Patents

Literature

36results about How to "High conversion rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

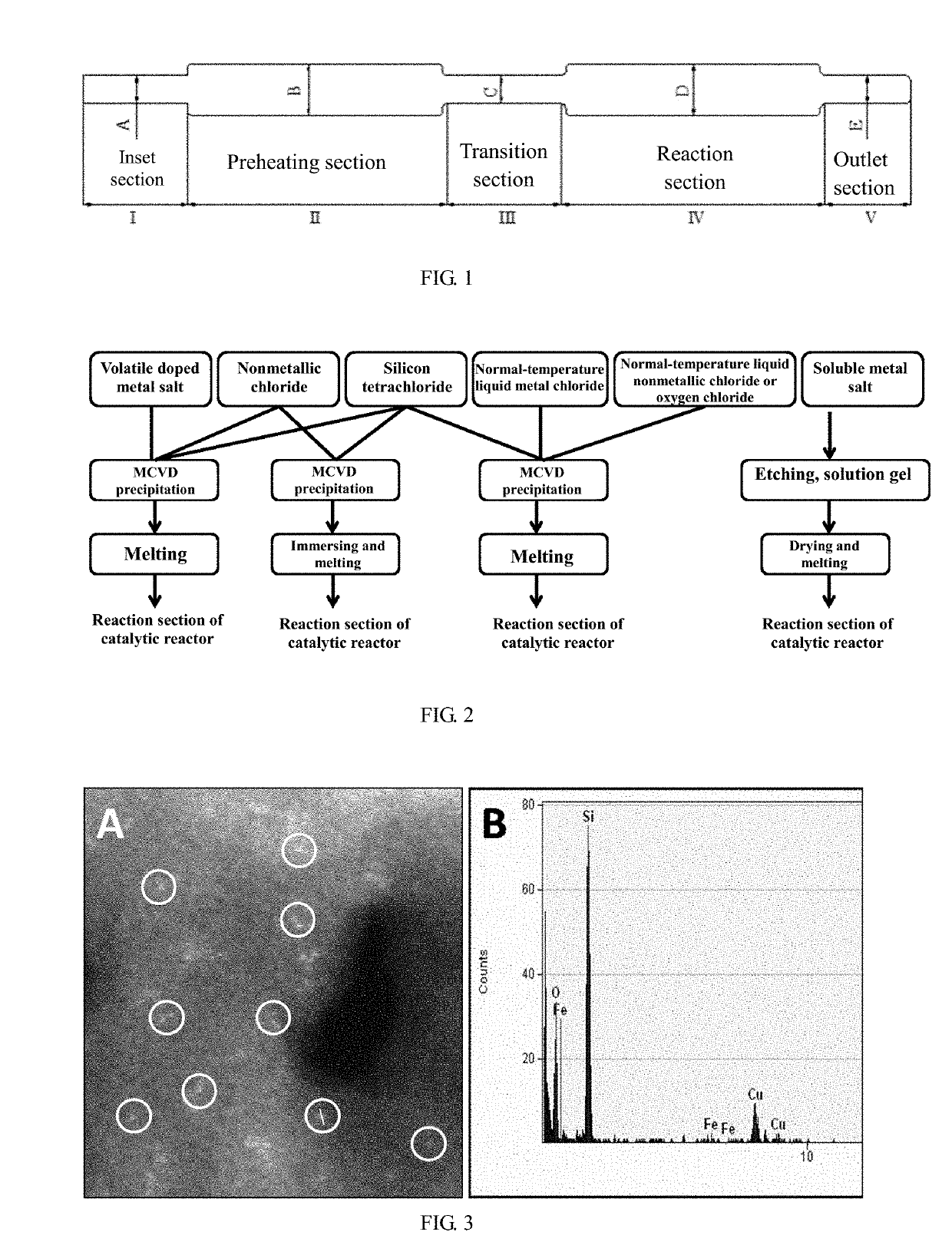

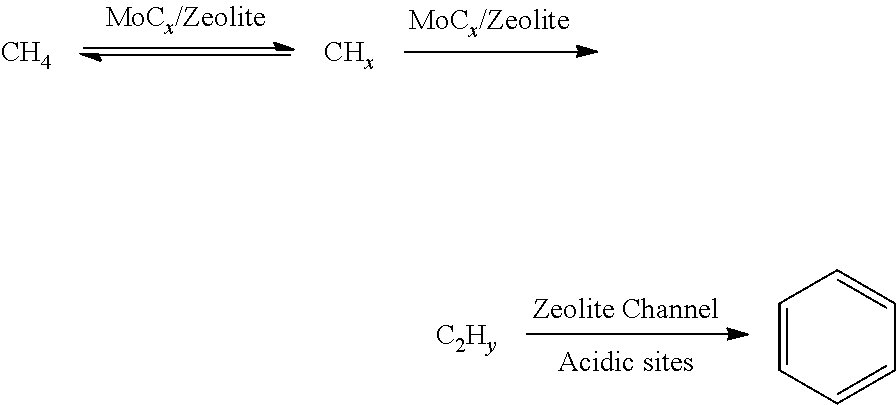

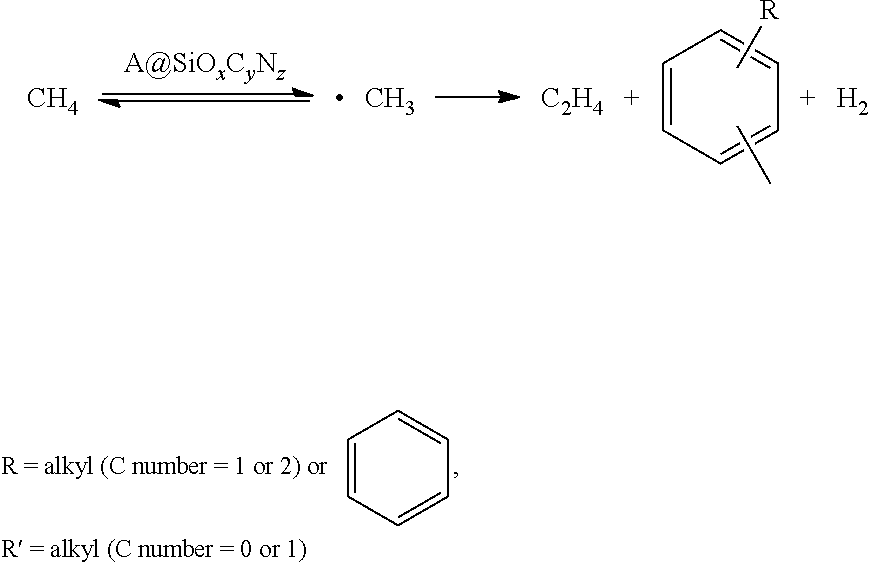

Catalytic reactor configuration, preparation and method of direct synthesis of ethylene through oxygen-free catalysis of methane

ActiveUS20190143288A1High stability of redoxHigh conversion rateCatalytic gas-gas reactionGaseous chemical processesHigh selectivityCoke deposition

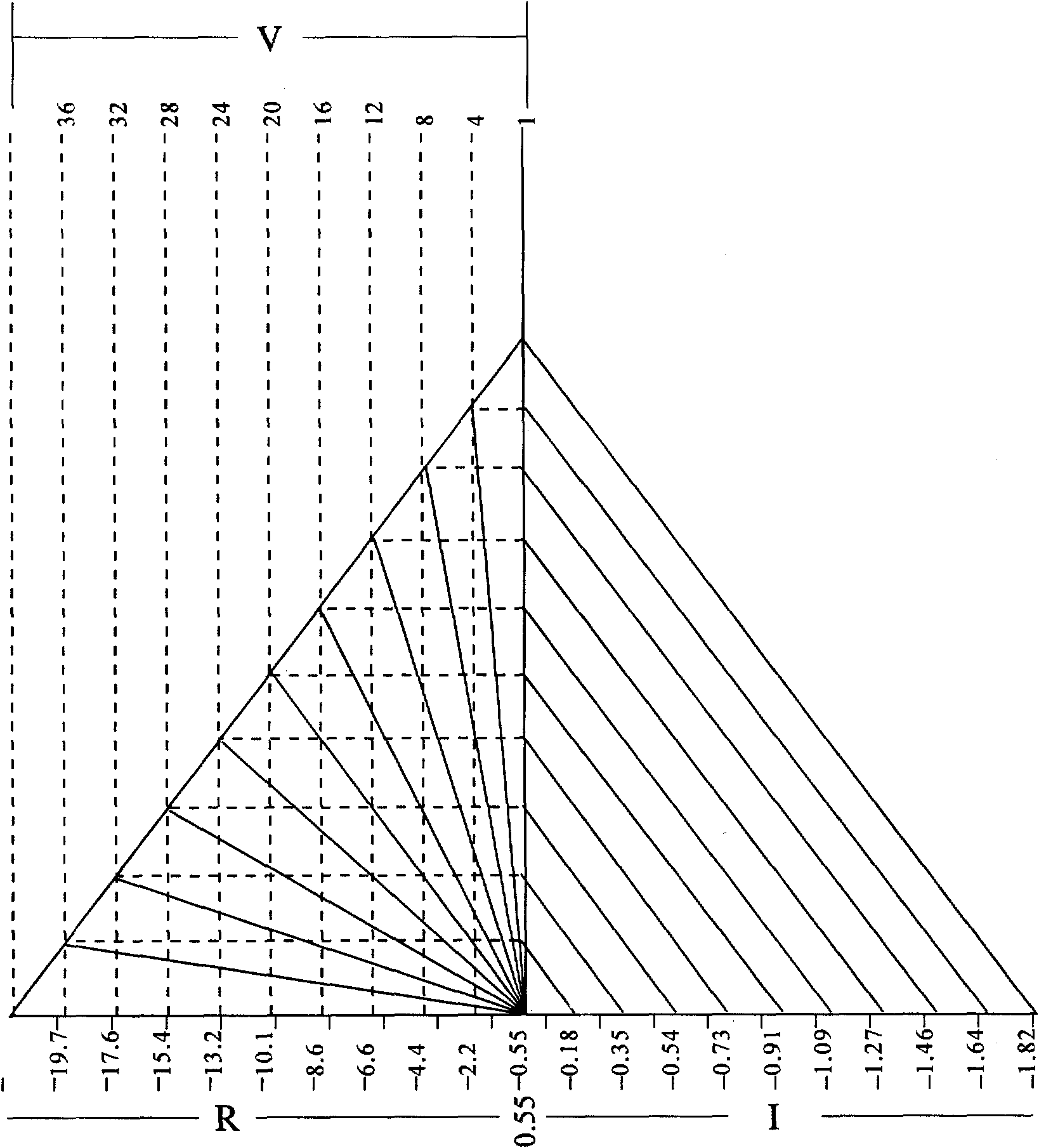

A reactor configuration comprises an inlet section I, a preheating section II, a transition section III, a reaction section IV and an outlet section V; except for the preheating section II and the reaction section IV, the existence of the inlet section I, the transition section III and the outlet section V depends on reaction conditions; and the process realizes no coke deposition synthesis of methane and high selectivity synthesis of ethylene. The methane conversion rate is 20-90%; ethylene selectivity is 65-95%; propylene and butylene selectivity is 5-25%; aromatic hydrocarbon selectivity is 0-30%; and coke deposition is zero.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

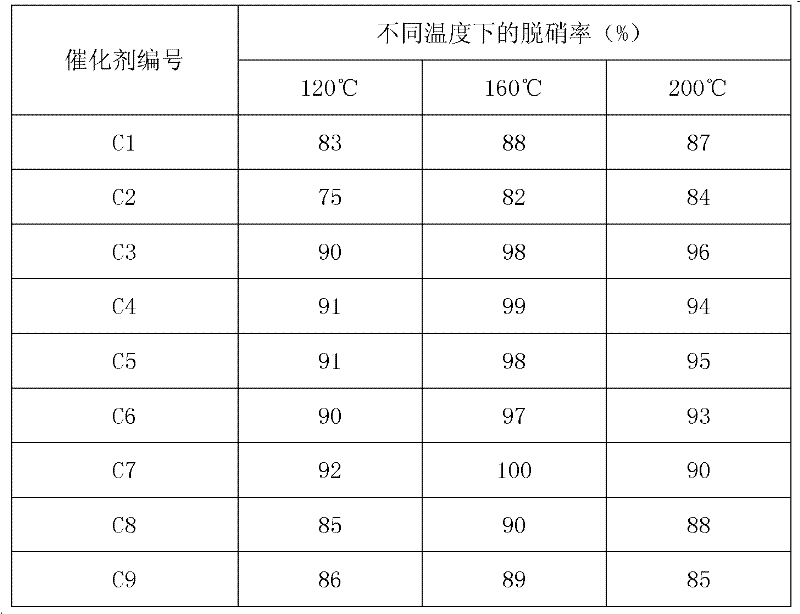

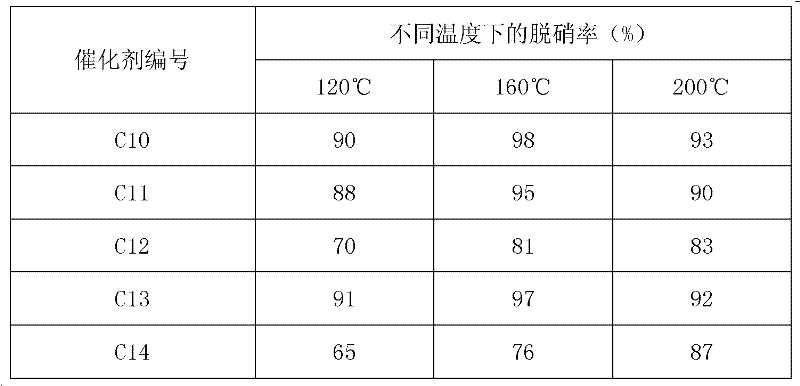

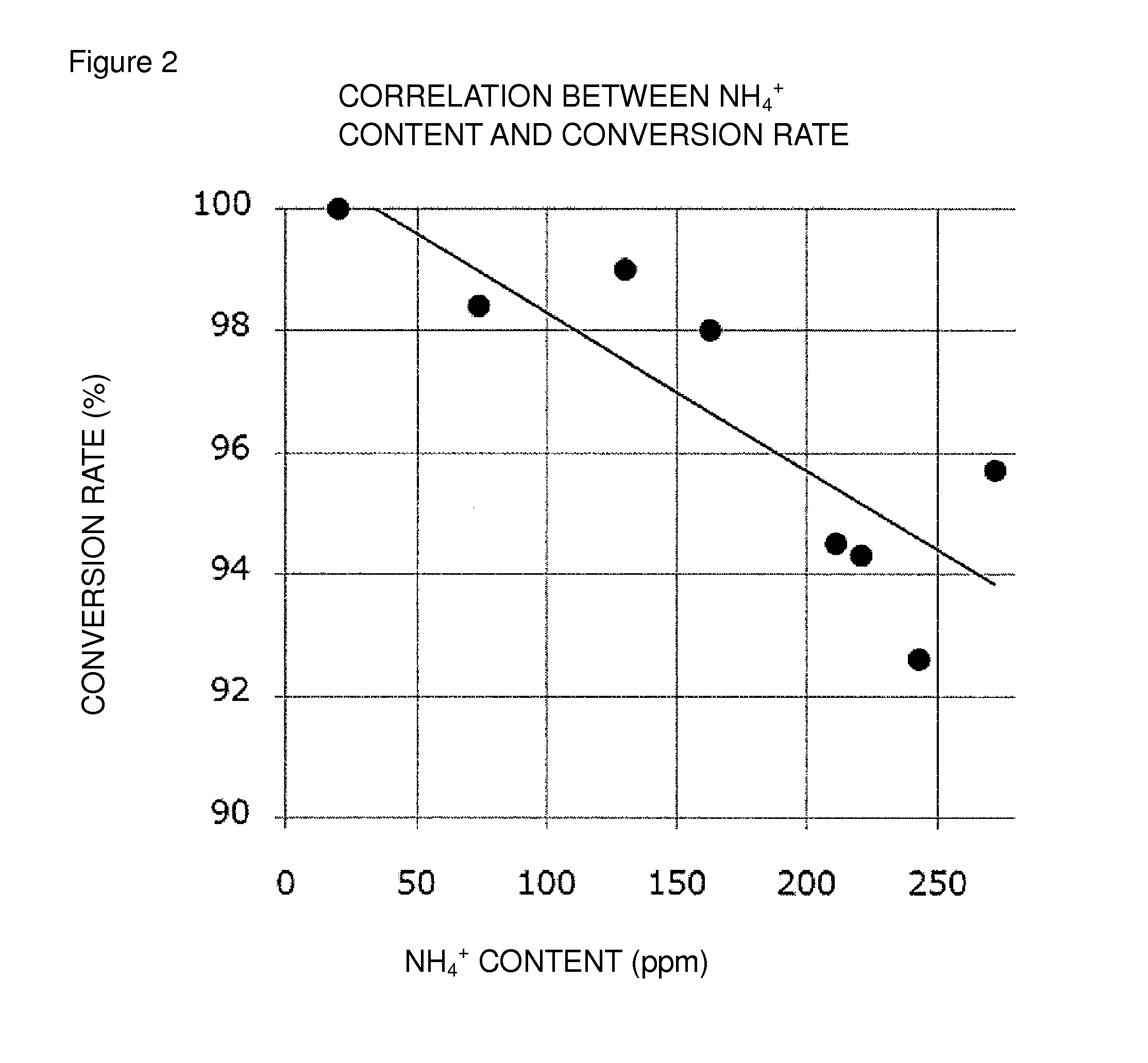

Catalyst for denitrating smoke at low temperature and production method and application thereof

ActiveCN102649077AObvious advantages of energy saving and consumption reductionHigh conversion rateDispersed particle separationCatalyst activation/preparationCeriumManganese

The invention discloses a catalyst for denitrating smoke at a low temperature and a production method and an application thereof, the catalyst consists of a main active component (A) and an assistant active component (B), wherein the main active component (A) is oxide of manganese, the assistant active component (B) is one or a plurality of metal oxides of cobalt, cerium, copper, iron, molybdenum, zinc and tin, and a mole ratio range of metal elements of the main active component (A) to the assistant active component (B) is that (A) : (B) is equal to 2:1 to 100:1. The catalyst provided by the invention is produced by the method of precipitation. The catalyst works at the low temperature of 120-200 DEG C, and works by directly adopting the waste heat of smoke at the low temperature in a coal-fired power plant, therefore the advantages of energy-saving and consumption-reducing are obvious; under a space velocity of 100,000h<-1>, a high efficiency of nitrogen oxide conversion rate is maintained, and a high activity is realized at the high space velocity. Compared with selective catalytic reduction (SCR) catalyst, the consumption of the catalyst provided by the invention is less with same treatment amount of smoke, and expenses on investment and maintenance are saved more.

