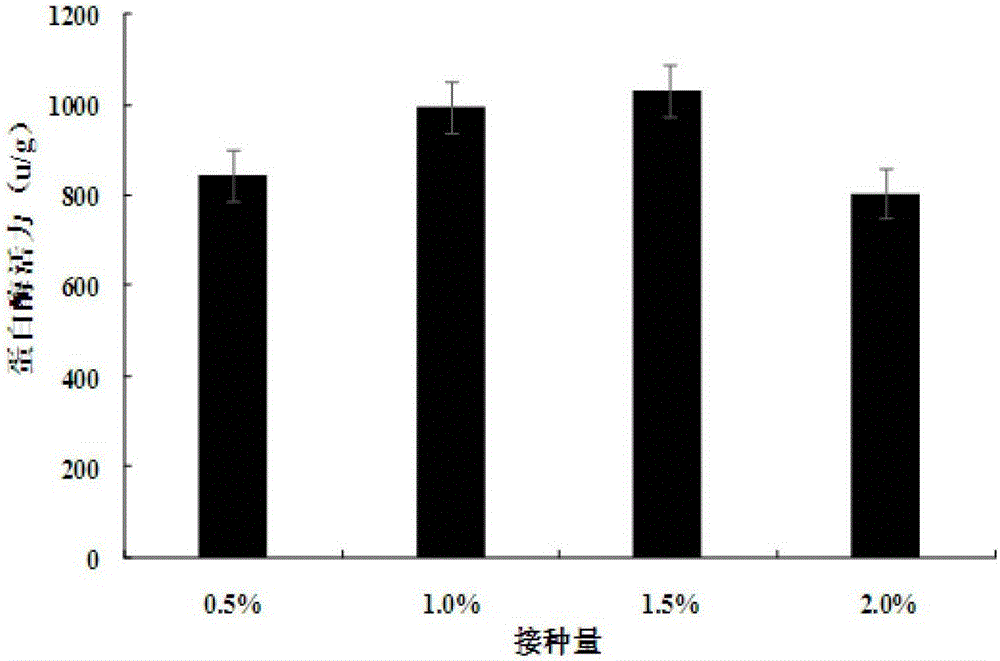

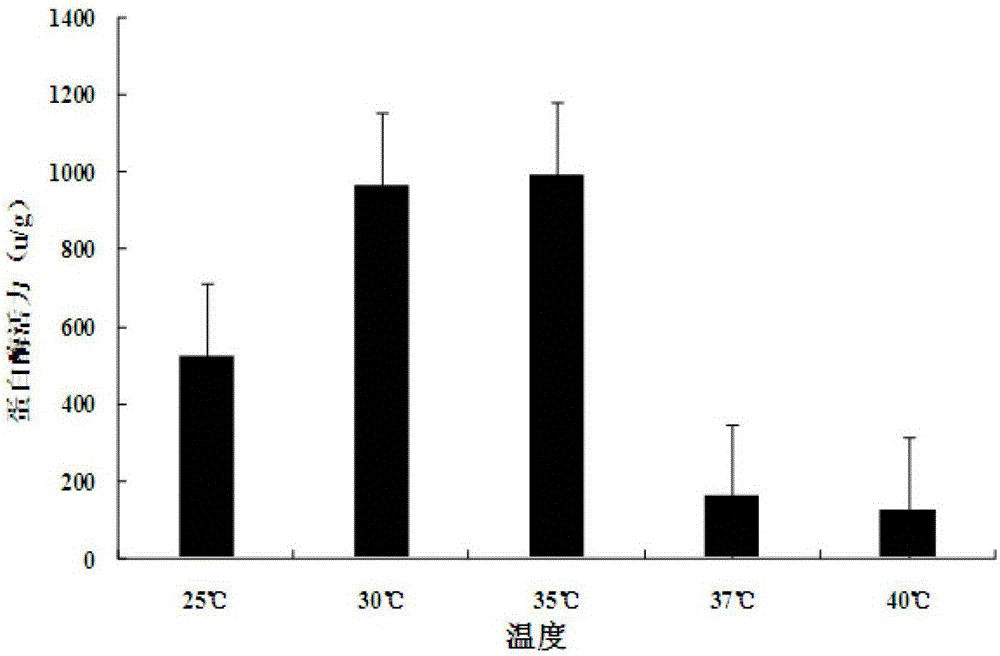

The invention discloses a method for manufacturing lactobacillus fermented soybean rich in gamma-aminobutyric acid. The method includes: sequentially subjecting soybeans to cleaning, soaking, draining and steaming, and performing bacterial powder inoculation for starter propagation and fermentation to obtain fermented soybean, wherein before starter propagation, mixed bacterial powder of aspergillus oryzae and aspergillus niger is adopted for inoculation in a mass weight of 1.5-4:1, and after starter propagation, lactobacillus plantarum containing bacteria liquor is adopted for inoculation prior to fermentation. By adoption of the mixed bacterial powder of aspergillus oryzae and aspergillus niger for starter propagation, adoption of the lactobacillus plantarum containing bacteria liquor for fermentation, and coordination of appropriate starter propagation and fermentation processes, protease activity of finished starter, content of amino nitrogen generated in fermentation and content of gamma-aminobutyric acid are increased remarkably, and finished products of fermented soybean are healthier and greater in quality and flavor. In addition, the preparation process is simple, a fermentation period is greatly shortened, and production cost is reduced.

Owner:ZHEJIANG UNIV

Strain of Aspergillus oryzae and applications in preparation of feed additives through microbial fermentation

ActiveCN103642695AEnhance cellulase productionImprove protease abilityFungiAnimal feeding stuffBiotechnologyNutritive values

The invention provides a new bacterial strain-Aspergillus oryzae 2013-DP1, and applications in preparation of feed additives through microbial fermentation. The strain is preserved in China Center for Type Culture Collection. The address is Wuhan University, Wuhan, China. The postcode is 430072. The preservation date is June 21th, 2013. The preservation number is CCTCC No: M2013276. Through fermentation and enzymatic hydrolysis conversion of low-value cellulose substances of straws and the like, the strain raises the protein content properly, raises nutritive values, can promote development of feed sources, raises the utilization rate of waste biological resources, and has obvious economic and ecological significances.

