Immobilization method of Aspergillus niger

An Aspergillus niger, immobilized medium technology, applied in microorganism-based methods, biochemical equipment and methods, immobilized on or in inorganic carriers, etc., can solve problems such as affecting fermentation performance, and achieve reduced fermentation time and good transmission. The effect of quality performance, reducing the loss of cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

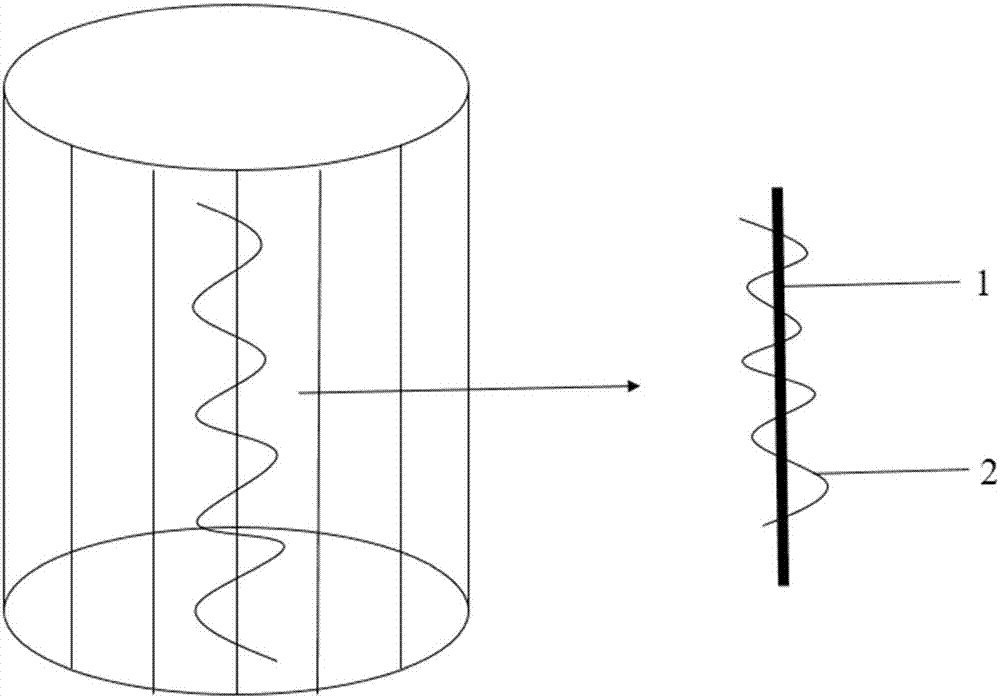

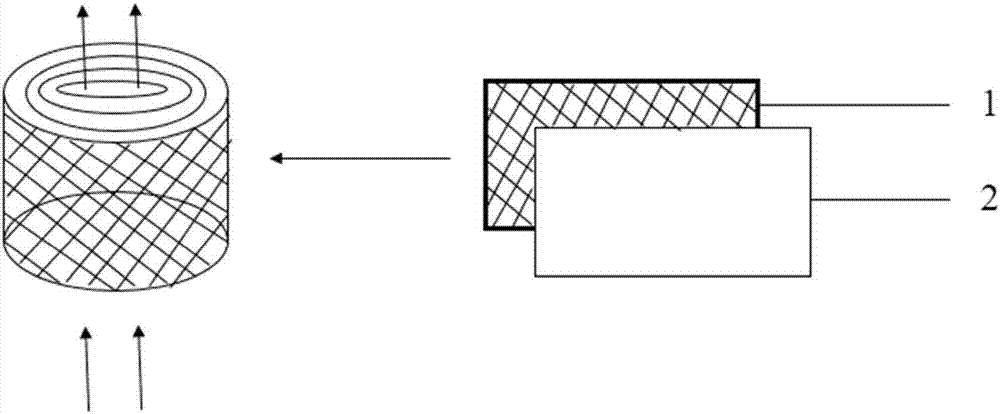

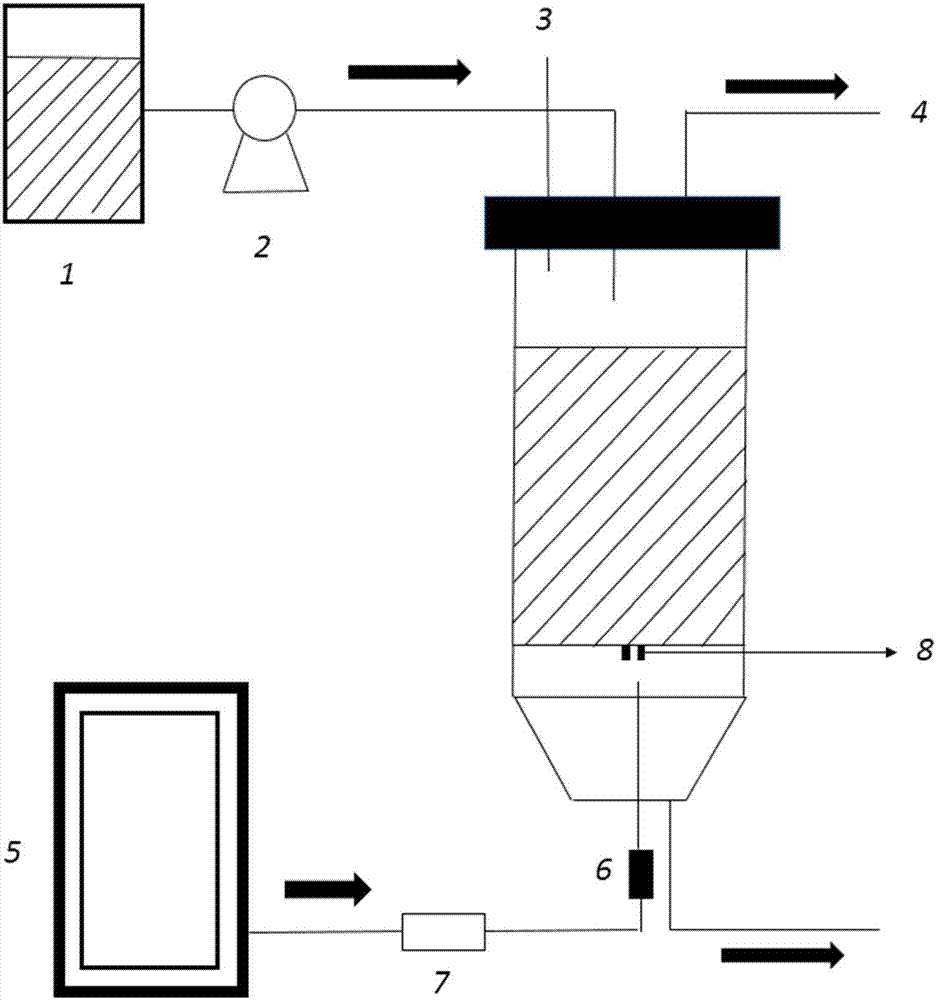

[0032] (1) Wash the fiber material in deionized water for 1-3 hours, then soak the cleaned material in 10-50% (mass fraction) NaOH for 1-6 hours, and then wash the material in deionized water for 1 hour ~3h, until the NaOH is cleaned and the surface of the carrier is neutral;

[0033] (2) Place the porous fiber material treated in step (1) in 0.1-10% (volume fraction) aqueous solution of silane coupling agent, soak for 10-60min, then place the porous fiber material in deionized water to fully rinse Then put it in 120 ℃ drying, save for future use.

[0034]The silane coupling agent is vinyltriethoxysilane, vinyltrimethoxysilane, 1,2-bistrimethoxysilylethane, methylphenyldimethoxysilane, methyltriacetyl Any one or more of oxysilanes.

Embodiment 1

[0035] The preparation of embodiment 1 porous fibrous material immobilization medium

[0036] (1) Wash the polyester fiber in deionized water for 1 h, then soak it in 25% (mass fraction) NaOH for 3 h, then wash the polyester fiber in deionized water for 3 h until the NaOH is cleaned, and the surface of the carrier is neutral;

[0037] (2) Soak the polyester fiber in 6% (volume fraction) vinyltriethoxysilane aqueous solution for 30 minutes, then place the polyester fiber in deionized water for full rinsing, dry at 120°C, and store at 4°C for later use .

Embodiment 2

[0038] The preparation of embodiment 2 porous fibrous material immobilization medium

[0039] (1) Wash the polyethylene carrier in deionized water for 1.5h, then soak it in 25% (mass fraction) NaOH for 2h, then wash the polyethylene in deionized water for 2h until the NaOH is cleaned, and the surface of the carrier is neutral;

[0040] (2) Soak the polyethylene in a 3% (volume fraction) vinyltrimethoxysilane aqueous solution for 20 minutes, then rinse the polyethylene fully in deionized water, dry it at 120°C, and store it at 4°C for later use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com