Aspergillus oryzae ZA116 bacterial strain and application thereof

A ZA116, Aspergillus oryzae technology, applied in fungi, biochemical equipment and methods, food science and other directions, can solve the problems of difficult to control the amount of mycelium added, increase the difficulty of crude oil filtration, affect the fermentation process, etc., and achieve easy industrialization. The effect of promotion, large-scale production and application value, and increasing glutamic acid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

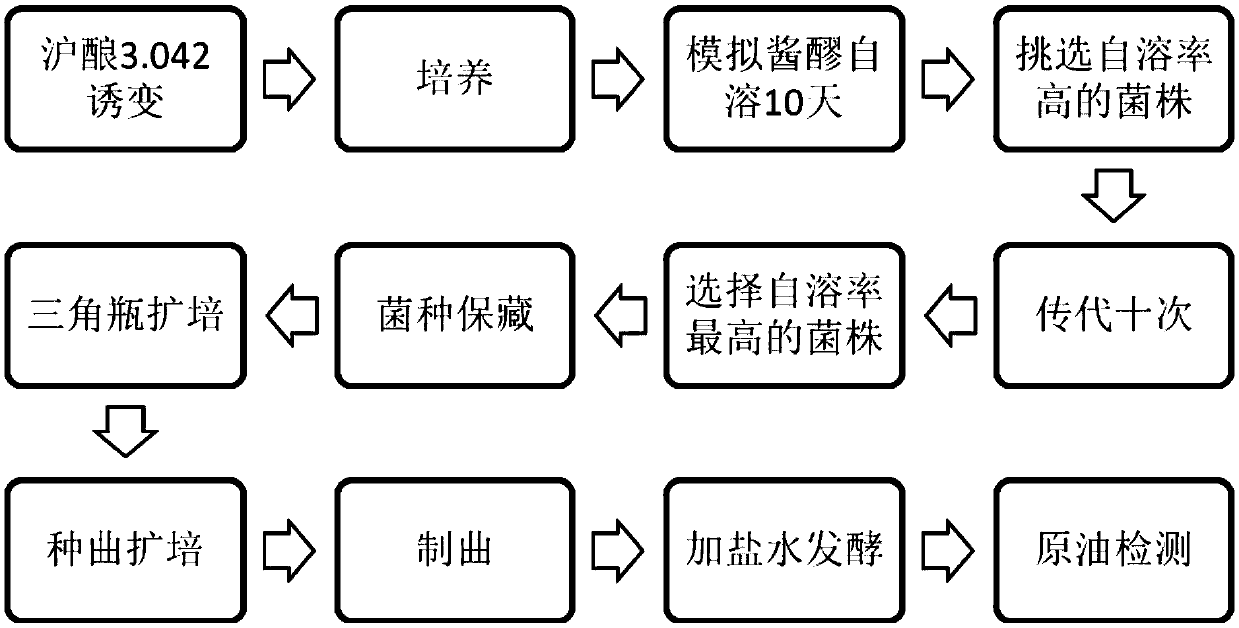

[0037] Embodiment 1 Aspergillus oryzae strain mutagenesis breeding and screening

[0038]Aspergillus oryzae Huyao 3.042 is subjected to one or more mutagenesis by one or a combination of ultraviolet mutagenesis and ARTP mutagenesis, and then the conidia are diluted with physiological saline to prepare a spore dilution, and then the spores are The diluted solution was inoculated on soybean juice medium and cultured at 30°C. After the bacteria are obtained, they are transferred to the soybean juice slant medium, cultivated at 30°C until they are mature, and then autolyzed under the conditions of simulated soy mash fermentation for 10 days. After that, the high-throughput autolysis rate is detected, and the initial screening is carried out according to the autolysis rate. Six Aspergillus oryzae strains were obtained.

[0039] Preliminary screening of Aspergillus oryzae strains with high autolysis rate by the high-throughput autolysis rate detection method, specifically adopting ...