Owner:安徽希普生物科技有限公司

Aspergillus niger strain and application thereof

InactiveCN102796670AHigh activityEasy to realize industrial productionFungiHydrolasesFeruloyl esteraseHigh activity

The invention discloses an Aspergillus niger strain and an application thereof. The strain is named Aspergillus niger ZJUQH2012147, which is collected in China General Microbiological Culture Collection Center (CGMCC) on May 23, 2012 with the collection number of CGMCC No. 6152. The invention further discloses a method for producing feruloyl esterase by using the strain, and the method comprises the following steps: (1) inoculating the Aspergillus niger ZJUQH201217 into a seed culture medium for propagation culture to obtain seed liquid; and (2) inoculating the seed liquid into a fermentationculture medium for fermentation culture. The method for producing feruloyl esterase by using the Aspergillus niger strain disclosed by the invention has high activity and is easy to realize industrial production of the feruloyl esterase. The process for producing the feruloyl esterase disclosed by the invention adopts soybean meal, wheat bran and other crude raw materials as fermentation raw materials, pretreatment of the crude raw materials is not required, and the production cost is low.

Owner:ZHEJIANG UNIV

Aspergillus niger for largely producing xylanase and application thereof

The invention discloses aspergillus niger for largely producing xylanase and application thereof. The collection number of the Aspergillus niger SM751 is CGMCC No. 8670. The xylanase generated by the Aspergillus niger SM751 is activated in enzyme activity under the action of mixing of multiple inhibitors; compared with blank control, the maximal activation rate of the enzyme activity achieves 33.43%. The Aspergillus niger SM751 provided by the invention can be used for largely producing xylanase which has high enzyme activity and can tolerate the pretreated fermented inhibitors, thereby having wide application in the field of lignocellulose enzymolysis.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

