Method for manufacturing lactobacillus fermented soybean rich in gamma-aminobutyric acid

A technology of aminobutyric acid and a production method, which is applied in the direction of lactobacillus, bacteria used in food preparation, food science, etc., can solve the problems of less production and promotion of health-care fermented soy sauce, less flavor, and low salt content in products, and achieve Improve the activity of koji protease, better quality and flavor, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] (1) Sample preparation: Weigh about 5g of sample, put it into a 200mL beaker, add 50mL of distilled water, break it up evenly with a homogenizer, transfer it to a centrifuge tube, and centrifuge it at 3500r / min for 15min. Transfer the solution into a 100mL volumetric flask, add 10mL of distilled water to the centrifuge tube sedimentation, centrifuge again, pour the supernatant into the volumetric flask, repeat this operation 3 times, and finally dilute to 100mL with distilled water, and mix well.

[0048] (2) Determination of samples: draw 10mL of sample solution into a 200mL beaker, add 60mL of distilled water, start the magnetic stirrer, titrate the pH of the acidity meter to 8.2 with 0.05mol / L NaOH solution, add 10mL of formaldehyde solution to mix, and then use 0.05 The mol / L NaOH is titrated to 9.2, and the NaOH volume V consumed from pH 8.2 to 9.2 is recorded 1 ;Blank experiment only needs to change the sample into 10mL distilled water, write down the consumed NaO...

Embodiment 1

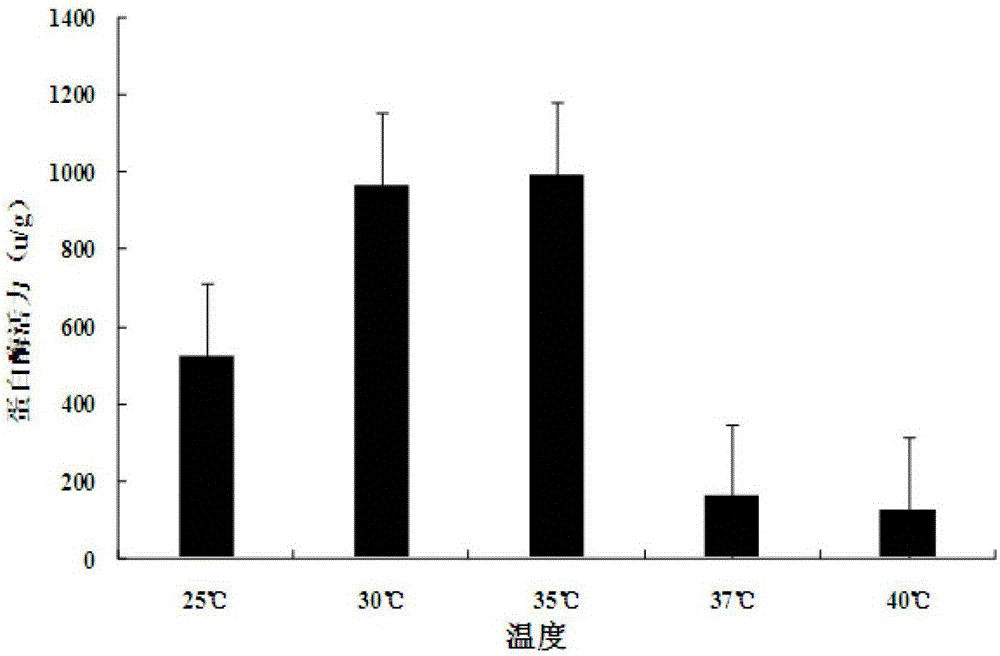

[0071] Taking protease activity as an index, factors such as bacteria powder ratio, inoculation amount, koji-making temperature, relative humidity and koji-making time were evaluated.