Embodiment 2

[0046] Example 2 Screening bacterial strain genetic stability detection

[0047] The six Aspergillus oryzae strains obtained in Example 1 were inoculated on the soybean juice medium for ten consecutive passages, and the 1st generation, the 5th generation, and the 10th generation soybean juice slant strains were used for high-throughput autolysis rate experiments. Huyao 3.042 strain was used as a control. If the error of the high-throughput autolysis rate in the 10-generation determination is within 10%, it indicates that the strain has good genetic stability. The results are shown in Table 1: HS5 always maintains the highest autolysis rate in the test , and its genetic stability is good.

[0048] Table 1 Genetic stability detection of strains with high autolysis rate (high-throughput autolysis rate / %)

[0049]

[0050]

[0051] The colony morphology of Aspergillus oryzae HS5 is as follows: on the soybean juice medium, cultivated at 30°C for 72h, the diameter of the colo...

Embodiment 3

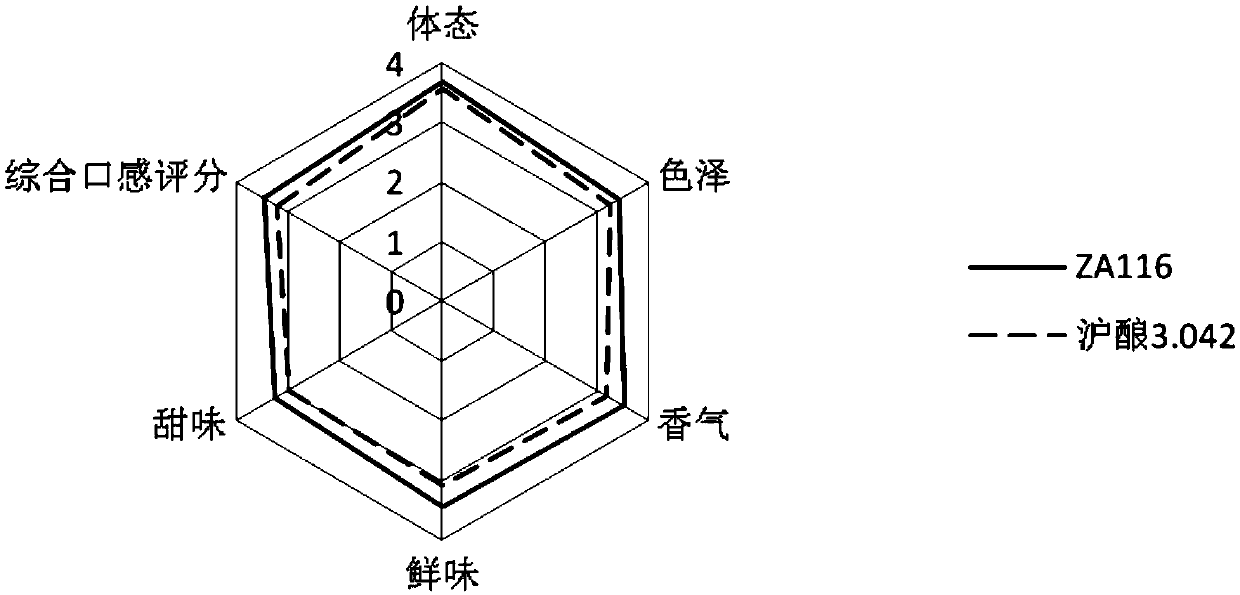

