Aspergillus niger and method for catalytically producing fructo-oligosaccharide by virtue of whole-cells of aspergillus niger

A technology of fructooligosaccharides and Aspergillus niger, applied in the field of oligosaccharides, can solve the problems of complex separation and purification process, restriction of industrial application, high cost of enzymatic conversion, etc., achieve simple process, reduce investment in fermentation tanks and auxiliary equipment, Avoid the effect of enzyme inactivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

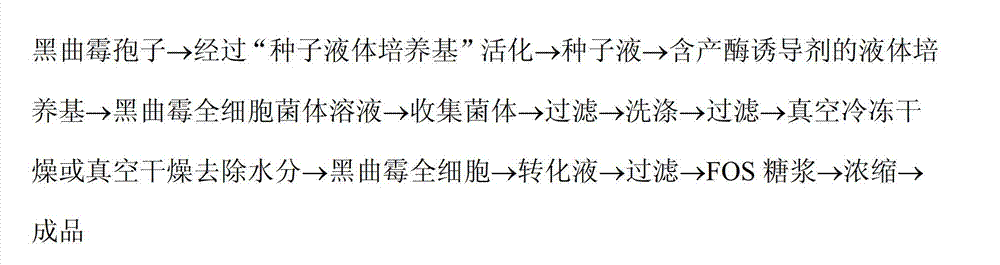

Method used

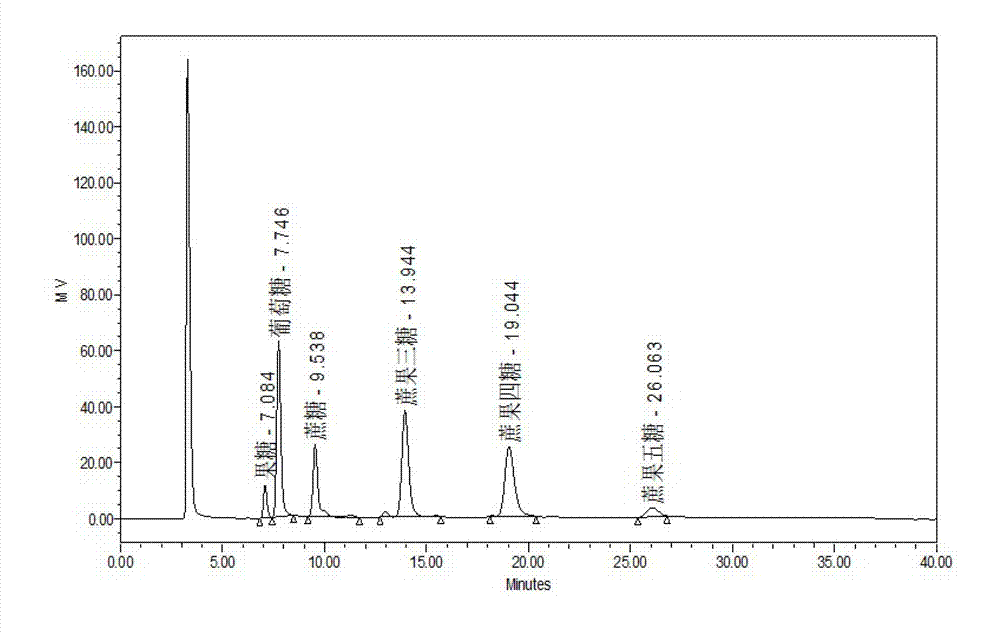

Image

Examples

Embodiment 1

[0035] The first step: inoculate the spores of Aspergillus niger FOS-0620 into the seed liquid medium, and the inoculum size is 1×10 5 A / L, at 33 DEG C, the bacterial cell solution after 16 hours of cultivating on a shaker with a rotating speed of 150r / min is made into a seed liquid; the seed liquid culture medium is: 20g / L sucrose, 30g / L corn flour, 100g / L Yeast extract, 2g / L NaNO 3 ;Stir and dissolve evenly, then sterilize, and cool for later use;

[0036] The second step: Inoculate the seed solution obtained in the first step into the liquid medium containing the enzyme-producing inducer at a volume ratio of 5:100, and cultivate it at 33°C for 24 hours at a rotational speed of 150r / min. The whole cell solution of Aspergillus niger was made from the cell solution of Aspergillus niger; the liquid medium containing the enzyme inducer was: 70g / L sucrose, 20g / L yeast extract, 15g / L corn flour, 3g / L NaNO 3 ;Stir and dissolve evenly, then sterilize, and cool for later use;

[0...

Embodiment 2

[0042] The first step: inoculate the spores of Aspergillus niger FOS-0620 into the seed liquid medium, and the inoculum size is 1×10 10 A / L, at 28 ℃, under the condition of rotating speed of 100r / min, the bacterial liquid after culturing for 24h is the seed liquid; the seed liquid culture medium is: 50g / L sucrose, 7g / L malt powder, 10g / L peptone, 3g / L NaCl; stir and dissolve evenly, sterilize with sterilizer, cool for later use;

[0043] Step 2: Inoculate the seed solution obtained in the first step into a liquid medium containing an enzyme-producing inducer at a ratio of 10:100 by volume, and cultivate it for 16 hours at 28°C with a rotation speed of 100r / min. The thalline solution of Aspergillus niger whole cell thalline solution is made; The liquid medium containing the enzyme inducer is: 70g / L sucrose, 35g / L yeast extract, 15g / L corn flour, 12g / L K 2 HPO 4 , 1.5g / LMgSO 4 .7H 2 O, 10g / L NaNO 3 ;Stir and dissolve evenly, then sterilize, and cool for later use;

[0044]...

Embodiment 3

[0048] The first step is to inoculate the spores of Aspergillus niger FOS-0620 into the seed liquid medium, and the inoculum size is 1×10 6 cells / L, at 25°C, with a rotation speed of 120r / min, the bacterial cell solution was cultivated for 20h to make seed liquid; the seed liquid culture medium was: 30g / L sucrose, 5g / L malt powder, 7g / L Peptone, 50g / L yeast extract, 1.5g / L NaCl, 1.5g / L NaNO 3 ;Stir and dissolve evenly, then sterilize, and cool for later use;

[0049] The second step is to inoculate the seed solution obtained in the first step into the liquid medium containing the enzyme-producing inducer at a volume ratio of 8:100, and cultivate it for 20 hours at 25°C with a rotation speed of 300r / min. The thalline solution is made into Aspergillus niger whole cell thalline solution; The liquid medium containing the enzyme inducer is: 10g / L sucrose, 50g / L yeast extract, 20g / L corn flour, 6g / L K 2 HPO 4 , 0.5g / L MgSO 4 .7H 2 O, 6.5g / L NaNO 3 ;Stir and dissolve evenly, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com