Aspergillus niger strain with high yield of beta-D-fructofuranosidase and liquid-state fermentation and enzyme production method of aspergillus niger strain

A technology of fructofuranosidase and Aspergillus niger strains, applied in the field of microorganisms or enzymes, can solve the problems of undisclosed applicability, heat resistance, and low production costs, and achieve the effects of shortening the fermentation cycle, reducing fermentation costs, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Embodiment 1 culture medium preparation

[0054] PDA slant medium: sucrose 25g, NaNO3 2g, MgSO 4 0.5g, KCl 0.5g, FeSO 4 0.01g, K 2 HPO 4 1g, 20g agar, 1000mL distilled water, pH 4.5, sterilize at 121°C for 20min;

[0055] Seed medium: 150mL wort juice, 3g agar, adjust pH to 4.5, sterilize at 121°C for 20min;

[0056] The composition of the seed tank medium by mass fraction: glucose 2%, yeast powder 1.5%, KH 2 PO 4 0.15%, CaCl 2 0.005%, prepared with distilled water, adjusted to pH 4.5, sterilized at 121°C for 30 minutes;

[0057] The fermenter culture medium is composed by mass fraction: 4% corn starch, 4% corn flour, 4% bean cake powder, 1% ammonium sulfate, KH 2 PO 4 0.3%, corn steep liquor 0.6%, CaCl 2 0.5%, prepared with distilled water, adjusted to pH 4.5, sterilized at 121°C for 30 minutes;

[0058] The feed medium is composed by mass fraction: cornstarch 10%, ammonium sulfate 1%, KH 2 PO 4 0.1%, corn steep liquor 0.6%, CaCl 2 0.5%, prepared w...

Embodiment 2

[0060] Example 2 Aspergillus niger strain QL-225 fermented to produce enzyme and the extraction and refining method of the produced FFase

[0061] An Aspergillus niger strain with high production of β-D-fructofuranosidase, specifically the Aspergillus niger strain (Aspergillus niger) QL-225, and the preservation number is CGMCC No.13168.