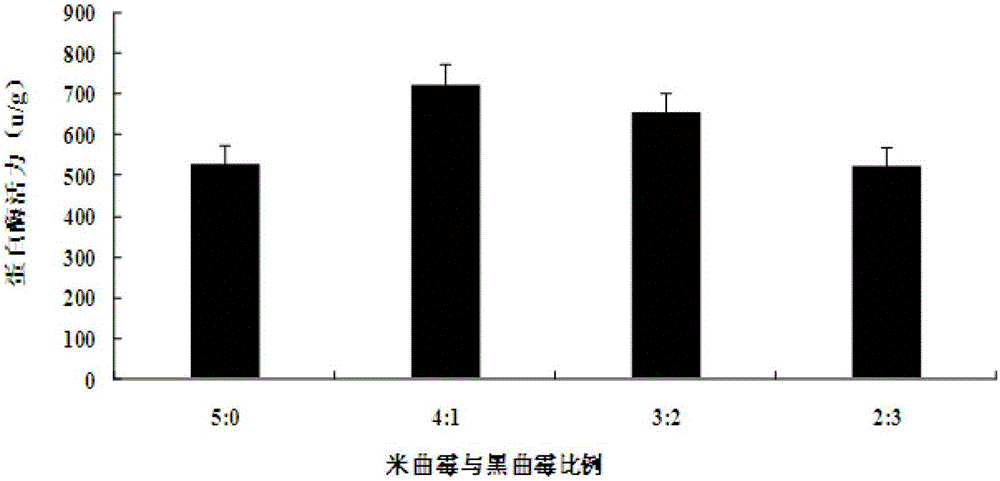

[0072] 1. Proportion of bacterial powder: select 100g of plump raw soybeans, wash them with clean water, then add 300mL, soak in water at 30°C for 4 hours, drain, add 1g of bacterial powder (inoculation amount 1.0%, w / w), The ratio of Aspergillus oryzae and bacteria powder was set to 5:0, 4:1, 3:2, 2:3. Under the conditions of temperature 30°C and relative humidity 75%, protease activity was measured after koji making for 60 hours.

[0073] Depend on figure 1 It can be seen that when the ratio of Aspergillus oryzae and Aspergillus niger powder is 4:1, the protease activity produced by koji making is the highest.

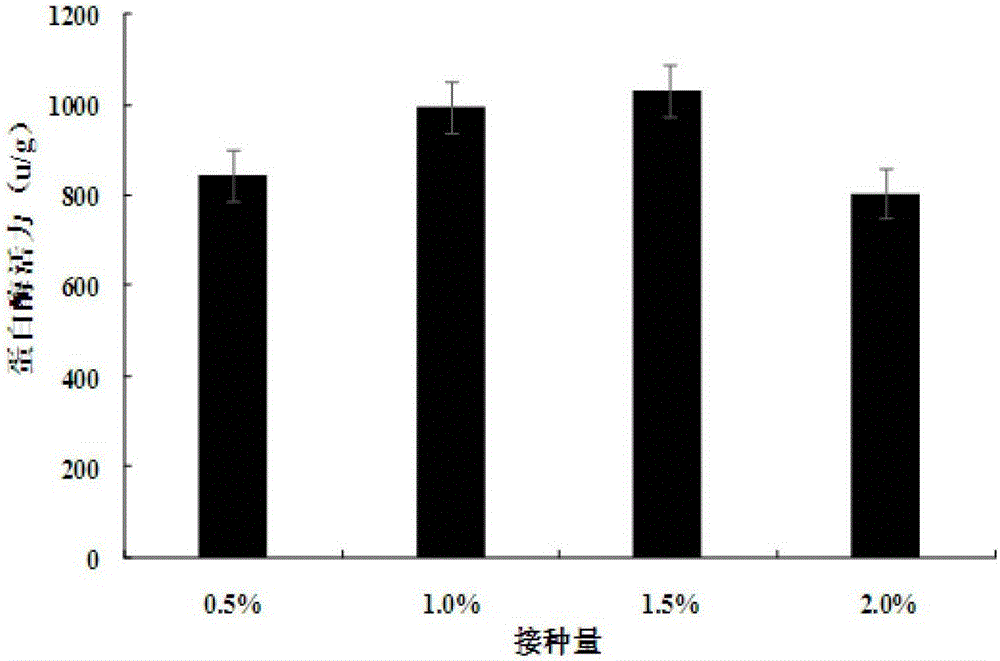

[0074] 2. Inoculum amount: select 100g of plump raw soybeans, wash them with clean water, then add 300mL, soak in water at 30°C for 4 hours, drain, and add fungal powder, wherein the...

Embodiment 2

[0083] Through the research of Example 1, the best koji-making process of fermented soybeans was obtained.

[0084] Specific steps are as follows:

[0085](1) Take 1 kg of plump soybean granules, wash them with clean water until they are clean, add 3L of 30°C warm water to soak for 4 hours, drain the water, put them in a 121°C high-pressure cooking pot for 20 minutes, cool to room temperature, and obtain cooked soybeans particles;

[0086] (2) Add 15g of mixed bacteria powder to the cooked soybean granules, wherein the mass ratio of Aspergillus oryzae and Aspergillus niger powder is 4:1, mix well, put it into an incubator to make koji for 48h, and the temperature is 30°C. The relative humidity is 75%;

[0087] (3) After the koji making is completed, add salt and sterile water, and inoculate 1 mL containing 10 7 cfu / mL Lactobacillus plantarum (Lactobacillus plantarum) CGMCC NO.3782 bacterial liquid, add 50g salt and 500mL sterile water, adjust the temperature to 37°C, adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com