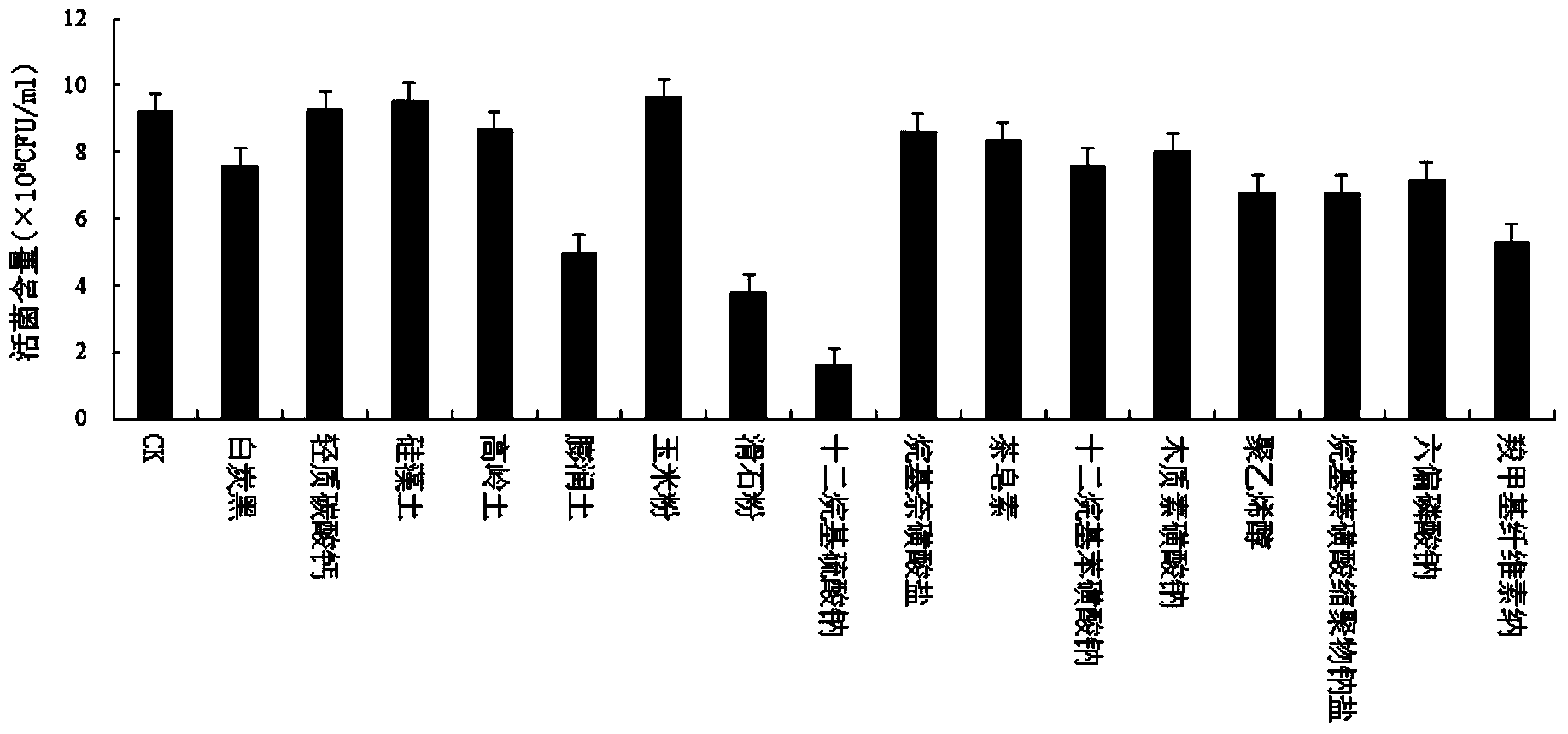

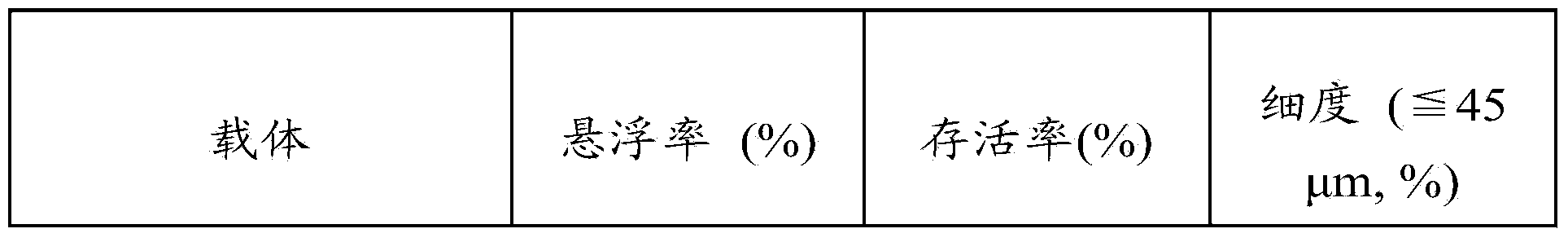

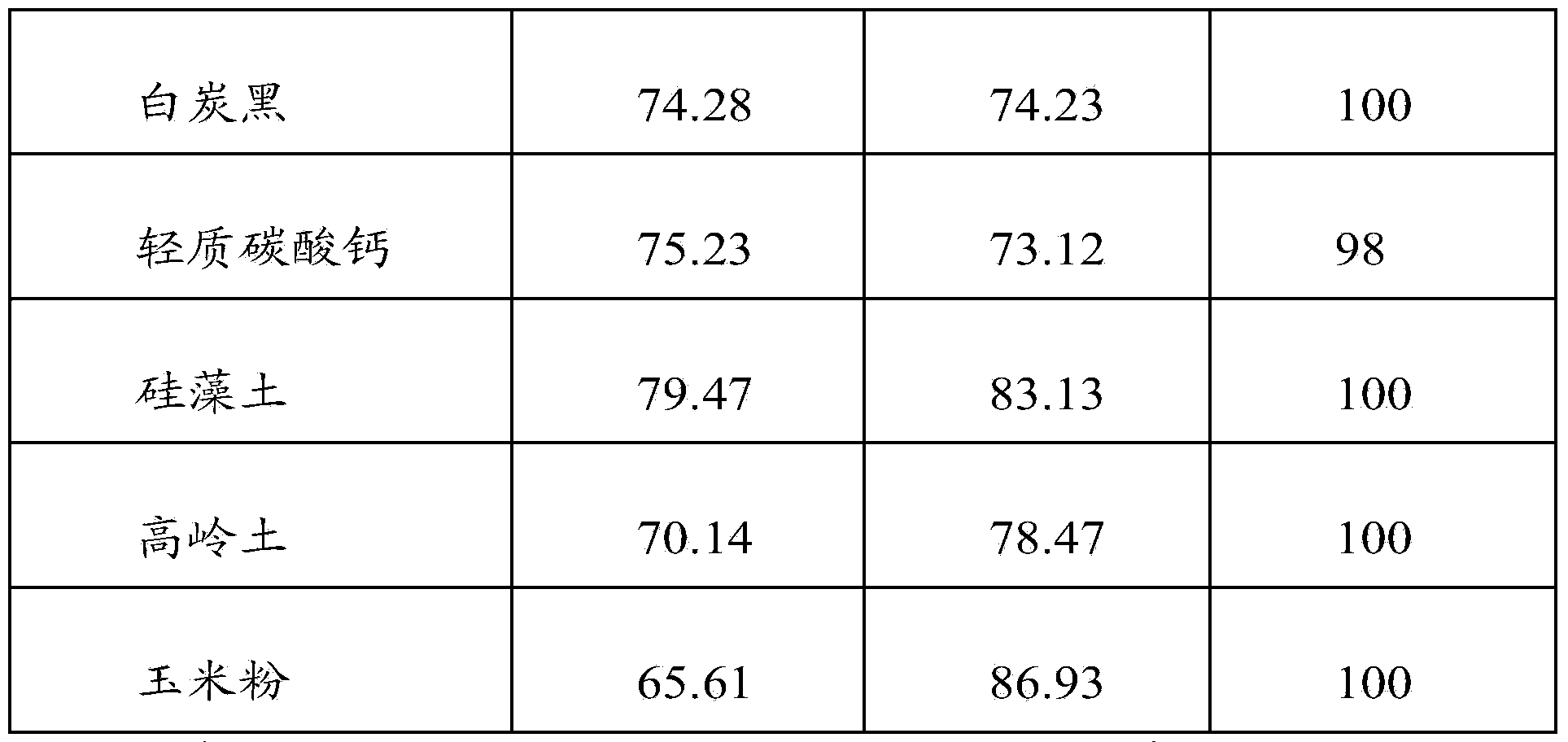

Bacillus cereus wettable powder as well as preparation method and applications of bacillus cereus wettable powder

ActiveCN104232518ASolving Room Temperature Storage ProblemsNo harmBiocideBacteriaBacillus cereusPlant disease

