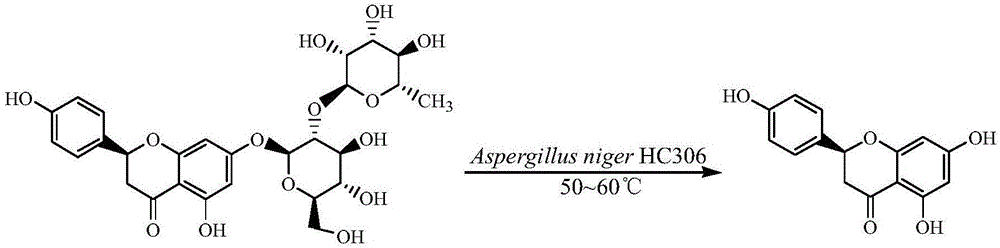

Aspergillus niger HC306 and application of aspergillus niger HC306 to prepare naringenin through naringin conversion

A technology of Aspergillus niger and catalyst, which is applied in the field of preparation of naringenin, can solve the problems of few by-products, low conversion yield, poor specificity, etc., and achieves low by-products, high conversion yield and stable batch Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1: Enrichment and isolation of transformed bacterial strains

[0024] Add about 20 g of crushed fresh pomelo peel into a 250 mL Erlenmeyer flask, and incubate at a constant temperature of 28°C for 5 days. Dilute the moldy enrichment 1 x 10 with sterile water 6 After doubling, spread it on the PDA plate medium, culture at 28°C for 4 days, pick mold colonies with different colors and shapes and transfer them to PDA slant medium, and place them at 28°C for 3 days to obtain slant strains rich in spores The 9 strains were numbered (HC301-HC309) respectively and stored in a refrigerator at 4°C for future use.

[0025] Both the plate medium and the slant medium are potato dextrose agar medium (PDA), prepared according to the following composition and method: potatoes are washed, peeled and cut into small pieces, weighed 200g, added tap water 1000mL, boiled for 30min, 4 Filter with a layer of gauze to remove the slag, make up the filtrate to 1000mL, then add 20g of su...