Owner:CHINESE TEXTILE ACAD

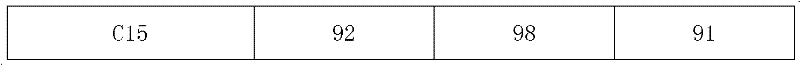

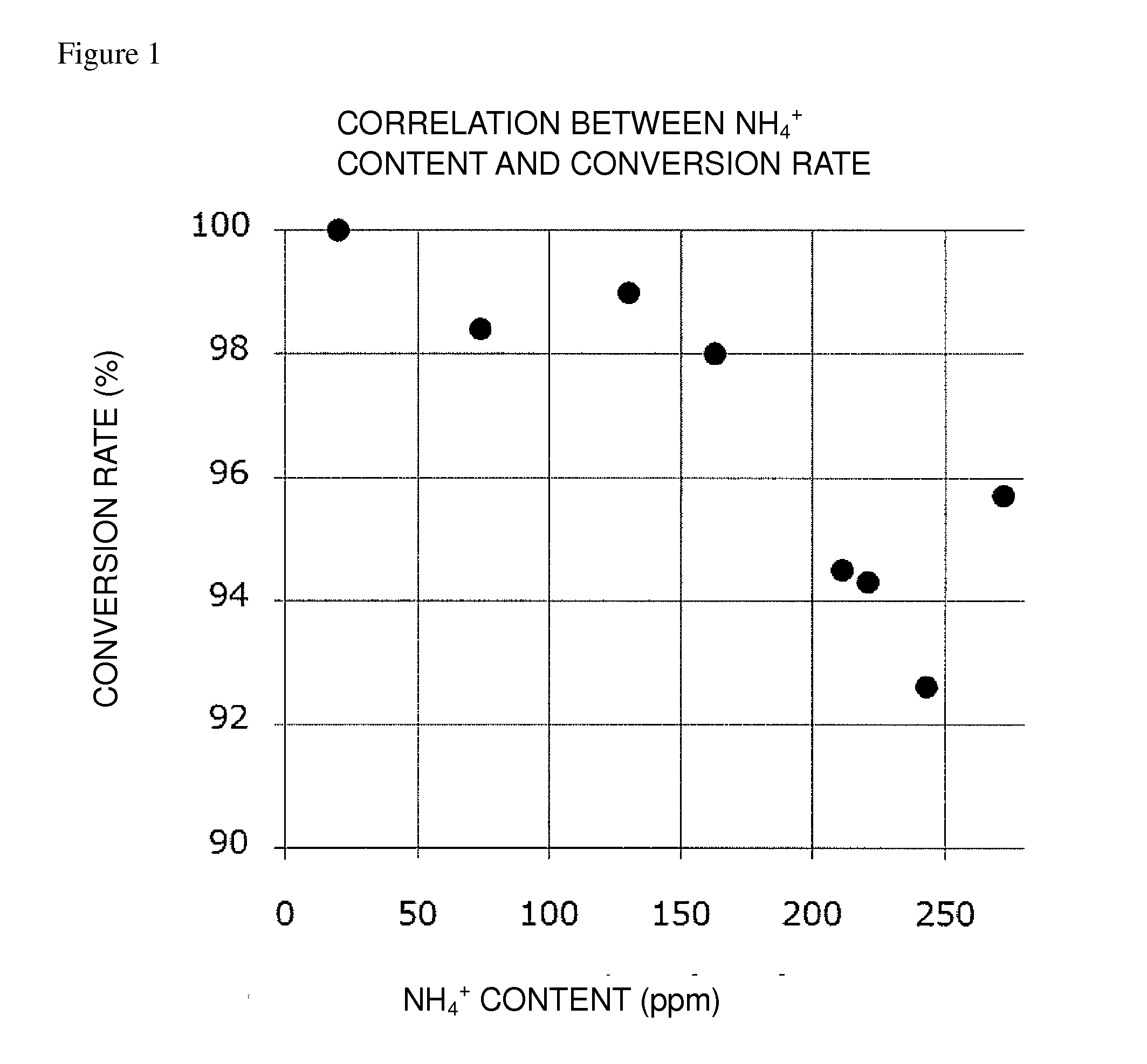

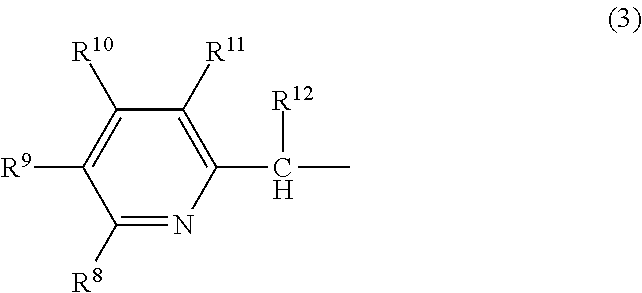

Oxidation reaction excellent in conversion rate

ActiveUS20160009680A1High conversion rateGood reproducibilityOrganic active ingredientsNervous disorderBenzeneAmmonium

A process for preparing 3-[(S)-7-bromo-2-(2-oxo-propylamino)-5-pyridin-2-yl-3H-1,4,-benzodiazepin-3-yl]propionic acid methyl ester at a high conversion rate with good reproducibility by oxidizing 3-[(S)-7-bromo-2-(2-hydroxy-propylamino)-5-pyridin-2-yl-3H-benzo[e][1,4]diazepin-3-yl]propionic acid methyl ester in the presence of an oxidation catalyst is provided by defining the ammonium ion content of 3-[(S)-7-bromo-2-(2-hydroxy-propylamino)-5-pyridin-2-yl-3H-benzo[e][1,4]diazepin-3-yl]propionic acid methyl ester.

Owner:PAION UK

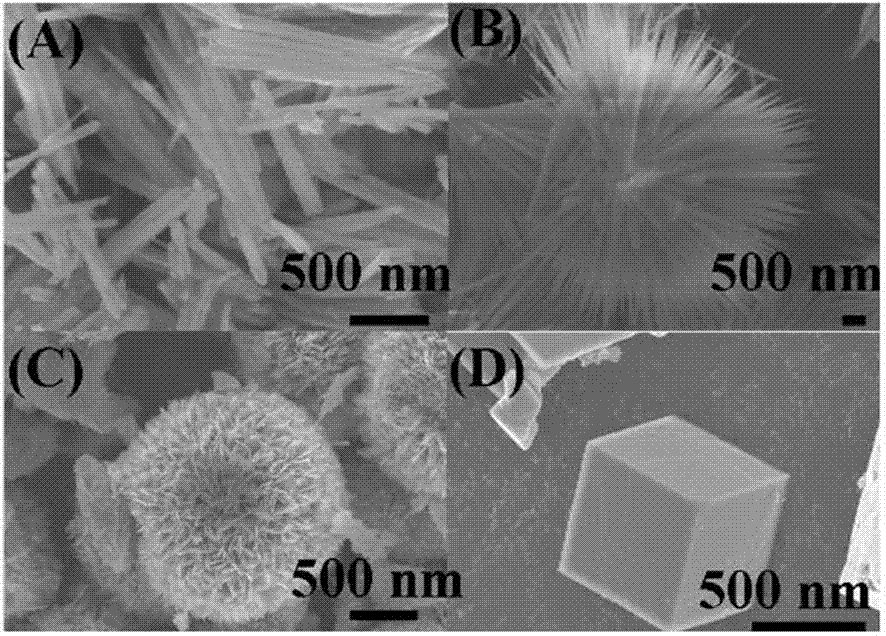

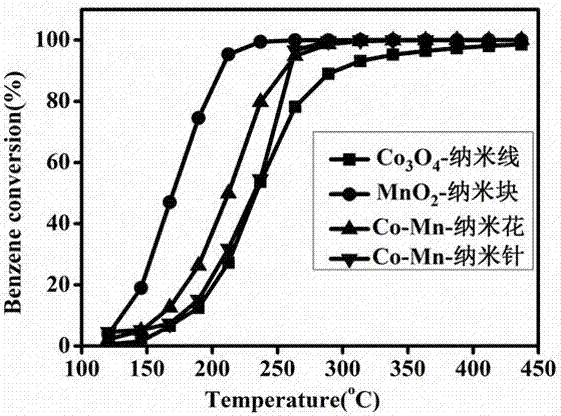

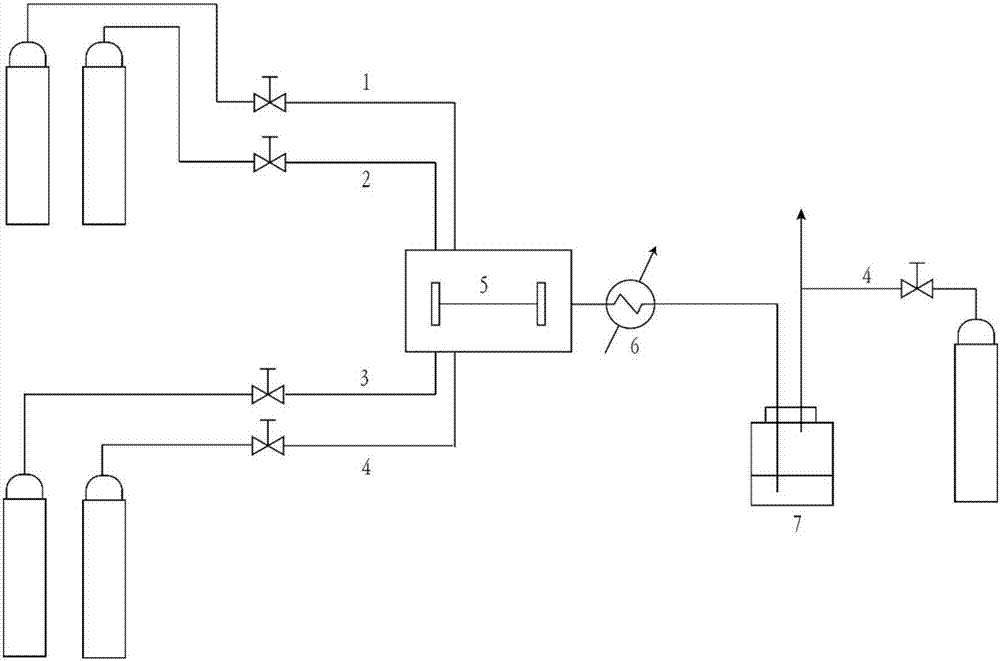

VOCs elimination catalyst and preparation method thereof

ActiveCN107362800AGood purification effectHigh Benzene Catalytic Oxidation ActivityGas treatmentDispersed particle separationBenzeneNanoparticle

The invention discloses a VOCs elimination catalyst and a preparation method thereof. According to a hydrothermal process, a reducer and an accelerator are added, and the Co / Mn mole ratio is regulated to regulate and control the shape and nanoparticle size of the catalyst. The catalyst has higher benzene catalytic oxidation activity within a wider temperature range. The benzene catalytic conversion rate of the catalyst at 207 DEG C is up to 90%. The catalyst disclosed by the invention has better purifying effects than the traditional benzene catalytic oxidation catalyst. The preparation method has the advantages of simple preparation technique and low cost, and is convenient to operate. The catalyst has high benzene conversion rate, and has obvious industrial application values.

Owner:FUZHOU UNIV +1

Method for preparing epoxypropane in microchannel reactor

ActiveCN107216296APrecise control of dwell timePrecise control of reaction timeOrganic chemistryChemical/physical/physico-chemical microreactorsState of artHydrogen

The invention relates to a method for preparing epoxypropane in a microchannel reactor. The method mainly solves the problems of existence of explosive danger, low conversion rate and low selectivity in the prior art. The technical scheme is as follows: by adopting the method for preparing epoxypropane in a microchannel reactor, gas-phase propylene contacts hydrogen peroxide generated by hydrogen and oxygen in-situ compounding in the microchannel reactor to directly generate the epoxypropane under the action of a catalyst; and propylene and oxygen directly react under the action of a catalyst to generate the epoxypropane, the epoxypropane is collected at the lower reach of the microchannels in the liquid-phase form, and the unreacted gas cyclically enters the microchannel reactor inlet or is evacuated after being diluted. The microchannel reactor comprises at least one microchannel, wherein the sectional dimension of each microchannel is 1 micrometer-1 centimeter, and the sectional dimensions of the microchannel in positions of different lengths are identical or different; and the catalyst is positioned in at least one part of the axial length of the microchannel. The technical scheme well solves the problems, and can be used for preparing epoxypropane.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for preparing syndiotactic styrenic polymers by recycling the products

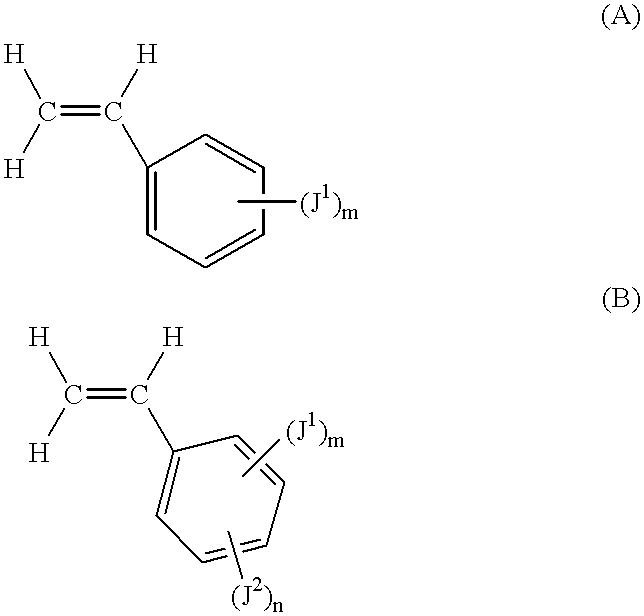

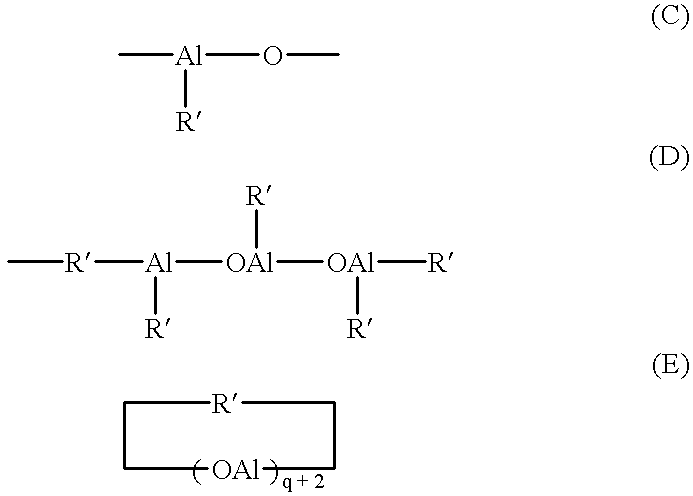

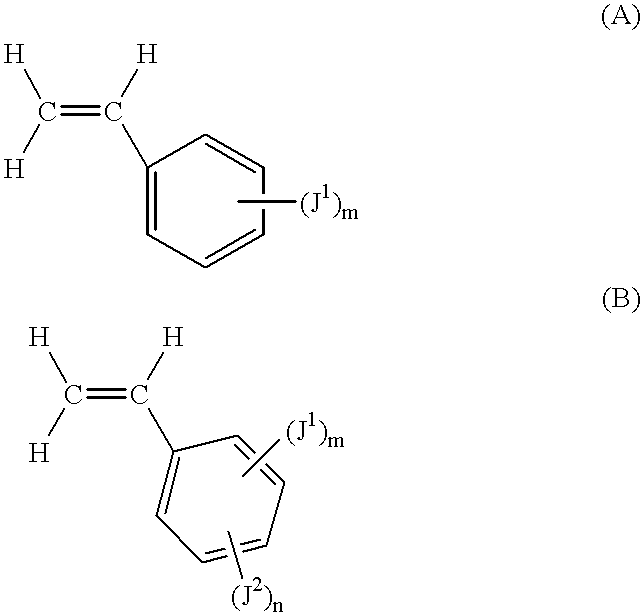

InactiveUS6369173B1High conversion ratePrevent agglomerationChemical/physical/physico-chemical reactor detailsChemical/physical/physico-chemical stationary reactorsSolid-statePolymerization reactor

The present invention relates to a process of preparing syndiotactic styrenic polymers with a high conversion rate in the form of fine powder, which comprises (a) preparing styrenic polymers in a solid state by reacting a mixture consisting of styrenic monomers, a metallocene catalyst, a cocatalyst and inert organic solvent in a polymerization reactor, (b) separating a portion of the styrenic polymers from the reactor, (c) recycling the portion of the styrenic polymers in the reactor, and (d) reacting the recycled styrenic polymers with styrenic monomers. The styrenic monomers may include olefinic monomers. The monomers can be introduced to a single inlet or multiple inlets of the reactor. A single reactor or a plural number of reactors can be operated in the present invention. The plural numbers of reactors are arranged in series or in parallel. In the present invention, a self-cleaning mono- or twin-axis reactor can be employed to prevent the polymers from agglomerating on the inner wall or the axis. Alternatively, a cylindrical reactor can be employed, where the styrenic polymers are transported in a solid or powder state rotating in a certain direction at the range of Froude Number of from 0.1 to 10 and polymerization proceeds toward the exit of the reactor.