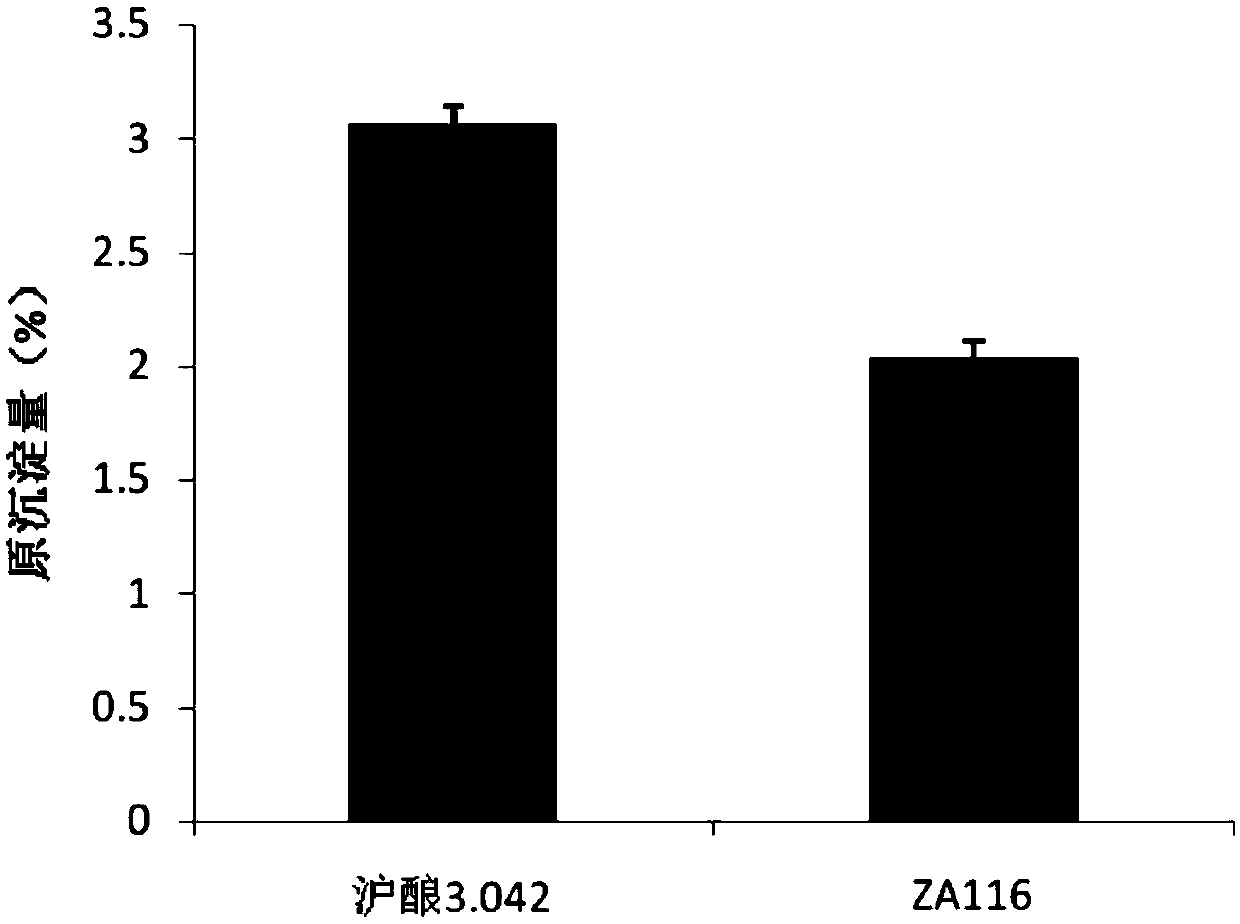

[0054] Example 3 Comparison of autolysis rate between Aspergillus oryzae ZA116 and Shanghai Niang 3.042 strain

[0055] Using Aspergillus oryzae as the production strain, the hydrolysis and release of bacterial substances during the autolysis process can promote the nutrition and flavor of the fermented product, but the autolysis of Aspergillus oryzae is closely related to the environmental conditions. The effect of pH value, autolysis temperature and oxygen status on the autolysis of Aspergillus oryzae is particularly significant. Hou Chun et al. The conditions were optimized, and the mycelium dry weight loss rate of Aspergillus oryzae reached the highest under the conditions of 45°C, anoxic, and pH4.

[0056] Aspergillus oryzae ZA116 and Aspergillus oryzae Huniang 3.042 obtained in Example 2 were subjected to strain autolysis rate experiments under the conditions of the control group and the simulated moromi group, respectively, to detect the dissolution of nucleic acids, to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com