High xylanase yield Aspergillus niger and application thereof

A xylanase, Aspergillus niger technology, applied in the direction of enzymes, microorganism-based methods, and microorganism determination/inspection, etc., can solve problems such as low xylanase enzyme activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: the screening of bacterial strain

[0023] Screening samples are dead branches, rotten leaves, soil and other materials. After the screening samples are properly processed, they are serially diluted and applied to the xylan primary screening medium. The formula of the medium is: each liter of medium contains KH 2 PO 4 0.5g, (NH 4 ) 2 SO 4 2.0g, MgSO 4 ·7H 2 O0.25g, xylan (purchased from Shanghai Yuanju Biology) 5.0g, agar 18-20g, the balance is water, pH5.6. Culture at 30°C for 4-7d, pick the colony with larger hydrolysis transparent circle on PDA Purified on the culture medium, and the purified strains were stored on a PDA slant.

[0024] Re-screening of fermentation activity of xylanase-producing strains: Inoculate the purified strains preserved on PDA slant into the same amount of fermentation re-screening medium, culture at 30°C, 120 rpm, for 6 days. Based on the assay method of Bailey (1992) et al. with appropriate modifications. The specific...

Embodiment 2

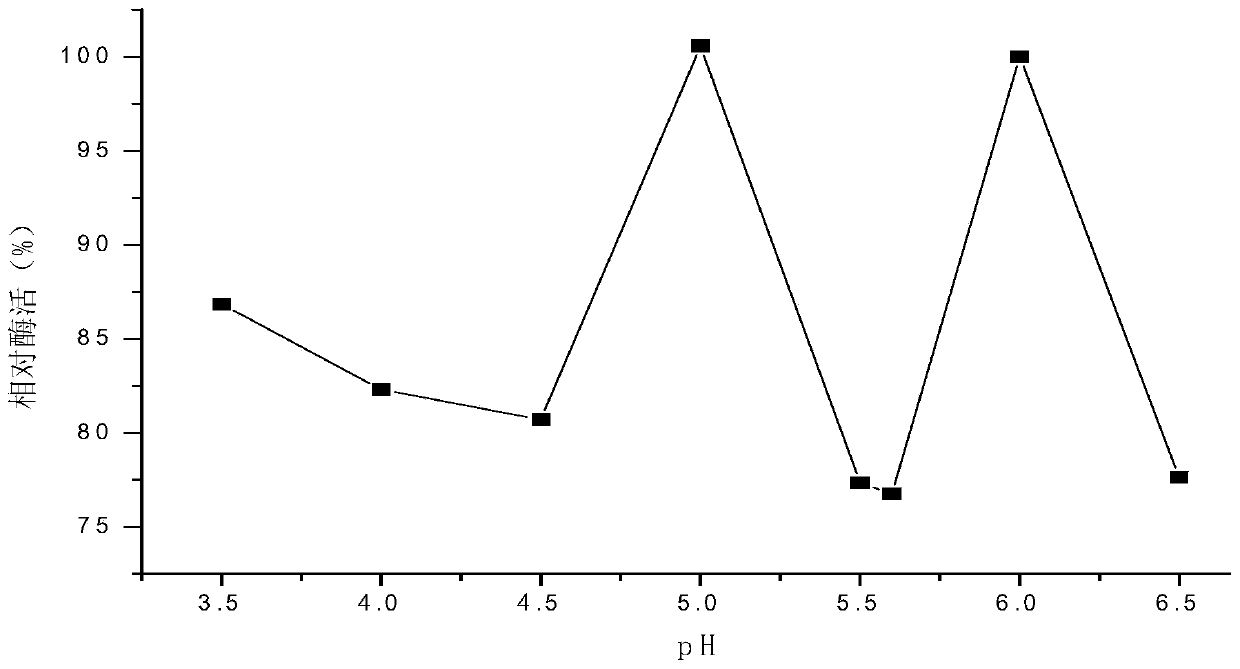

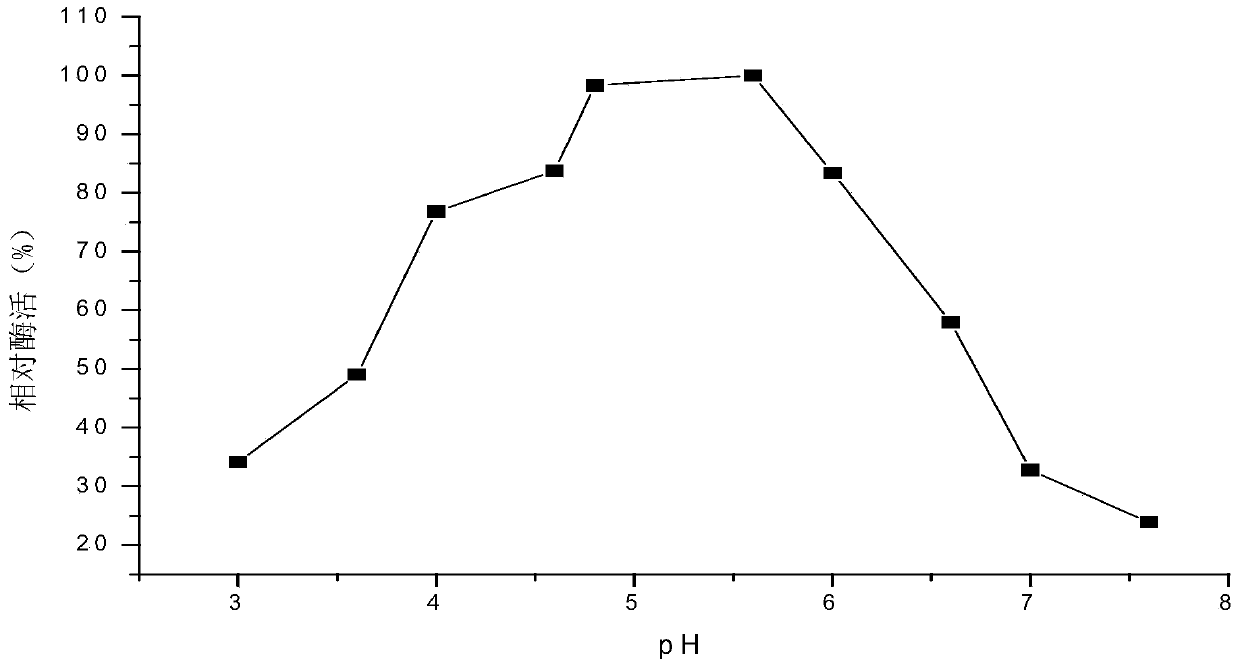

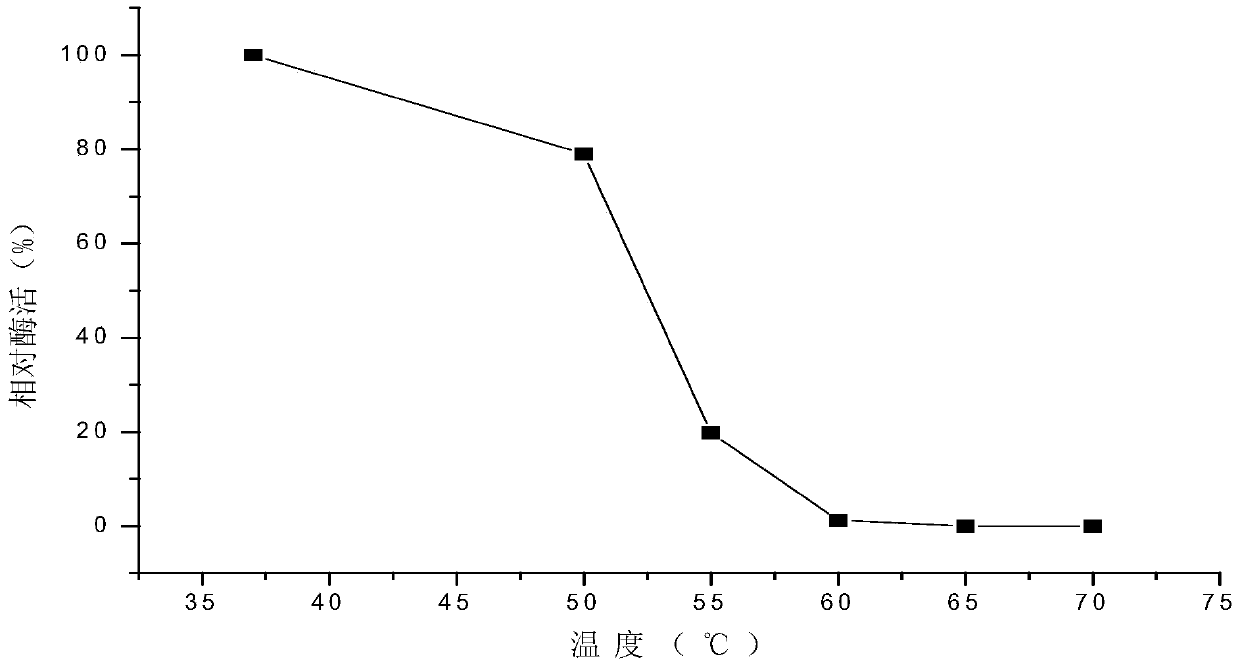

[0028] Embodiment 2: Preparation of xylanase and determination of its enzyme activity and enzymatic properties