Owner:SAMSUNG ATOFINA CO LTD

Manufacturing method of (METH) acrylic polymer

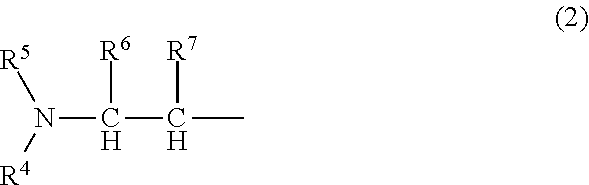

ActiveUS20130197175A1Narrow molecular weight distributionHigh conversion rateWeight distributionAcrylic polymer

In a method for polymerizing a (meth)acrylic monomer by living radical polymerization in the presence of a transition metal complex catalyst, the combined use of a multidentate amine (A), a base (B) and a reducing agent (C) makes it possible to achieve a rapid polymerization reaction and high monomer conversion rate and obtain a polymer having a narrow molecular weight distribution when 5-30 ppm by weight of copper atoms and a mole amount of 7 mmol % or less of multidentate amine (A) are used, each based on the total amount of (meth)acrylic monomer introduced.

Owner:KANEKA CORP

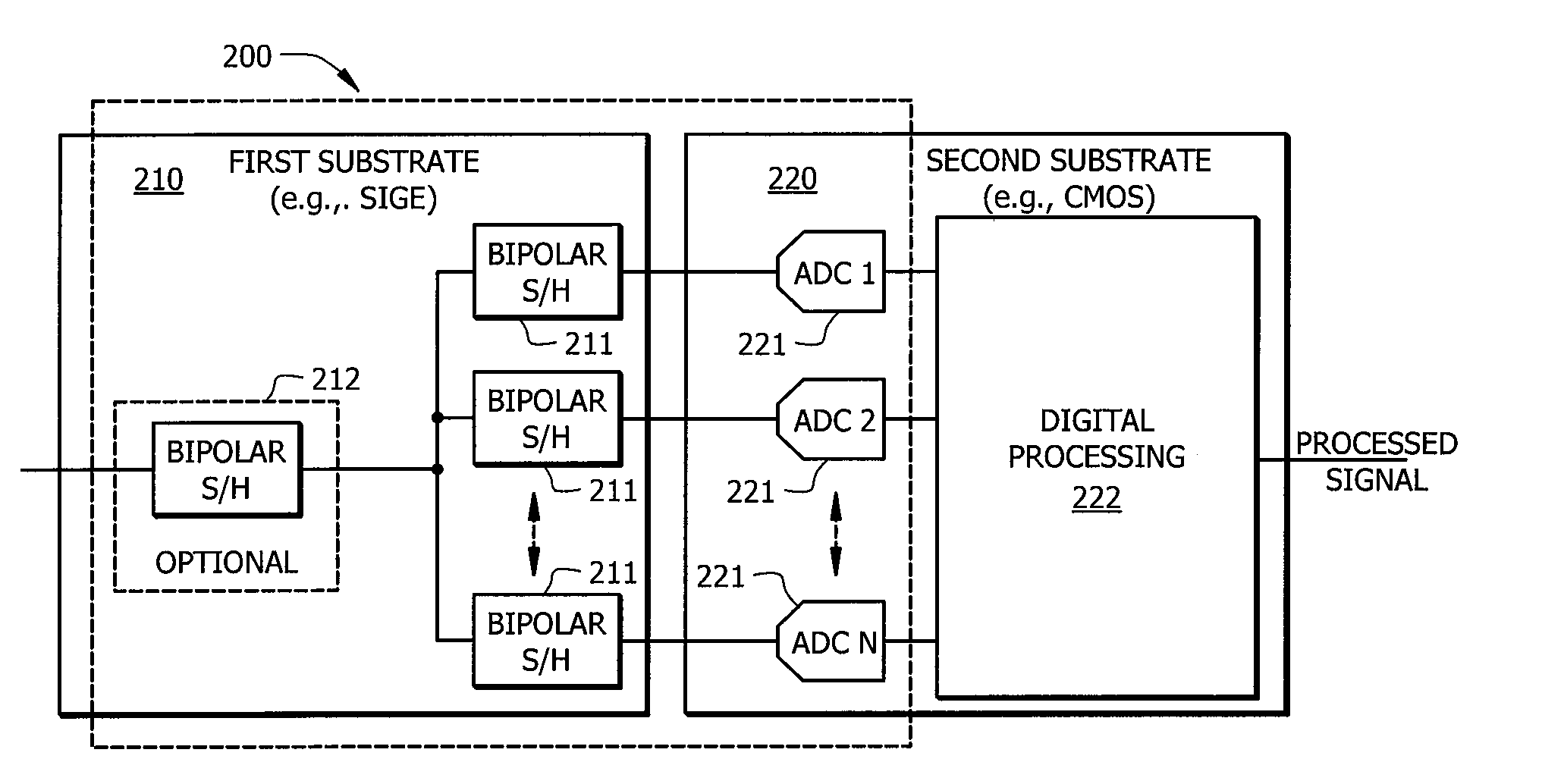

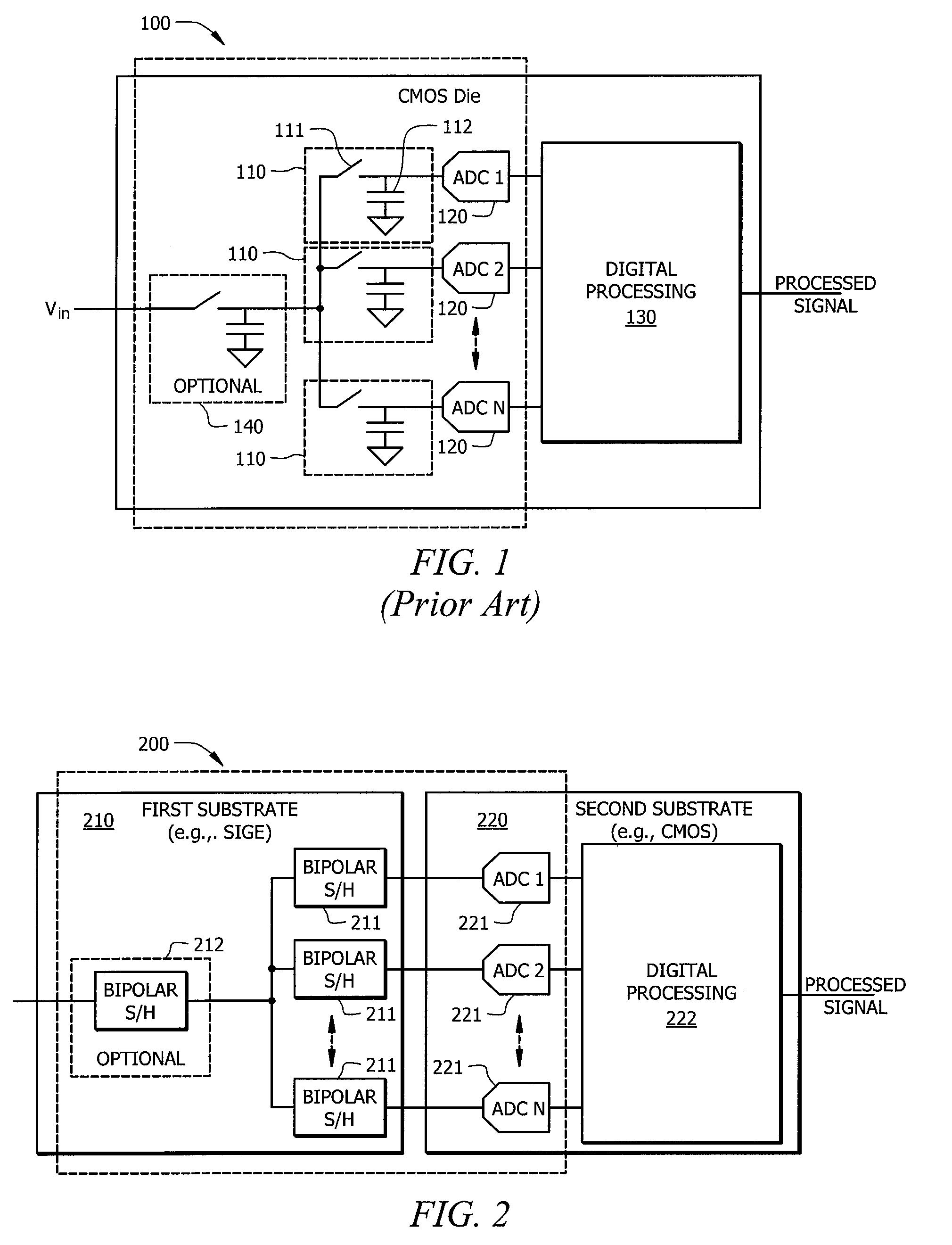

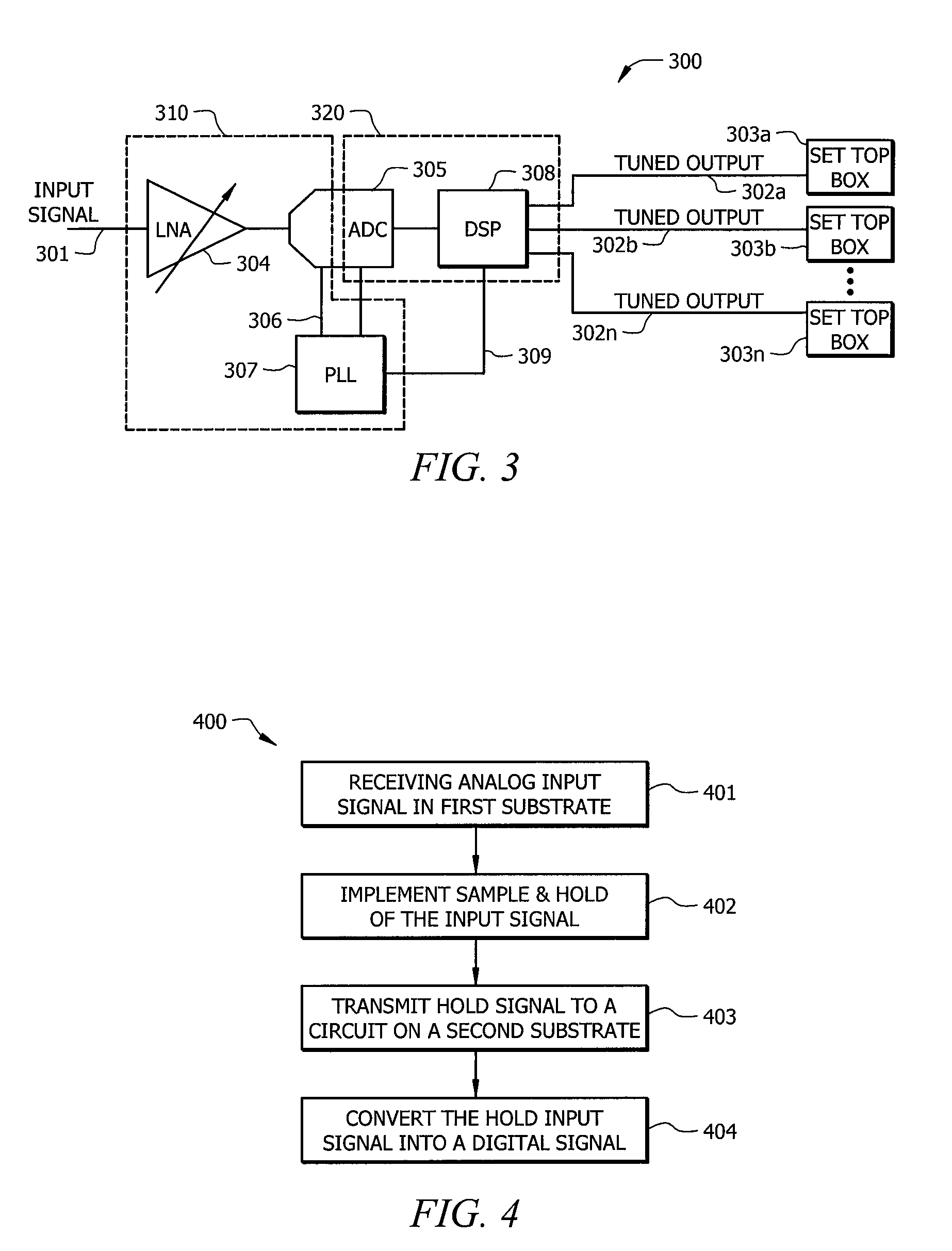

High-speed multi-type substrate analog to digital converter

ActiveUS8279101B1High conversion rateFaster processingElectric signal transmission systemsAnalogue-digital convertersCMOSVIT signals

High conversion rates are achieved in an analog to digital converter by tailoring the substrate type to specific operational elements of the converter. Embodiments place sample and hold processing circuitry on a substrate type having properties that allow for faster processing at high sampling / clock frequencies. Other operational elements of the converter are constructed on at least one other substrate type in keeping with the remainder of the circuitry for which the converter is being implemented. The sample and hold substrate may be implemented on any material which is capable of faster processing, such as silicon germanium, gallium arsenide, silicon bipolar, BiCMOS, and the like. Other portions may be implemented on a more CMOS substrate. Such systems and methods are able to implement analog-to digital conversion for broadband signals at high speeds without the need for extensive timing compensation, while also avoiding problems due to noise from further digital processing circuitry.

Owner:CSR TECH INC

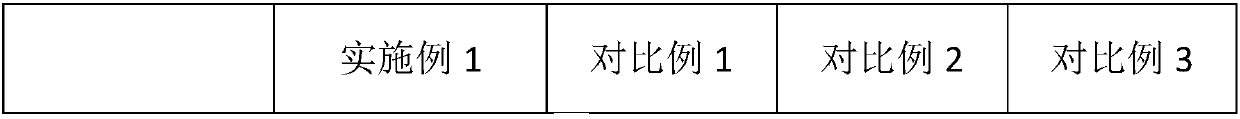

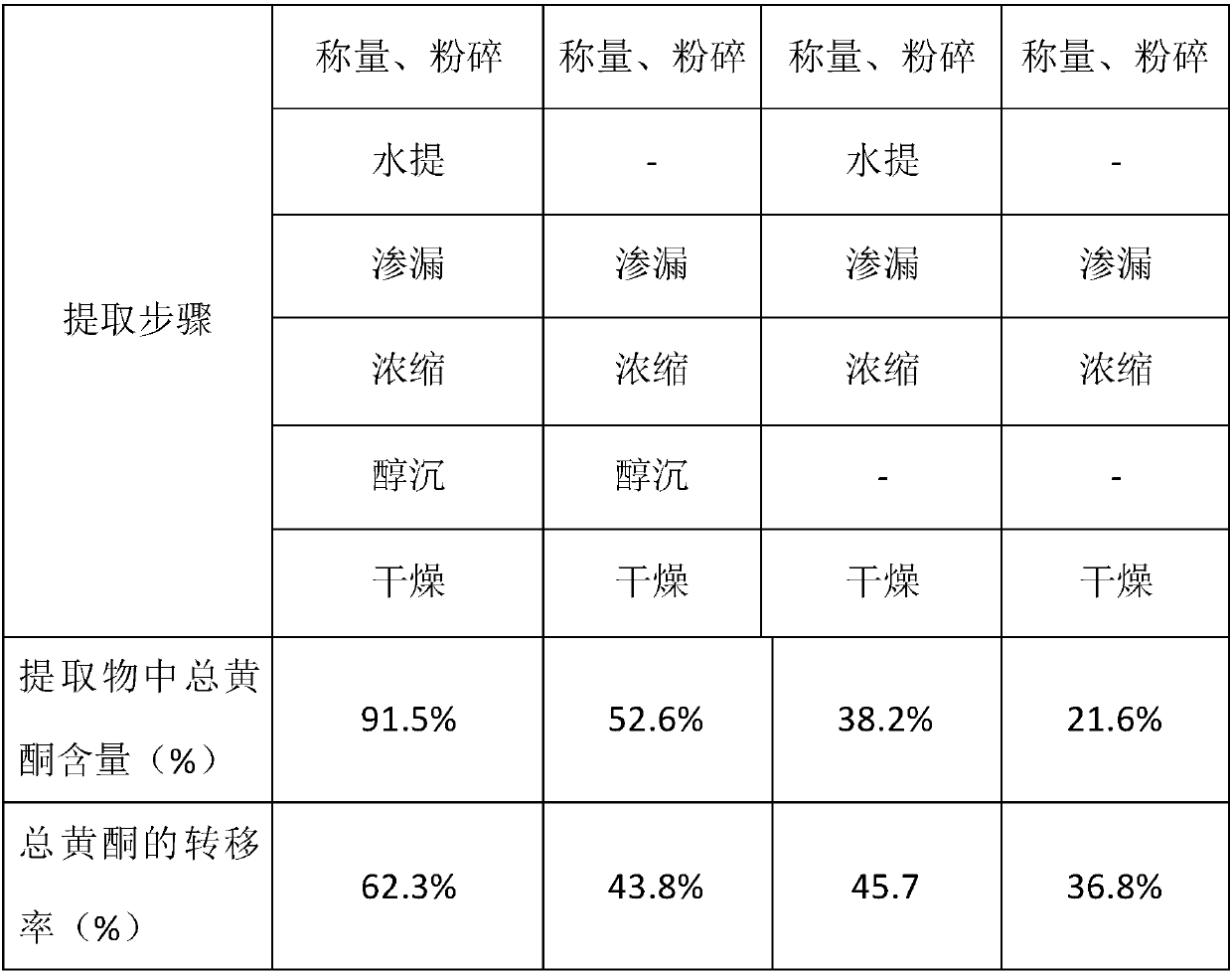

Extractionmethod of rhodiola

InactiveCN109589347ASimple preparation processReduce energy consumptionPlant ingredientsPurification methodsAlcohol

The invention provides anextraction method of rhodiola. The extraction methodcomprises the following steps: weighing, crushing, removing impurities through water extraction, performing leaching extraction, concentrating an extract,performing alcohol precipitation and drying. The method of simultaneous extraction and separation is adopted, an extraction system and a separation and purification system are combined,specific and simple impurity removing method, extraction method and purification method are combined, the content of the obtained total flavones in the extract is higher than 90%, a selected preparation technology is simple and low in energy consumption and an environment-friendly production mode is achieved.

