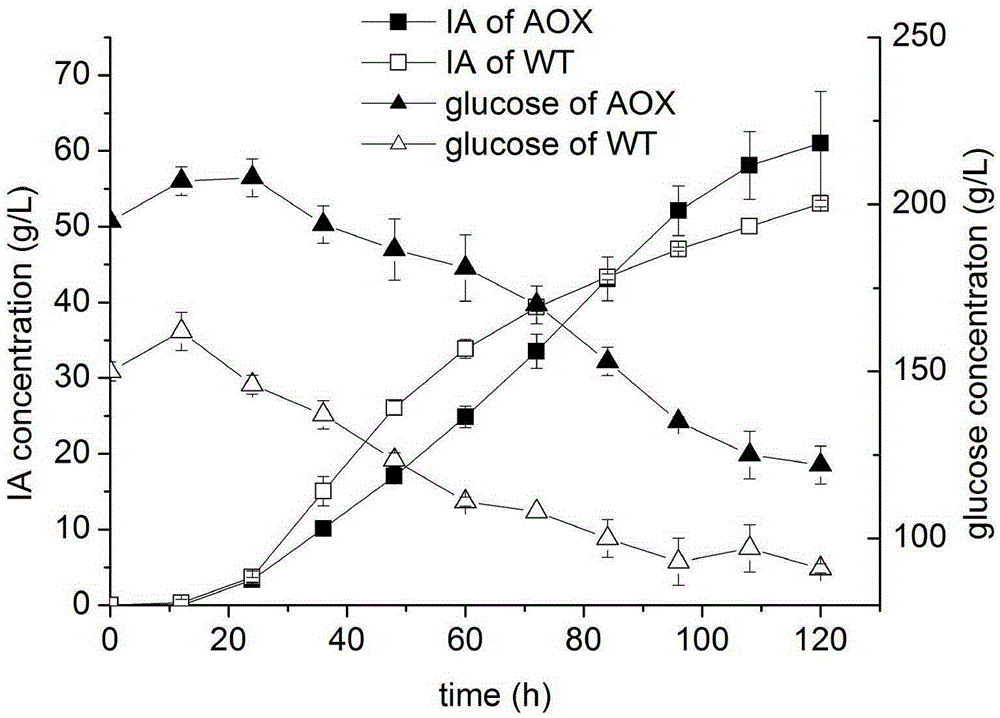

Method for increasing yield of itaconic acid produced by fermentation of aspergillus terreus

A technology of Aspergillus terreus and itaconic acid, applied in the field of bioengineering, can solve problems such as excess ATP and uncoupling, and achieve the effect of increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: the extraction of Aspergillus niger RNA

[0033] Aspergillus niger spores were inoculated into citric acid fermentation medium, cultured at 35°C and 250 r / min for 48 hours, the balls were collected with mirocloth, washed 3 times with sterile ultrapure water, filtered to dry, and quickly frozen in liquid nitrogen. The tissue was thoroughly ground by grinding with liquid nitrogen, and the total RNA of Aspergillus niger was extracted by QIAGEN RNeasyPlantMiniKit. The RNA was reverse-transcribed into cDNA with PrimeScriptRTreagentKitwithgDNAEraser from TAKARA Company.

Embodiment 2

[0034] Embodiment 2: the extraction of Aspergillus niger genomic DNA

[0035] Inoculate Aspergillus niger spores into ME liquid medium (3% malt extract, 0.5% tryptone), culture at 250 r / min at 35°C for 48 hours, collect the balls with mirocloth, wash 3 times with sterile ultrapure water, and filter dry Moisture, quickly frozen in liquid nitrogen. The tissue was thoroughly ground by grinding with liquid nitrogen, and the filamentous fungal genome was extracted by QIAGEN DNeasyPlantMiniKit.