[0029] 1. Preparation of xylanase preparation: Aspergillus niger (Aspergillus niger) SM24 / a was activated, cultured in seeds, and the seed medium was modified Mandel's nutrient solution (same as in Example 1), and then xylan was added to make Its final concentration is 5g / L, pH5.6, and sterilized at 115°C for 30min. The parameters of the shaker were set as follows: 30° C., 120 rpm, and the seed culture solution was obtained after culturing for 3 days. The seed culture liquid was inoculated into the solid fermentation medium with an inoculation amount of 7.5% (v / w). The formula of the solid fermentation medium was: the mass ratio of corncob to bran was 1:5, and the corncob and A mixture of substrate and support material, with 1.4g / L (NH4) 2 SO 4 , 2.0g / L KH 2 PO 4 , 0.3g / L CaCl 2 , 0.3g / L MgSO 4 , adding an appropriate amount of trace elements (FeSO 4 ·7H 2 ...

Embodiment 3

[0035] Example 3: Tolerance of xylanase to fermentation inhibitors

[0036] 1. Tolerance of xylanase to a single inhibitor

[0037] The relative enzymatic activity of xylanase to different concentrations of the same fermentation inhibitor (such as ethanol, acetic acid, furfural, vanillin and ferulic acid) showed certain differences, but generally speaking, they all retained a higher Enzyme activity residual rate. When the concentrations of ethanol and acetic acid are 5g / L, 15g / L and 30g / L, and furfural (2.5g / L, 1.25g / L and 0.4g / L), ferulic acid (1.2g / L, 0.6g / L and 0.2g / L) and vanillin (1.3g / L, 0.65g / L and 0.2g / L) concentration range, the enzyme activity retention rate of xylanase of the present invention is 93~108%.

[0038] 2. Tolerance of xylanase to mixed inhibitors added with 5-hydroxymethylfurfural:

[0039] Such as Figure 4 As shown, in the mixed inhibitor system of higher concentration (the concentrations of ethanol, acetic acid, furfural, vanillin, ferulic acid a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com