Owner:青海喜玛拉雅生物工程有限公司

Opto-electrical energy material base and high-efficiency conversion

InactiveCN101572277AHigh trafficHigh conversion ratePhotovoltaic energy generationSemiconductor devicesElectricityNew energy

The invention discloses deepest mystery of space static and constant unit of electric material; constant definite proportion transformational relation is adopted to multiply the conversion efficiency of the electric material, so as to overcome the crisis of being lack of electrical coal and oil geology resources; new energy including devices in the fields such as photovoltaic energy capital construction, transportation vehicles, photovoltaic grid-connected power station, sailing ships, toys, a telecommunication system, street lamps, wind power generation, excursion boats, computers and the like can be provided, thus benefiting mankind.

Owner:武湖月 +1

Synthesis technology of maleic anhydride-crylic acid-methyl acrylate copolymer

InactiveCN103804593AReduce manufacturing costFast preparationOrganic detergent compounding agentsStyrene maleic anhydrideCooling down

The invention discloses a synthesis technology of maleic anhydride-crylic acid-methyl acrylate copolymer. The synthesis technology comprises steps of (a) firstly, respectively preparing certain concentration of maleic anhydride solution, crylic acid solution, ammonium persulfate solution and a certain amount of methyl acrylate according to certain proportion; (b) then adding the maleic anhydride solution into a vessel; (c) then starting a stirring and temperature rising device; (d) after achieving certain temperature, keeping the constant temperature, dripping initiator and monomer solution, after dripping, rapidly raising temperature up to certain value; (e) after stirring and reacting for a period at the constant temperature, stopping, cooling down naturally, so as to obtain the target product. The synthesis technology can be used for rapidly preparing the maleic anhydride-crylic acid-methyl acrylate copolymer, the preparation process is simple, the conversion rate of the preparation is high, and the preparation cost of the maleic anhydride-crylic acid-methyl acrylate copolymer is greatly lowered.

Owner:谭勇

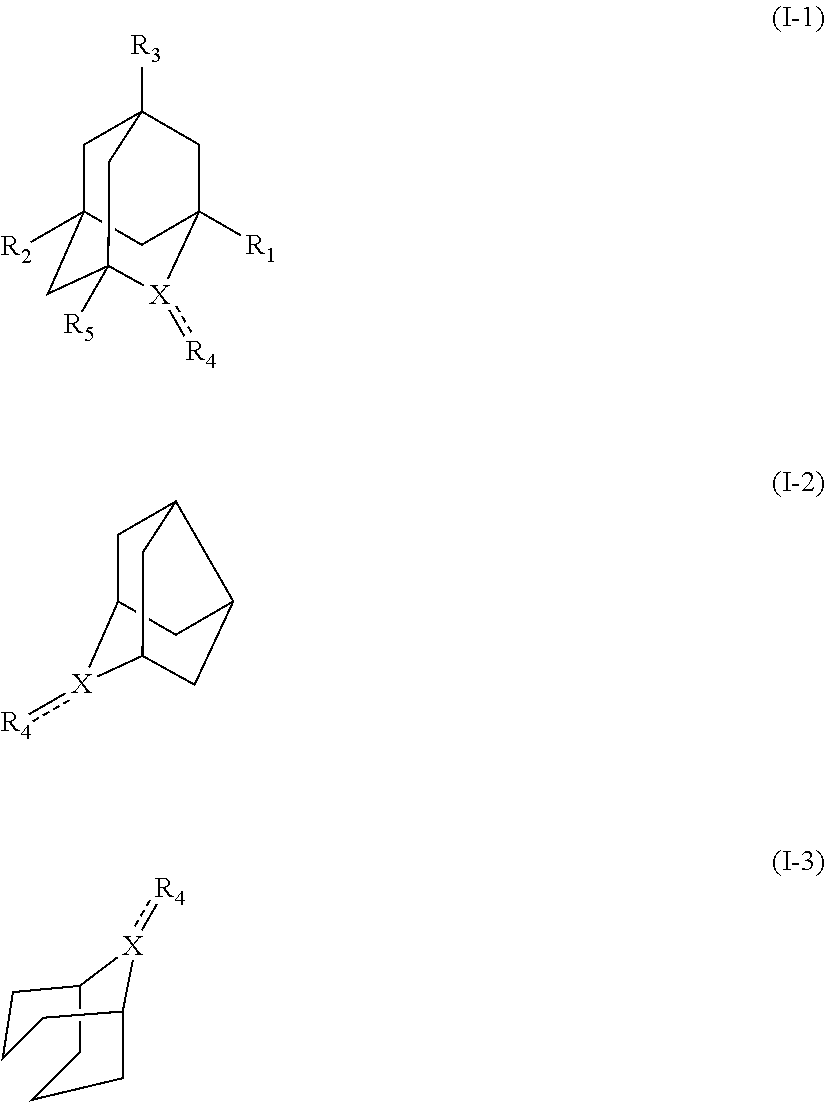

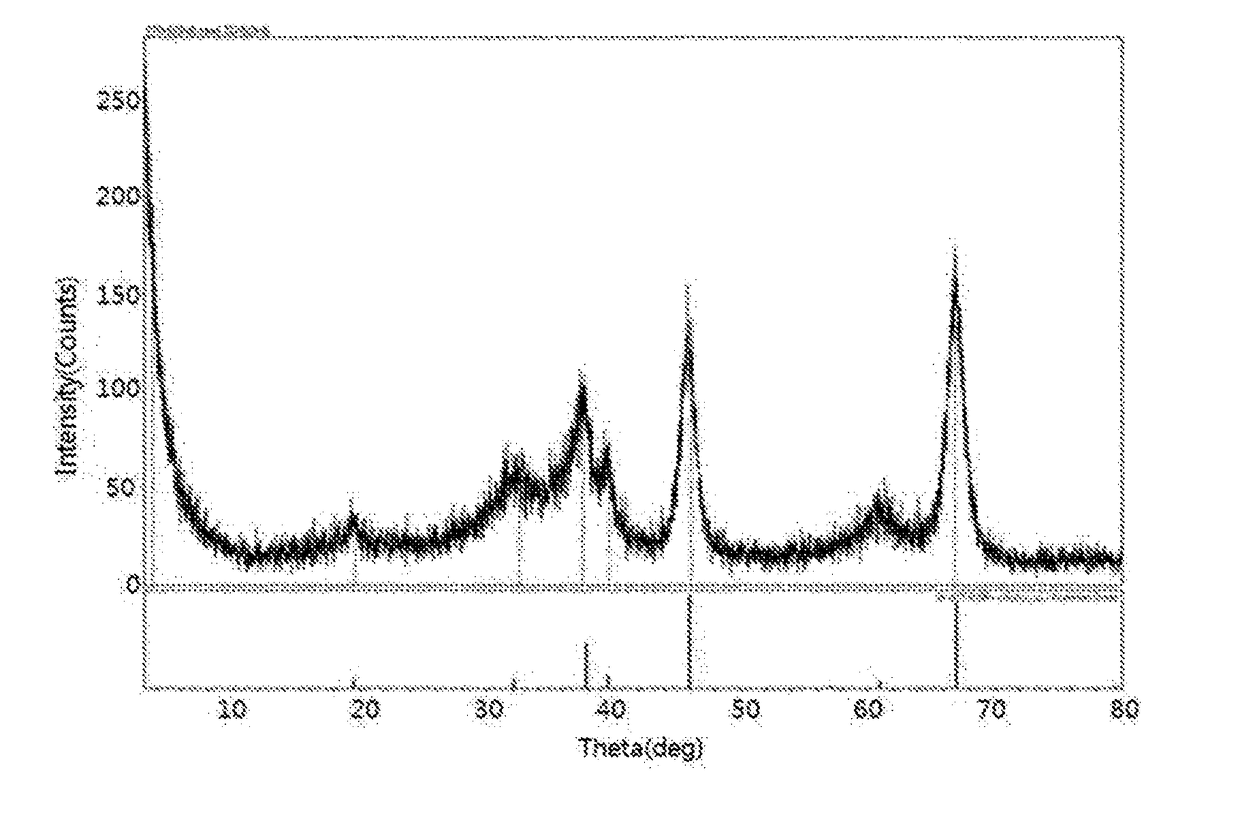

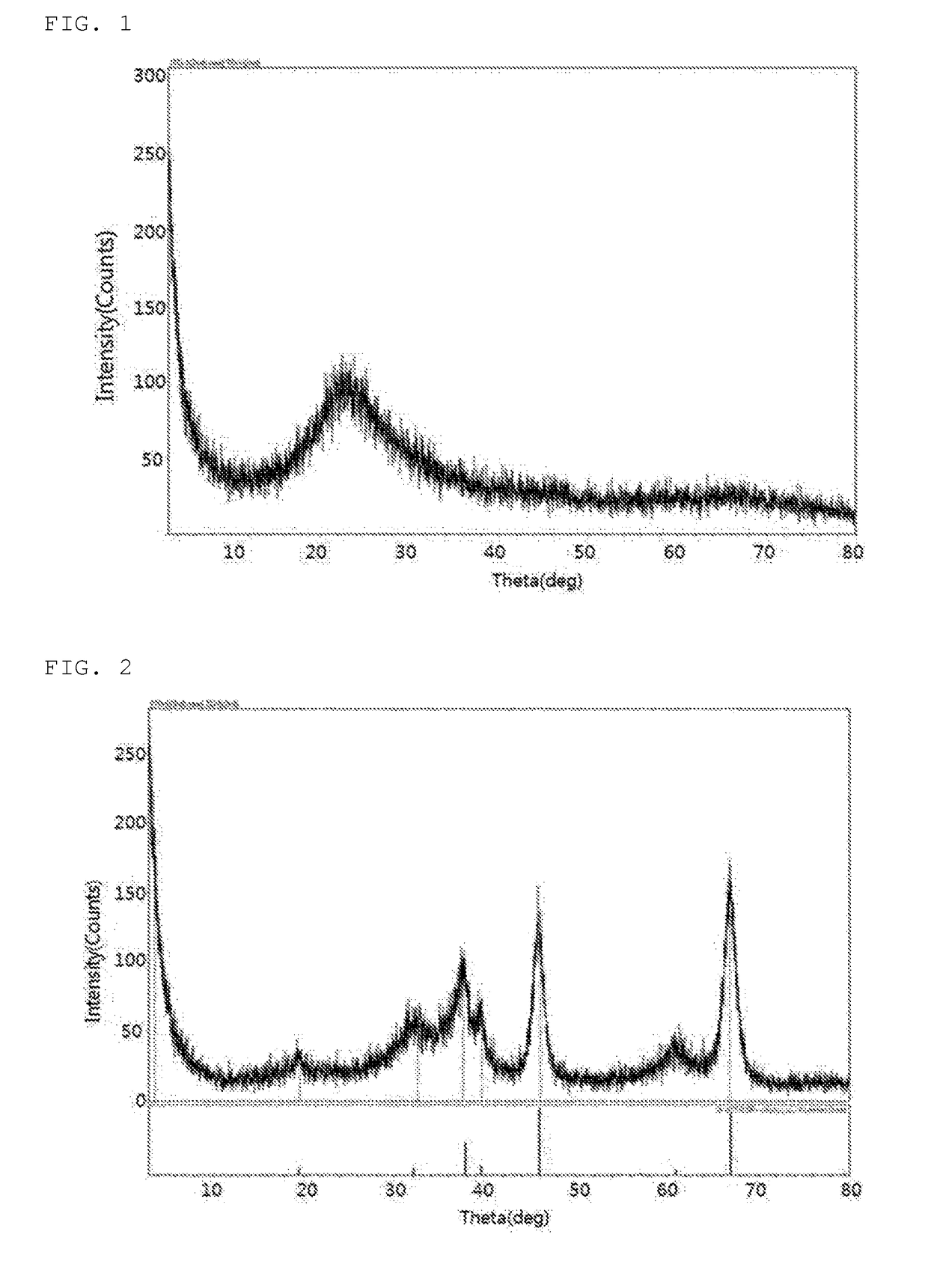

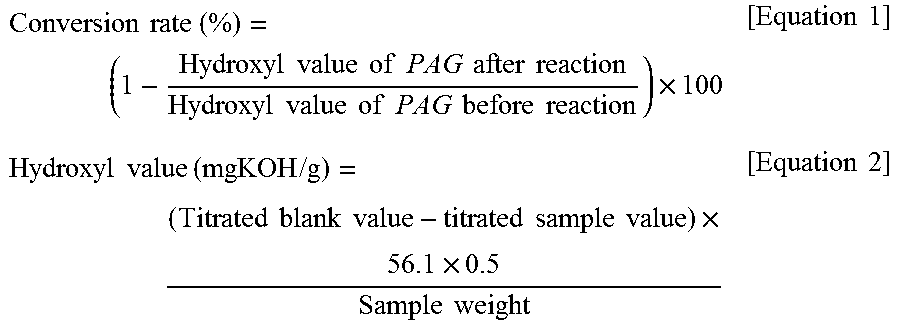

Catalyst for alkylation of polyalkylene glucol and alkylation method using the same

ActiveUS20180154337A1High conversion rateIncrease conversion rateCatalyst activation/preparationChemical/physical/physico-chemical processesPtru catalystOrganic chemistry

This invention relates to a catalyst for alkylating polyalkylene glycol and a method of alkylating polyalkylene glycol using the same, wherein the catalyst enables polyalkylene glycol to be alkylated at a high conversion rate without generating harmful materials and the terminal of polyalkylene glycol can be alkylated using the same. Thereby, the terminal of polyalkylene glycol can be alkylated in an environmentally friendly and economical manner through a simple process.

Owner:NH CHEM

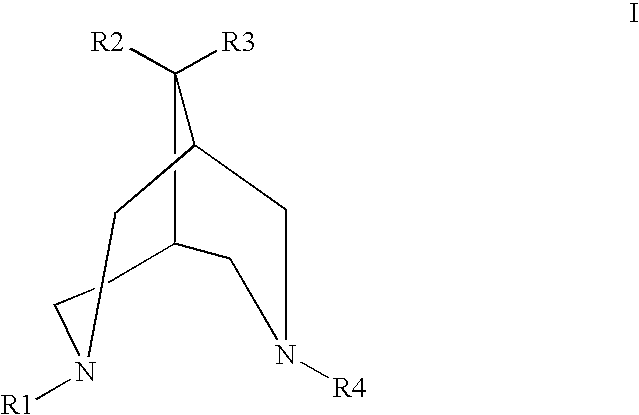

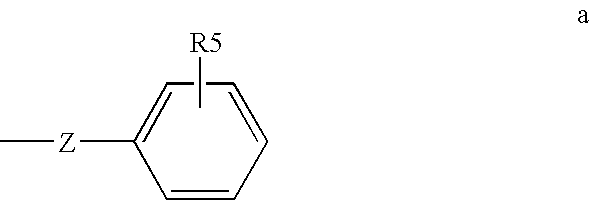

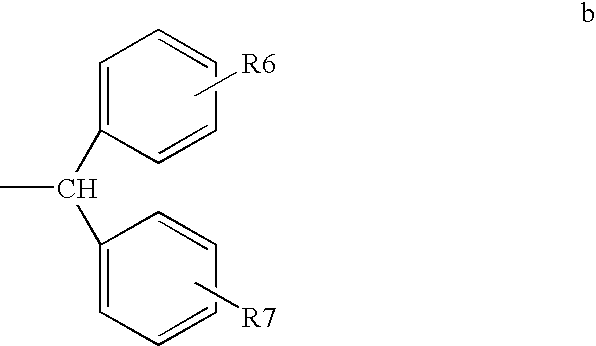

Method of treating or inhibiting anti-arrhythmic events in male human patients

InactiveUS20050054667A1High conversion rateImproved profileBiocideAnimal repellantsTedisamilRecent onset

A method of treating or inhibiting anti-arrhythmic events in male human patients by administering to a patient in need thereof a pharmaceutically effective amount of a 3,7-diazabicyclo[3,3,1]nonane compound, preferably a 9,9-alkylene-3,7-diazabicyclo[3,3,1]nonane compound, and especially preferably tedisamil, or a physiologically acceptable acid addition salt thereof or a solvate thereof. The method is particularly useful in converting recent onset of atrial fibrillation (Afib) or flutter to normal sinus rhythm (NSR) in male human patients.