The invention relates to the field of microorganisms, and particularly relates to a bacillus cereus wettable powder as well as a preparation method and applications of the bacillus cereus wettable powder. The bacillus cereus wettable powder comprises the following components in percentage by weight: 50-70% of bacillus cereus lyophilized powder, 8-12% of auxiliaries, 0.5-1.5% of a stabilizer, 0.05-0.15% of an ultraviolet protective agent, and the balance of carriers. The bacillus cereus wettable powder is prepared by the following method comprising the following steps: evenly mixing and grinding all the components to obtain powder with meshes of less than or equal to 150, wherein the temperature through the preparation process is held at 0-45DEG C. The bacillus cereus wettable powder plays a good role in inhibiting common fungal diseases such as cryponectria parasitica, stachybotrys atra, fusarium solani, penicillium expansum, colletotrichum gloeosporioides and aspergillus niger during storage of fruits such as Chinese chestnuts, and is non-toxic to human and livestock, and low in cost; and the room-temperature Chinese chestnut storage problem can be well solved, and the storage cost can be lowered.

Owner:WUHAN POLYTECHNIC UNIVERSITY

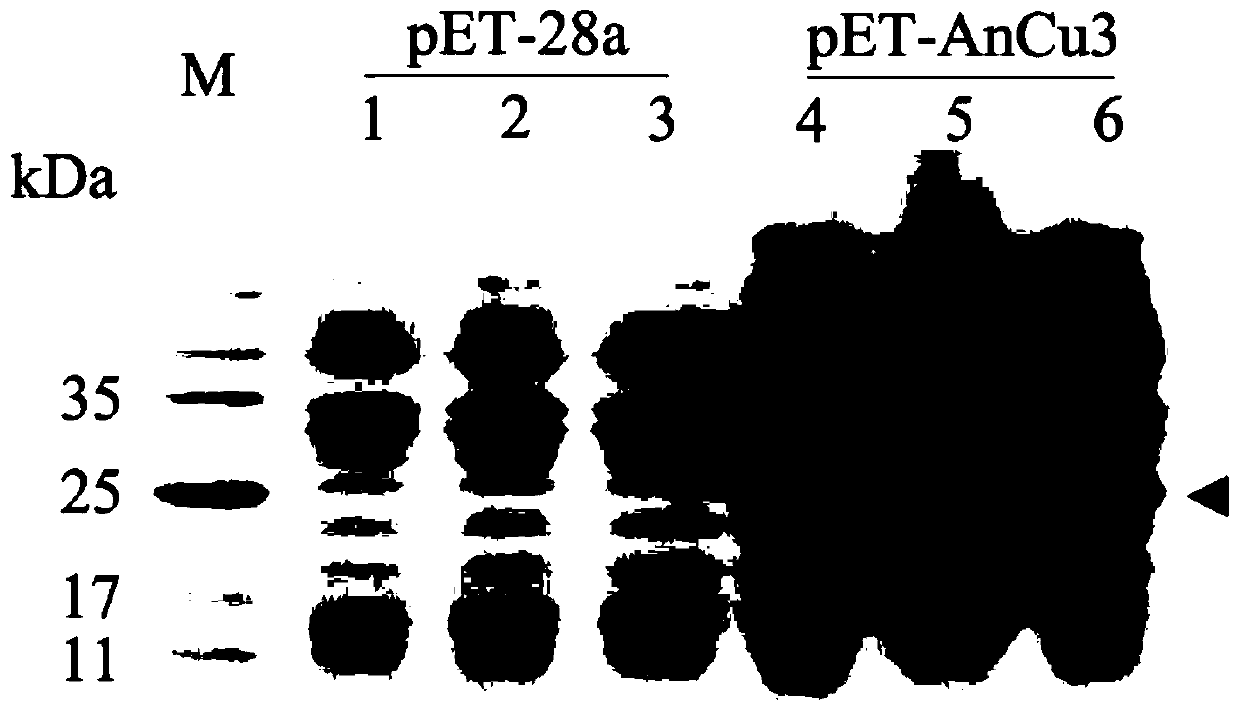

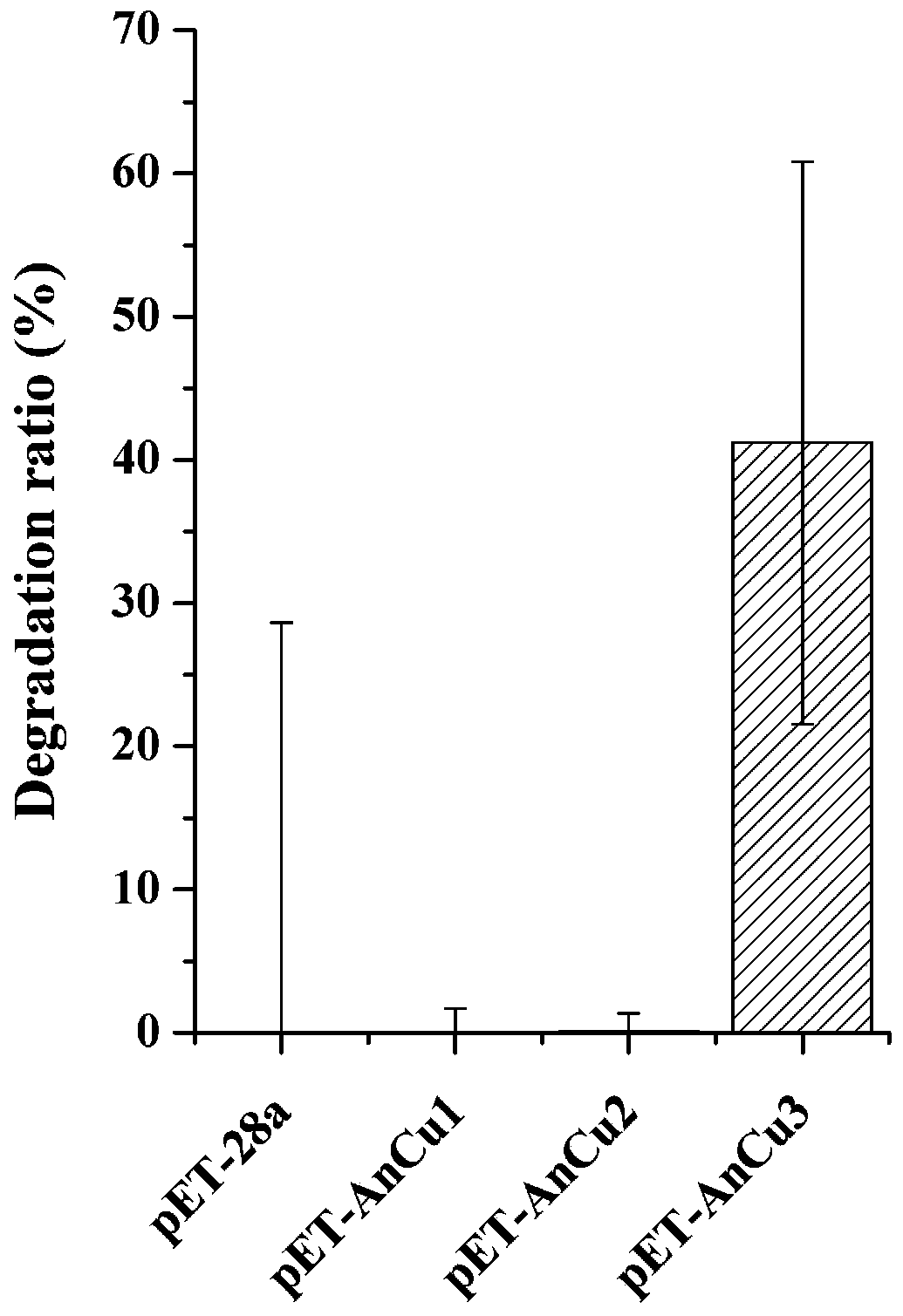

Aspergillus niger hydrolytic enzyme AnCu3, coding gene and application of aspergillus niger hydrolytic enzyme AnCu3

ActiveCN110592049AIncrease hydrolysis rateEffective for hydrolysisBacteriaHydrolasesPlasticizerAspergillus niger

The invention discloses an aspergillus niger hydrolytic enzyme AnCu3. The amino acid sequence of the aspergillus niger hydrolytic enzyme AnCu3 is shown as SEQID No.1. The invention further discloses an application of the aspergillus niger hydrolytic enzyme AnCu3 to catalyzing and hydrolyzing of plasticizer dimethyl glycol phthalate (2-ethylhexyl) ester (DEHP) in a water phase system. The inventionprovides an enzyme which can catalyze and hydrolyze the dimethyl glycol phthalate (2-ethylhexyl) ester, and a coding gene for the first time, and a new way is provided for hydrolyzing of the dimethylglycol phthalate ( 2-ethylhexyl) ester.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com