Embodiment 2

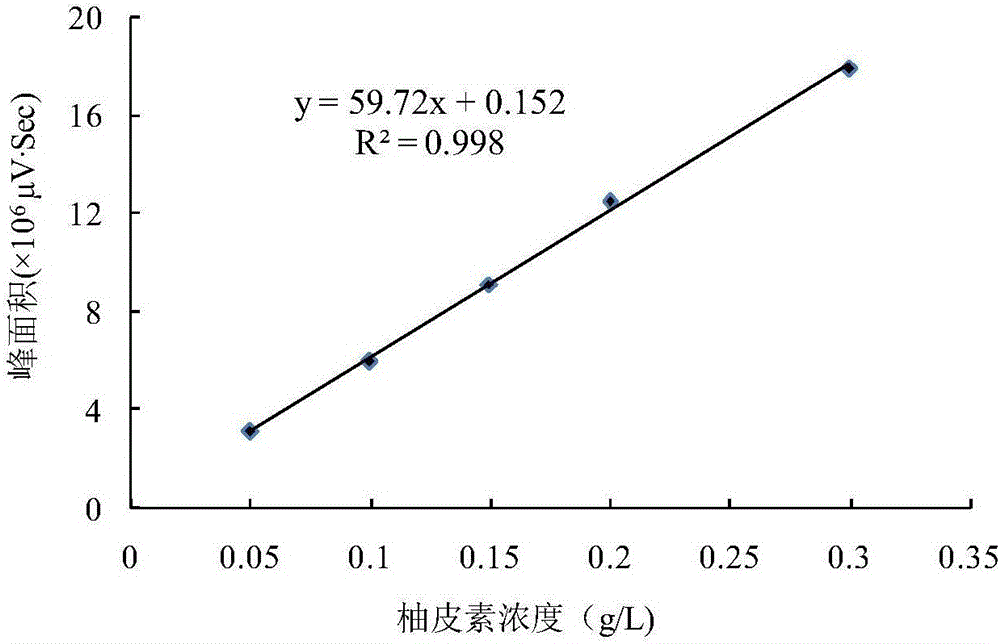

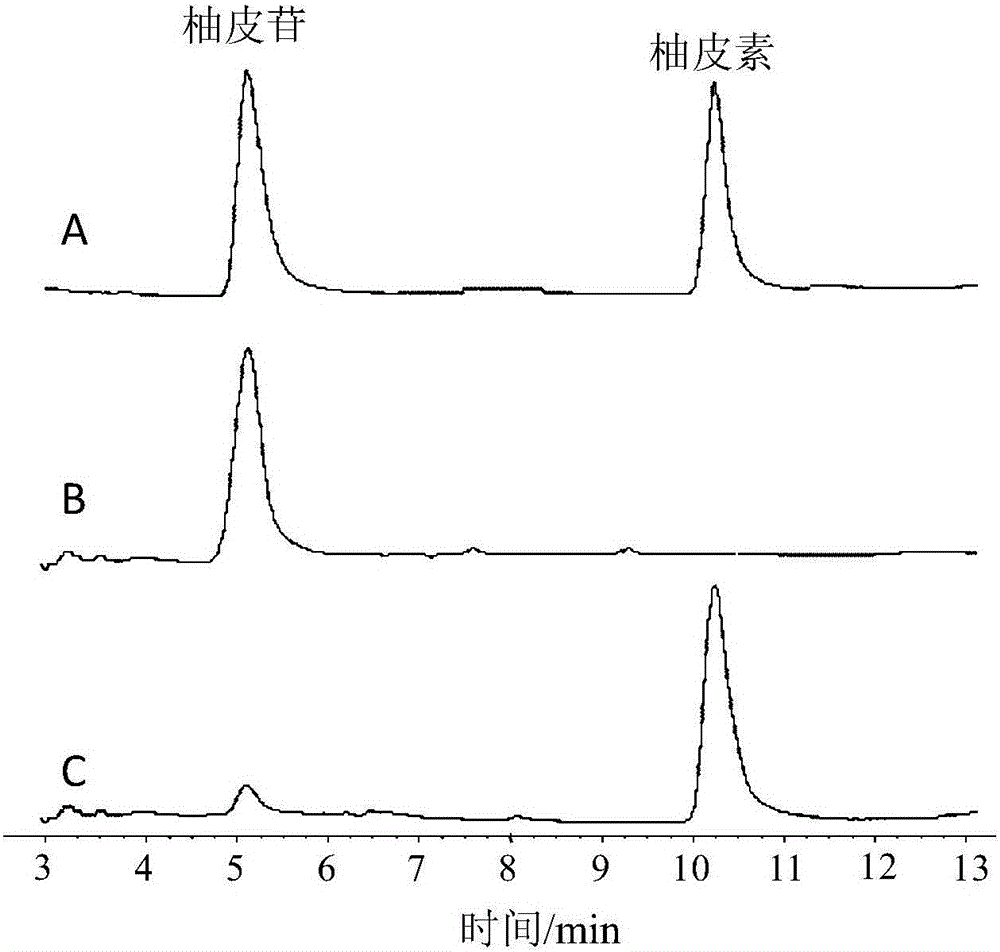

[0026] Example 2: Screening and classification identification of transformed strains

[0027] Dip the slant spores of each strain obtained in Example 1 with a cotton swab for 3 times, insert them into 50 mL of fermentation medium, and culture them for enzyme production at 28°C and 200 r / min constant temperature shaking conditions for 4 days, then pump 50 mL of fermentation liquid with a Buchner funnel. Filter, and the collected filtrate is the crude enzyme solution, about 40mL. Take 25mL of crude enzyme solution and place it in a 150mL Erlenmeyer flask, dissolve 0.25g of naringin in 25mL of pH 4.0 phosphate buffer, mix the two to form a transformation system (total volume 50mL), shake at 40°C and 200r / min at a constant temperature The transformation was carried out for 2 hours under the same conditions; after the transformation reaction, 5 mL of the transformation solution was centrifuged at 8000 g for 10 minutes, filtered through a 0.45 μm microporous membrane, and the concen...

Embodiment 3

[0038] Example 3: Application of Aspergillus niger HC306 strain transforming naringin to generate naringenin 1

[0039] Using the Aspergillus niger HC306 obtained by screening in Example 2 as the enzyme-producing strain, through seed expansion cultivation, the crude enzyme liquid prepared by fermentation was converted to treat naringin, and the molar conversion yield of naringenin was slightly improved compared with Example 2, and repeated There was no significant difference in the results of the 3 batches of experiments, indicating that the performance of the enzyme-producing naringenin produced by the strain to produce naringenin was stable, and the specific process steps were as follows:

[0040] (1) Inoculate the slant strain of Aspergillus niger HC306 stored in a refrigerator at 4°C in fresh PDA slant medium, and culture the slant at a constant temperature of 28°C for 3 days. Described PDA slant culture medium composition and preparation method are with embodiment 1;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com