Owner:SOLVAY PHARMA GMBH

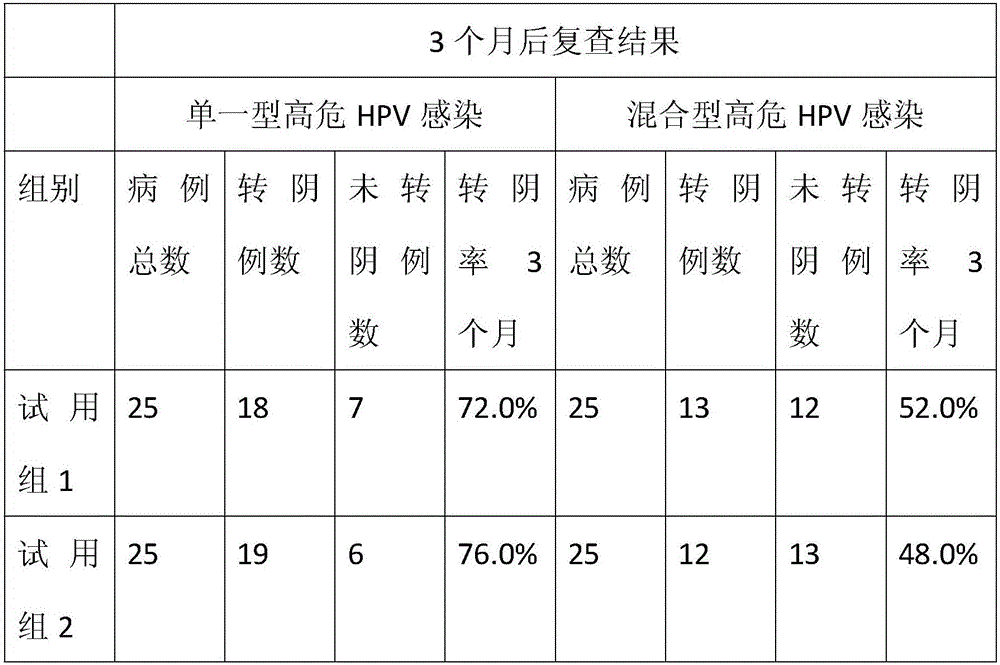

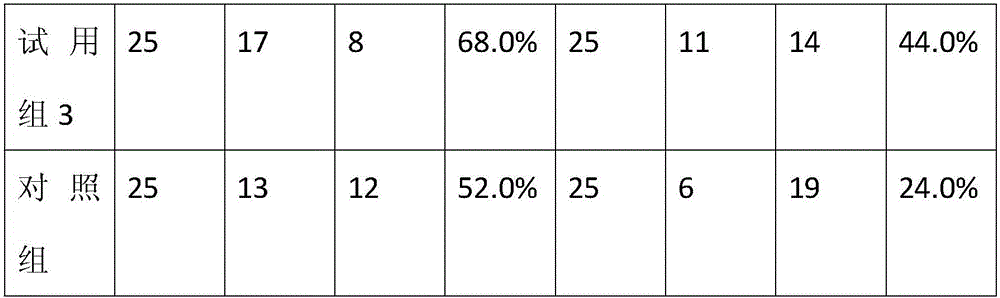

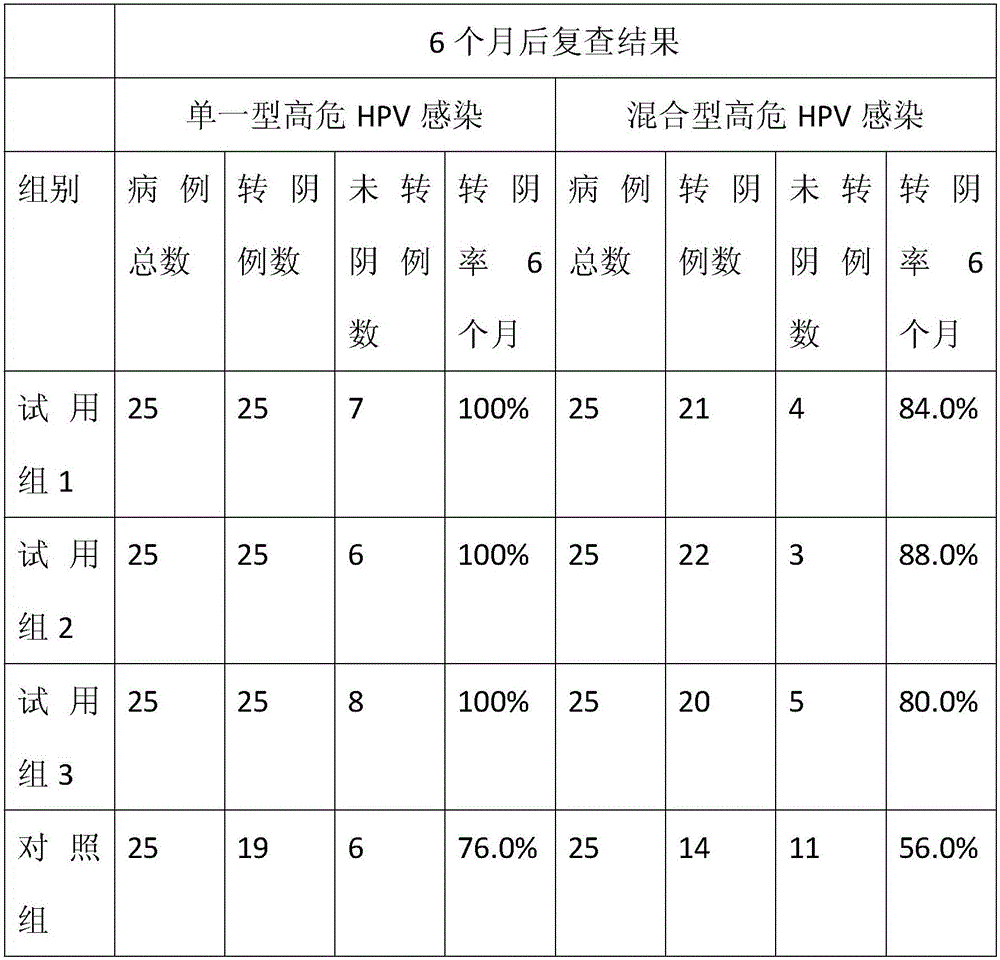

Lactalbumin-oleic acid compound and carrageenan composite medicine as well as preparation method and application thereof

InactiveCN106267167AHigh conversion rateEasy to useAntibacterial agentsOrganic active ingredientsSuppositoryGlycerol

The invention discloses a lactalbumin-oleic acid compound and carrageenan composite medicine, which consists of 0.01-1 part by weight of a lactalbumin-oleic acid compound, 0.5-1.5 parts by weight of carrageenan, 1-3 parts by weight of carbomer, 1-5 parts by weight of glycerol and 0.1-0.2 part by weight of ethylparaben. The composite medicine is in the form of a gel, a suppository or a dressing. The composite medicine can be used for preventing and treating female human papilloma virus infection as well as for preventing and treating female gynecological gram negative bacterium infection.

Owner:深圳婕熹卡生物科技有限公司

Method for producing ketoxime

ActiveUS20140179951A1Simple processHigh conversion rateOrganic compound preparationOximes preparationMolecular sieveKetone

A method for producing a ketoxime is provided. The method includes the step of performing a reaction of a nitrogen-containing compound, ketone and an oxidant by using a titanium-silicon molecular sieve as a catalyst, so as to form the ketoxime, thereby increasing the yield and selectivity of the ketoxime.

Owner:CHINA PETROCHEM DEVMENT

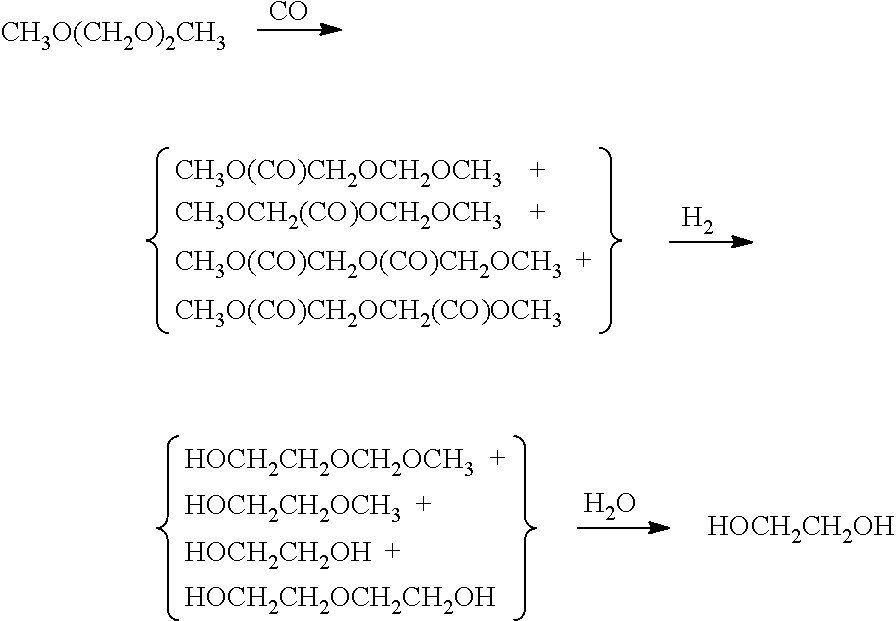

Method for preparing polyoxymethylene dimethyl ether carbonyl compound and methyl methoxyacetate

ActiveUS20170001941A1High conversion rateHigh selectivityPreparation by carbon monoxide or formate reactionSolventMolecular sieve

A method for preparing a polyoxymethylene dimethyl ether carbonyl compound and / or methyl methoxyacetate as intermediates for producing ethylene glycol, which comprises passing a raw material: polyoxymethylene dimethyl ether or methylal together with carbon monoxide and hydrogen gas through a reactor carrying an acidic molecular sieve catalyst, and performing a reaction to prepare a corresponding product under an appropriate condition where no other solvent is added, in which the process of the reaction is a gas-liquid-solid three-phase reaction, the raw material of polyoxymethylene dimethyl ether or methylal has a high conversion rate, each product has a high selectivity, the catalyst has a long service life, additional solvents are not required to be used, and reaction conditions are relatively mild.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

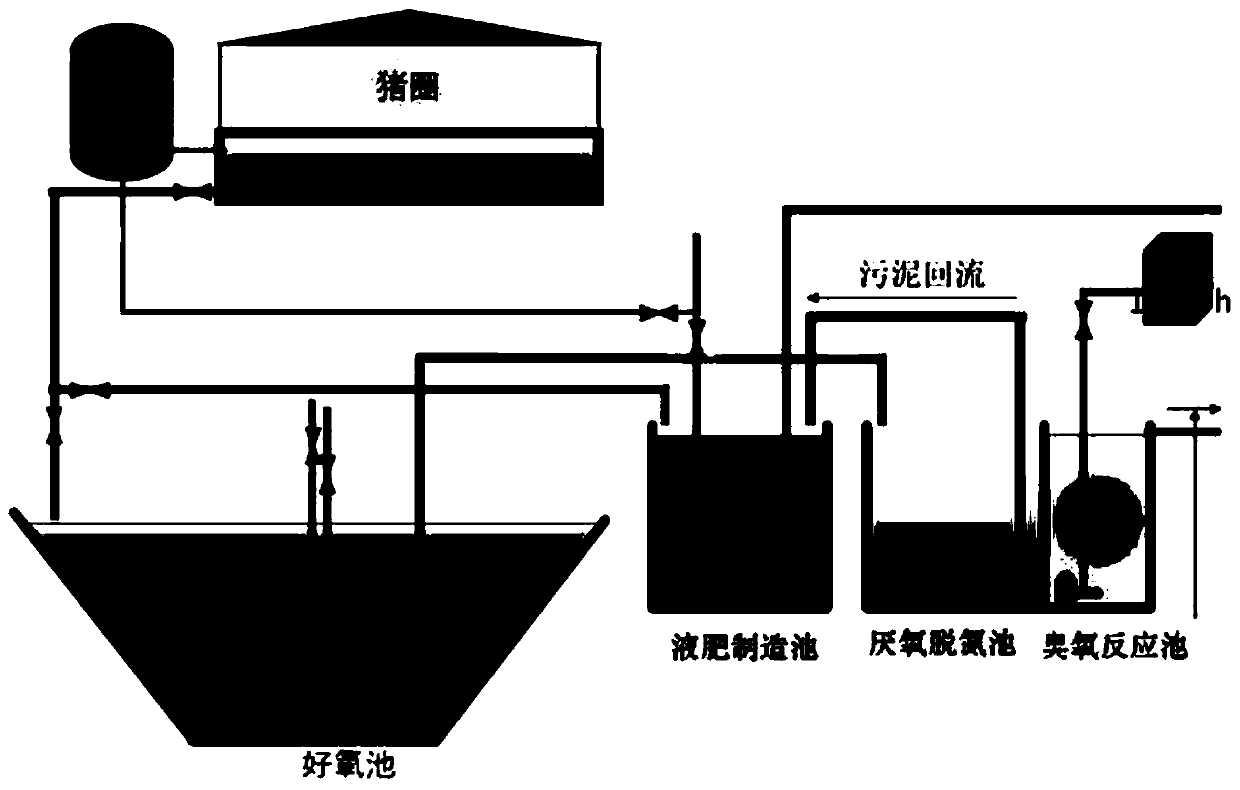

Liquid fertilizer treatment method of pig farm urine and manure wastewater

InactiveCN111268855AHigh conversion rateEfficient decompositionSpecific water treatment objectivesClimate change adaptationFertilizerEnvironmental chemistry

The invention discloses a liquid fertilizer treatment method of pig farm urine and manure wastewater and belongs to the field of excrement and urine wastewater treatment and recycling. The treatment mehtod comprises the following steps of: a) before pigs are herded into a pigsty, adding bacillus subtilis activated bacteria liquid into a urine and excrement pool, performing deodorization and nitration reaction pretreatment on pig excrement and urine, and keeping dissolved oxygen in the urine and excrement pool not less than 0.5 ppm during the pretreatment period; b) introducing the excrement and urine treated in the step a) into an aerobic tank at one time for aerobic aeration treatment, carrying out anaerobic denitrification treatment on effluent, carrying out advanced oxidation treatmenton the treated effluent, and discharging the treated effluent after reaching the standard; and c) periodically introducing the biochemical sludge generated by the anaerobic denitrification treatment into a liquid fertilizer manufacturing tank, culturing bacillus subtilis in the liquid fertilizer manufacturing tank in an aerobic aeration manner, and generating a liquid fertilizer in the liquid fertilizer manufacturing tank, wherein after the system operates stably, the liquid fertilizer in the liquid fertilizer manufacturing pool can be taken out according to the fertilizer requirements of thesurrounding planting industry to be used as a compound microbial fertilizer.

Owner:浙江亲水园生物科技有限公司

Method for preparing acetal carbonyl compound

ActiveUS20180201567A1High conversion rateHigh selectivityMolecular sieve catalystsMolecular sieve catalystSolventProtein carbonyl

The present application provides a method for preparing acetal carbonyl compound used as a mediate for producing ethylene glycol, which comprises a step in which a raw material acetal and a raw gas carbon monoxide go through a reactor loaded with a catalyst containing an acidic microporous silicoaluminophosphate molecular sieve, for carrying out a carbonylation reaction. In the method of the present invention, the conversion rate of the raw material acetal is high, and the selectivity of acetal carbonylation is high, and the catalyst life is long, and no additional solvent is needed in the reaction process, and the reaction condition is relatively mild, and the process is continuous, showing the potential for industrial application. Moreover, the product of acetal carbonyl compound can be used for producing ethylene glycol by hydrogenation followed by hydrolysis.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for ecologically treating organic waste by using eupolyphaga

InactiveCN108142372AReduce the cost of farmingHigh conversion rateClimate change adaptationExcrement fertilisersEconomic benefitsBiological waste

The invention belongs to the technical field of environmental protection and relates to a method for ecologically treating organic waste by using eupolyphaga. Particularly, the pretreated organic waste is subjected to biological waste conversion by using eupolyphaga. According to the method, organic waste treatment is combined with eupolyphaga breeding, the organic waste is converted and utilized,no pollution is generated in the process, a large amount of eupolyphaga is bred, eupolyphaga polypide and ootheca are good-quality protein feed raw materials, and excrement can be used as fertilizerfor use; the whole process is ecological and environmentally friendly, by pretreating the organic waste, the treatment conversion rate of the organic waste in eupolyphaga is high, the cost of breedingeupolyphaga is lowered, and the economic benefit is good.

Owner:山东鲲鹏农业发展有限公司

Production method for extracting chromium by mixed roasting of chromium-containing material

InactiveCN107760863ASolve material bondingHigh conversion rateProcess efficiency improvementSodium carbonateSodium chromate

The invention discloses a production method, and particularly discloses a production method for extracting chromium by mixed roasting of a chromium-containing material, belonging to the technical field of metallurgical production process. The invention provides a production method for extracting chromium by mixed roasting of a chromium-containing material, which is simple and short in procedure, easy to implement and good in extraction effect and realizes roasting instead of sintering. According to the production method, chromium is extracted by a procedure of uniformly mixing chrome ore, sodium carbonate and clinker according to a mass ratio of 100:(50-120):(200-400), then roasting, crushing, grinding and subsequently immersing with water to obtain a sodium chromate solution, wherein theparticle diameter of ground roasted clinker does not exceed 0.2mm.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Synthesis process of poly-MA-AA-Mac (poly-maleic anhydride-acrylic acid-methyl acrylate) anti-scale agent based on control of pH value

InactiveCN103804592AReduce manufacturing costEasy to makeOrganic detergent compounding agentsStyrene maleic anhydrideMethyl acrylate

The invention discloses a synthesis process of a poly-MA-AA-Mac (poly-maleic anhydride-acrylic acid-methyl acrylate) anti-scale agent based on control of pH value. The synthesis process disclosed by the invention comprises the following steps of: (a), firstly, respectively preparing maleic anhydride solution, acrylic acid solution and methyl acrylate with a certain concentration according to a certain proportion; (b), then, adding maleic anhydride solution, acrylic acid solution and methyl acrylate into different containers by adopting different monomer dropping manners, and adjusting the pH of the solution to be 7-10; (c), starting a stirring and temperature-increasing device, stopping after keeping constant-temperature stirring reaction for a certain time, naturally cooling, and thus obtaining the target object. The synthesis process disclosed by the invention is capable of rapidly preparing the poly-MA-AA-Mac anti-scale agent; furthermore, the preparation process is simple; the preparation conversion rate is high; the preparation cost of maleic anhydride-acrylic acid-methyl acrylate copolymer is greatly reduced; in addition, the product conversion rate and the product performance are improved by controlling the pH value in the synthesis process.