Embodiment 3

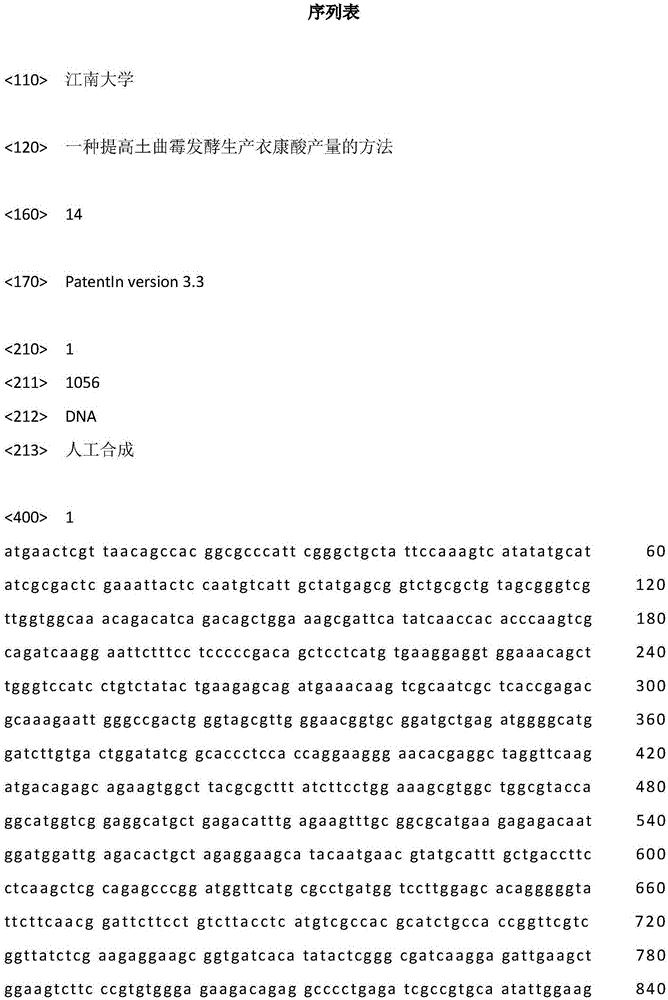

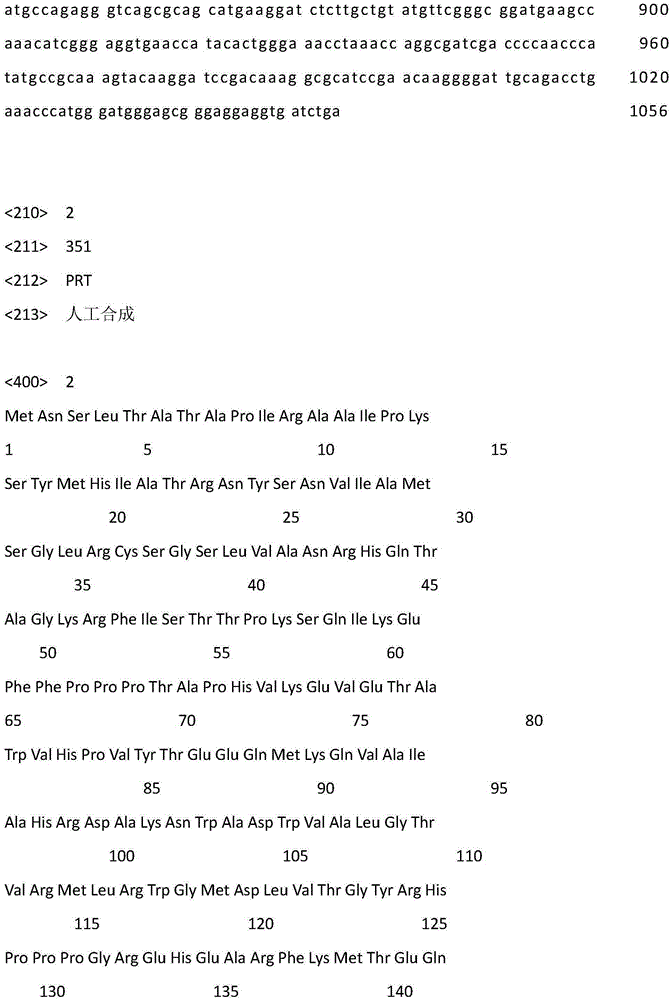

[0036] Embodiment 3: Construction of AOX protein expression cassette

[0037]Use primers trp-F (sequence shown in SEQIDNO.7) and trp-R (sequence shown in SEQIDNO.8) to amplify the trp terminator with pAN7-1 as a template, the sequence contains PstI and HindIII sites upstream and downstream, ligated Sequencing was performed on pMD19, digested with these two restriction endonucleases, and the sequence was ligated to pUC19 digested with the same restriction enzymes to obtain pUC19-trp. Utilize primers Pgas-F (sequence shown in SEQIDNO.9) and Pgas-R (sequence as shown in SEQIDNO.10) to amplify the Pgas promoter from Aspergillus niger genomic DNA, the two ends of the sequence contain EcoRI and KpnI restriction sites, Digested with restriction enzymes, and ligated the sequence to pUC19-trp which was also digested with restriction enzymes to obtain pUC-Pgas-trp. Utilize primer AOX-F (sequence as shown in SEQIDNO.11) and AOX-R (sequence as shown in SEQIDNO.12) to amplify AOX gene fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com