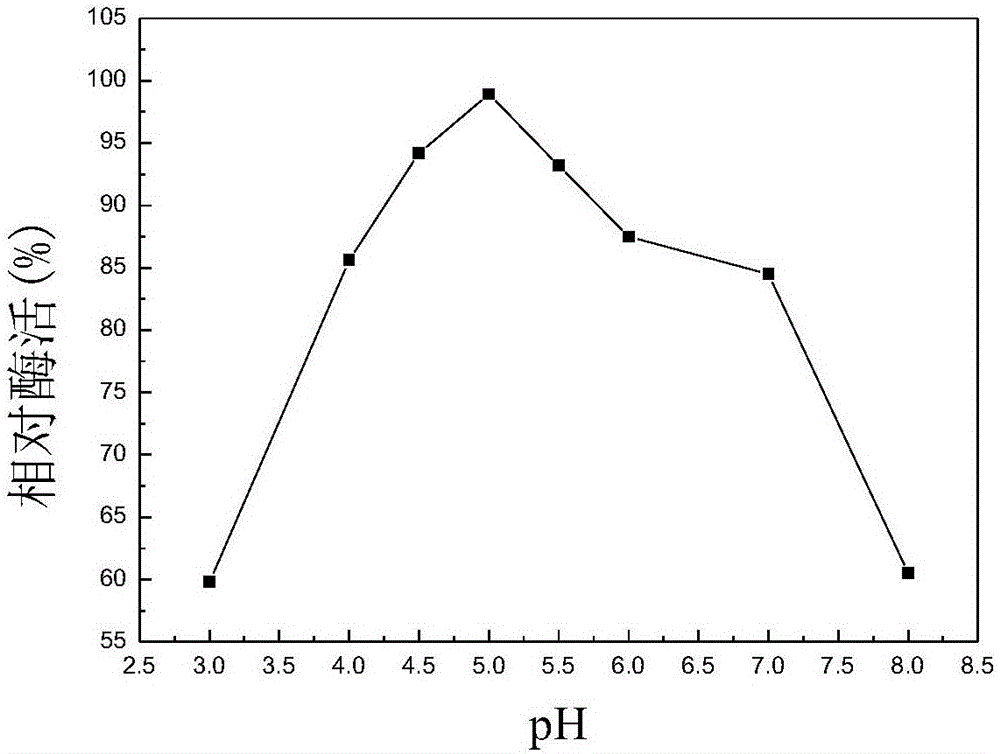

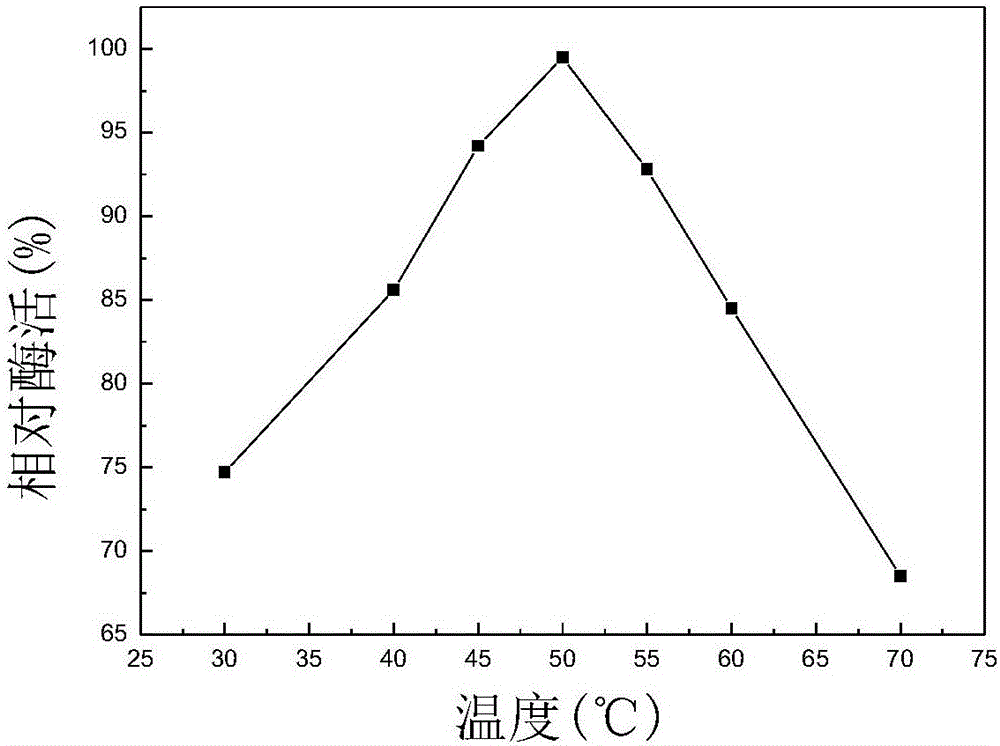

[0062] Aspergillus niger strain QL-225 produces β-fructosidase by liquid fermentation, the optimum pH is 4.0-7.0, and the optimum temperature range is 40°C-60°C.

[0063] The method for producing enzyme by liquid fermentation of Aspergillus niger strain QL-225 mainly comprises the following steps:

[0064] Slant culture: Take a ring of Aspergillus niger strain QL-225 and inoculate it on the PDA slant medium, and cultivate it at a constant temperature at 30°C for 72 hours to obtain first-class seeds;

[0065] Shake flask culture: Pick a ring of first-grade seeds and insert them into the seed medium, and cultivate them for 72 hours at a const...

Embodiment 3

[0075] Example 3 Aspergillus niger strain QL-225 fermented to produce enzyme and the extraction and refining method of the produced FFase

[0076] An Aspergillus niger strain with high production of β-D-fructofuranosidase, specifically the Aspergillus niger strain (Aspergillus niger) QL-225, and the preservation number is CGMCC No.13168.

[0077] Aspergillus niger strain QL-225 produces β-fructosidase by liquid fermentation, the optimum pH is 4.0-7.0, and the optimum temperature range is 40°C-60°C.

[0078] The method for producing enzyme by liquid fermentation of Aspergillus niger strain QL-225 mainly comprises the following steps:

[0079] Slant culture: Take a ring of Aspergillus niger strain QL-225 and inoculate it on the PDA slant medium, and cultivate it at a constant temperature at 30°C for 72 hours to obtain first-class seeds;

[0080] Shake flask culture: Pick a ring of first-grade seeds and insert them into the seed medium, and cultivate them for 72 hours at a const...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com