Owner:陈春林

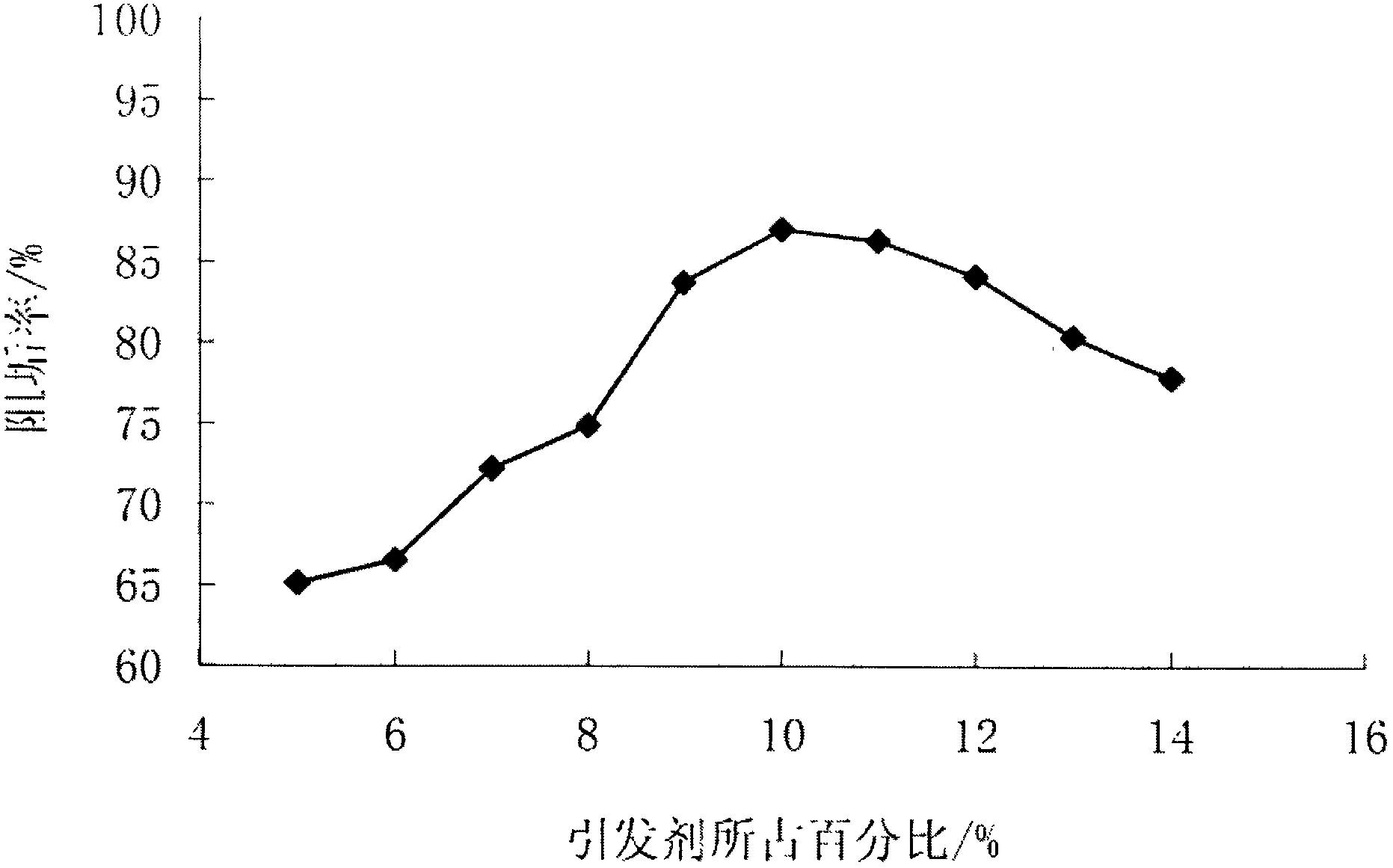

Poly(MA-AA-Mac) (Poly(Maleic Anhydride-Acrylic Acid-Methyl Acrylate)) anti-scaling agent synthesis process based on control on using amount of initiator

InactiveCN103804597AEasy to prepareHigh conversion rateDrilling compositionMaleic anhydrideMethyl acrylate

The invention discloses a poly(MA-AA-Mac) (Poly(Maleic Anhydride-Acrylic Acid-Methyl Acrylate)) anti-scaling agent synthesis process based on control on the using amount of an initiator. The process comprises the following steps: (a) preparing a maleic anhydride solution, an acrylic acid solution and methyl acrylate; (b) adding the maleic anhydride solution, the acrylic acid solution and methyl acrylate into a reaction container; (c) adding an initiator into the reaction container while controlling the amount of the initiator to be 8-12 percent based on the total mass of monomers; (d) starting a stirring and heating device, keeping reacting at a constant temperature while stirring for a certain period, stopping reacting, and naturally cooling to obtain a target product. By adopting the synthesis process, a poly(MA-AA-Mac) anti-scaling agent can be prepared rapidly. Moreover, the preparation process is simple, the preparation conversion rate is high, and the preparation cost of a maleic anhydride-acrylic acid-methyl acrylate copolymer is reduced greatly. Moreover, by controlling the using amount of the initiator in the synthesis process, the anti-scaling performance of the target product is improved.

Owner:谭勇

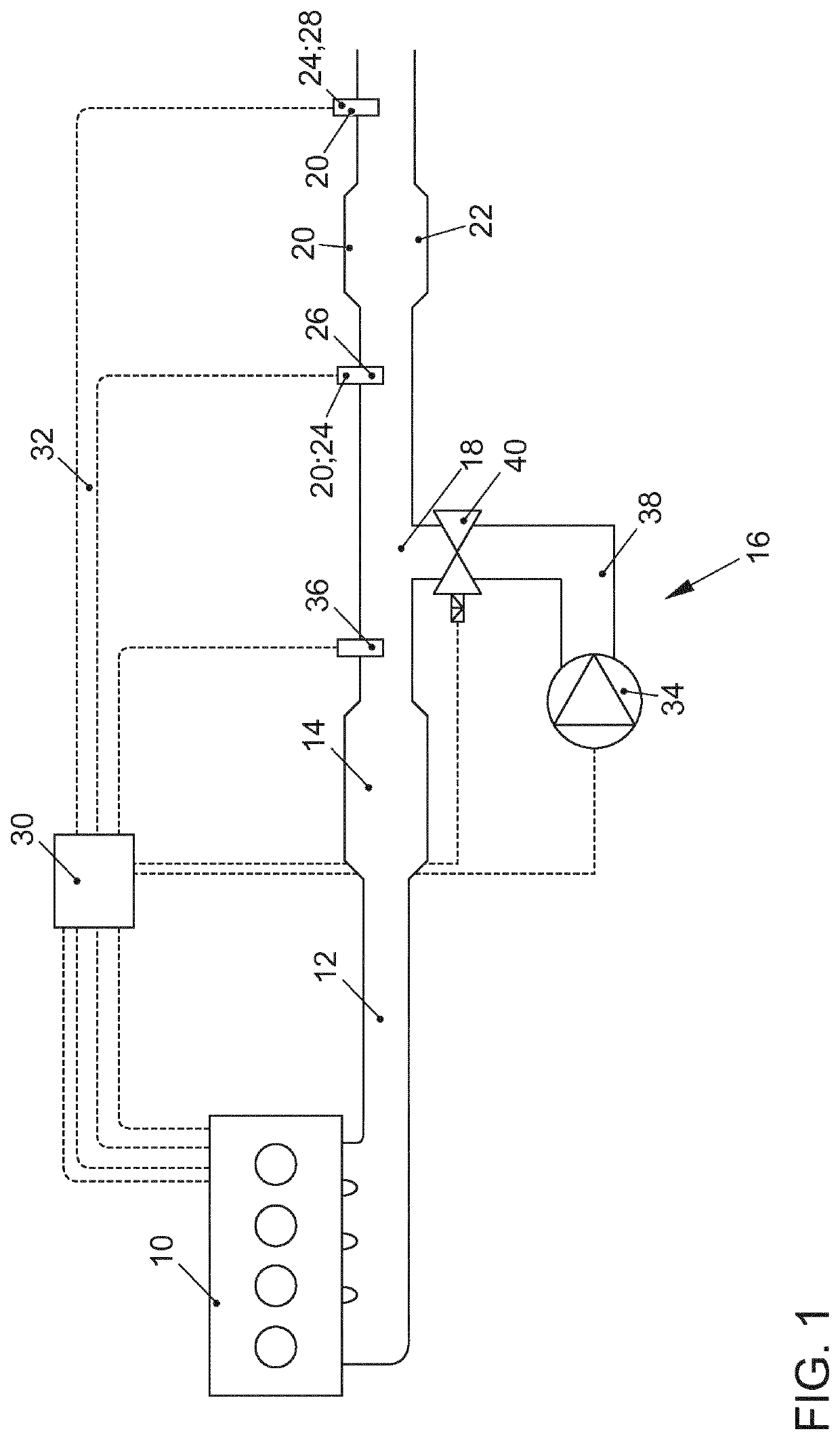

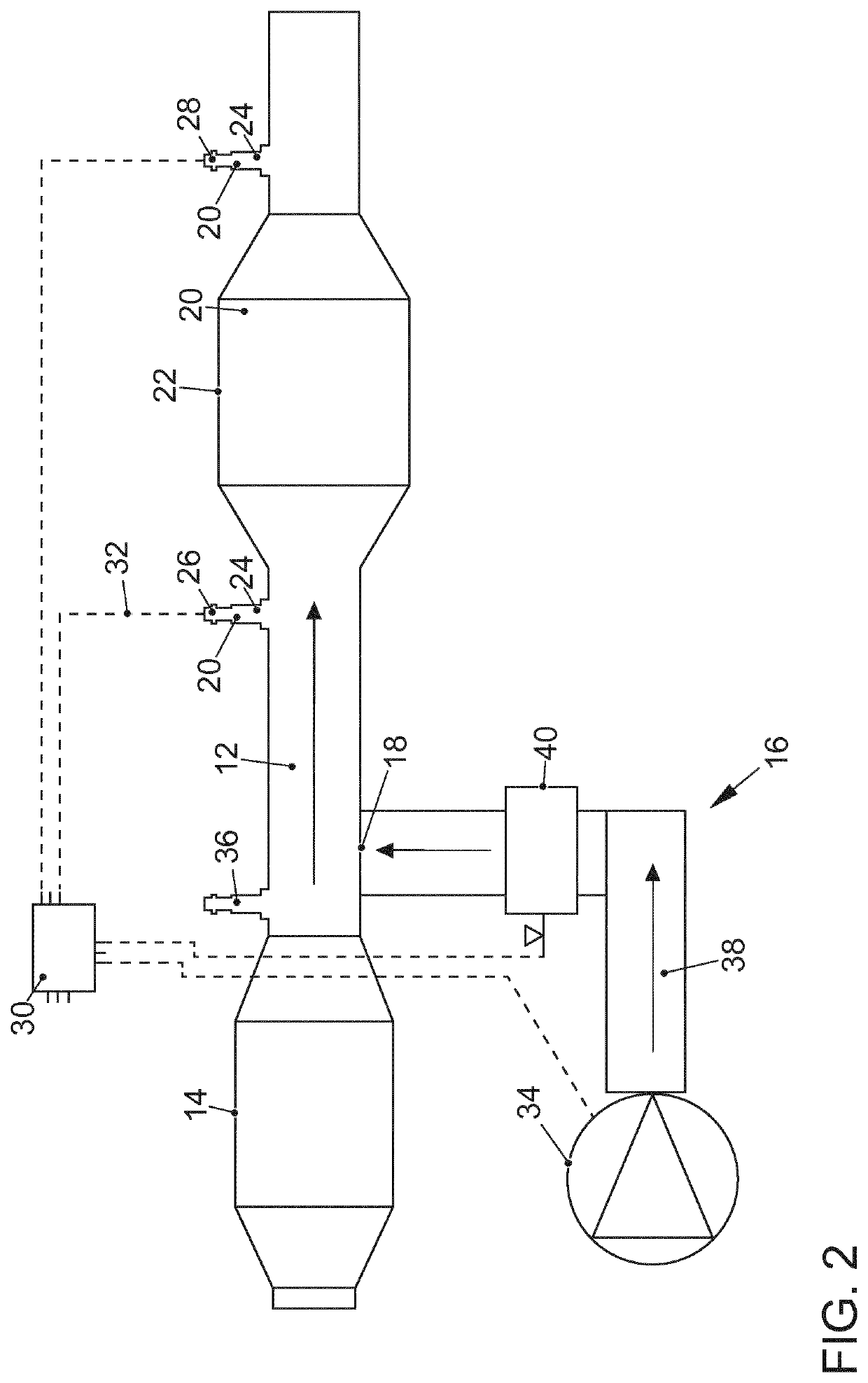

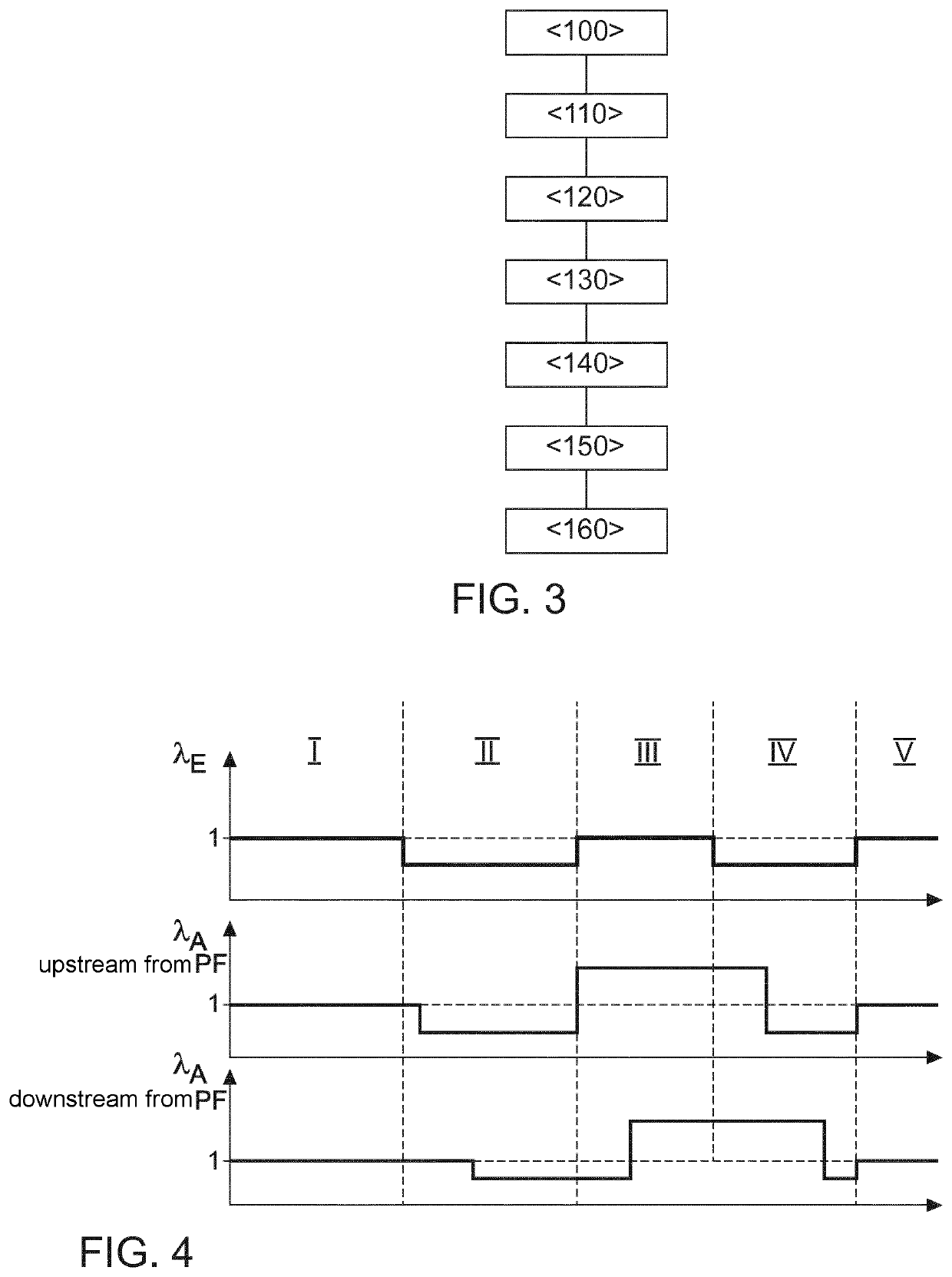

Diagnostic method and device for checking the functionality of a component for exhaust-gas aftertreatment

ActiveUS11236659B2High conversion rateHigh capacityInternal combustion piston enginesExhaust apparatusExhaust gasExhaust fumes

The invention relates to a diagnostic method for checking the functionality of a component for the exhaust-gas aftertreatment of an internal combustion engine. For this purpose, in an internal combustion engine, a secondary air supply is provided by means of which an excess of oxygen can be generated in the exhaust gas channel essentially independently of the operating conditions of the internal combustion engine, and wherein said excess of oxygen is utilized for the measurement of an oxygen storage capacity of the component or of a signal change at the component. It is provided that the component is subsequently subjected to a substoichiometric exhaust gas in order that the oxygen release capacity or the signal change upon a change from superstoichiometric exhaust gas to a substoichiometric exhaust gas is also taken into consideration in the diagnosis. The invention also relates to a device for exhaust-gas aftertreatment, which is designed to be able to carry out a method of said type.

