Poly(MA-AA-Mac) (Poly(Maleic Anhydride-Acrylic Acid-Methyl Acrylate)) anti-scaling agent synthesis process based on control on using amount of initiator

A synthesis process and initiator technology, which is applied in the field of polyMA-AA-Mac antifouling agent synthesis process, can solve the problems of high cost, large amount of addition, limited use and the like, and achieves reduced preparation cost, simple preparation process, and improved The effect of antifouling properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0024] A kind of polyMA-AA-Mac antifouling agent synthetic technique of controlling initiator consumption that the present invention relates to comprises steps:

[0025] (a) at first, prepare maleic anhydride solution, acrylic acid solution and methyl acrylate respectively;

[0026] (b) Then, in reaction vessel, add maleic anhydride solution, acrylic acid solution and methyl acrylate;

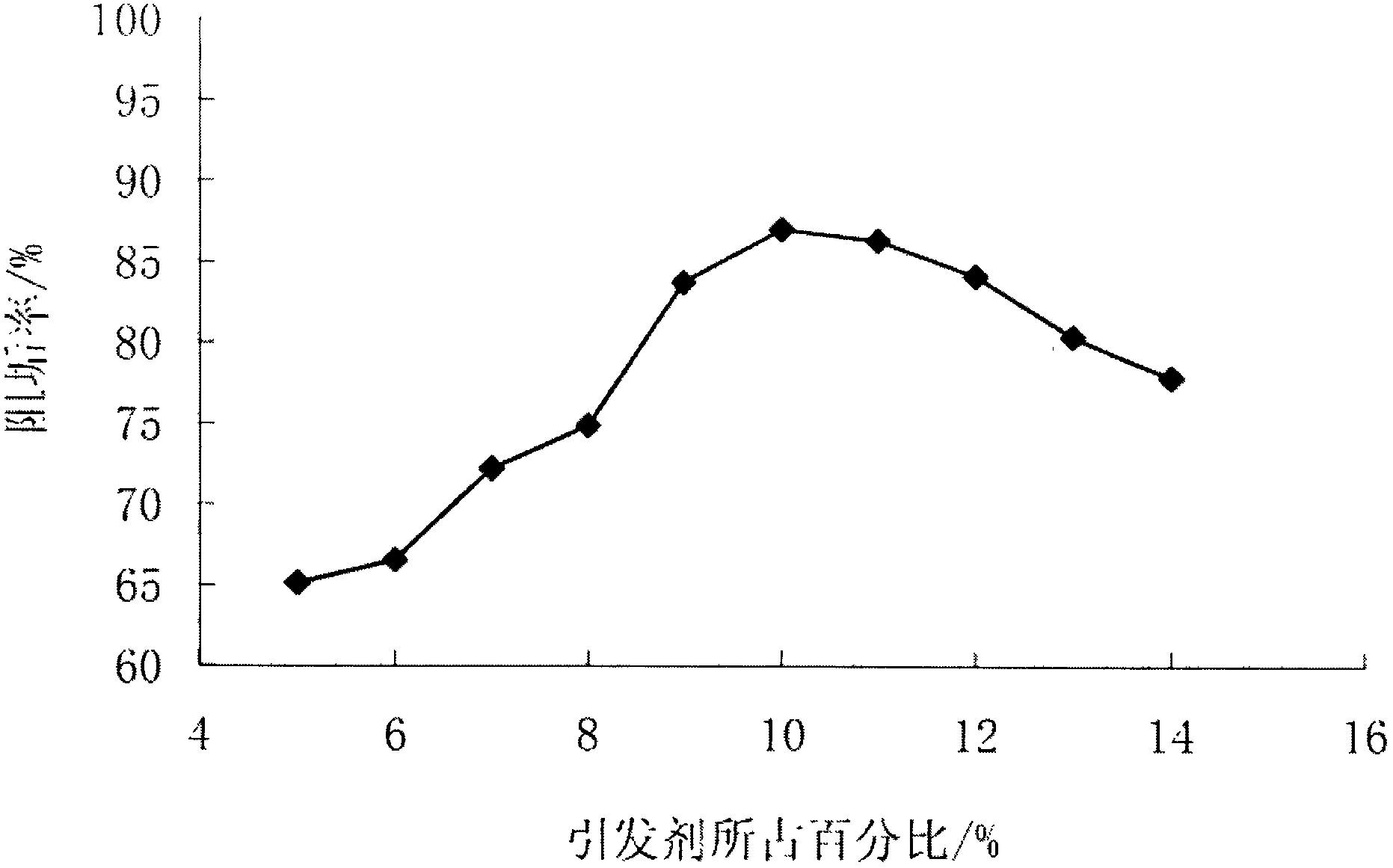

[0027] (c) adding an initiator to the reaction vessel, and controlling the initiator to account for 8% to 12% of the total mass of the monomer;

[0028] (d) Then start the stirring and heating device, keep the constant temperature and stir the reaction for a period of time, then stop, and cool naturally to obtain the target product.

[0029] The container is a four-necked bottle with stirring device, dropping funnel, thermometer and condensing device.

[0030] The three dropping funnels were filled with acrylic acid solution, methyl acrylate and ammonium persulfate solution respectively.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com