Owner:VOLKSWAGEN AG

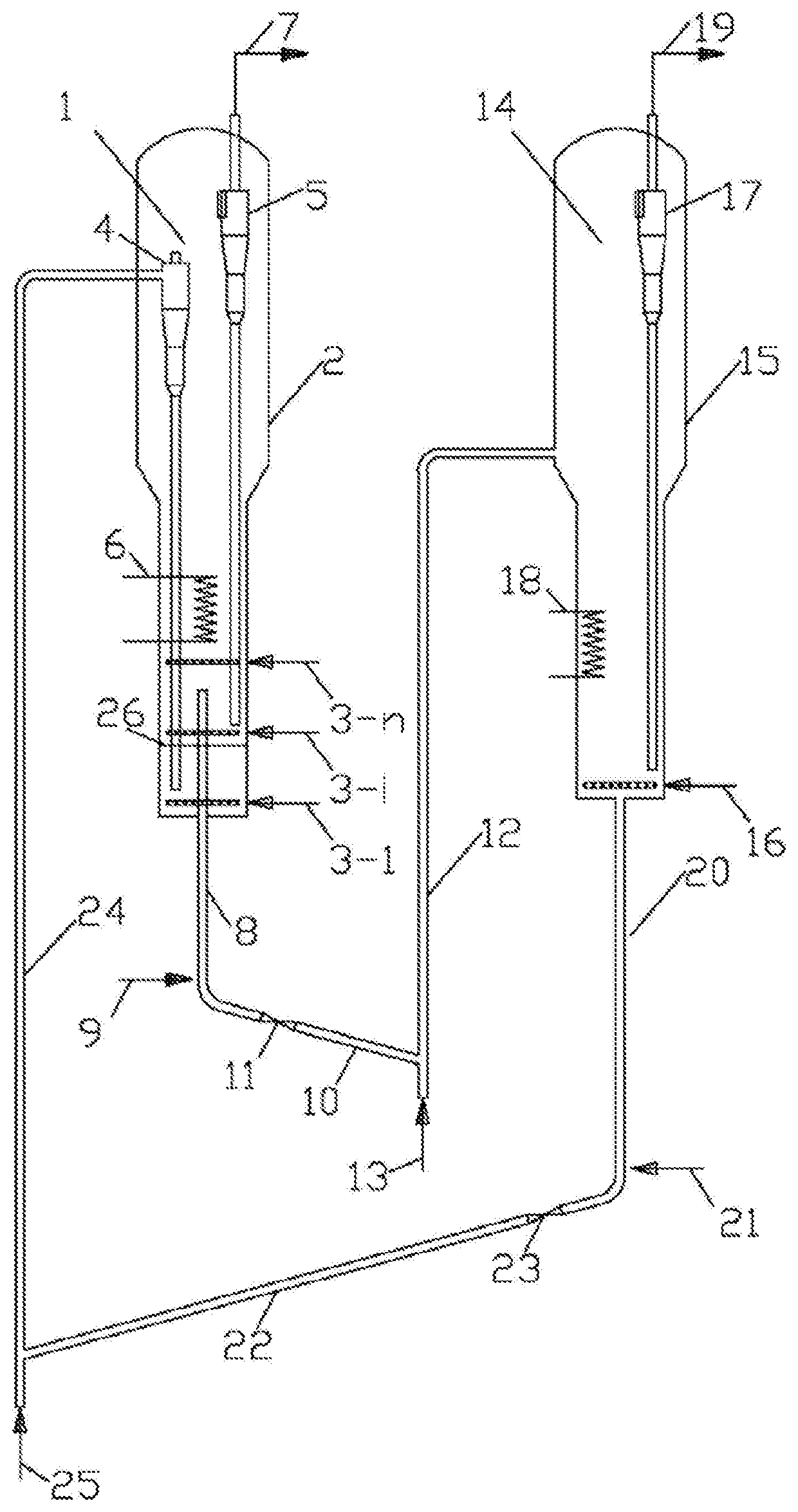

Fluidized bed device and method for preparing para-xylene and co-producing light olefins from methanol and/or dimethyl ether and benzene

ActiveUS20210121842A1Improve reaction yieldHigh conversion rateMolecular sieve catalystCatalystsBenzeneDimethyl ether

A turbulent fluidized bed reactor, device and method for preparing para-xylene and co-producing light olefins from methanol and / or dimethyl ether and benzene, resolving or improving the competition problem between an MTO reaction and an alkylation reaction during the process of producing para-xylene and co-producing light olefins from methanol and / or dimethyl ether and benzene, and achieving a synergistic effect between the MTO reaction and the alkylation reaction. By controlling the mass transfer and reaction, competition between the MTO reaction and the alkylation reaction is coordinated and optimized to facilitate a synergistic effect of the two reactions, so that the conversion rate of benzene, the yield of para-xylene, and the selectivity of light olefins are increased. The turbulent fluidized bed reactor includes a first reactor feed distributor and a number of second reactor feed distributors; the first reactor feed distributor and the plurality of second reactor feed distributions are sequentially arranged.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

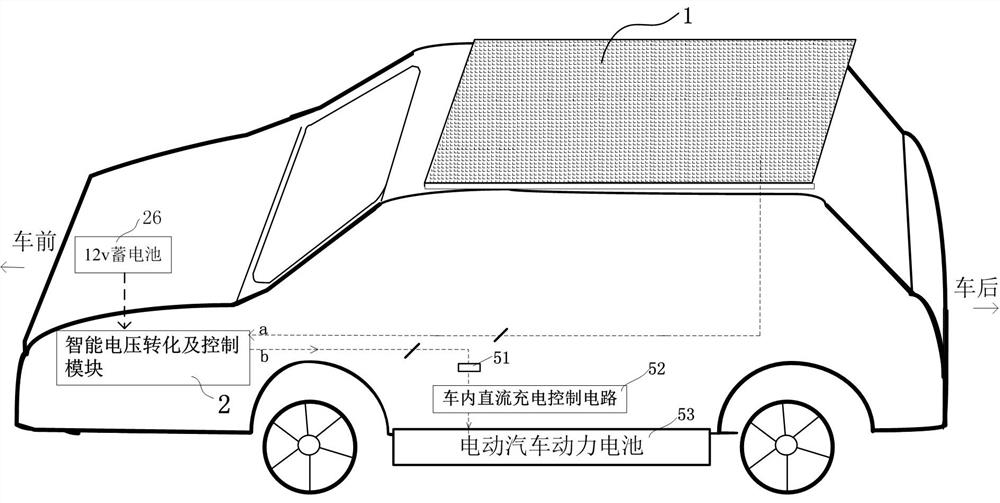

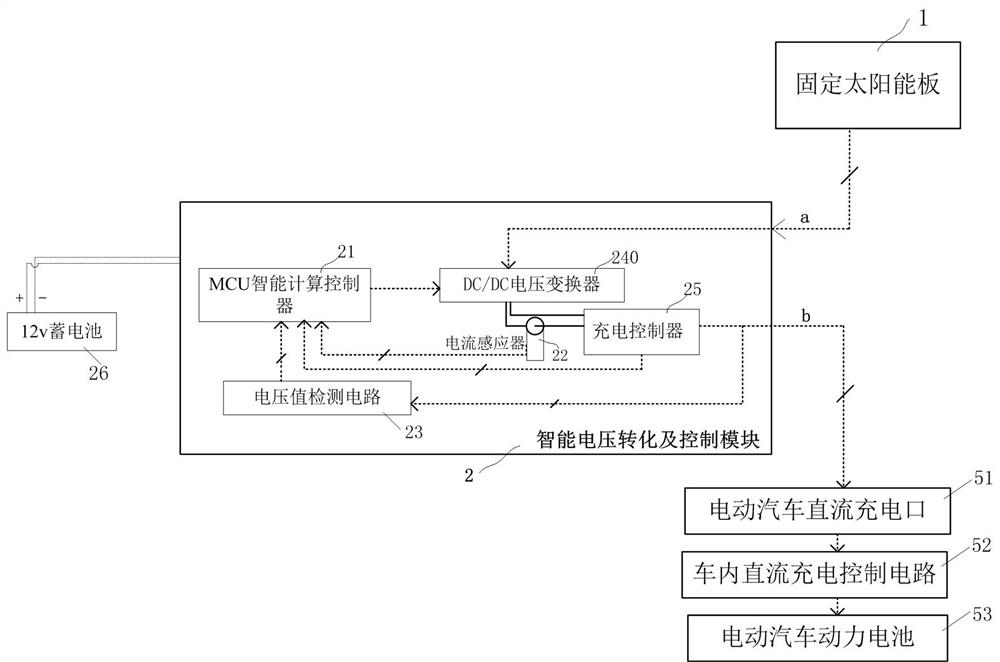

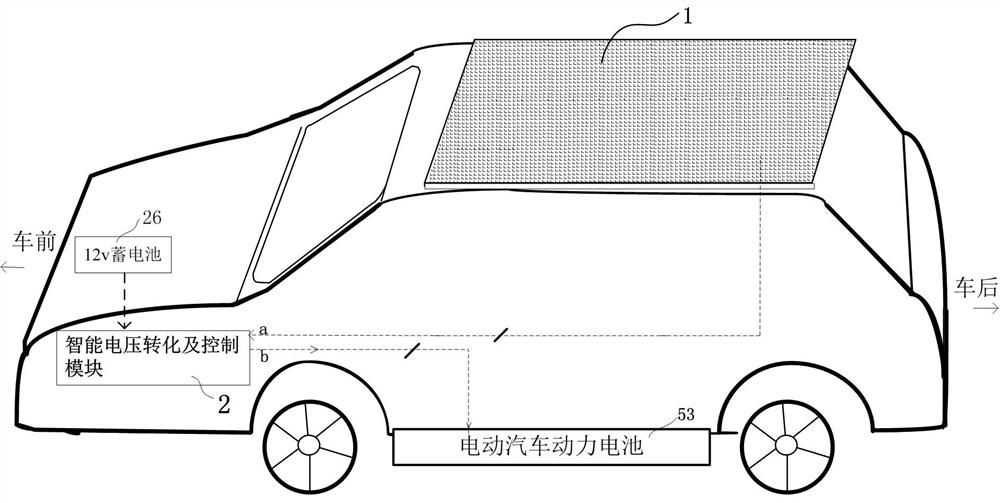

Electric vehicle charging system capable of generating power by solar energy

PendingCN114013291AHave valueReal-time chargingBatteries circuit arrangementsPhotovoltaicsPower batteryElectric vehicle

The invention provides an electric vehicle charging system capable of generating power by solar energy, which comprises a solar panel fixed on a vehicle roof and an intelligent voltage conversion and control module, and is characterized in that the voltage output of the solar panel fixed on the vehicle roof is connected with the intelligent voltage conversion and control module; the output voltage of the intelligent voltage conversion and control module is used for charging a power battery of the electric vehicle, and the intelligent voltage conversion and control module is used for controlling and exciting the fixed solar panel to generate power at the maximum conversion rate at different time and different illumination intensities and realizing communication butt joint with the electric vehicle through an internal charging controller; and the maximum power is output to charge the power battery, so that the charging amount reaches the practical level, charging is monitored and protected, and the device is attractive and safe. Solar charging is applied to the electric vehicle, and the popularization and promotion value is achieved.

Owner:林浩生

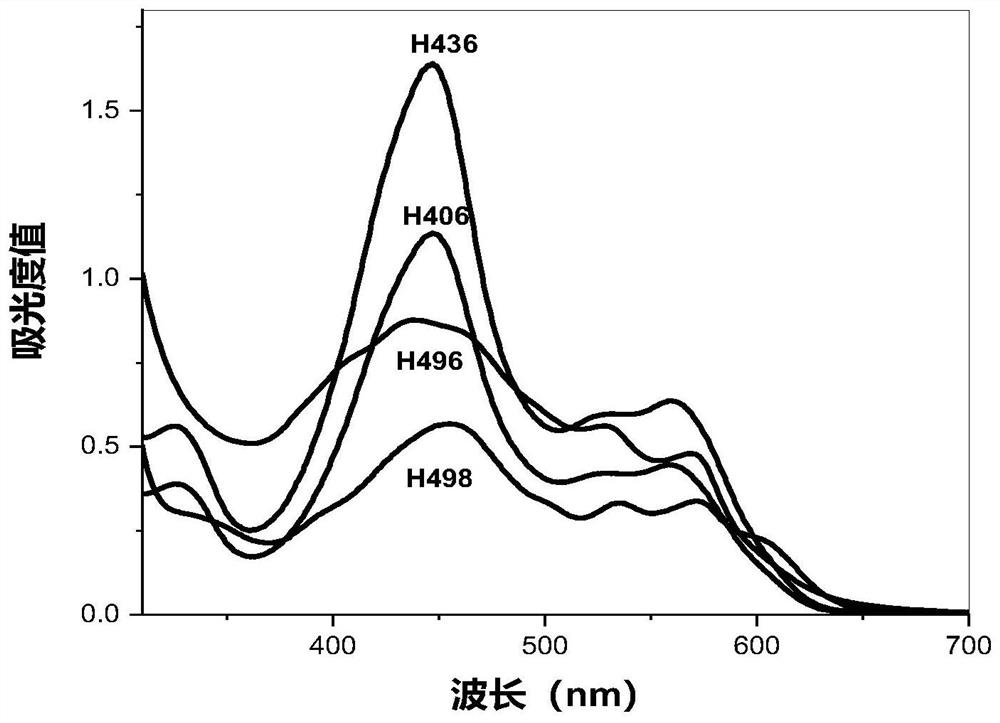

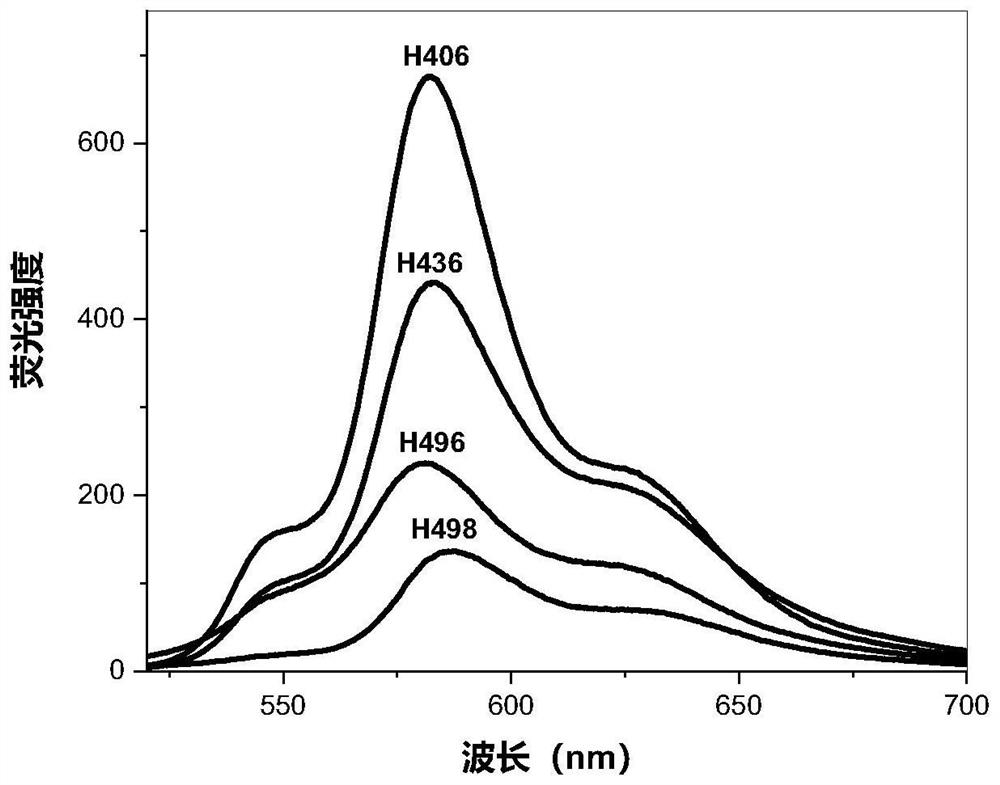

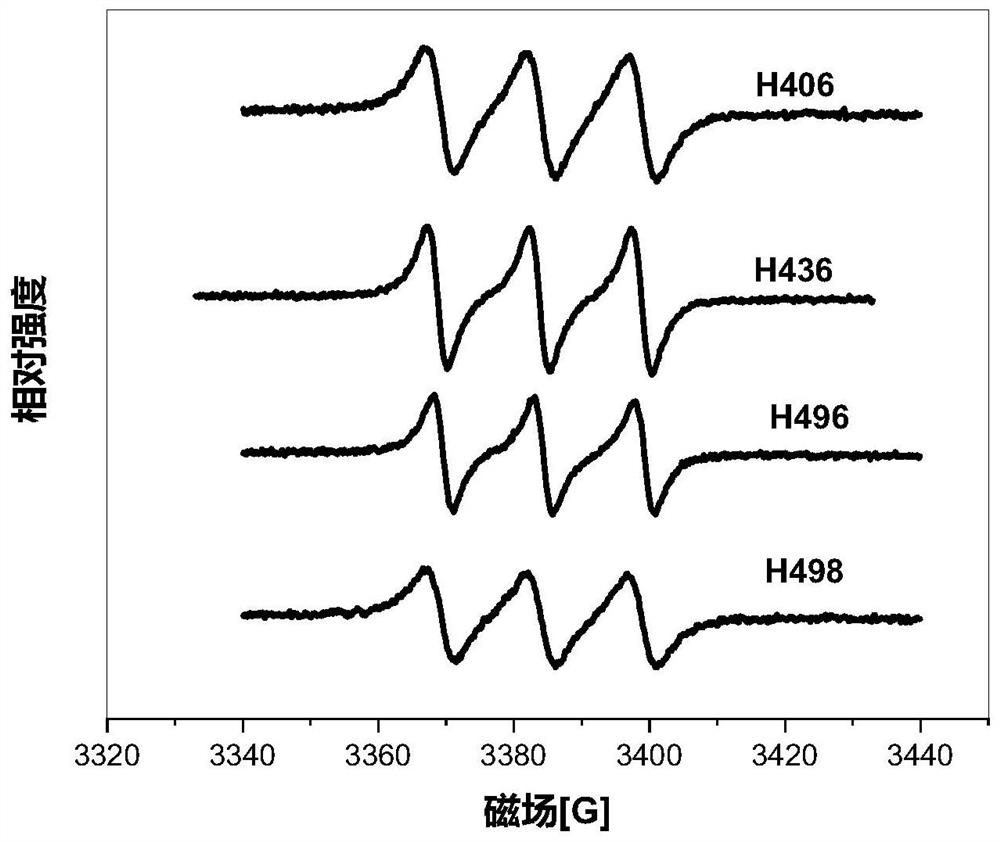

Hypocrellin derivative as well as preparation method and application thereof

PendingCN114644607AHigh conversion rateHigh yieldOrganic chemistryPhotodynamic therapyPhotosensPharmaceutical drug

The invention belongs to the technical field of photodynamic phototherapy photosensitizer medicines for microvascular diseases. In particular to a hypocrellin derivative as shown in a formula I, and a stereoisomer, a position isomer, an isotope label, a solvate, a polymorphic substance, a prodrug or a pharmaceutically acceptable salt thereof. The maximum light absorption wavelength of the hypocrellin derivative as shown in the formula I is 400-600nm, and the depth of penetrating tissues conforms to the focus depth of microvascular diseases. The problem of scar-free treatment can be solved, absorption of visual pigments can be avoided as far as possible, and teratogenic new blood of a focus is selectively destroyed without damaging normal tissues or visual pigments, so that the effect of photodynamic phototherapy is exerted to the greatest extent.

Owner:INST OF CHEM CHINESE ACAD OF SCI

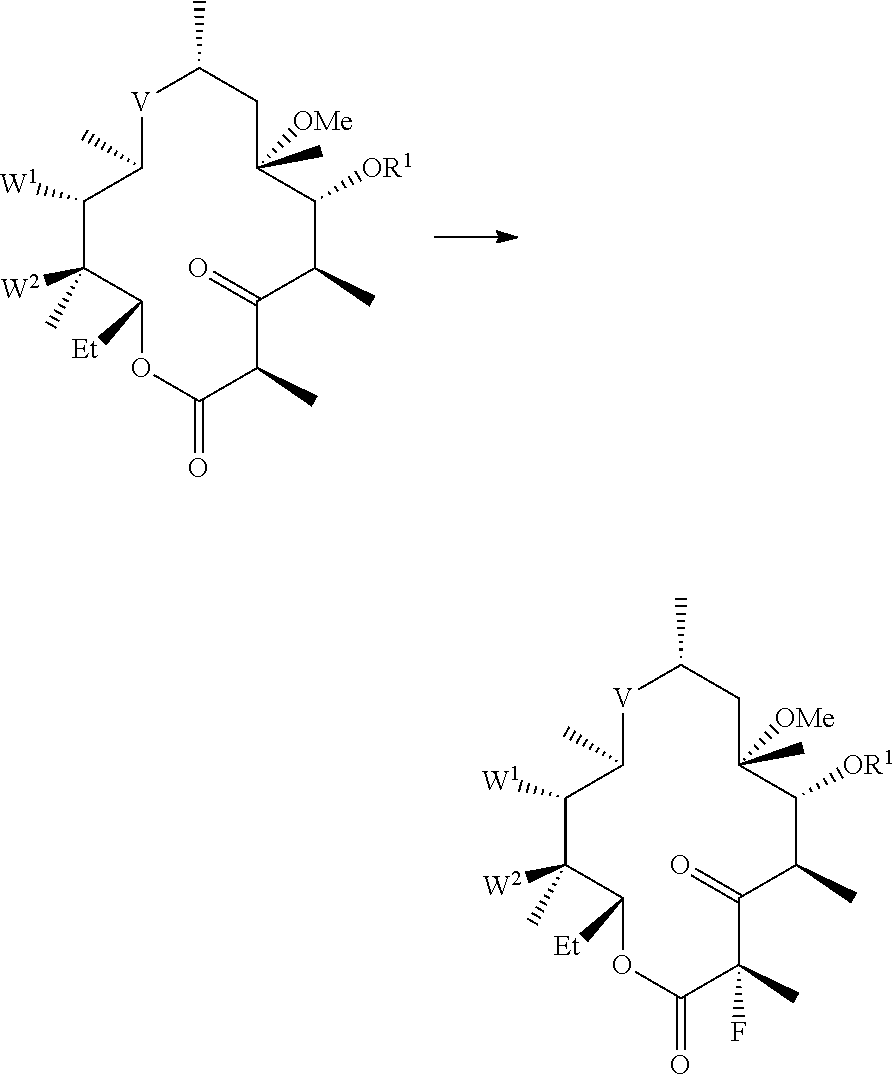

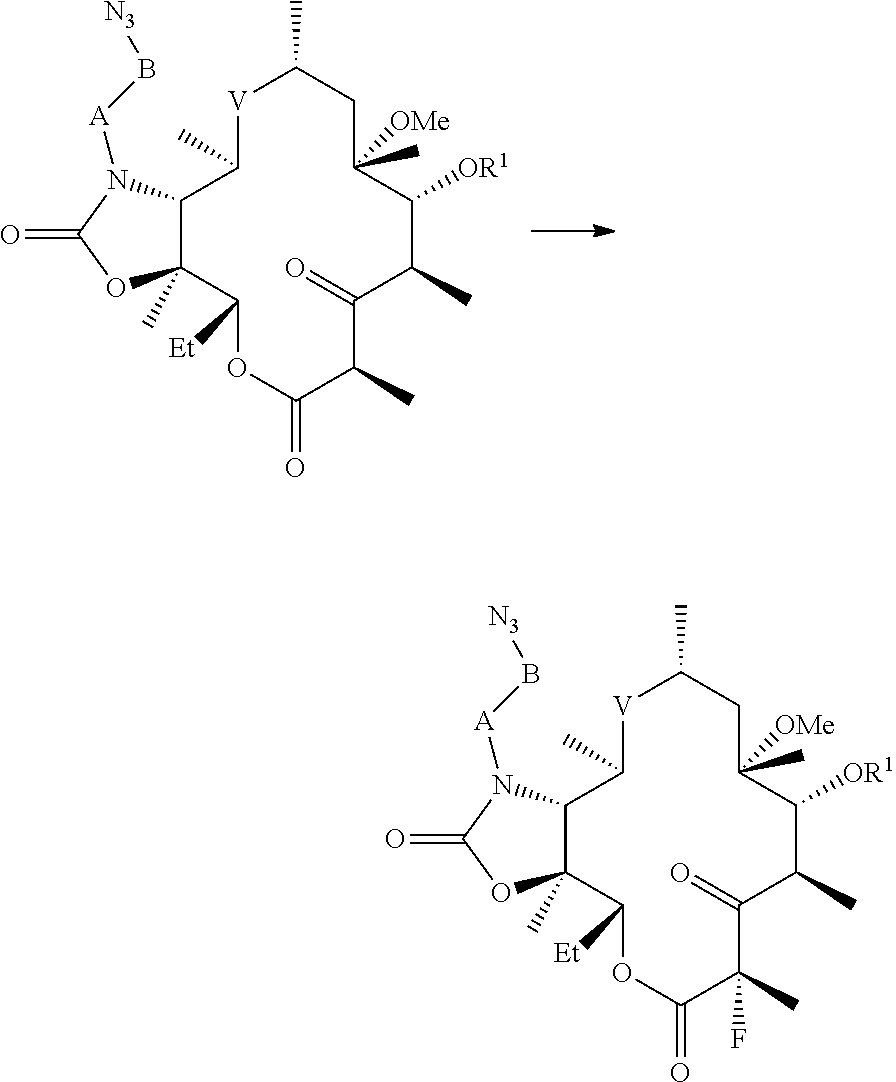

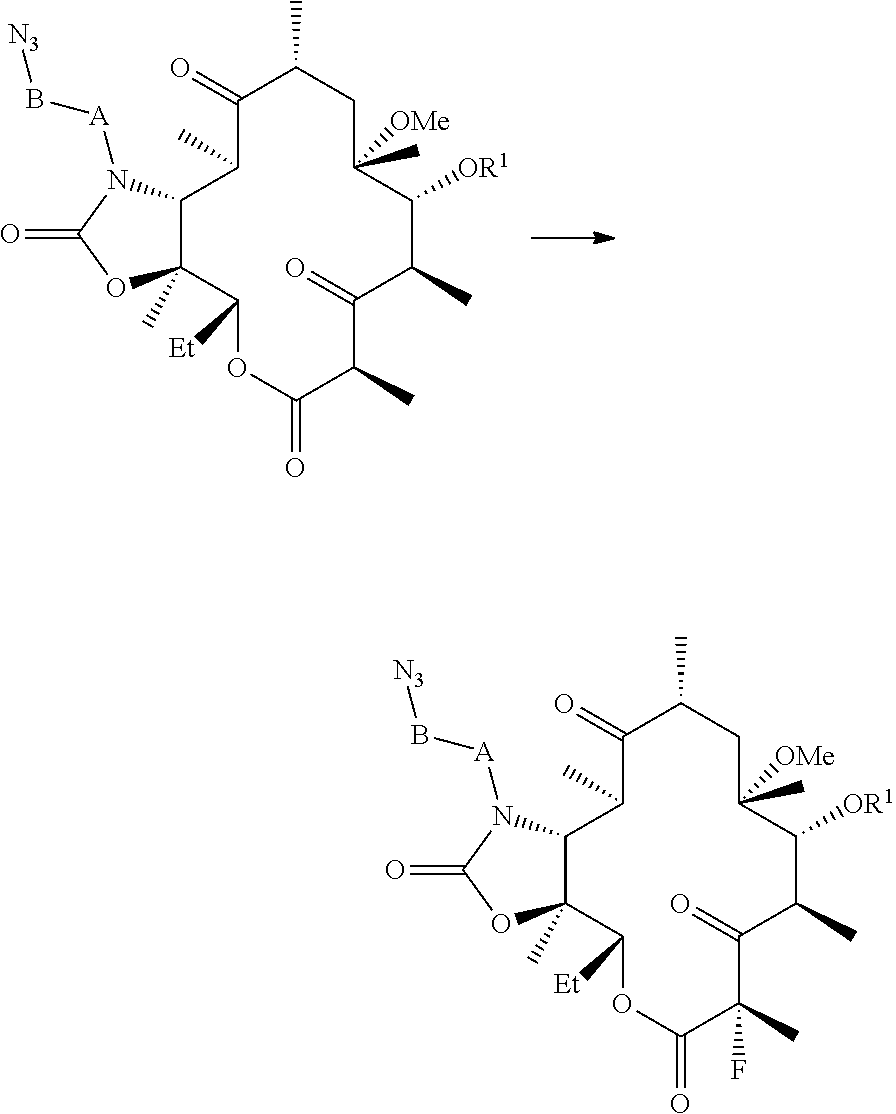

Processes for preparing fluoroketolides

InactiveUS20180044365A1High conversion rateAntibacterial agentsSugar derivativesLactone CompoundCombinatorial chemistry

Owner:TETARD INC

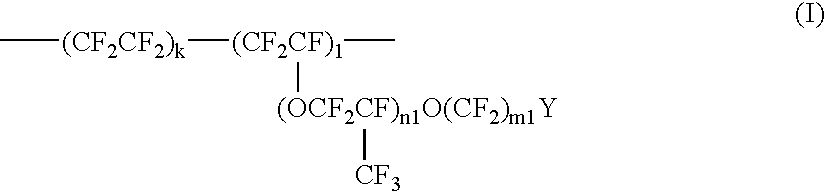

Process for producing fluorinated vinyl ether

InactiveUS7196235B2High conversion rateHigh yieldOrganic compound preparationCarboxylic acid esters preparationSolventFluoride salt

There is provided a process for producing a fluorinated vinyl ether from a fluorinated acid fluoride compound having an ester group as a precursor of a carboxylic acid group, or a SO2F group as a precursor of a sulfonic acid group, in high yield by simple operations.Said process is a production process comprising pyrolyzing a carboxylic acid potassium salt with a specific structure represented by the following formula in the absence of a solvent and / or while maintaining the salt in the solid state:wherein X is —CO2R or —SO2F, and R is an alkyl group.

Owner:ASAHI KASEI KK

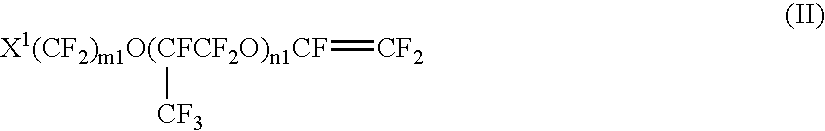

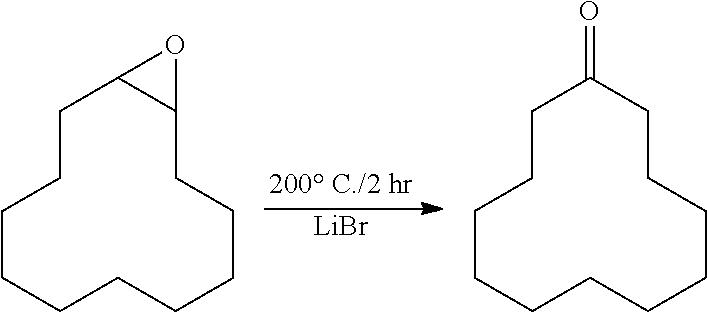

Method for manufacturing cyclododecanone

ActiveUS20220064094A1High conversion rateRatio decreaseOrganic-compounds/hydrides/coordination-complexes catalystsCatalytic reactionsSide productProcess engineering

The present invention relates to a method of preparing cyclododecanone. According to the present invention, a method of preparing cyclododecanone which allows implementation of a high conversion rate and minimization of production of unreacted materials and reaction by-products may be provided. In addition, the present invention implements a high conversion rate and a high selectivity even by a simplified process configuration, and thus may be usefully utilized in an economical method of preparing laurolactam, allowing commercially easy mass production.

Owner:HANWHA SOLUTIONS CORP

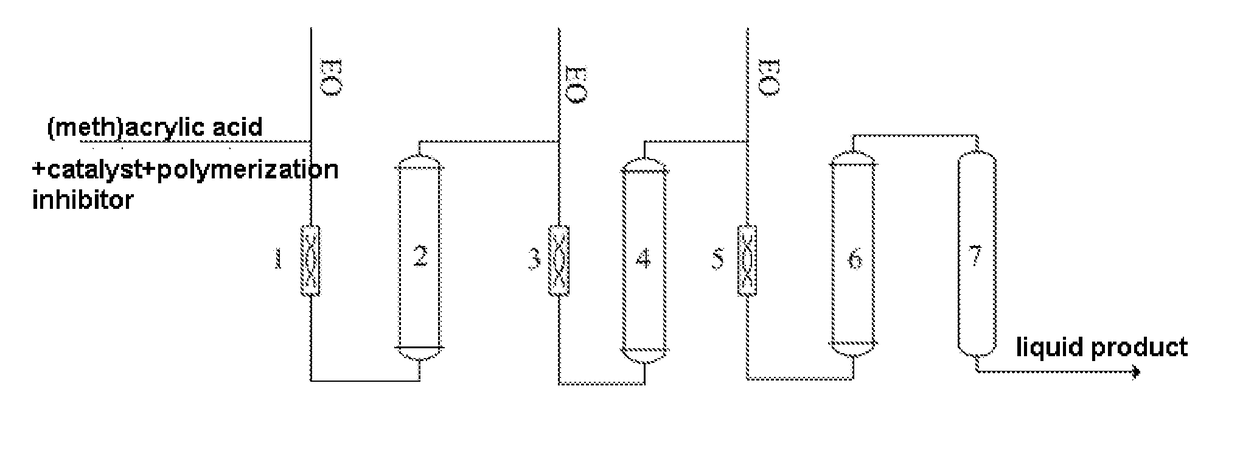

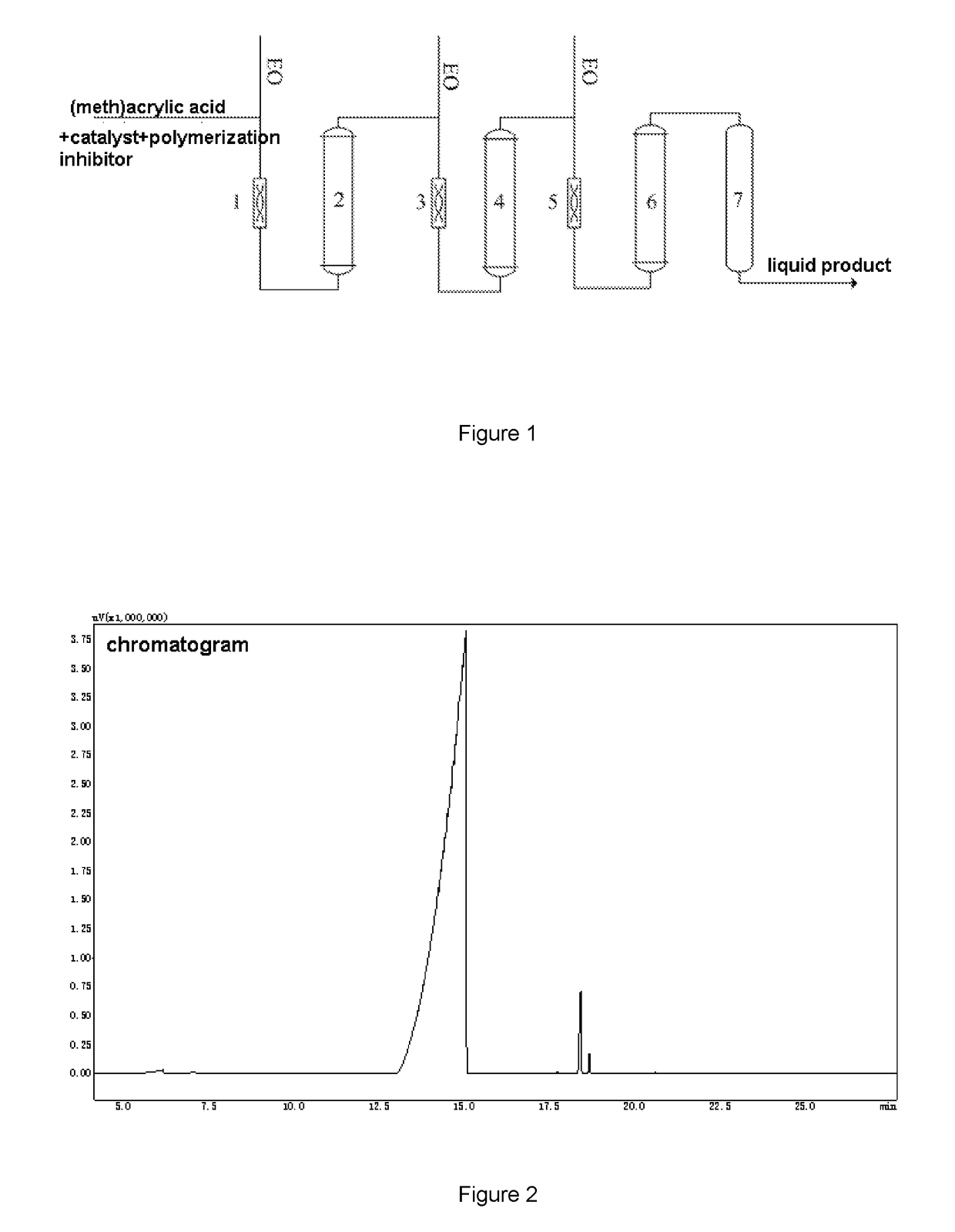

Method for preparing hydroxyethyl (METH) acrylate

ActiveUS20170183288A1Fast reaction rateHigh conversion rateOrganic compound preparationCarboxylic acid esters preparationChemistryMeth-

Hydroxyethyl (methyl)acrylate is prepared by a process of a combination of a three-stage tubular reactor and a tower reactor, wherein, firstly, a catalyst, a polymerization inhibitor and (methyl) acrylic acid are mixed until the solids are dissolved, then mixed with a part of ethylene oxide and thereafter enter into a first tubular reactor for a reaction, a reaction liquid flowing out from the first tubular reactor is mixed with a certain amount of ethylene oxide and enters into a second tubular reactor for a reaction, a reaction liquid flowing out from the second tubular reactor is then mixed with a certain amount of ethylene oxide and thereafter enters into a third tubular reactor, and a reaction liquid flowing out from the third tubular reactor is then passed through a stage of an adiabatic tower reactor and aged such that a product liquid is obtained from extraction.

Owner:WANHUA CHEM GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com